Patents

Literature

98results about How to "Eliminate assembly errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

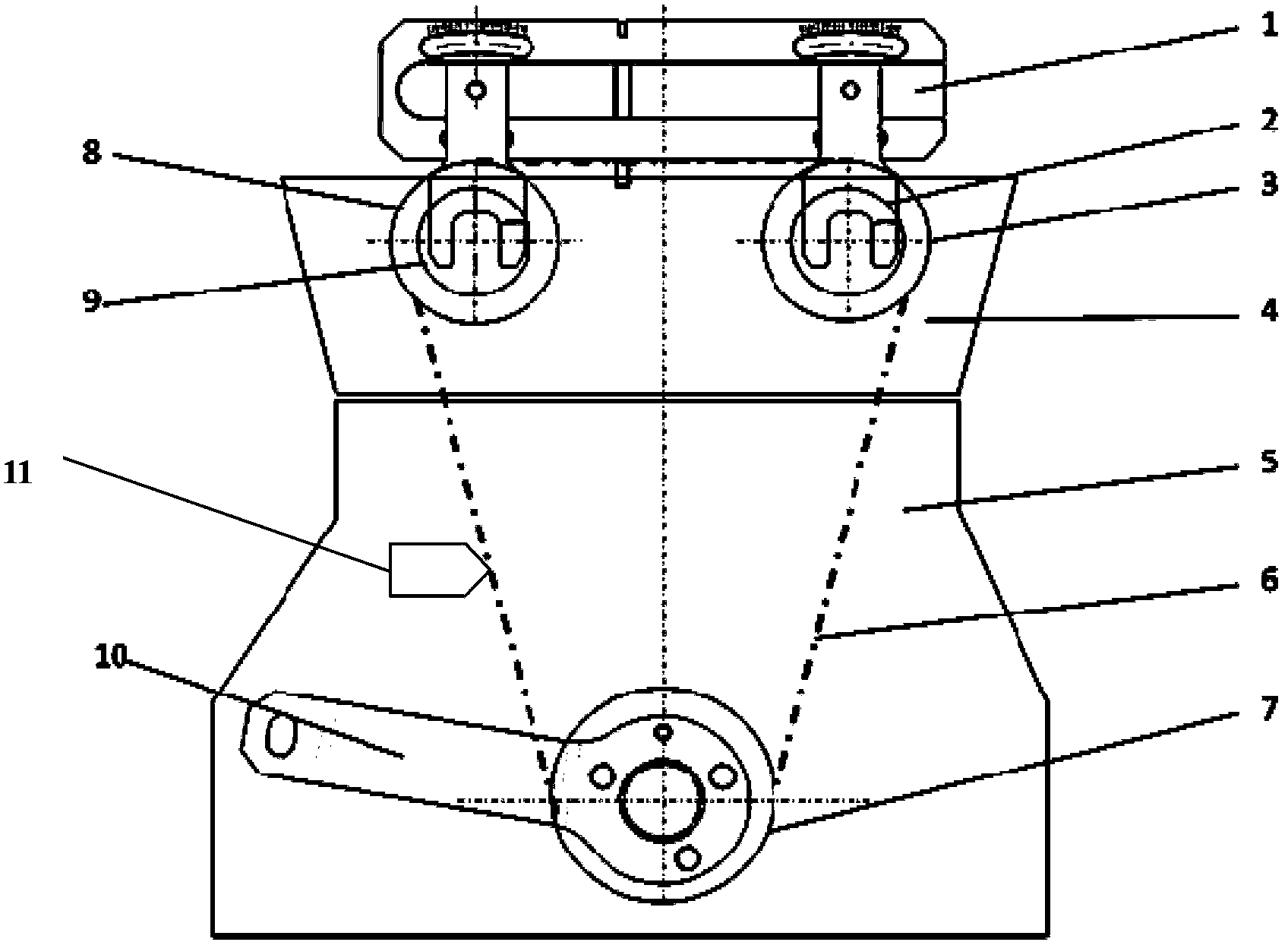

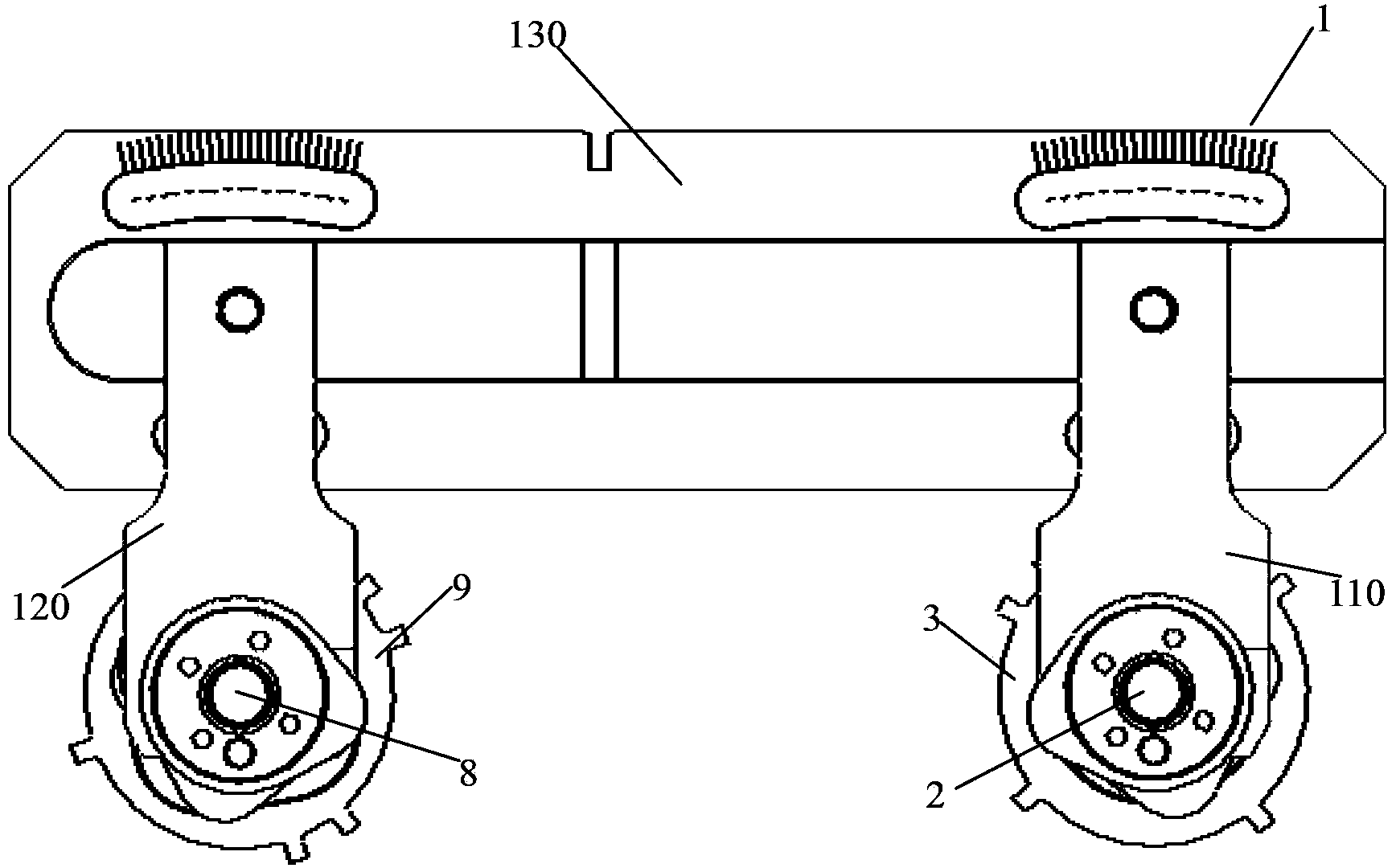

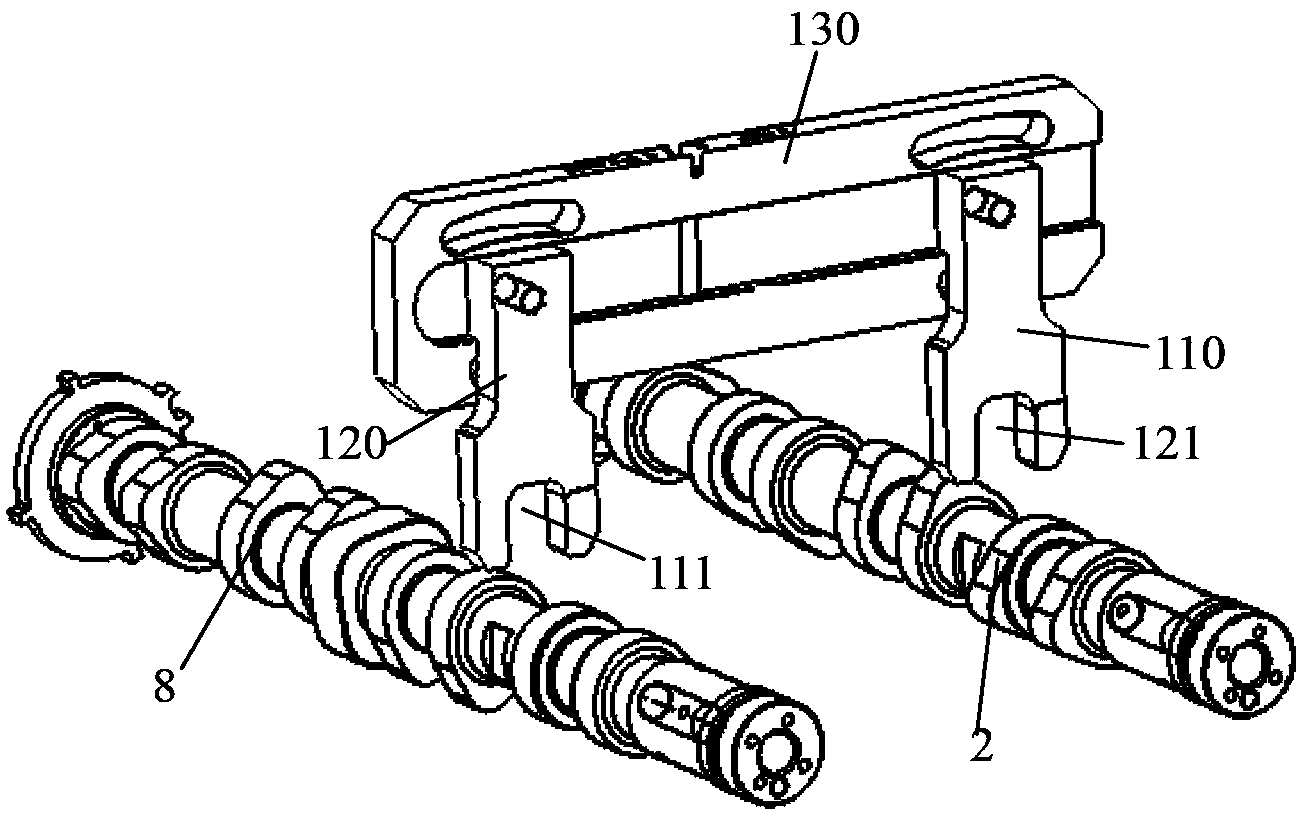

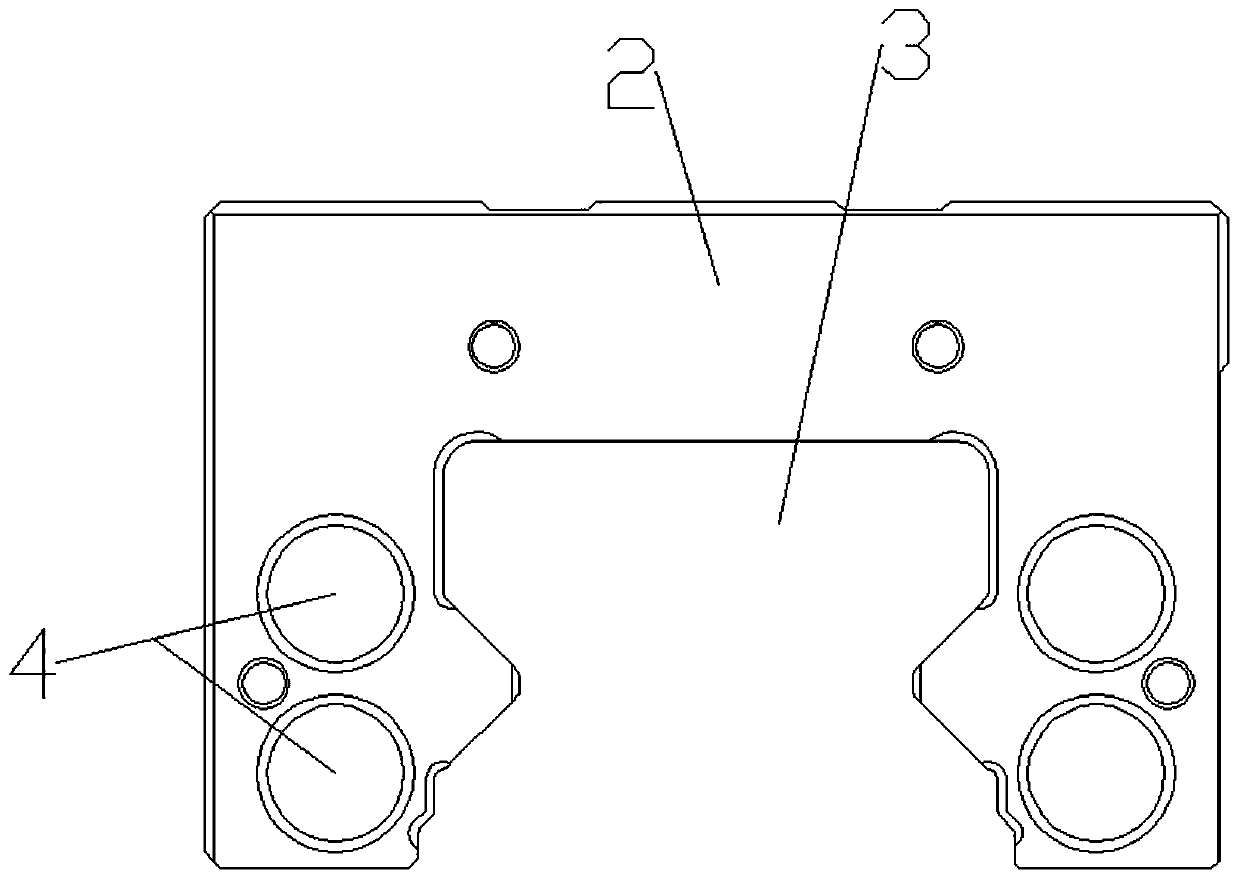

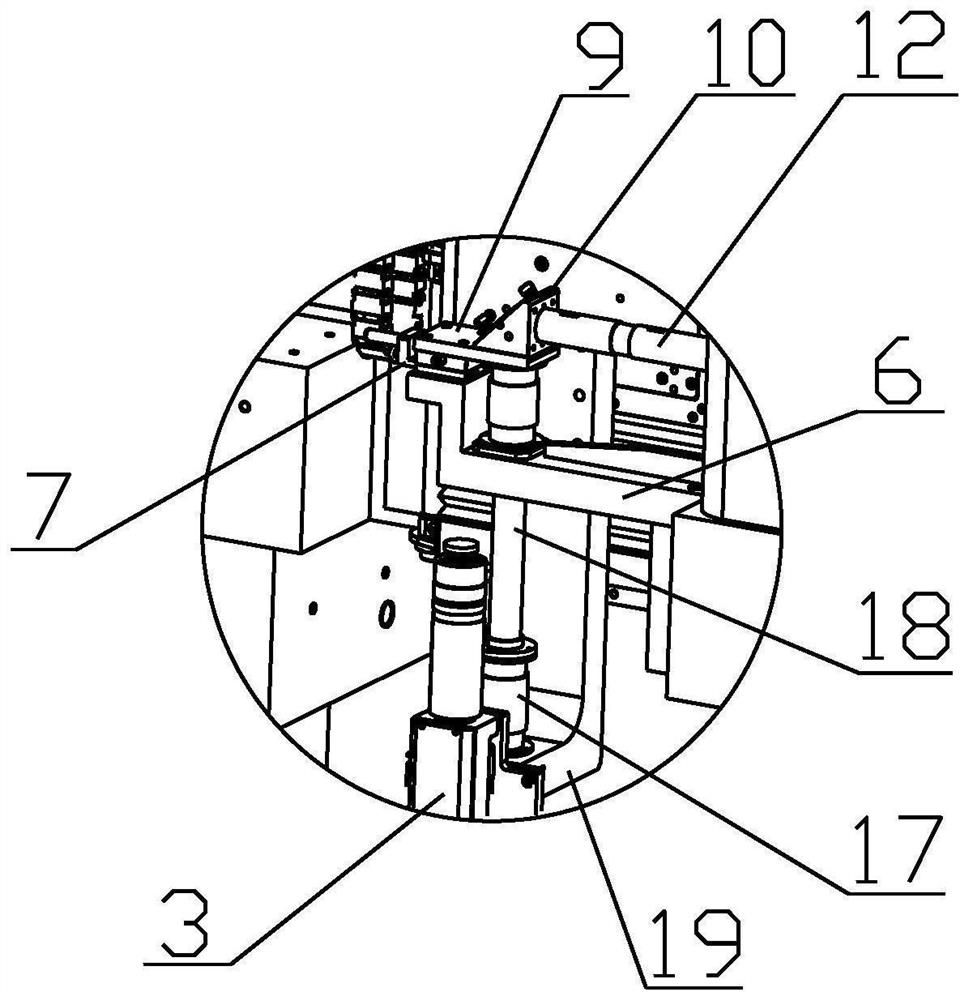

Positioning and mounting system and positioning and mounting method used for engine timing system

InactiveCN104249320AEliminate assembly errorsEliminate the effect of precisionWork holdersMetal-working hand toolsSprocketEngineering

The invention provides a positioning and mounting system and a positioning and mounting method used for an engine timing system. The positioning and mounting system comprises a cam shaft locking device and a crankshaft locking device, wherein the cam shaft locking device is used for locking and fixing a gas inlet cam shaft and a gas inlet cam shaft chain wheel on a first mounting position, and locking and fixing a gas outlet cam shaft and a gas outlet cam shaft chain wheel on a second mounting position; the crankshaft locking device is used for locking and fixing a crankshaft and a crankshaft chain wheel on a third position; a timing chain sleeves around the gas inlet cam shaft chain wheel, the gas outlet cam shaft chain wheel and the crankshaft chain wheel; the first mounting position, the second mounting position and the third mounting position are corresponding; a valve is located on a preset position. According to the positioning and mounting system and the positioning and mounting method used for the engine timing system, the cam shaft locking device, the crankshaft locking device and a chain adjusting device are mutually matched, and the aim of improving the timing assembly precision of an engine is reached.

