Mechanical press mounting structure of group large-power flat-plate power electronic device

A technology for power electronic devices and press-fit structures, which is applied in the field of mechanical press-fit structures of grouped high-power flat-panel power electronic devices, can solve the problems of increased thermal resistance of conductive contact surfaces, unfavorable heat dissipation, uncontrolled, etc., and eliminates the need for Assembly error, easy maintenance and replacement, the effect of constant pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings; it should be noted that: this embodiment is descriptive, not restrictive, and cannot be used to limit the protection scope of the present invention.

[0022] This embodiment is described by taking the IGCT power unit string as an example.

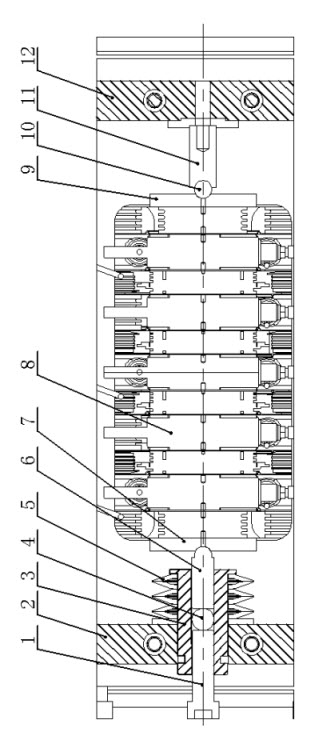

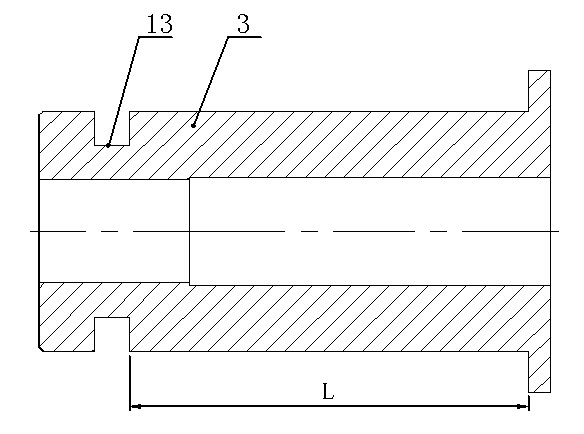

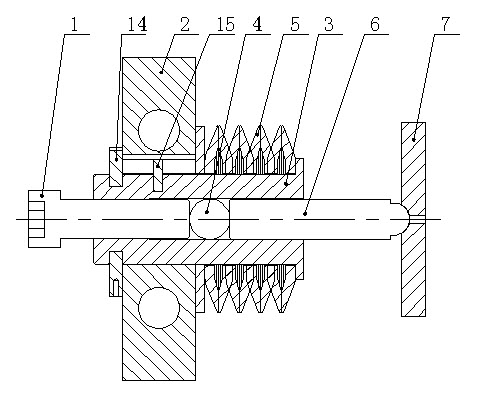

[0023] A group of high-power flat-plate type power electronic device mechanical press-fit structure, which is composed of a left support plate 2, a right support plate 12, a left ejector rod 6, a right ejector rod 11, a left pressure plate 7, and a right pressure plate 9. The power device string 8 is installed horizontally and coaxially between the right pressure plate. The top is installed on the left and right pressure plates. Innovation point of the present invention is:

[0024] (1) The left ejector rod is coaxially slidably installed in a spring mandrel 3, and the spring mandrel passes through its radially in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com