Owner:北京汽车动力总成有限公司

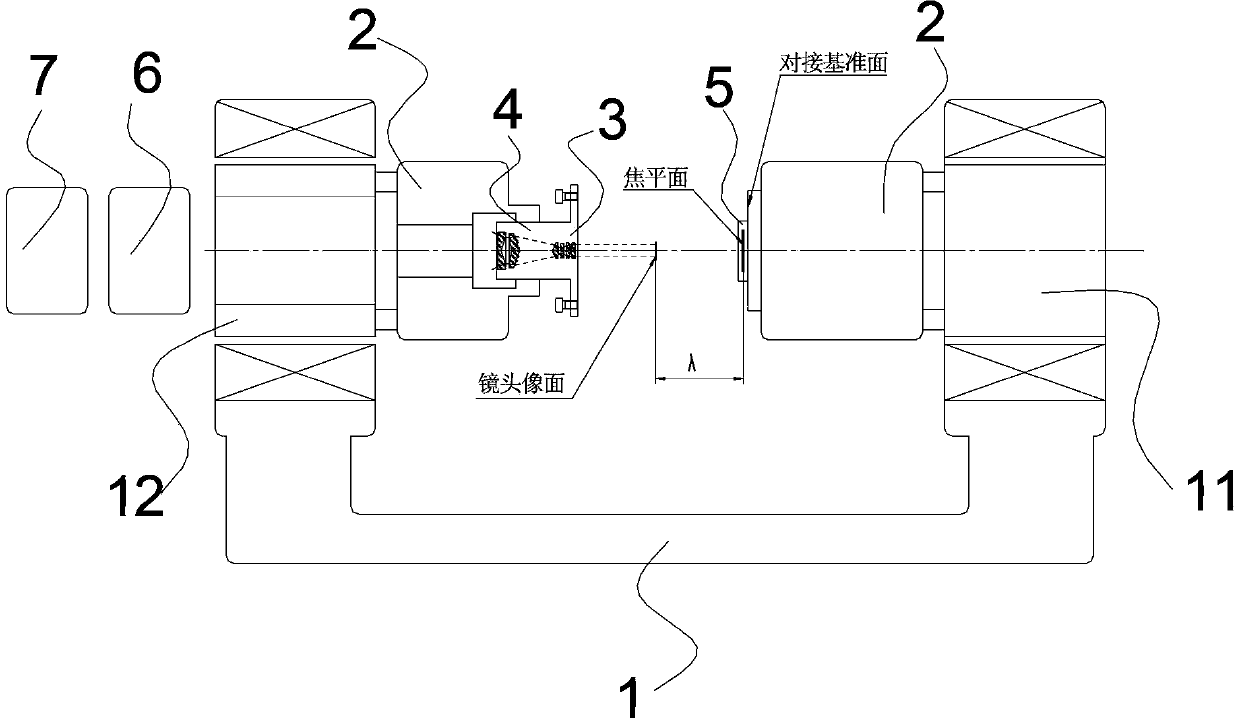

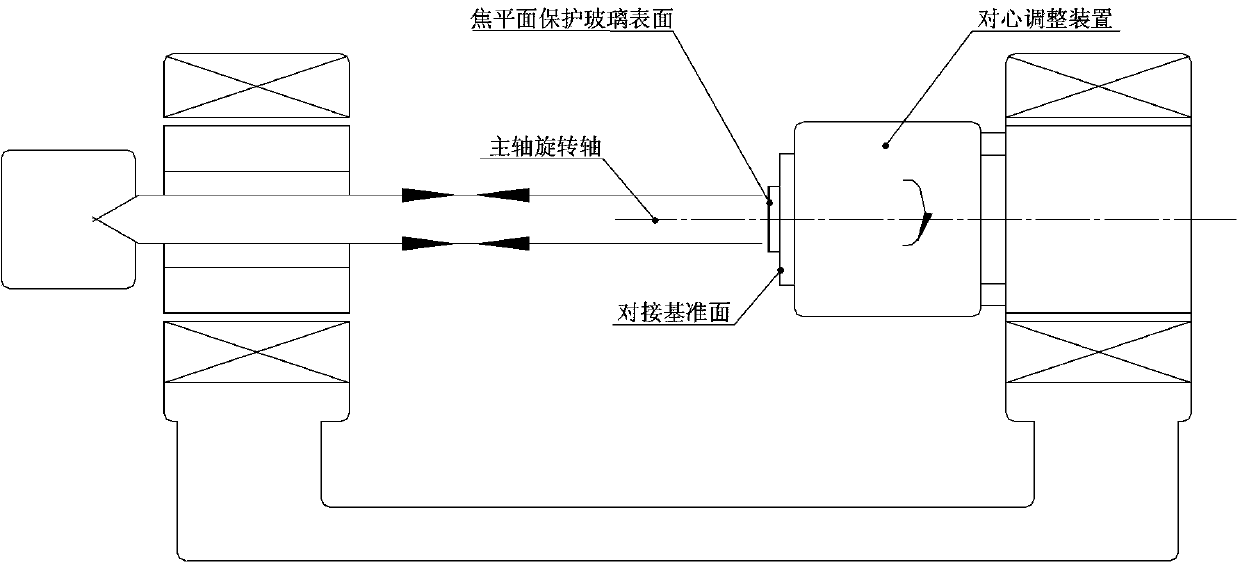

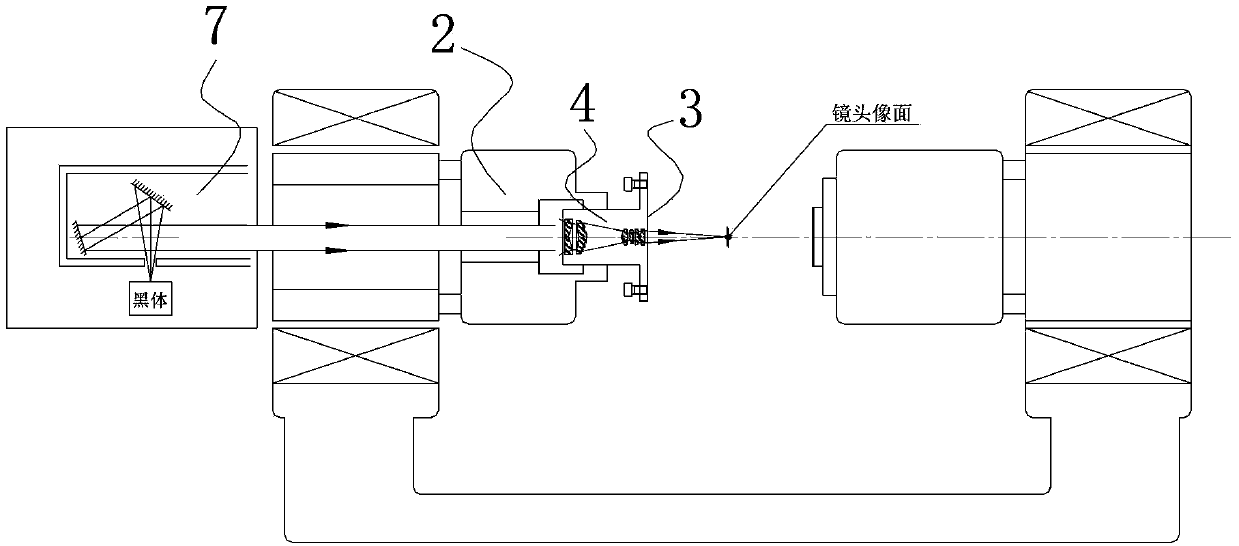

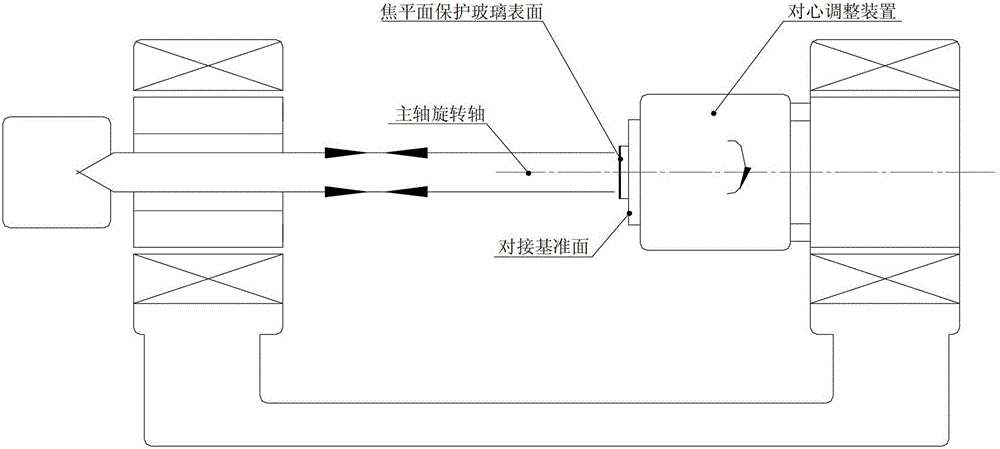

High-precision combined calibration and butt-joint method and mechanism for infrared imaging system

ActiveCN103399416AEliminate assembly errorsGuaranteed parallelismOptical elementsReference surfaceTarget surface

The invention provides a high-precision combined calibration and butt-joint method and a high-precision combined calibration and butt-joint mechanism for an infrared imaging system, which are mainly used for solving the problem that the verticality precision of the optical axis of an optical imaging system and an imaging focus plane, the verticality accuracy of the optical axis of the optical imaging system and the central normal of the target surface of an imaging focal plane and the verticality accuracy of the image plane of the optical imaging system and an imaging focal plane cannot be ensured in the conventional image plane but-joint process. According to the method and the mechanism, a high-precision dual-shaft lathe is used for clamping at one time, and meanwhile turning machining of the butt-joint reference surface of a focusing plane assembly and the flange mounting end face of an optical lens is realized after a given adjusting target is achieved and the adjusting precision is reached, so that the parallelism of two planes is ensured, and assembling errors caused by earlier assembling loops of the focal plane assembly and optical lens are fully eliminated.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

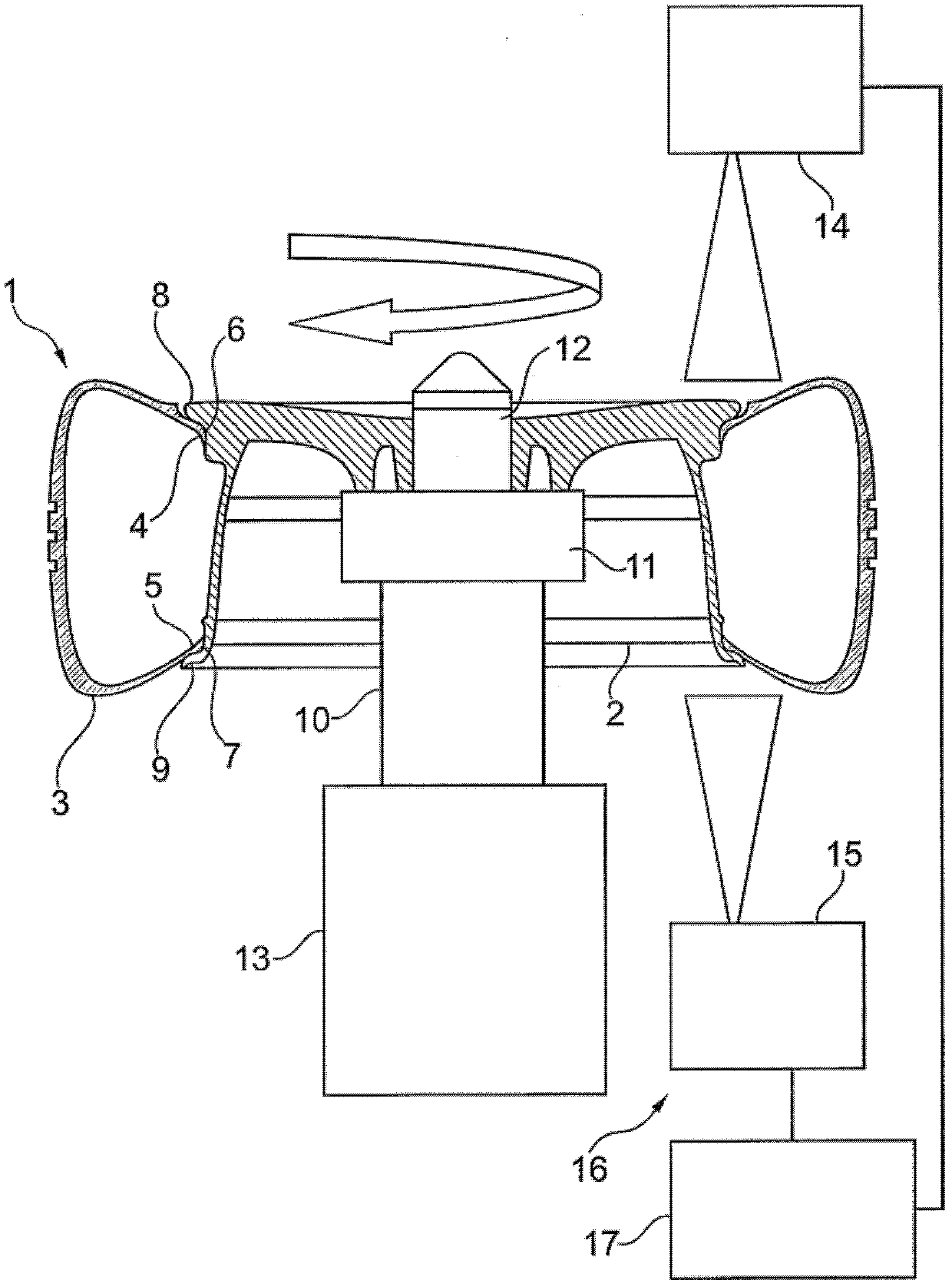

Method and device for checking the tyre seat on vehicle wheels

InactiveCN102384724AEliminate assembly errorsAccurate measurementVehicle testingStatic/dynamic balance measurementTubeless tireAxial distance

The invention relates to a method and a device for checking the seat of a tubeless tire (3) fitted to a rim (2) of a vehicle wheel (1), the vehicle wheel (1) is fastened with its rim (2) centrically on a rotary mount and is rotated about its axis of rotation through at least one revolution. During rotation of the wheel, the outer contours of the radially outer edge areas of the rim (2) and the adjoining areas of the tire (3) are scanned by means of a distance measuring device, and the axial distance differences between the rim (2) and the tire (3) are detected and evaluated.

Owner:SCHENCK ROTEC GMBH

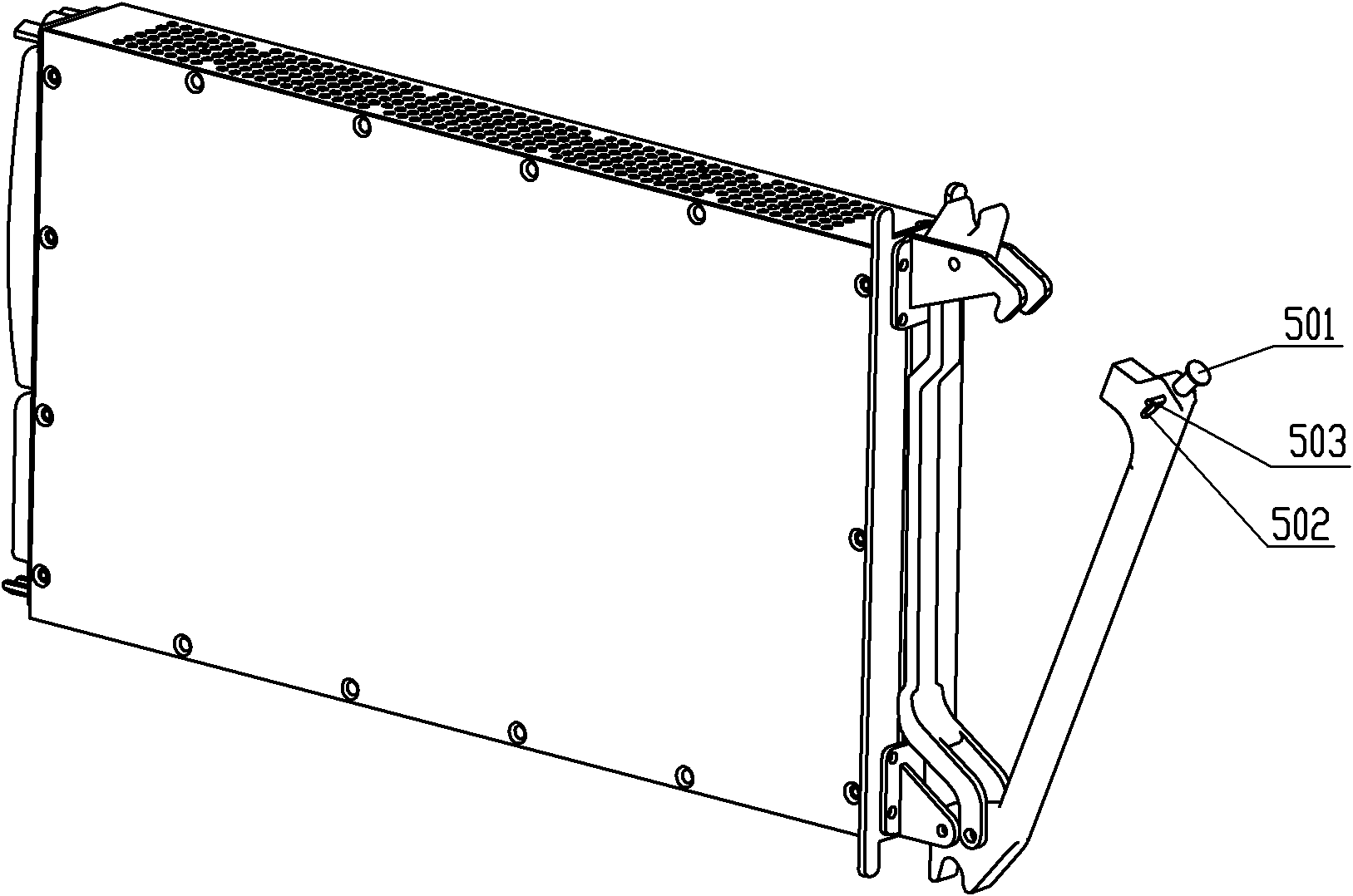

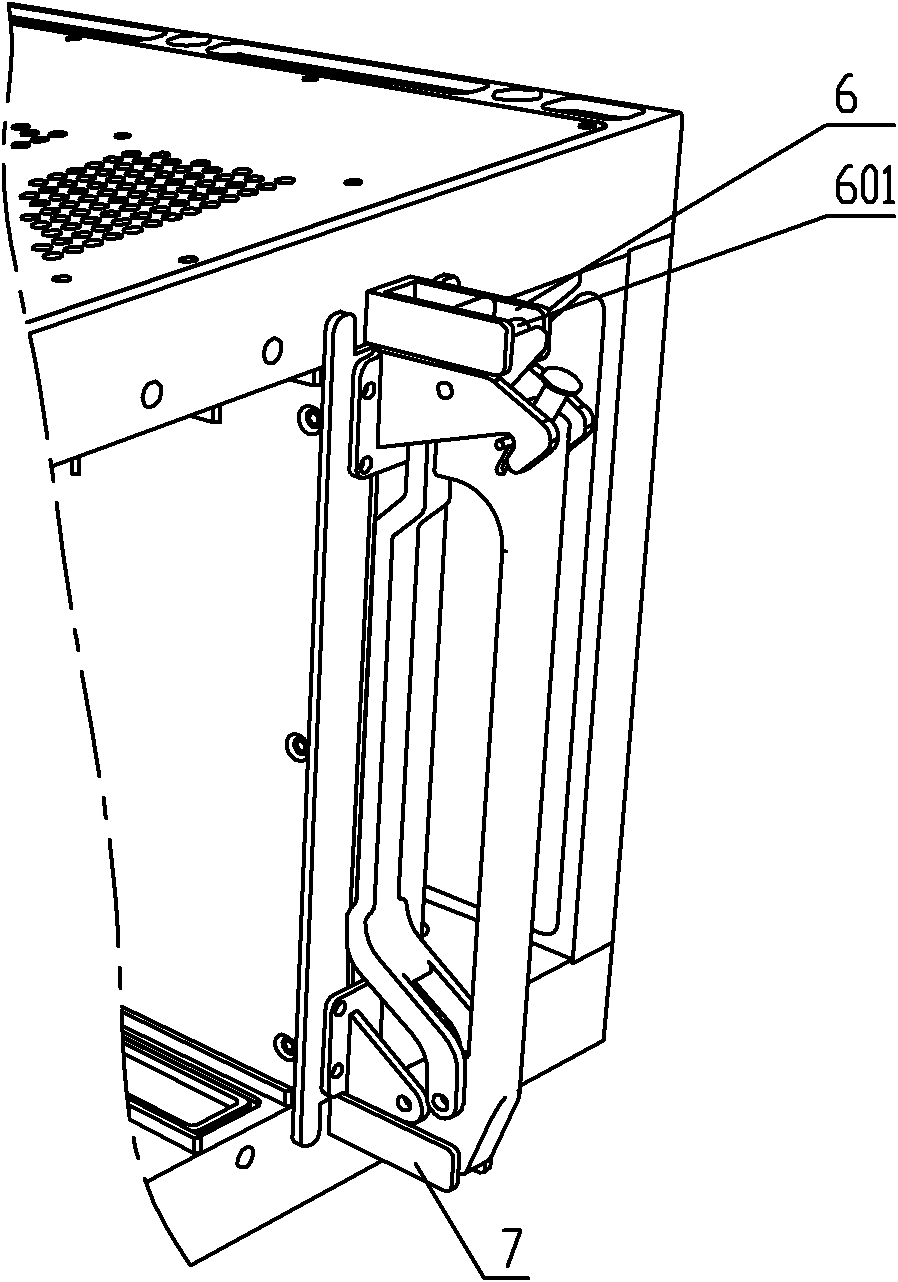

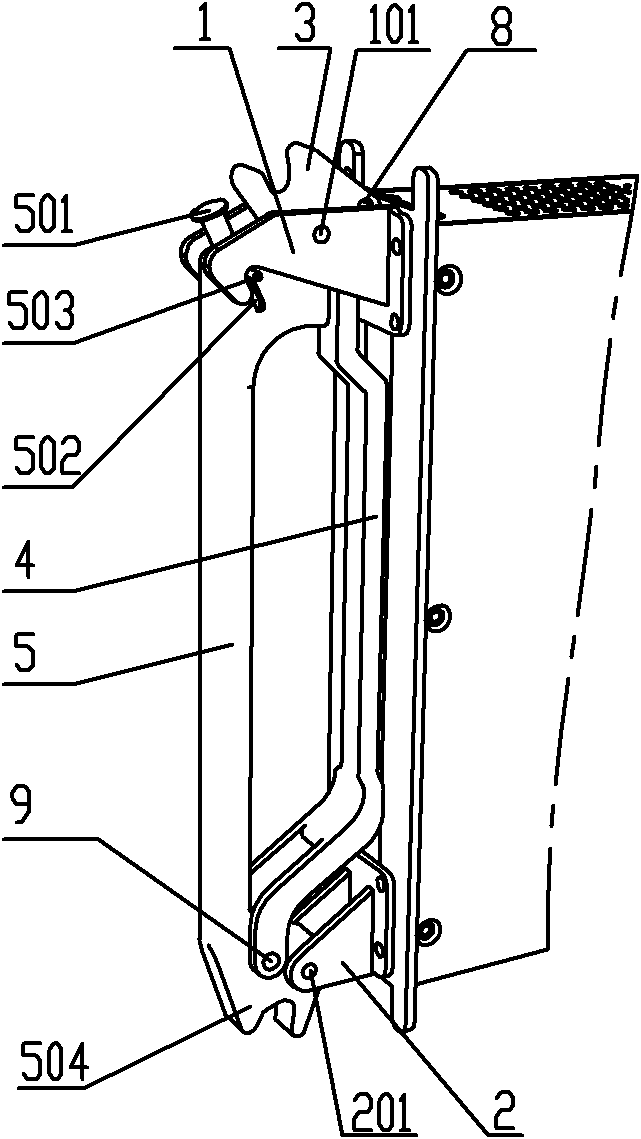

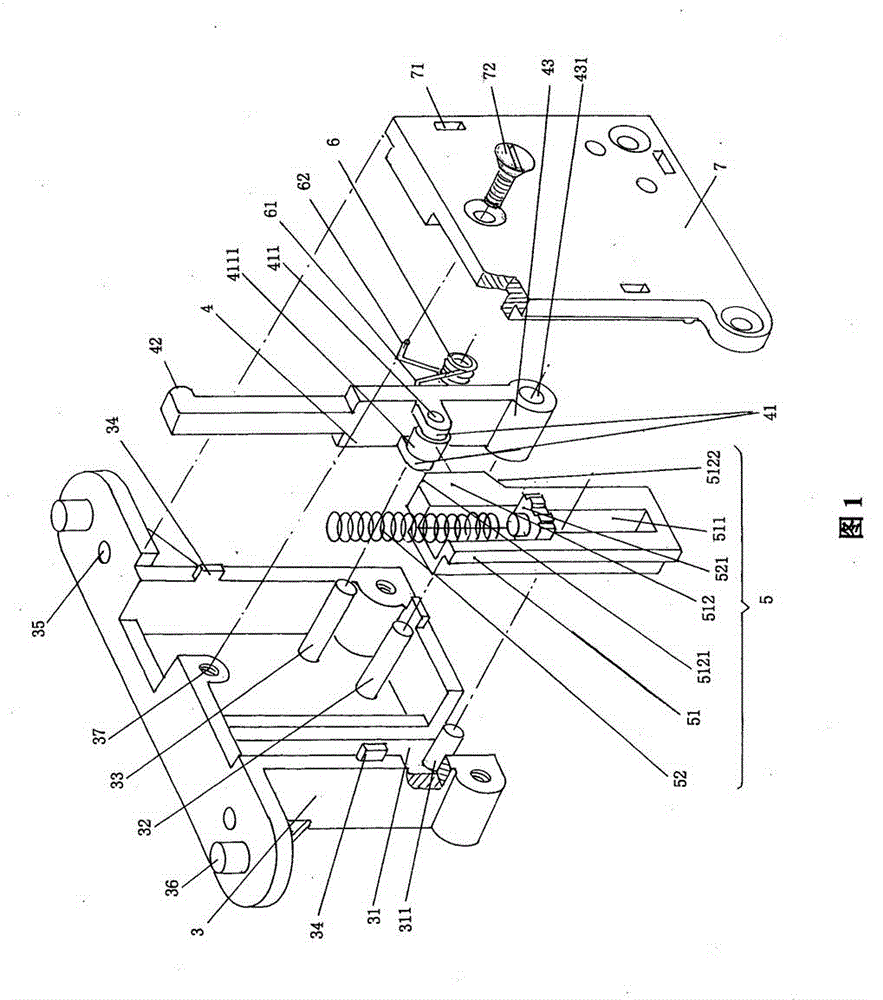

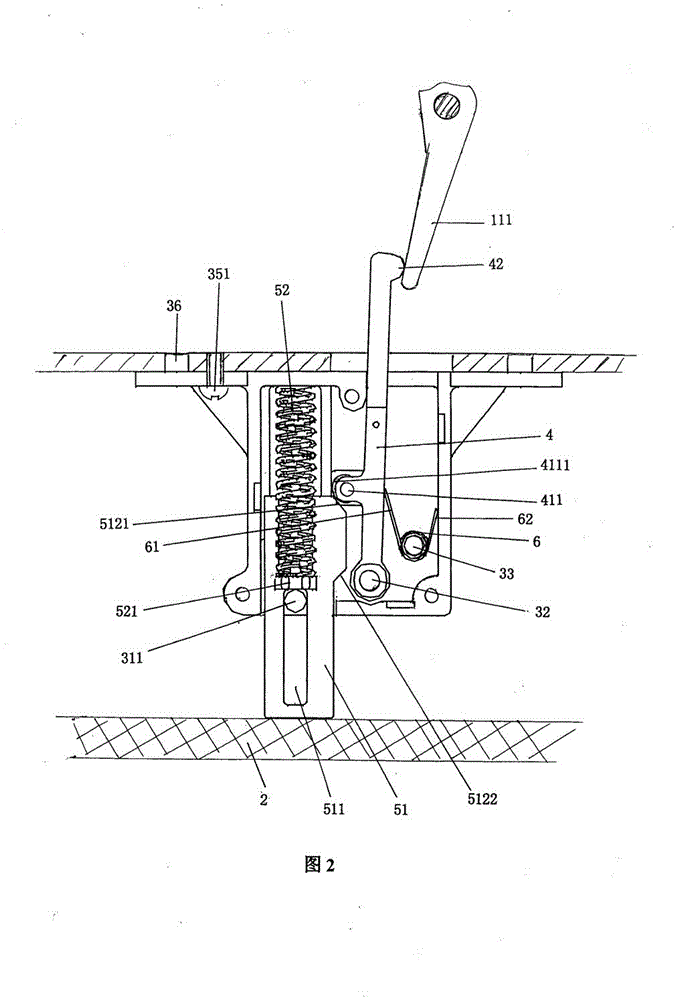

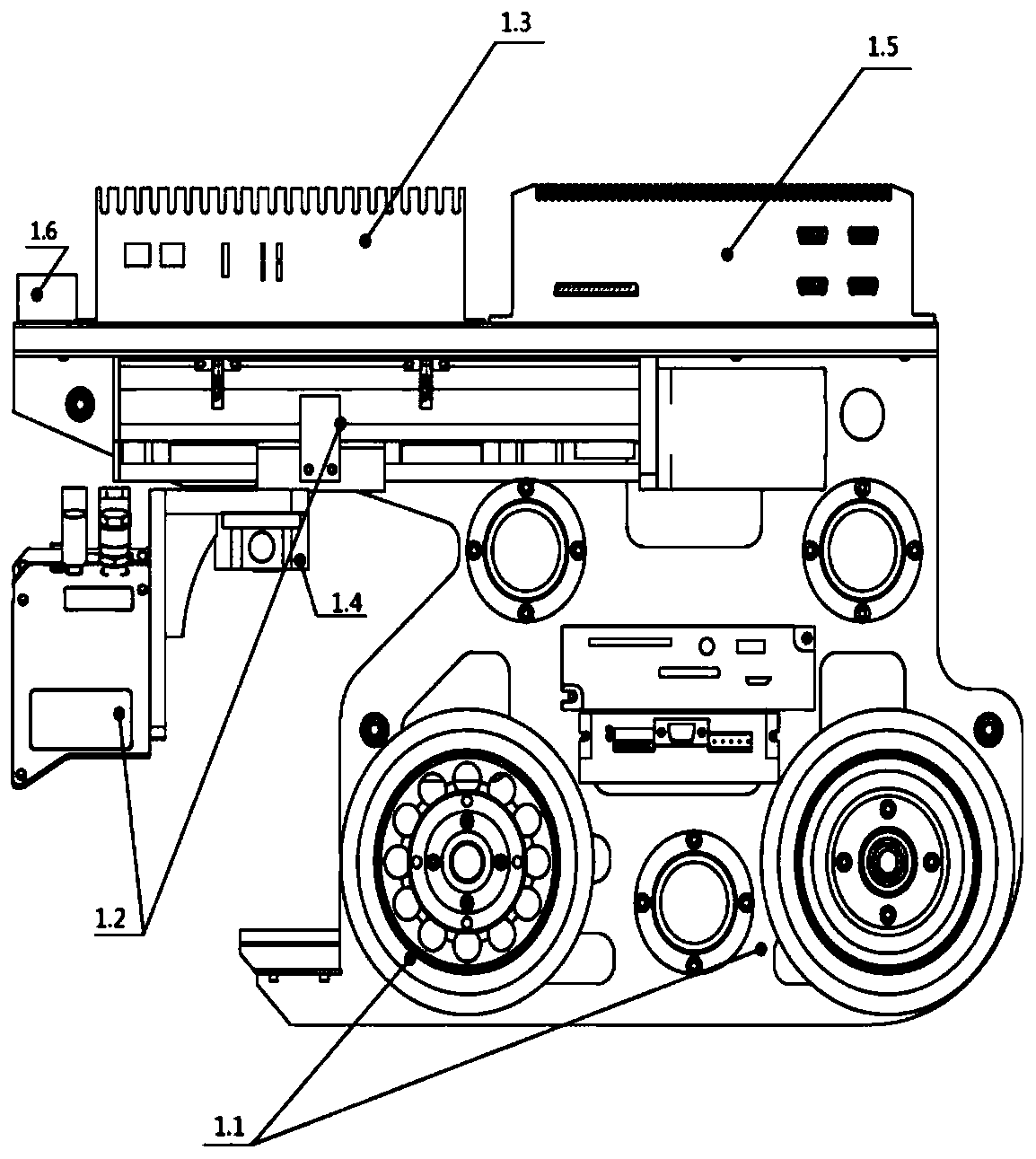

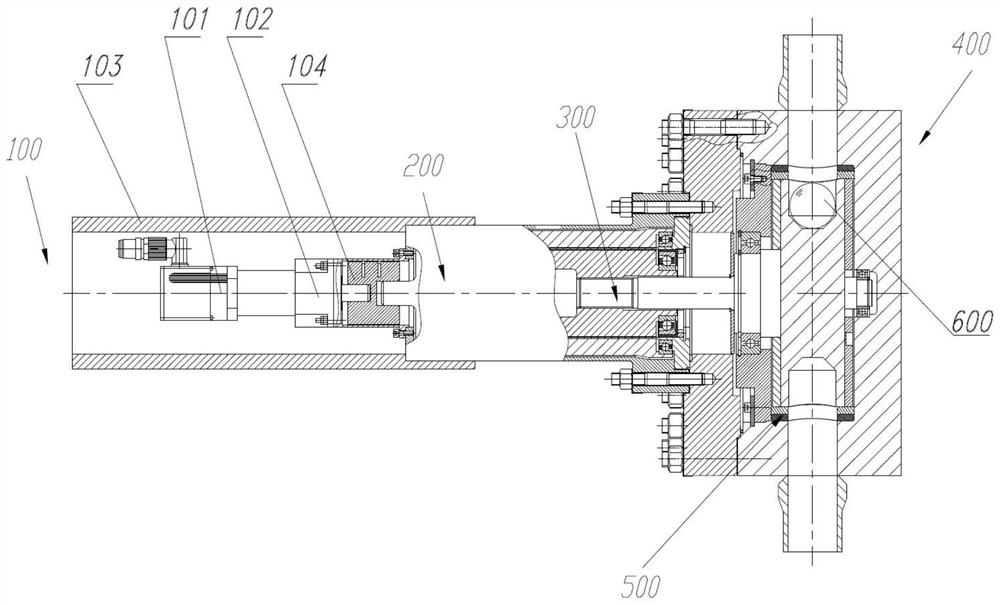

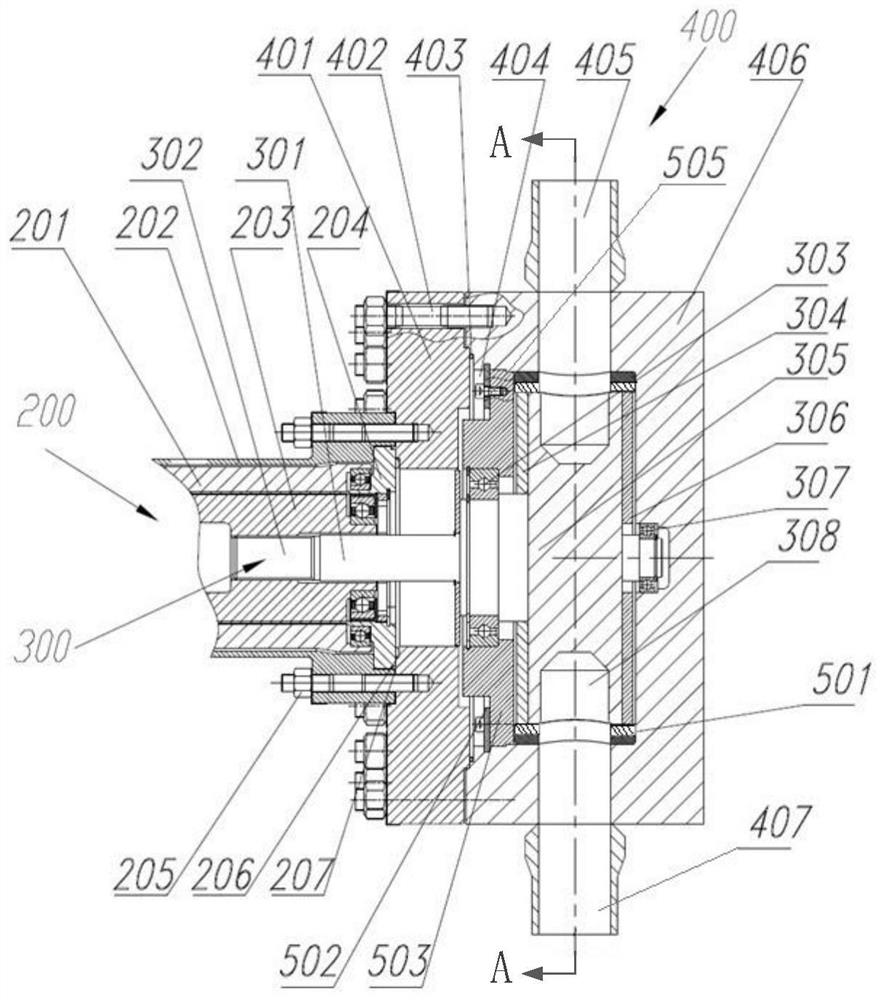

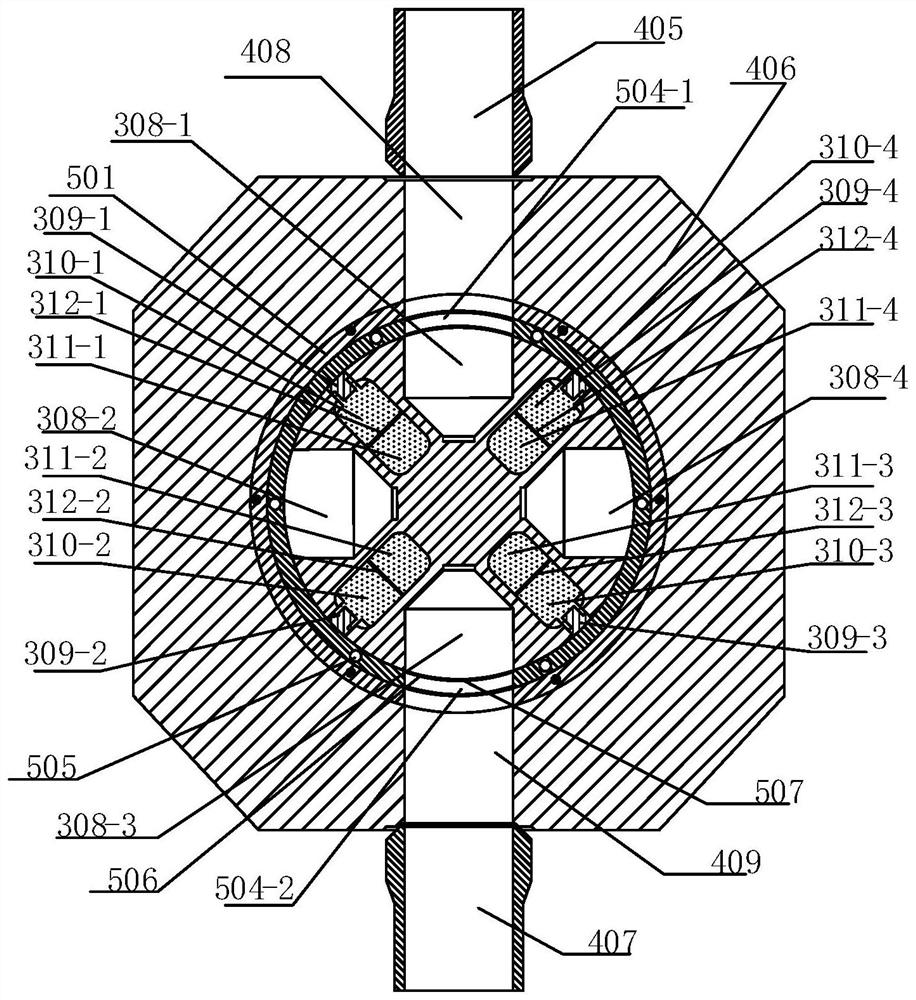

LRM (Line Replaceable Module) module locking and plugging device

ActiveCN102083288ARealize the locking functionQuick changeComponent plug-in assemblagesResilient/clamping meansEngineeringMechanical engineering

The invention provides an LRM (Line Replaceable Module) module locking and plugging device, which settles the problems of complex structure, poor stability and reliability and inconvenient locking and plugging operations in traditional products. The device is composed of a fork lever component fixed on a frame and a plugging component fixed on an LRM module, wherein the plugging component is designed in such a manner that double concave wheels are in elastic tight fit with a four-link movement mechanism, pressure is applied to a pin in the fork lever by pulling a push rod in order to lock or plug out the LRM module. The LRM module locking and plugging device realizes the onsite hand plugging and locking function for the first time on the premise of conforming to the ARINC650 standard, the entire mechanism achieves the automatic adjustment for tightening distance, eliminates processing and assembling errors and has predetermined pretightening force, thereby guaranteeing the reliable tightening of equipment under various harsh vibratory conditions.

Owner:AVIC NO 631 RES INST

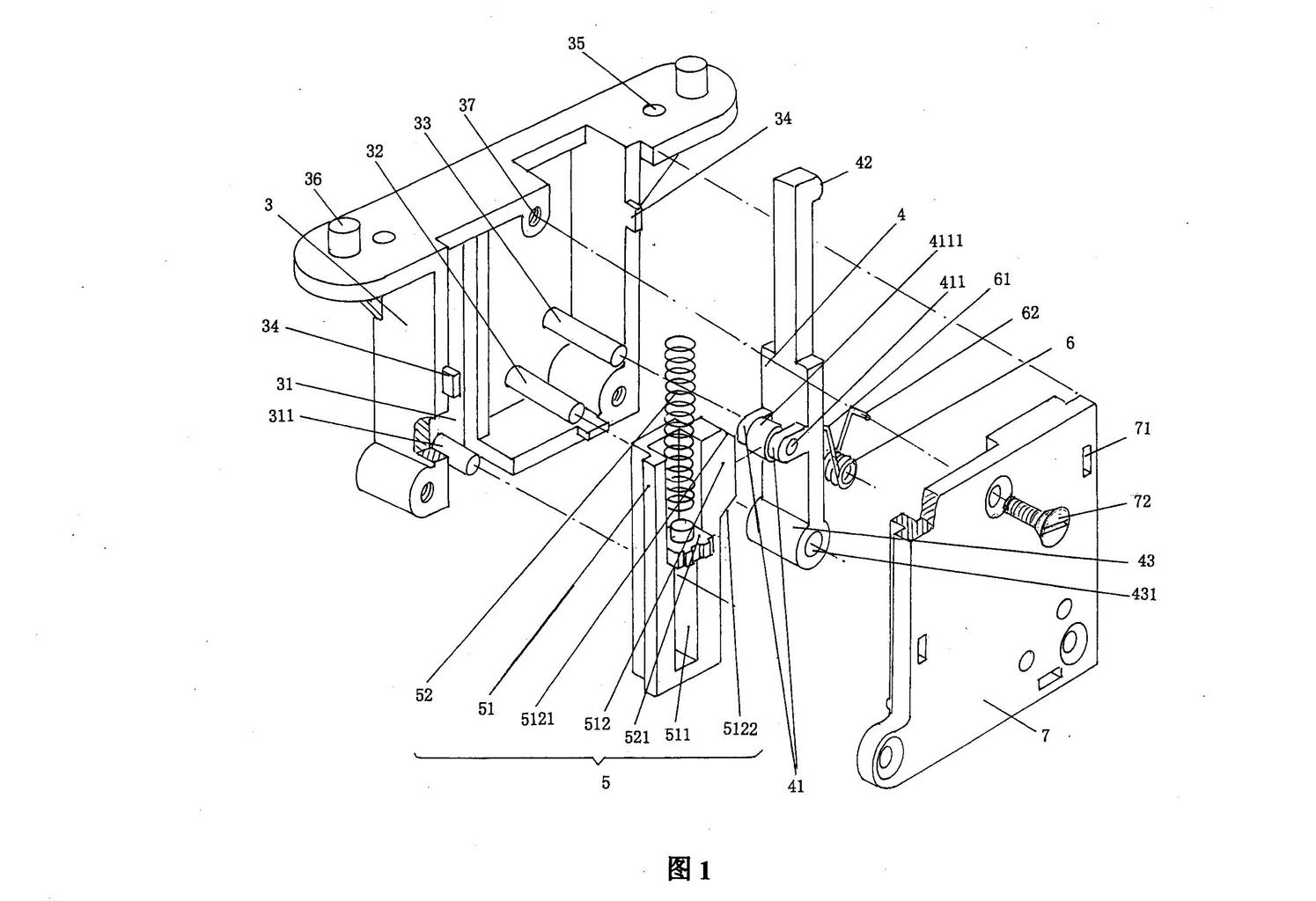

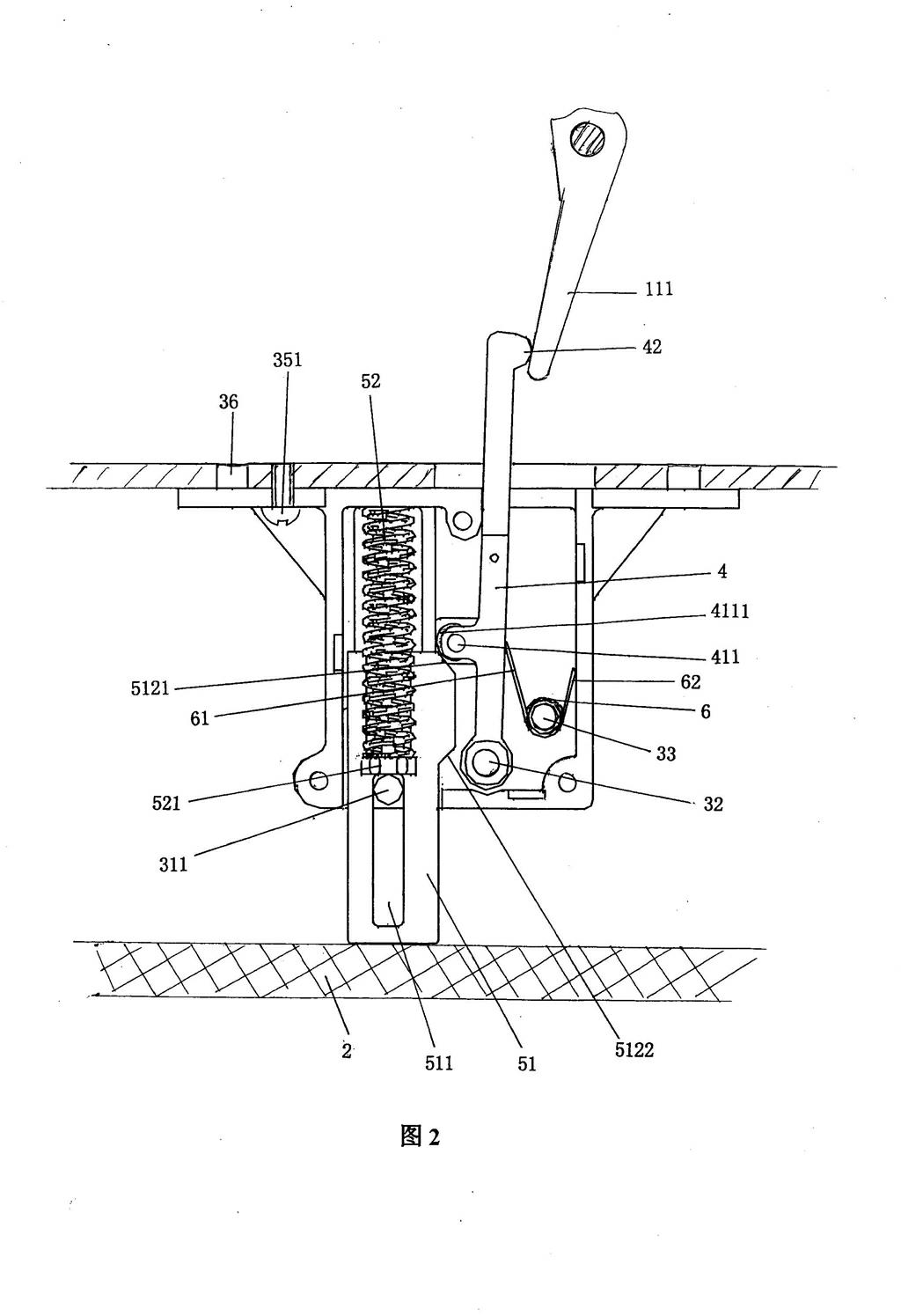

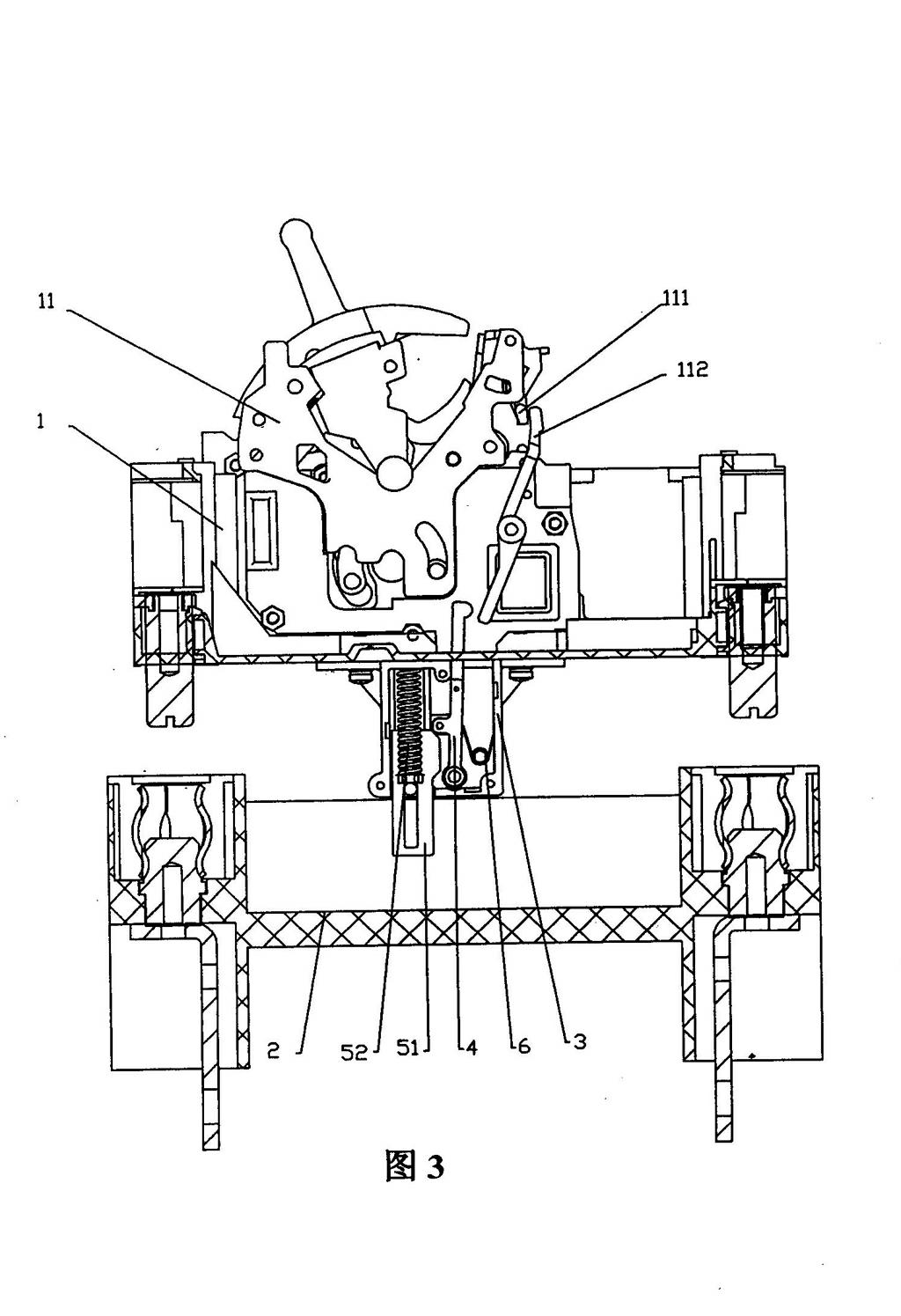

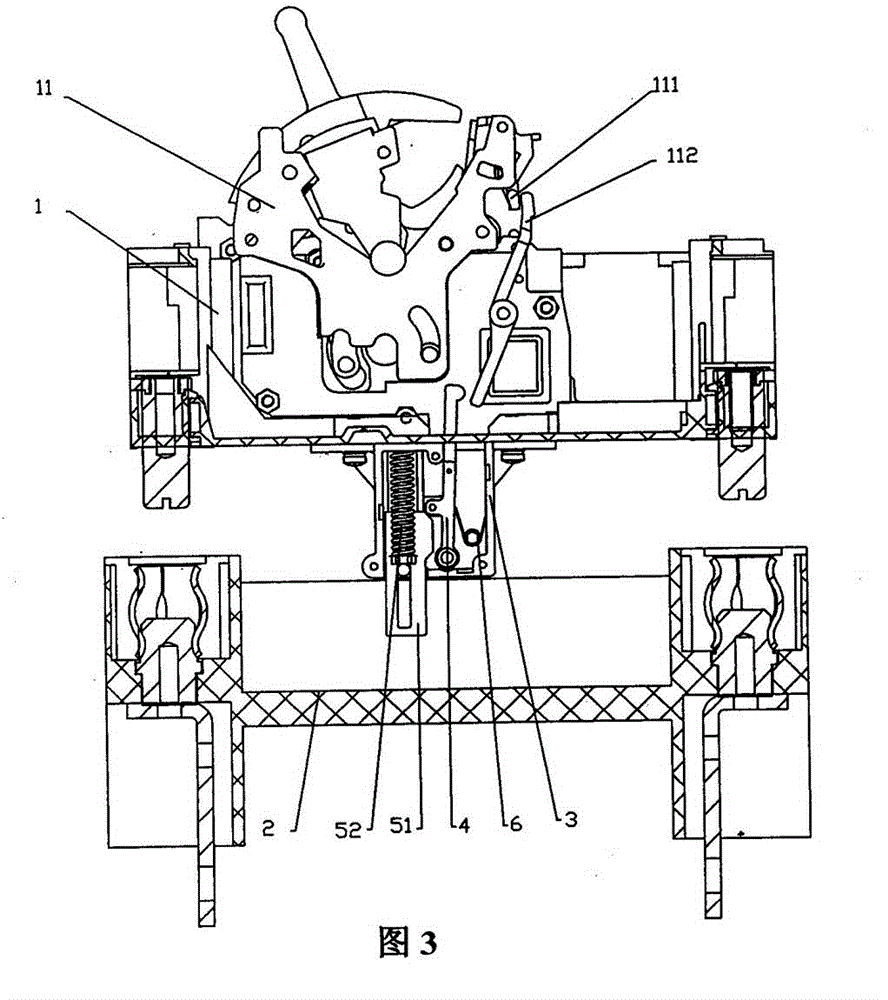

Interlocking device of draw-out circuit breaker

ActiveCN102427205AGuaranteed reliabilityPrevent invasionSwitchgear with withdrawable carriageForeign matterControl theory

The invention relates to an interlocking device of a draw-out circuit breaker, and belongs to the field of electrical techniques. The draw-out circuit breaker comprises a circuit breaker body and a socket. The circuit breaker body comprises an operating mechanism with a trip lever and a transmission rod. The interlocking device comprises a base, a rotating pushrod, a rotating pushrod actuating device and a rotating pushrod return spring, wherein the rotating pushrod is arranged on the base, and one end of the rotating pushrod which faces to the operating mechanism stretches out of the base, extends into the circuit breaker body and corresponds to the transmission rod; and the rotating pushrod actuating device is assembled on the base, one side of the rotating pushrod actuating device corresponding to the rotating pushrod is in contact with the rotating pushrod, and the part of the rotating pushrod actuating device which faces to the socket stretches out of the base and corresponds to the socket; and one end of the rotating pushrod return spring is born on the rotating pushrod and the other end of the rotating pushrod return spring is born on the base. The interlocking device of the draw-out circuit breaker has the advantages that the assembling errors caused by separate installation are eliminated and the action reliability is ensured; the invasion of dust and foreign matters is avoided; the interlocking device is universally suitable for draw-out circuit breakers at different current ratings; and since the overall structure is simple, the manufacturing, installation and maintenance are facilitated.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

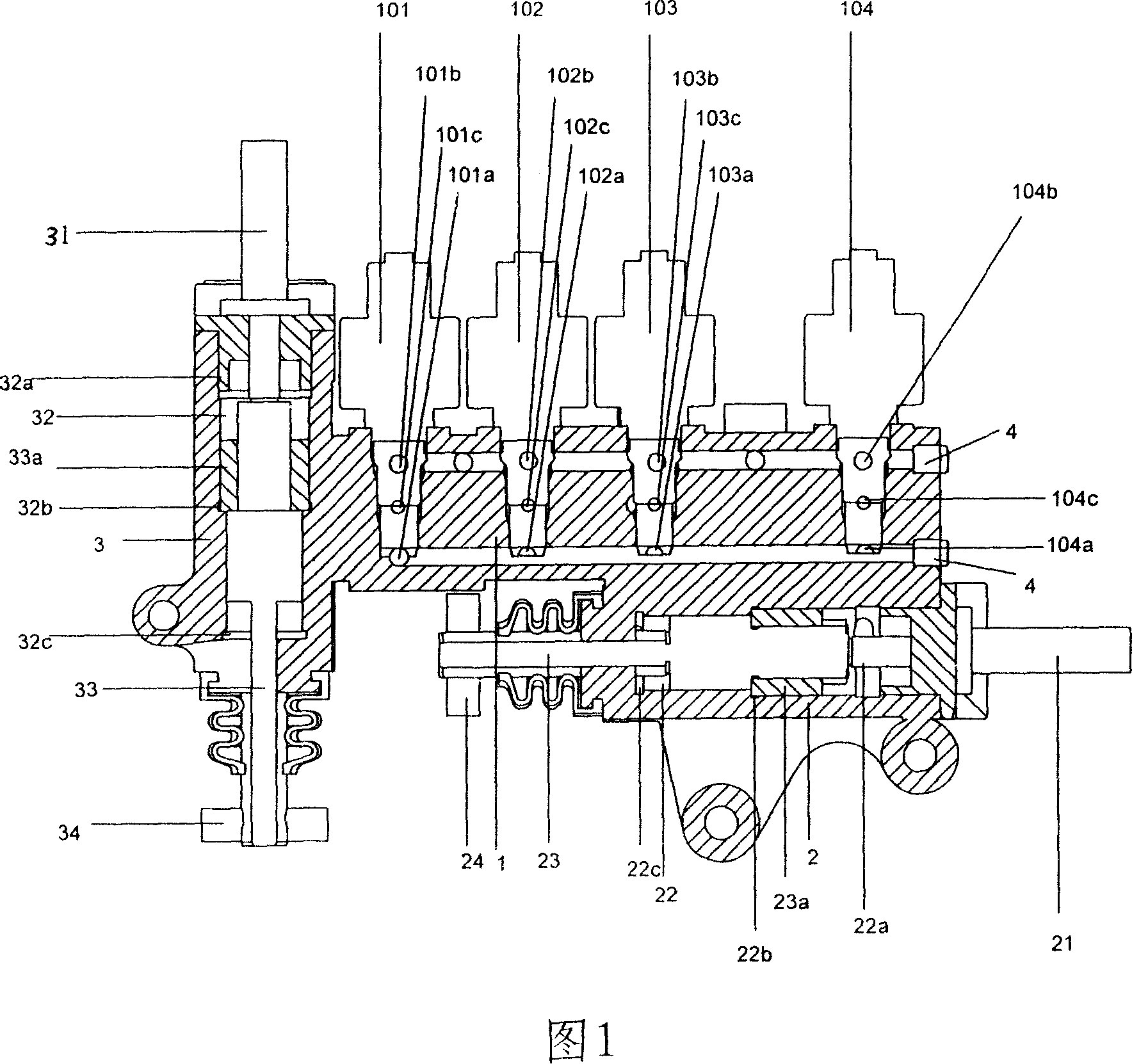

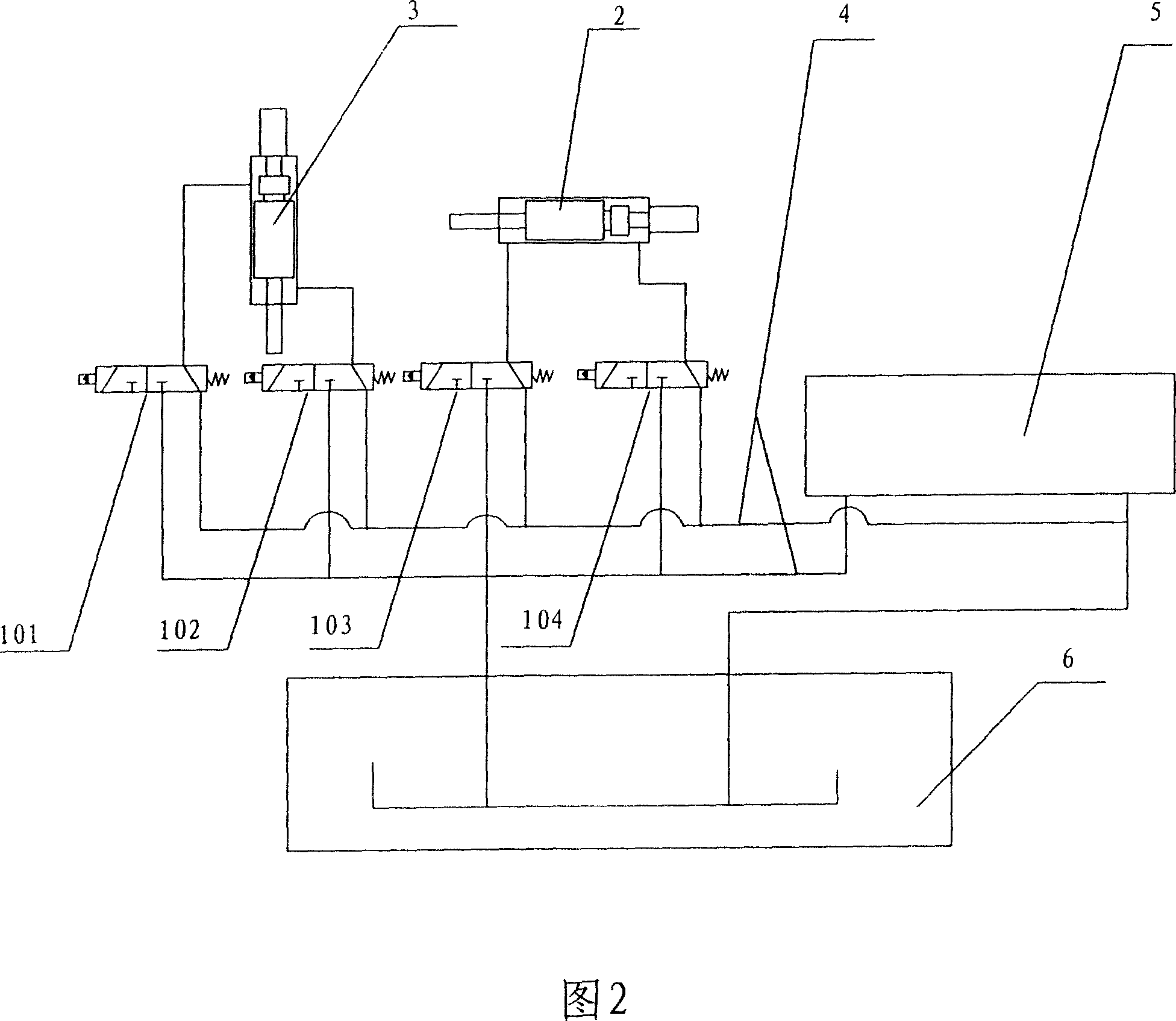

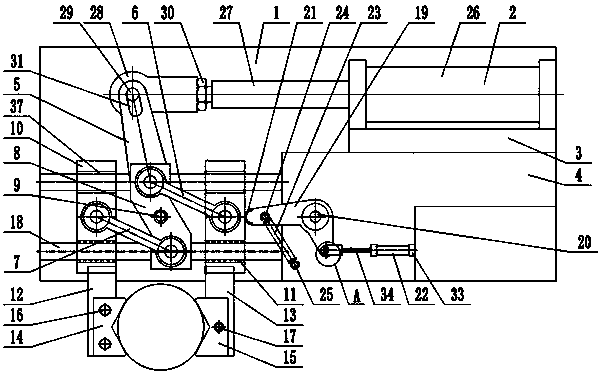

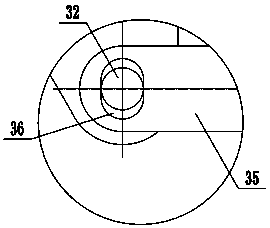

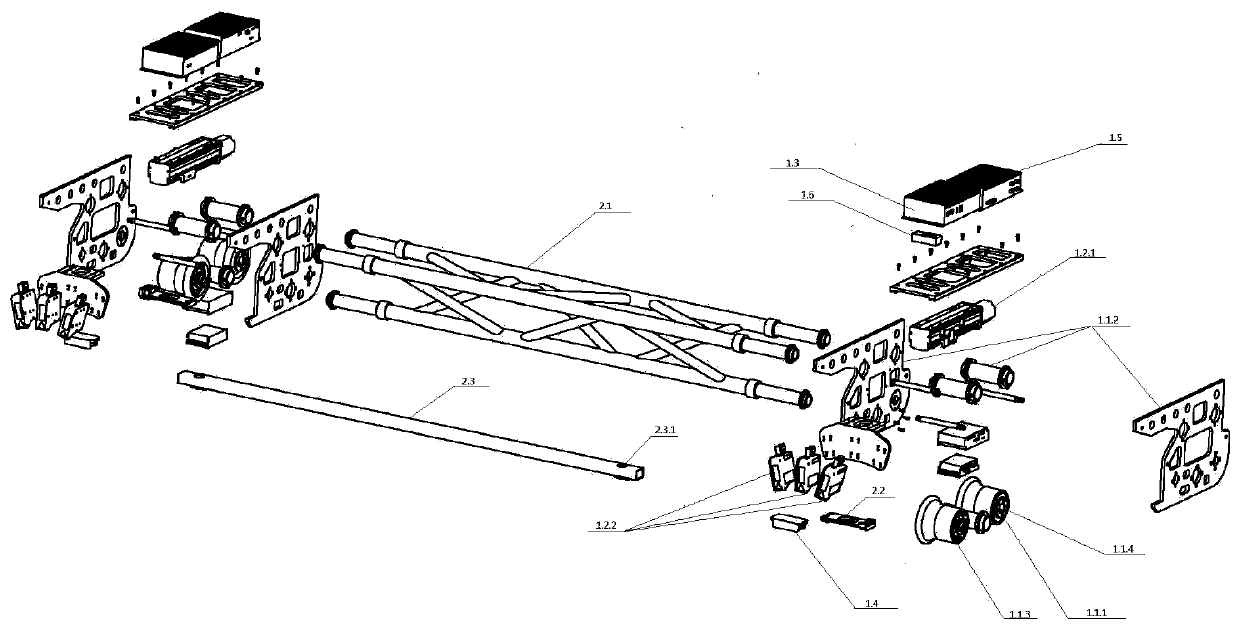

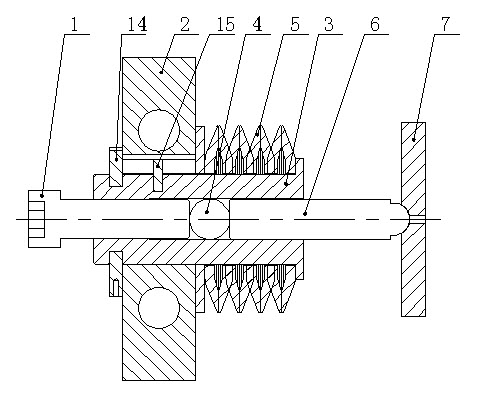

Gear-selecting and gear-shifting executive mechanism for automatic transmission

ActiveCN1971098AEliminate assembly errorsImprove transmission efficiencyGearing controlGearing detailsAutomatic transmissionEngineering

The invention relates to an actuator for selecting and exchanging gear of automatic transmission, comprising body, selector equipment, gear shift, control valve block. Selector oil cylinder of said selector equipment is assigned with exchanging oil cylinder of said gear shift in orthogonality. It is characterized in that said selector equipment, gear shift and control valve block is formed into a total part and is collected on said body, the equipment is connected with clutch mechanism and power resource by system oil pipe. The invention is provided with compact structure, good integrity, easily manufacturing, low cost and high stability. The actuator for selecting and exchanging gear is added on the mechanical transmission and there is almost no any change for mechanical transmission. The high transmission efficiency of mechanical transmission is maintained. The invention is commonly used to mechanical speed-changing box with different structure, especially the mechanical speed-changing box of automobile.

Owner:CHONGQING TSINGSHAN IND

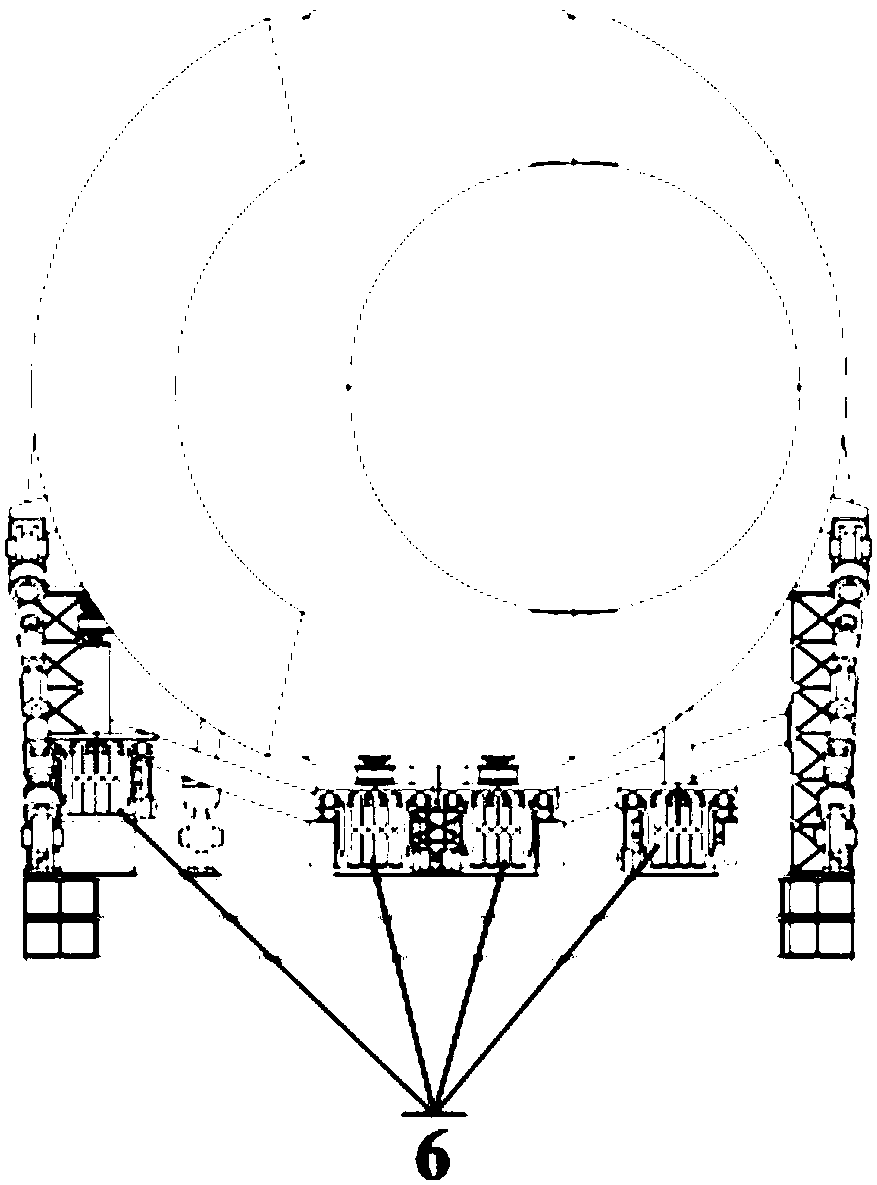

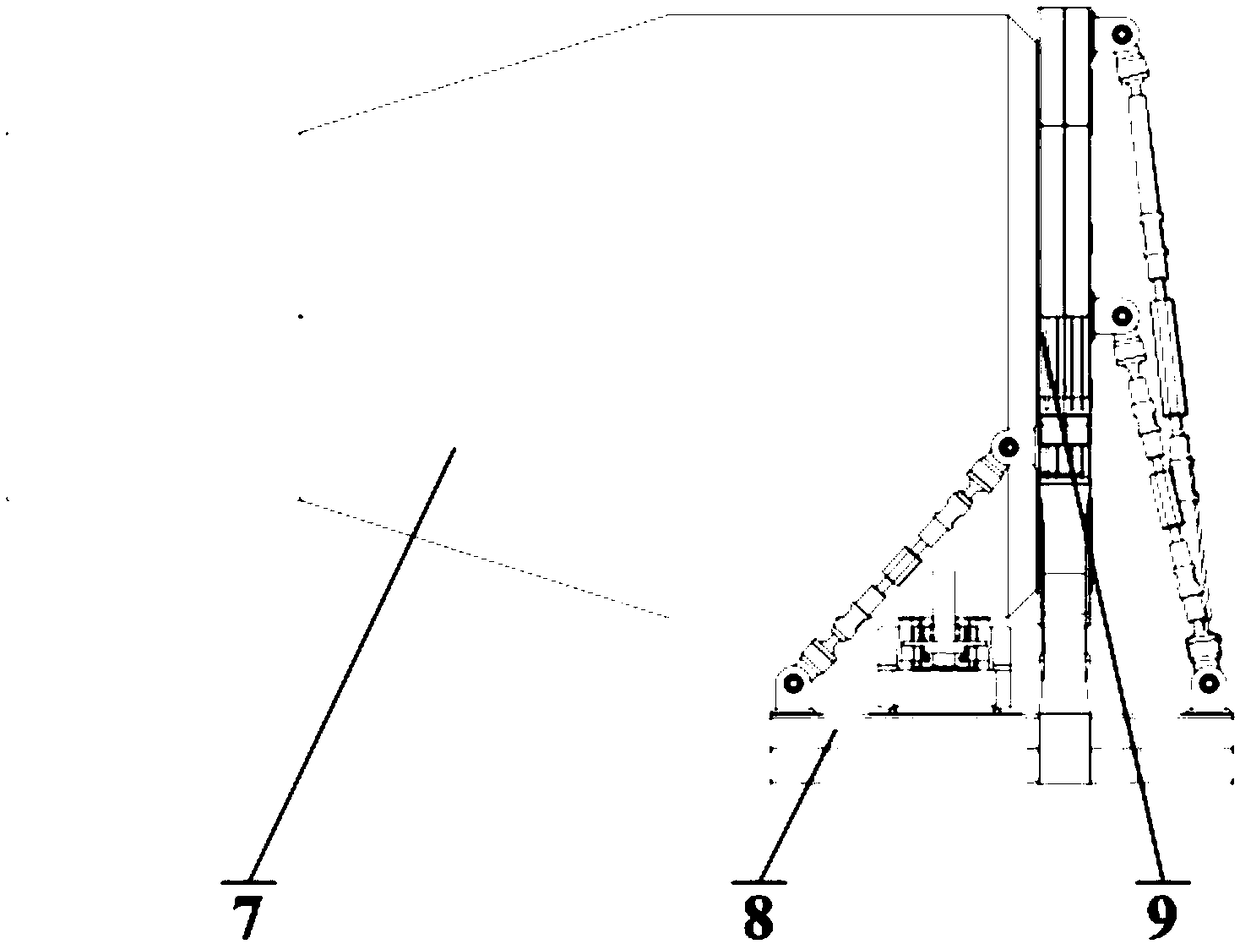

Floating support device for on-ground gravity unloading of aerospace optical load

ActiveCN109188648AImprove application accuracyReduce volumeMountingsImaging qualityOptical correction

The invention relates to the field of precision machinery and aerospace optical technology, and in particular discloses a floating support device for on-ground gravity unloading of aerospace optical load, comprising an unloading base, and multiple sets of gravity unloading devices arranged on the unloading base. The gravity unloading devices are fixedly arranged under the optical load. The floating support device also comprises multiple sets of fixed support devices arranged on the back of the optical load. Gravity unloading in the direction of the gravity vector can be achieved by the gravityunloading devices, thereby offsetting the maximum deformation introduced by the gravity of the large optomechanical structure, and significantly alleviating the effect brought by the inconsistency ofsky-earth mechanics on the accuracy of on-ground installation and alignment as well as the quality of on-orbit imaging of aerospace optical loading. Therefore, the invention provides basic image quality for on-ground pre-installation and alignment as well as active optical correction for high-sensitivity optical components. In addition, through on-ground gravity unloading, the unnecessary designof the large aperture optical load optomechanical structure and the launching cost can be greatly reduced, and the use efficiency of the aerospace vehicle can be improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

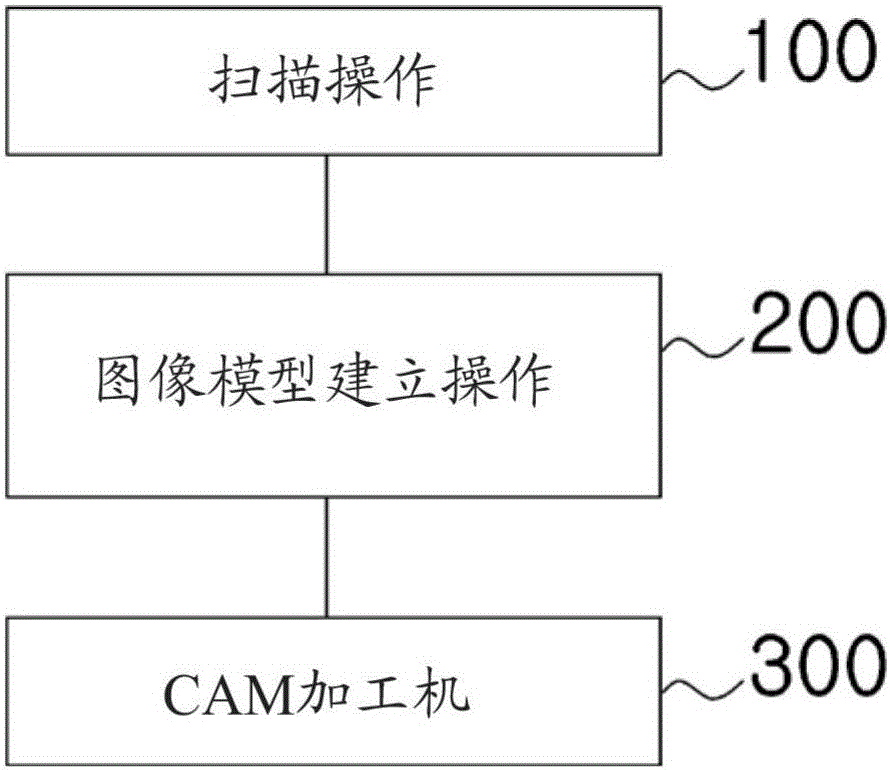

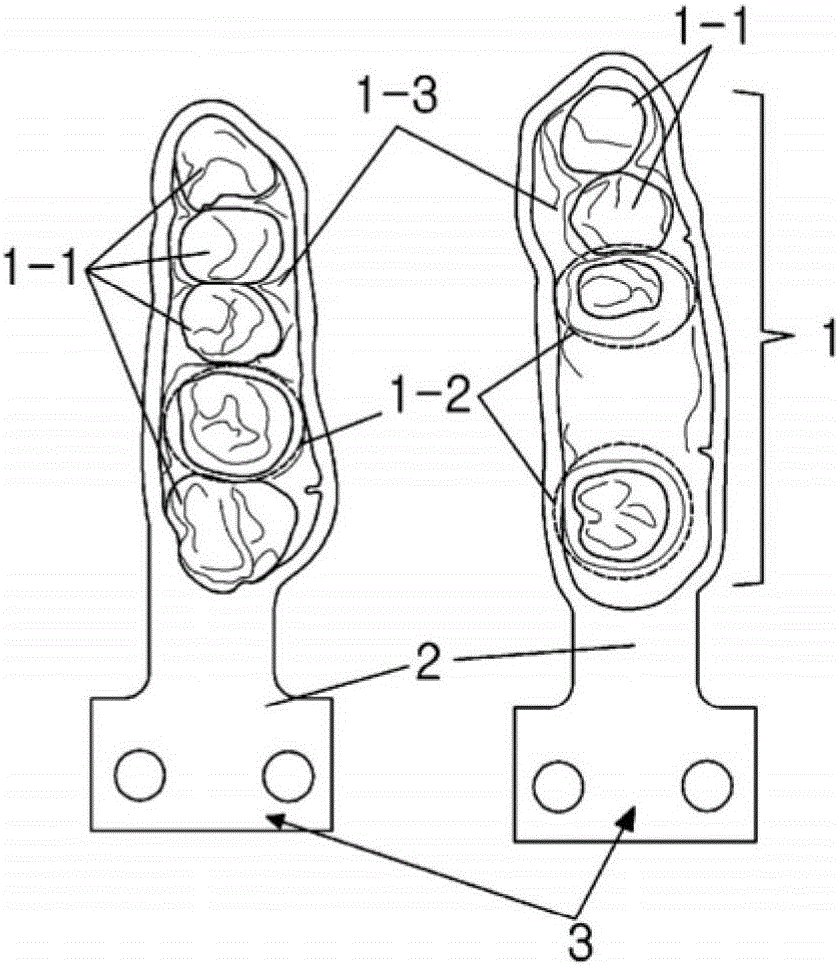

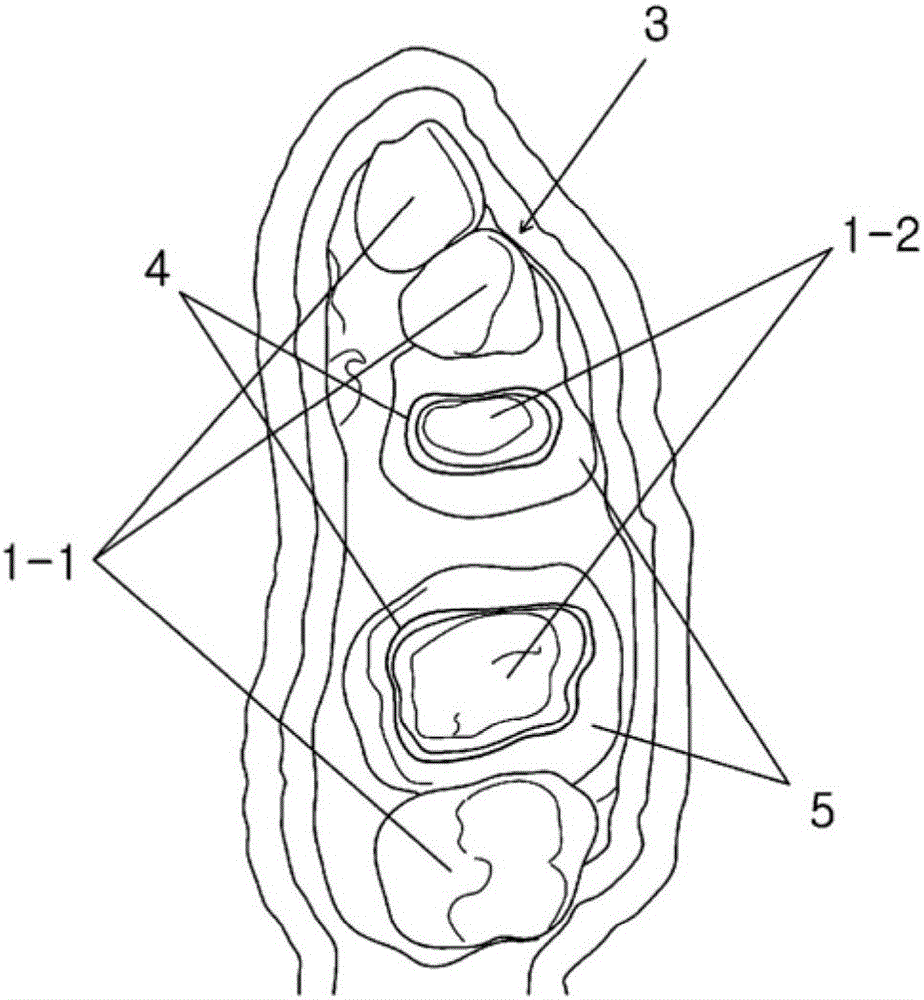

Method for manufacturing dental model

The present invention provides a method for manufacturing a dental model, which processes the dental model (3) having a model base (2) on which a teeth cast (1) of upper and lower jaws is disposed so as to promote productivity improvement through a reduction in processing time and enable an increase in precision due to the removal of errors when the upper and lower jaws occlude, in the processing and manufacturing of a dental model to be used for a dental treatment, the method comprising: a scan step (100) for acquiring data information by scanning dental information of a patient; an image model generation step (200) for implementing a dental model to be implemented as an image model by graphic-designing an image on the basis of data set on the basis of the dental information acquired through the scan step (100); and a computer aided manufacturing (CAM) processing step (300) for generating the dental model by processing through CAM on the basis of the image model generated through the image model generation step (200), wherein the image model and the dental model (3) acquired through the image model generation step (200) and the CAM processing step (300) are designed and mold-processed such that the teeth model (1) and the model base (2) are integrally formed.

Owner:ROBOTS & DESIGN

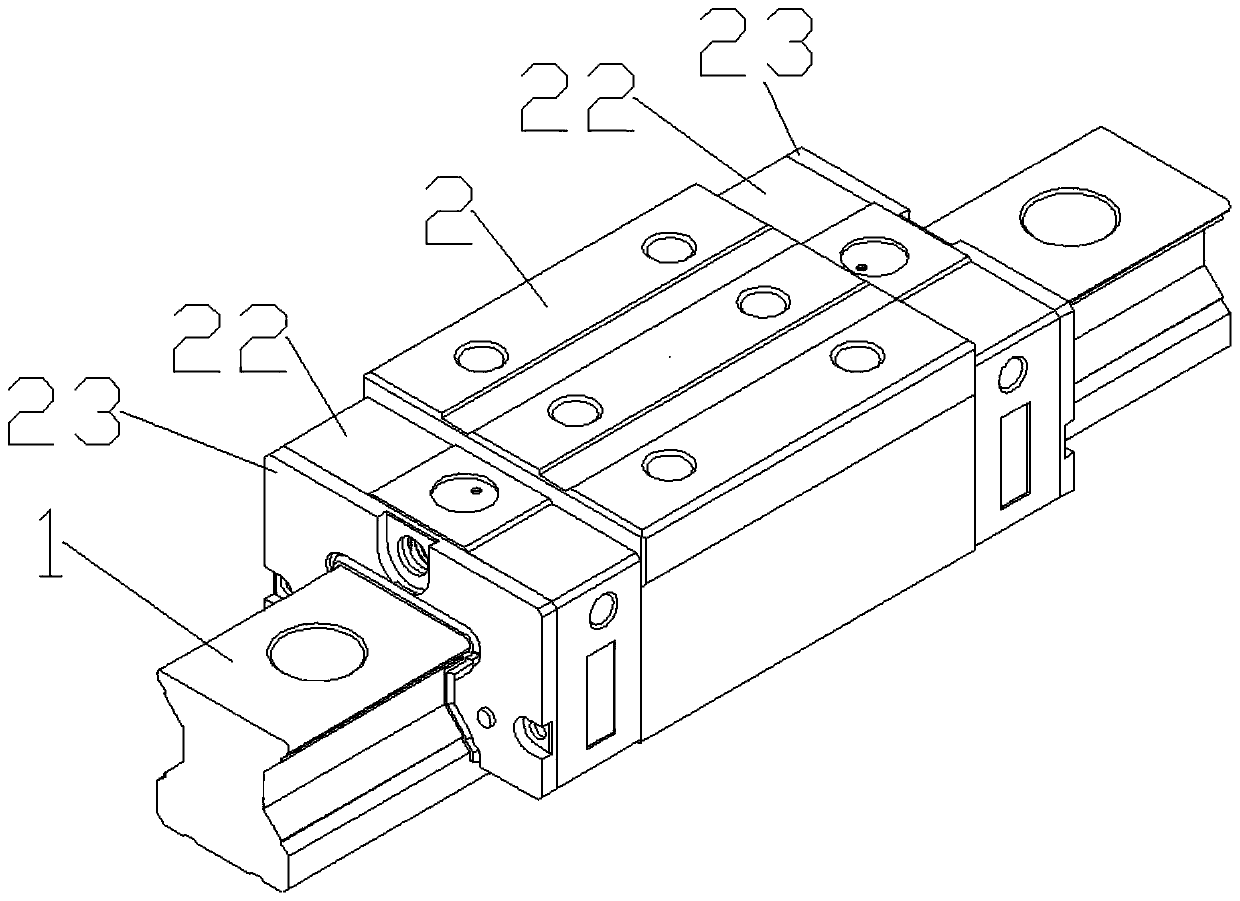

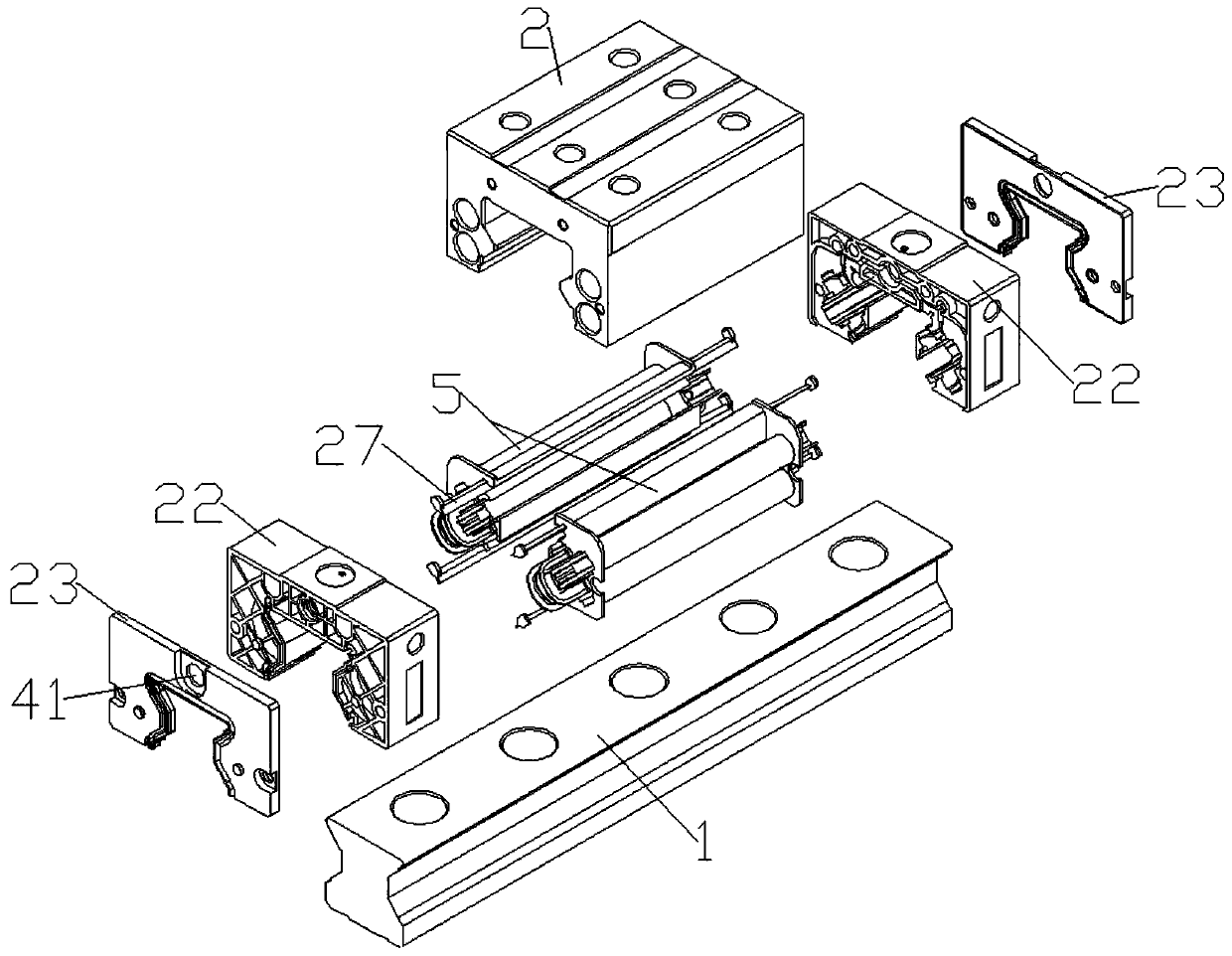

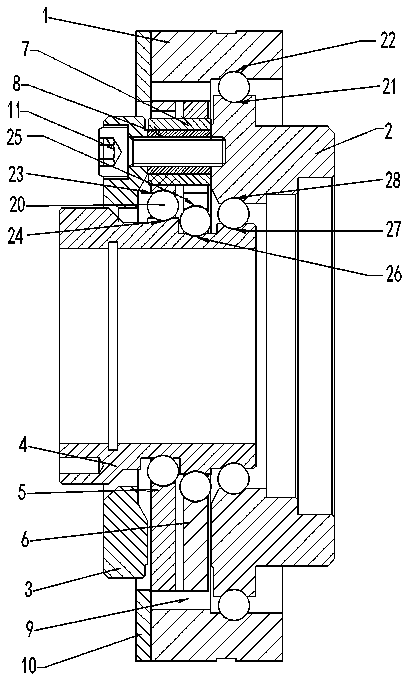

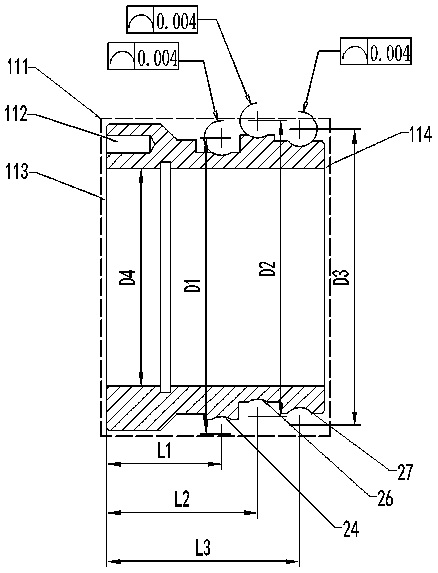

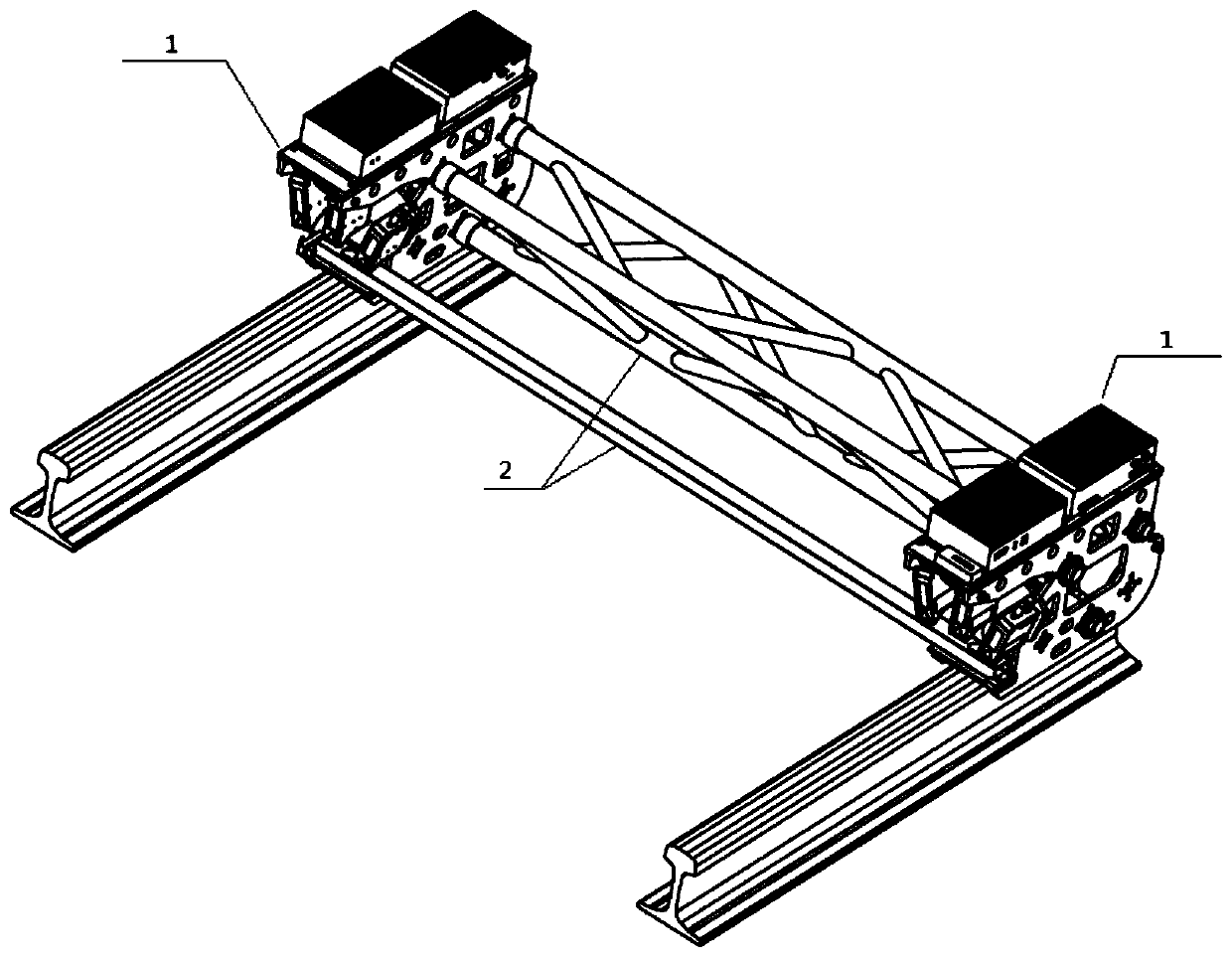

Pin roller linear guide rail

InactiveCN110360221ASave assembly timeImprove integrityLinear bearingsTrackwayArchitectural engineering

A pin roller linear guide rail comprises a guide rail, wherein a sliding block is arranged on the outer side of the upper end of the guide rail, the sliding block comprises a sliding block body, and amounting groove is formed in the center of the lower end of the sliding block body; two upper circulating channels and two lower circulating channels are respectively arranged on the left side and the right side of the mounting groove; circulating devices are arranged on the left side and the right side of the sliding block body; the left end circulating device comprises backflow pipes arranged on the inner side of the circulating channels; clamping plates are arranged at the front ends and the rear ends of backflow pipes; an upper support is connected to the right sides of the upper ends ofeach of the front clamping plate and rear clamping plate; a middle support is connected to the right sides of the middle ends of each of front clamping plate and rear clamping plate; a lower support is connected to the right sides of the lower ends of each of front clamping plate and rear clamping plate; the front ends of the second circulating channel and the third circulating channel are connected through a first circulating part; the front ends of the first circulating channel and the fourth circulating channel are clamped with a second circulating part; the rear ends of the first circulating channel and the fourth circulating channel are clamped with a third circulating part, the rear ends of the second circulating channel and the third circulating channel are clamped with a fourth circulating part; and the front and rear ends of the sliding block body are provided with sealing covers corresponding to the sliding block body, and the outer sides of the front sealing cover and the rear sealing cover are fixedly connected with end covers.

Owner:LISHUI JIEXIANG TECH CO LTD

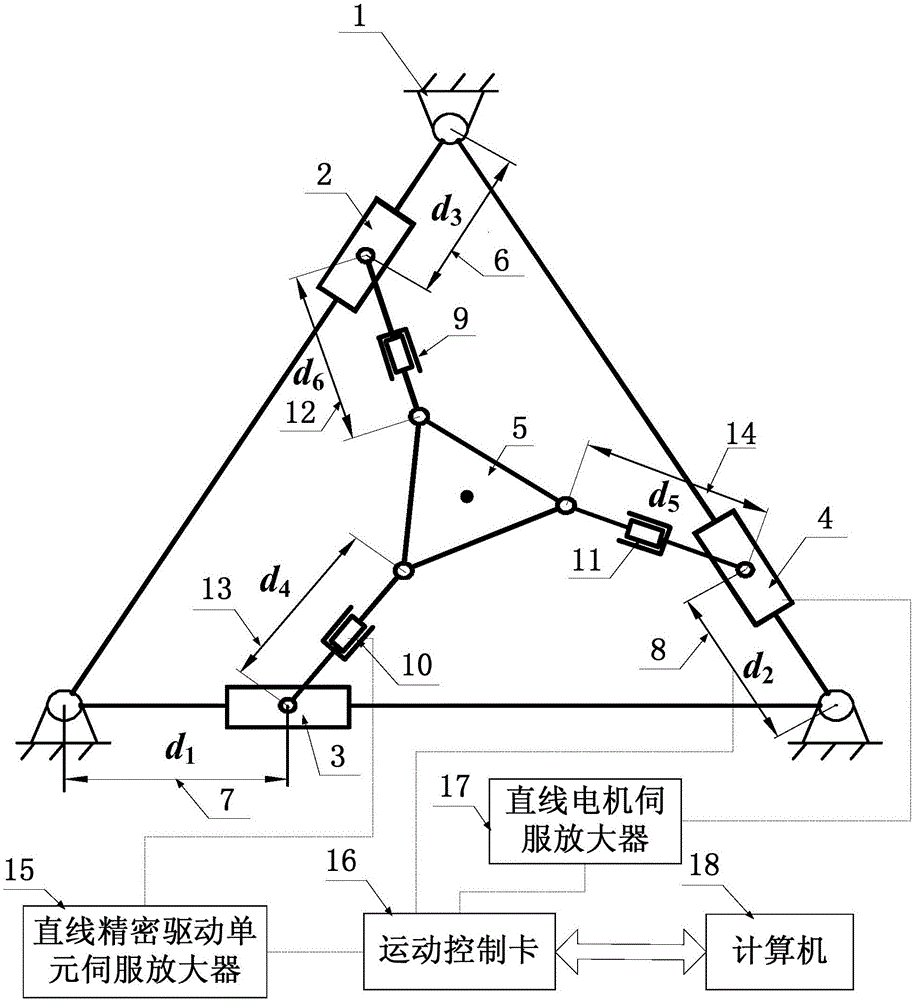

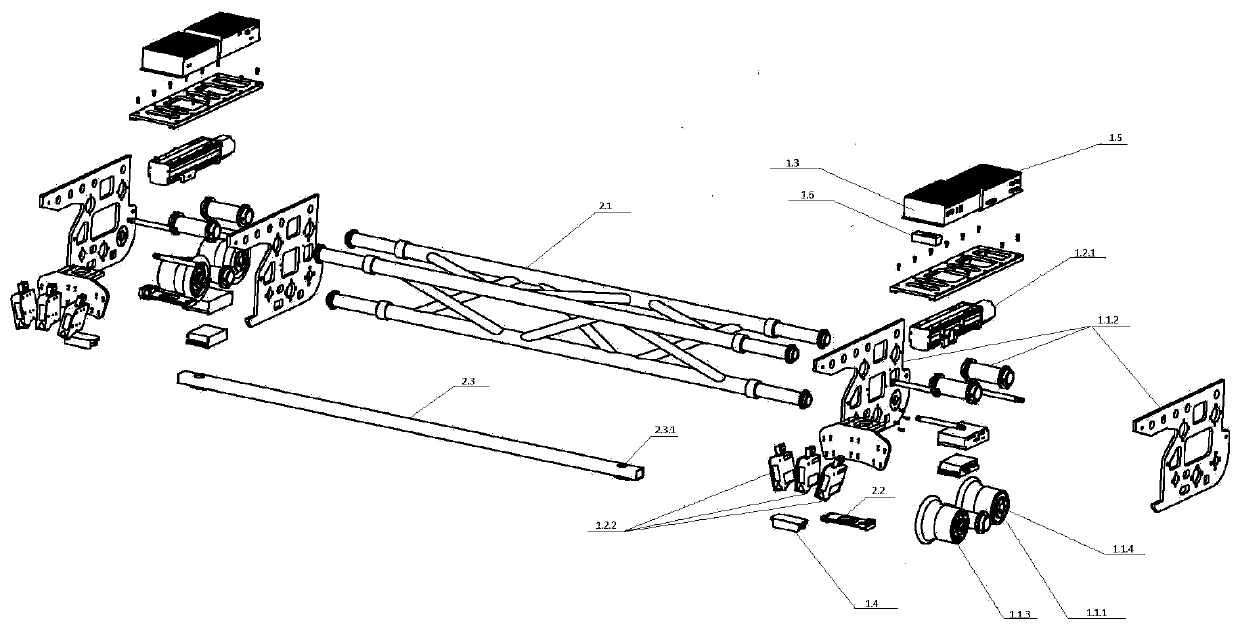

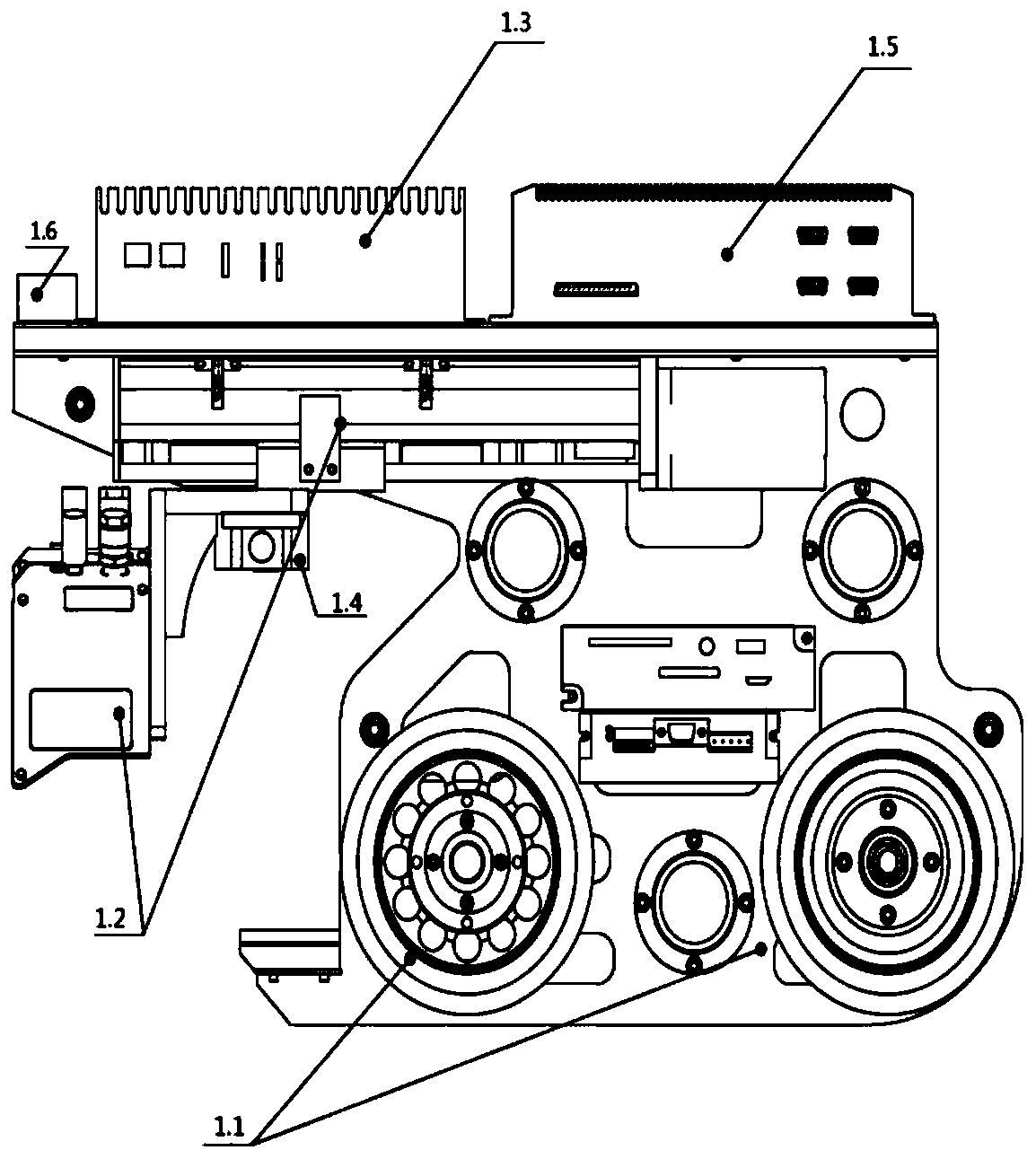

Macro-micro integrated motion high-precision parallel mechanism device and control method

InactiveCN106313013ADisadvantages of evasive movementAvoid disadvantagesProgramme-controlled manipulatorRange of motionEngineering

The invention discloses a macro-micro integrated motion high-precision parallel mechanism device and a control method. The macro-micro integrated motion high-precision parallel mechanism device comprises a mechanical body part and a control part. The mechanical body part comprises a fixed platform, a moving platform, linear motor drive branched chains for driving macro motion of the moving platform and micro motion branched chains for driving precise micro motion of the moving platform. The control part comprises a linear motor servo amplifier, a linear precise drive unit servo amplifier, a motion control card and a computer. Linear motor macro motion guarantees the trajectory tracking and motion range, high-precision locating control is achieved through micro motion driven by linear precise drive units, the contradiction of the large stroke and the high precision is solved through macro motion and micro motion integration, and high-precision locating control is achieved in large work space.

Owner:SOUTH CHINA UNIV OF TECH

Interlocking device of draw-out circuit breaker

ActiveCN102427205BGuaranteed reliabilityPrevent invasionSwitchgear with withdrawable carriageForeign matterControl theory

The invention relates to an interlocking device of a draw-out circuit breaker, and belongs to the field of electrical techniques. The draw-out circuit breaker comprises a circuit breaker body and a socket. The circuit breaker body comprises an operating mechanism with a trip lever and a transmission rod. The interlocking device comprises a base, a rotating pushrod, a rotating pushrod actuating device and a rotating pushrod return spring, wherein the rotating pushrod is arranged on the base, and one end of the rotating pushrod which faces to the operating mechanism stretches out of the base, extends into the circuit breaker body and corresponds to the transmission rod; and the rotating pushrod actuating device is assembled on the base, one side of the rotating pushrod actuating device corresponding to the rotating pushrod is in contact with the rotating pushrod, and the part of the rotating pushrod actuating device which faces to the socket stretches out of the base and corresponds to the socket; and one end of the rotating pushrod return spring is born on the rotating pushrod and the other end of the rotating pushrod return spring is born on the base. The interlocking device of the draw-out circuit breaker has the advantages that the assembling errors caused by separate installation are eliminated and the action reliability is ensured; the invasion of dust and foreign matters is avoided; the interlocking device is universally suitable for draw-out circuit breakers at different current ratings; and since the overall structure is simple, the manufacturing, installation and maintenance are facilitated.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

Parallel translation type connecting rod lever type clamping device

InactiveCN108673380AGuaranteed four-point contactInhibit sheddingWork holdersPneumatic circuitSoftware engineering

The invention provides a parallel translation type connecting rod lever type clamping device, and belongs to the technical field of machining. The parallel translation type connecting rod lever type clamping device comprises a swing rod, a first connecting rod, a second connecting rod and a lever, a left sliding block and a right sliding block are arranged on a guide rod in a sliding manner, a left V-shaped clamping claw is installed on the right side of a left finger through two fastening screws, a right V-shaped clamping claw is installed on the left side of a right finger through a fastening pin shaft, the lower end of the swing rod is fixedly connected with the upper end of the lever, the left end of the first connecting rod is hinged to the upper end of the lever, the right end of thefirst connecting rod is hinged to the middle end of the right sliding block, the left end of the second connecting rod is hinged to the middle end of the left sliding block, the right end of the second connecting rod is hinged to the lower end of the lever, the middle end of the locking lever is hinged to an L-shaped support through a locking lever pin shaft, and a hemispheric pressure pad is installed at the left end of the locking lever. According to the parallel translation type connecting rod lever type clamping device, it is guaranteed that the left V-shaped clamping claw and the right V-shaped clamping claw achieve four-point contact of disc type workpieces, and the disc type workpieces are prevented from falling when a pneumatic circuit breaks down.

Owner:张雅婷

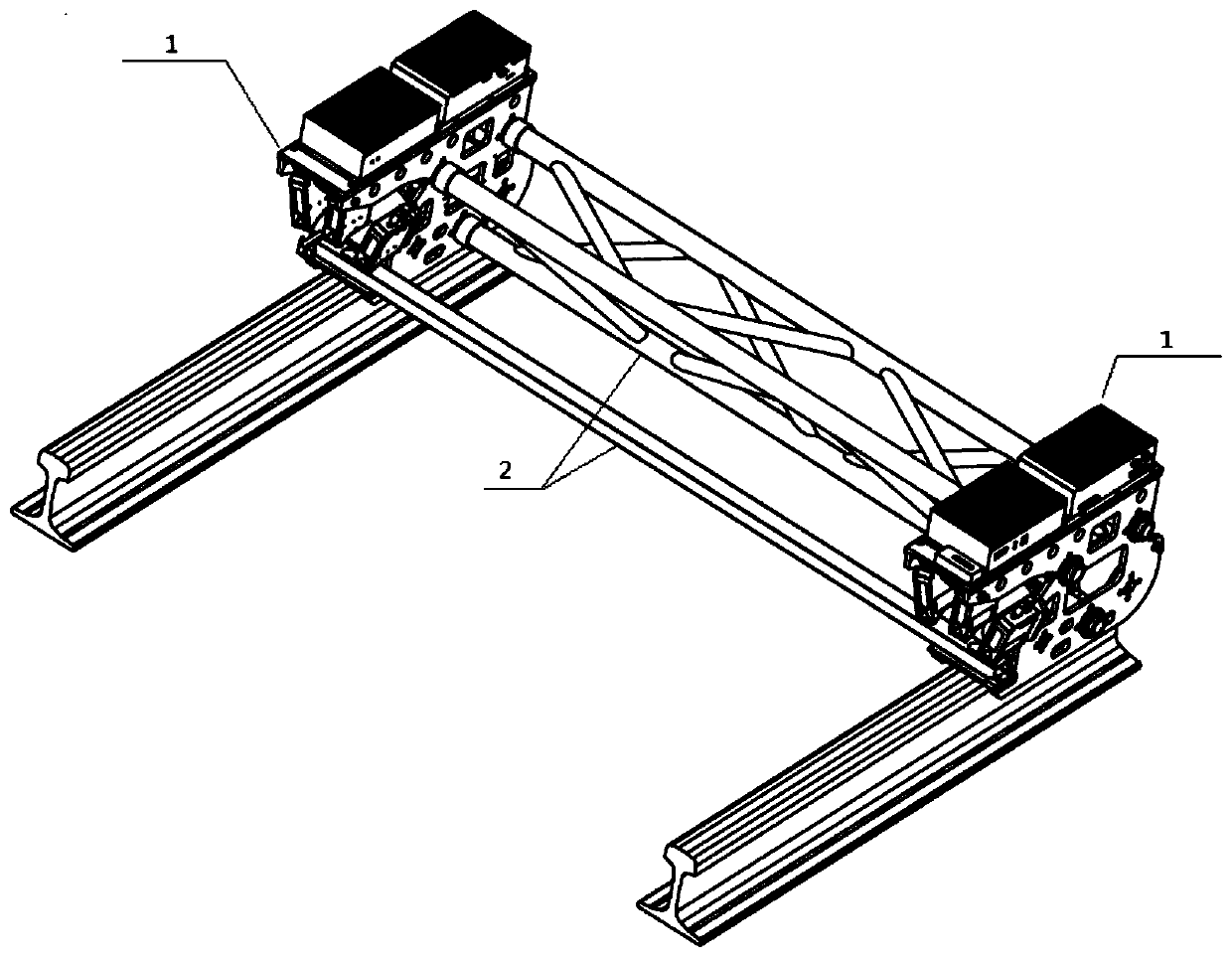

Use method of portable modular self-correcting rail three-dimensional detection system

PendingCN111469882AAvoid detection errorsEasy and fast on-site assemblyRailway auxillary equipmentRailway profile gaugesRail profile3d image

The invention belongs to the technical field of railway safety transportation, and relates to a use method of a portable modular self-correcting rail three-dimensional detection system. When the system is in use, the system is quickly assembled on site, and a manual operator is wirelessly connected with two detection units to complete the overall initialization of equipment; a marker of a calibration rod is scanned to obtain a 3D image, the 3D image is compared with factory calibration reference 3D images on the left and right sides to judge whether the 3D image is in an error range or not, the reading of a horizontal detection sensor is further read if no fault is detected, and a three-dimensional space coordinate system of the unit is self-corrected; the overall coordinate system is corrected according to the calibration rod, a coordinate system taking the geodetic horizontal plane as a reference is established through delivery calibration information of the horizontal detection sensor, and the 3D image of a railway track is integrally scanned; feature information including a rail, a rail top surface and a rail edge is identified, and feature information including a rail distance, a rail height, a rail extension angle and a rail profile is calculated; and the detection units acquire GPS positioning information and acquire walking information of a walking encoder.

Owner:青岛瑞捷轨道科技有限公司

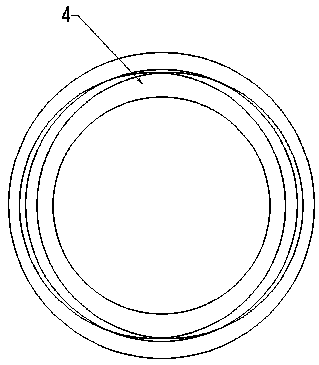

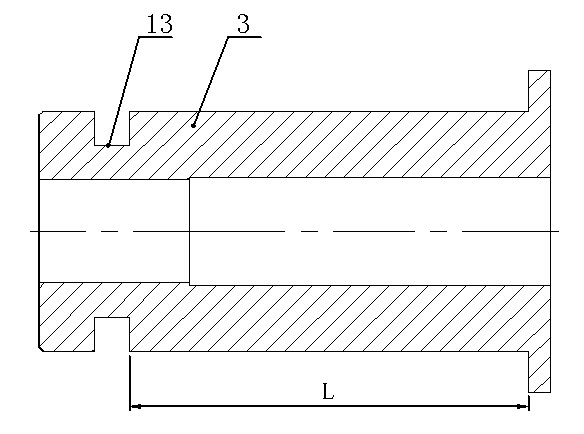

Cavity filter frequency adjustment mechanism

The present invention provides a frequency governing mechanism for cavum filter, which comprises of cavum body, inner and outer medium and connecting rod moved by gearing. The outer medium is placed in cavum body, the connecting rod is placed in outer medium, and the inner medium is mounted on connecting rod. Wherein, a stretch device capable of making connecting rod, inner medium axes and cavum body or / and outer medium concentric automatically is set on the connecting rod. The stretch device can be set in corresponding groove of cavum body, cover board or gearing, which comprises of at leasttwo elastic members symmetric to center of vacuum, the front end of each member has stretch working surface matched to connecting rod, the rear end is arc surface capable of swing automatically alonginner wall of groove and stretched touch with inner wall of groove. A pair of elastic double nuts space adjusting member is set on the lead screw. The present invention can eliminate assembly error, ensure the motor lead screw, connecting rod, vacuum body, inner or outer medium and cover board is concentric, improve the rigidity of connecting rod.

Owner:SHENZHEN GRENTECH RF COMM LTD

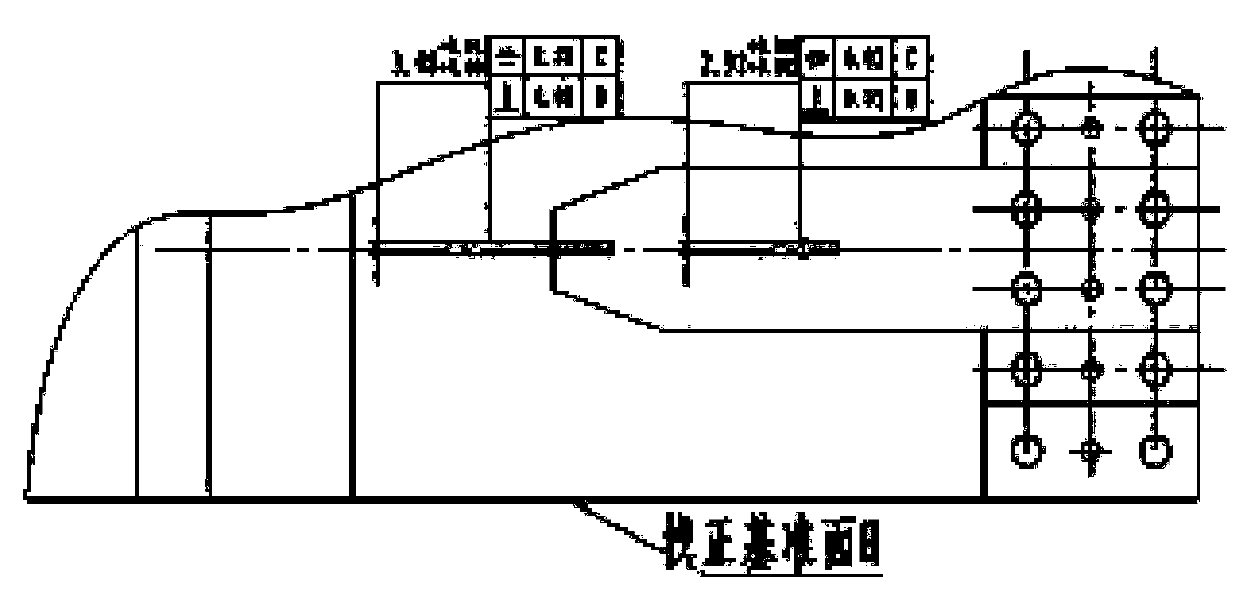

Processing method of input shaft of integral high-precision hollow speed reducer

The invention discloses a processing method of an input shaft of an integral high-precision hollow speed reducer. The processing method includes the steps of forging a blank of the input shaft, processing an inner bore of the blank of the input shaft, processing a first positioning plane and a second positioning plane of the blank of the input shaft, processing a positioning pin hole in the blankof the input shaft, clamping and assembling the blank of the input shaft by one step, and finishing a first outer race, a second outer race and a third outer race of the input shaft respectively. Without weakening various functions of the speed reducer, the processing method, aiming to improve service life of the input shaft, reduces error accumulation during assembling by reducing number of parts, eliminates three bearing stations of the conventional input shaft, processes the inner races of bearings onto the input shaft directly to eliminate assembly error between the bearings and the bearing stations, and accordingly improves precision.

Owner:SHANDONG SHKE MACHINERY MFG +1

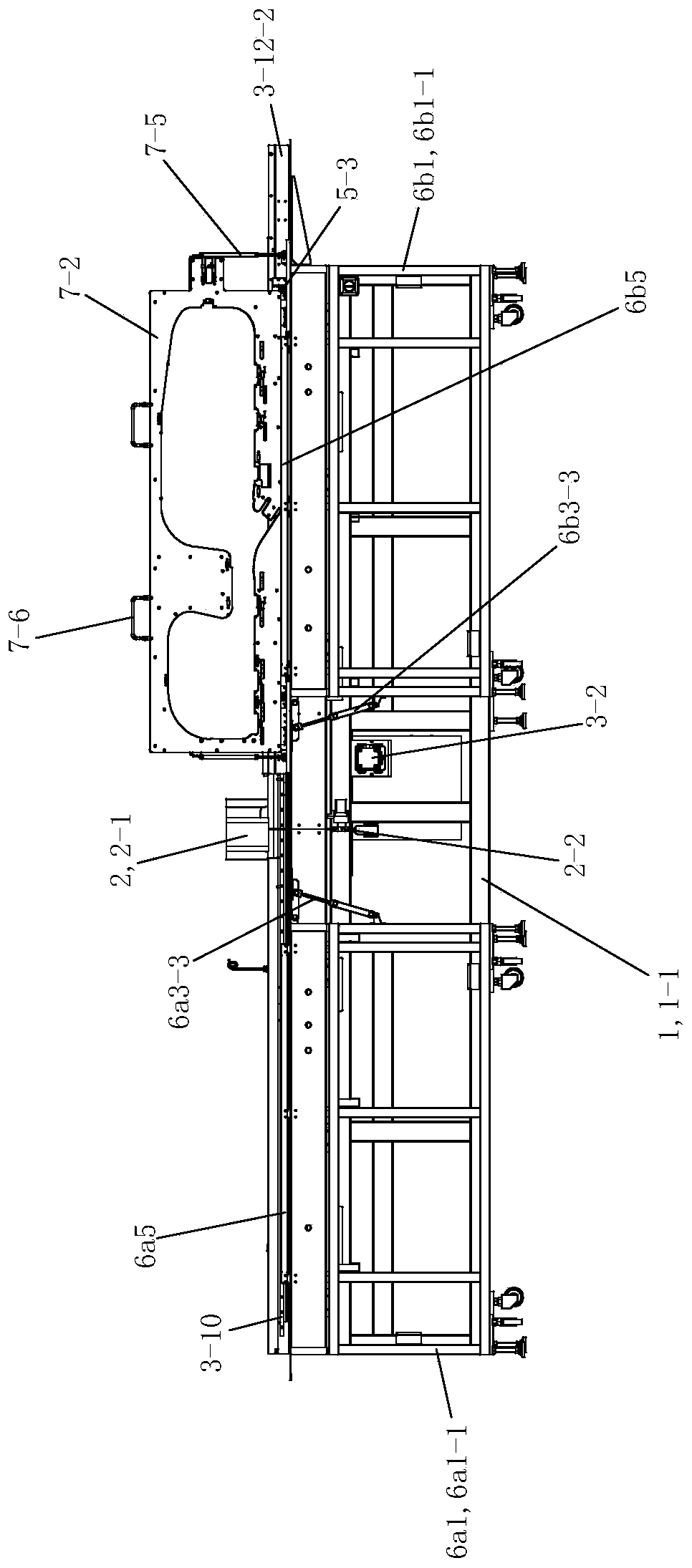

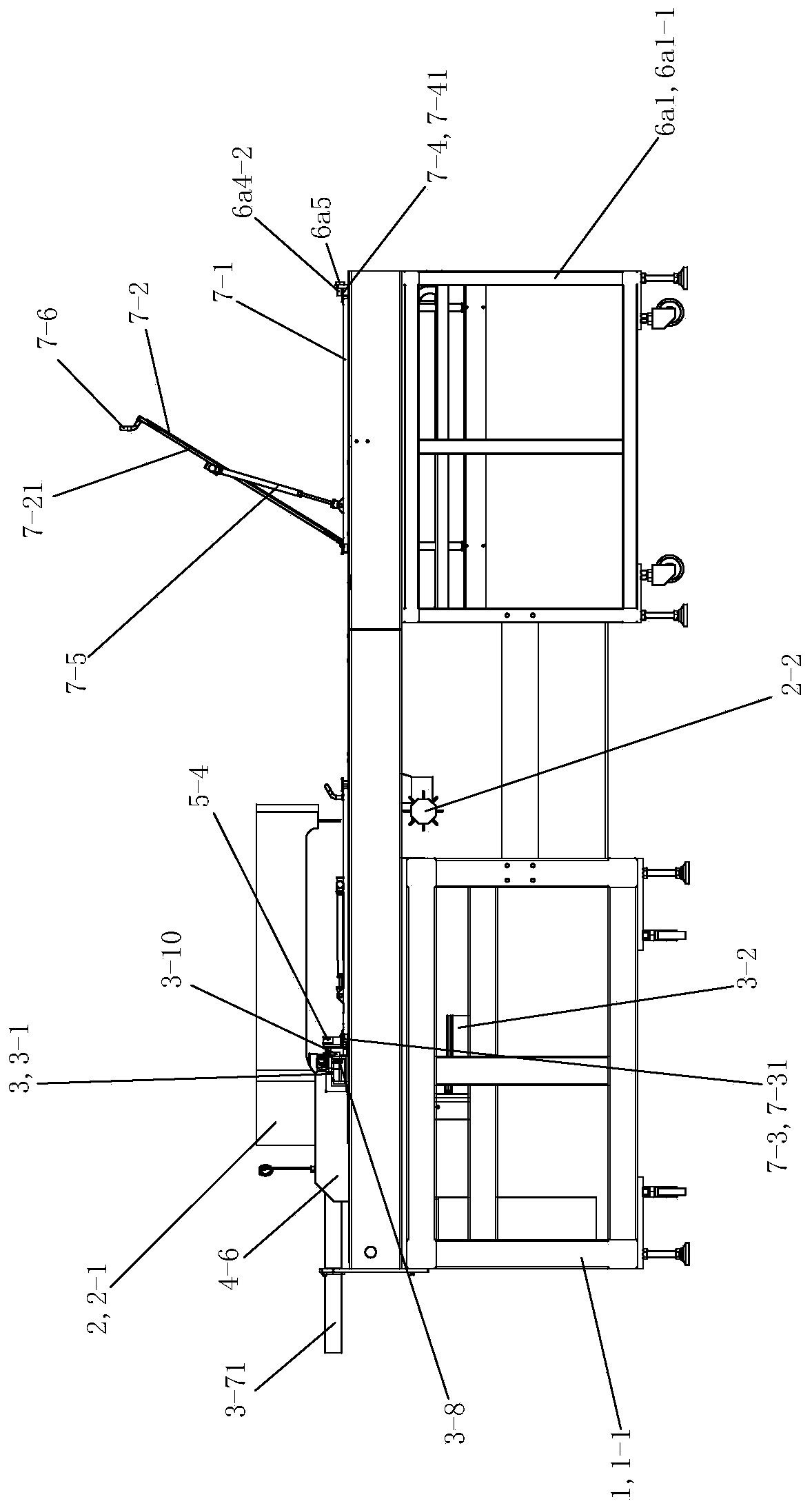

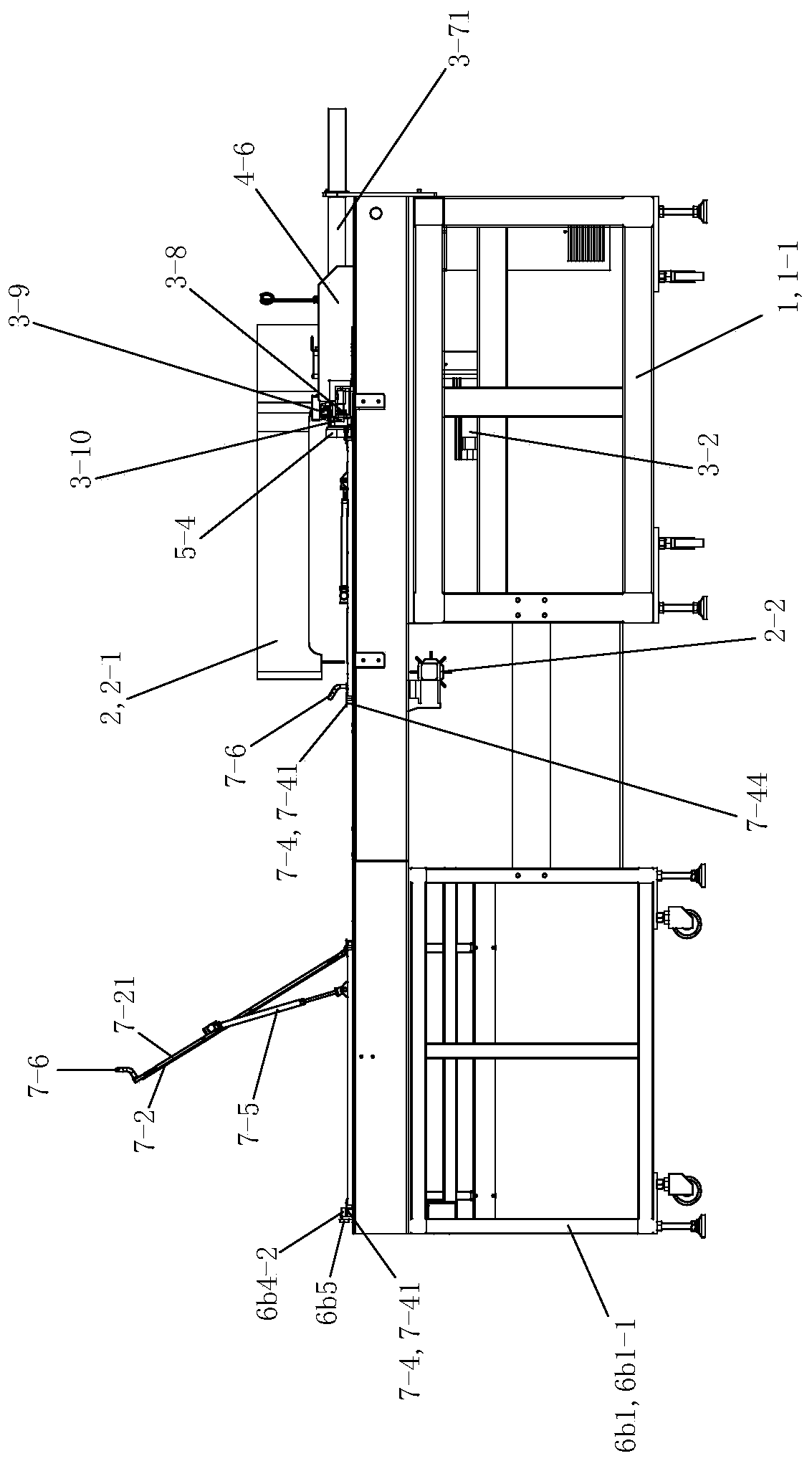

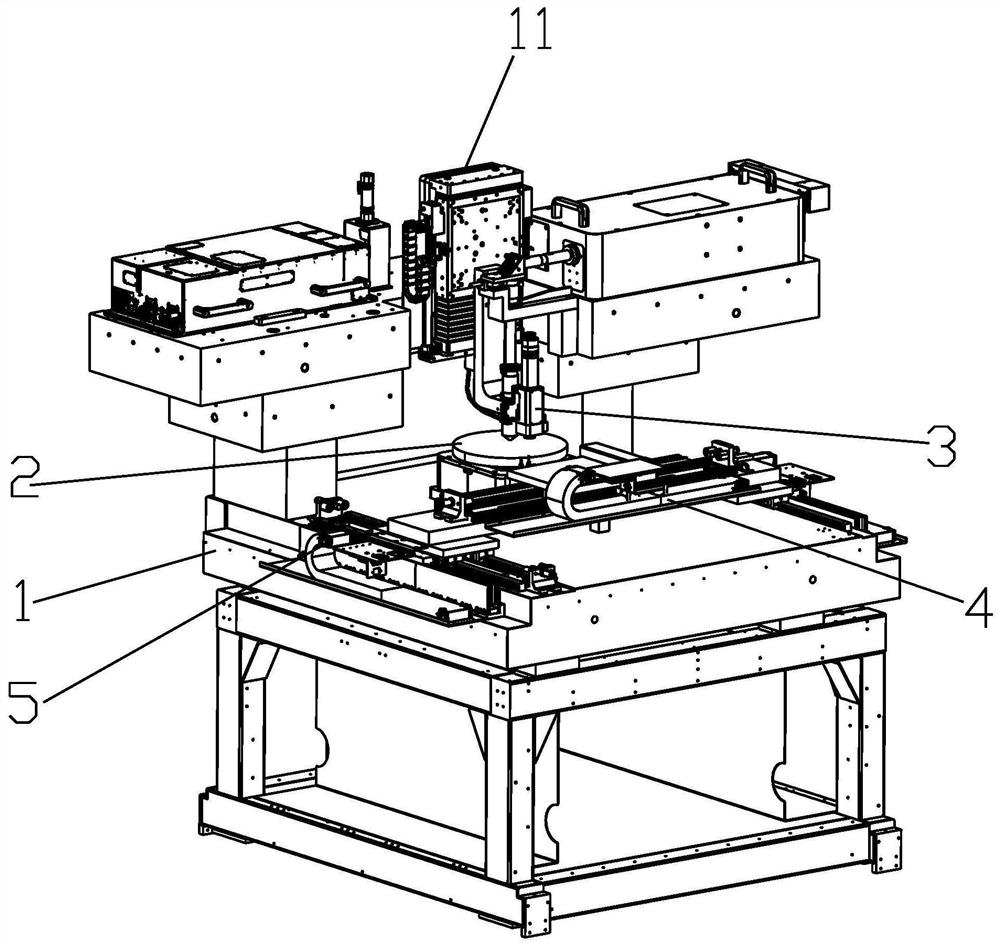

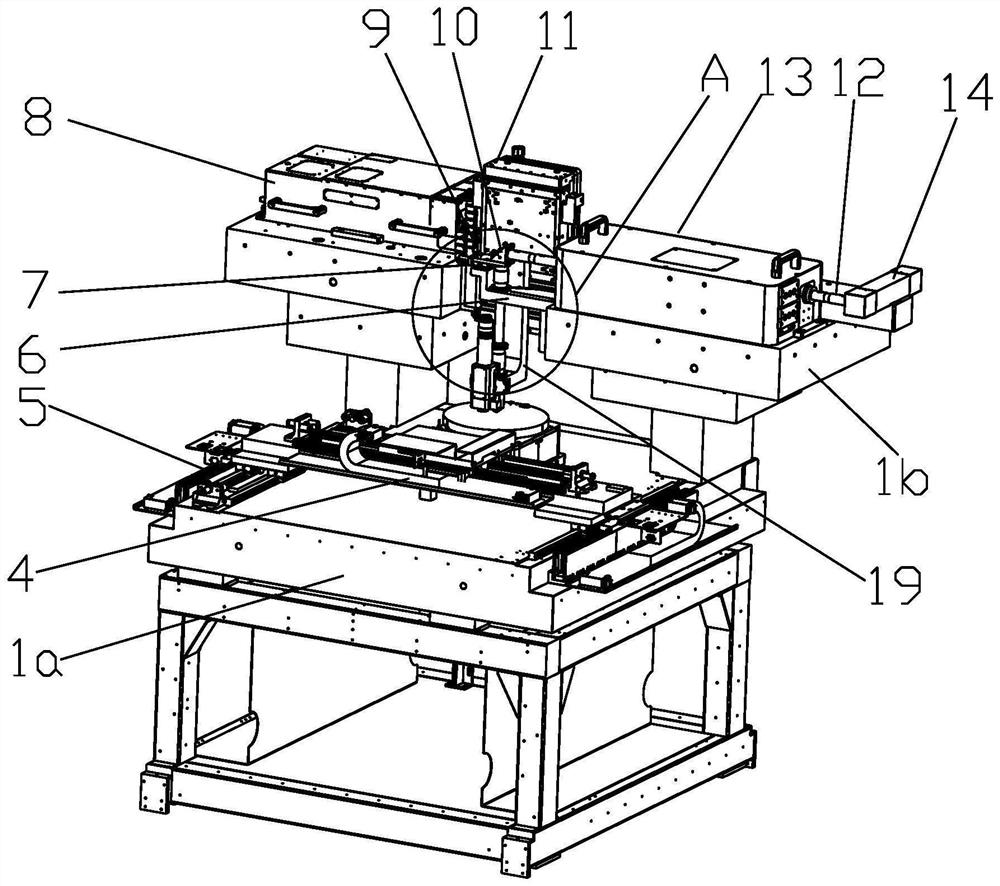

Pattern sewing machine

PendingCN111058197ASimple structureReduce waiting timeWork-feeding meansSewing-machine control devicesIndustrial engineeringSewing machine

The invention discloses a pattern sewing machine. The pattern sewing machine comprises a workbench mechanism, a sewing mechanism, an X-direction driving mechanism, a Y-direction driving mechanism anda template quick assembly component and a template component; the workbench mechanism comprises a main rack and a workbench board; the workbench board is arranged on the main rack; the sewing mechanism comprises a sewing machine head; the sewing machine head is fixedly arranged on the main rack; the X-direction driving mechanism and the Y-direction driving mechanism are arranged on the main rack;and the X-direction driving mechanism and the Y-direction driving mechanism drive the template quick assembly component and the template component to move. The pattern sewing machine is characterizedby further comprising a die change device, and the die change device sends the template component to the template quick assembly component for fixed connection or takes out the template component fromthe template quick assembly component.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Portable modular self-correcting rail three-dimensional detection system

PendingCN111559406AAvoid detection errorsEasy and fast on-site assemblyRailway auxillary equipmentRailway profile gaugesRail profileControl engineering

The invention belongs to the technical field of railway safety transportation, and relates to a system for automatically correcting a rail, in particular to a portable modular self-correcting rail three-dimensional detection system which can realize quick assembling and detection. A main body structure of the system comprises two detection units for detection, a mounting bracket for supporting andconnecting, and a manual operator. The main body structure of the detection unit comprises a walking mechanism, a scanning mechanism, a control unit, a horizontal detection sensor, a power supply unit and a temperature and humidity sensor. Rail geometrical characteristic detection including the rail height, rail gauge, rail profile and the like can be completed at the same time through one-time detection, rail geometrical position detection relative to the ground can be completed at the same time, and geographic coordinates of detection points are synchronously recorded and used for tracing,searching and detecting records while the detection is completed. The system is ingenious in main conception, scientific and reasonable in structural design, convenient, quick and accurate to use andmeasure, environment-friendly in application and wide in market prospect.

Owner:青岛瑞捷轨道科技有限公司

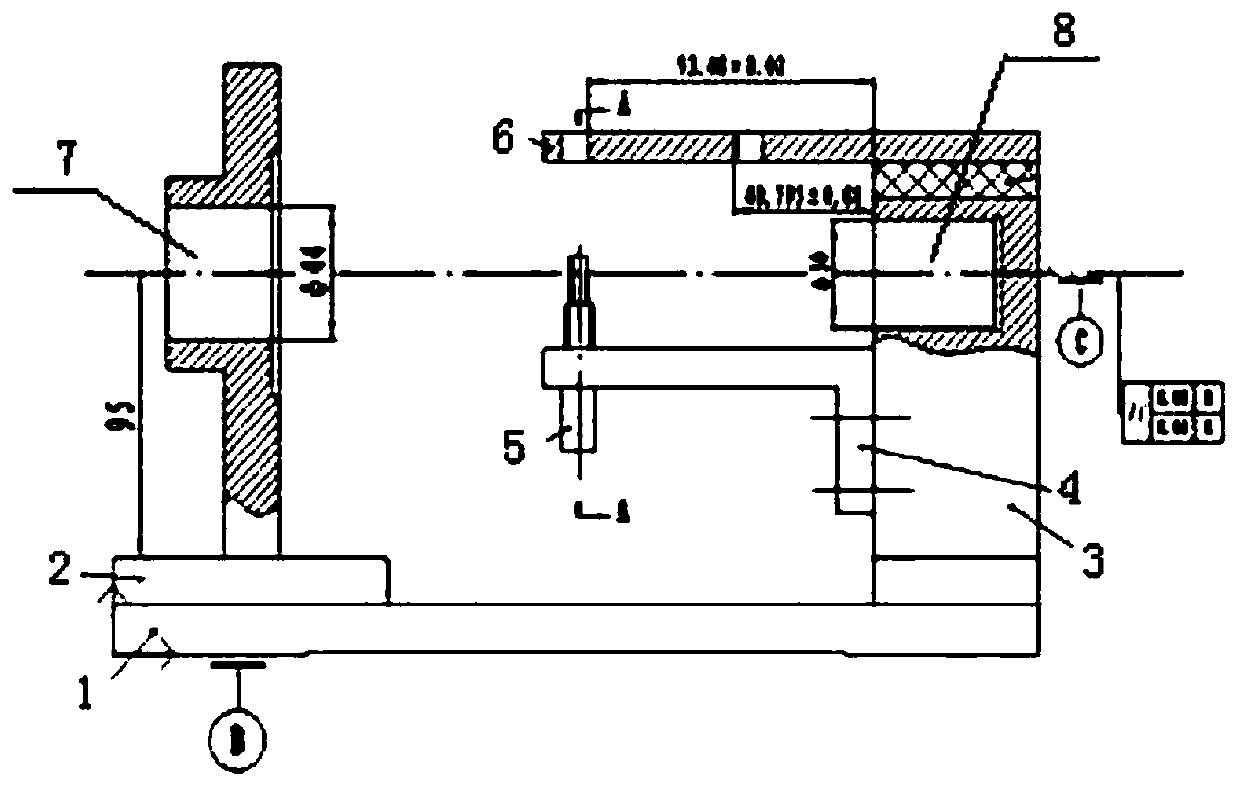

Assembly process of blind hole tool with high precision requirement

ActiveCN111168326AReduce dependency on skill levelGuaranteed accuracy requirementsStructural engineeringMachine

The invention belongs to the field of machining, and relates to an assembly process of a blind hole tool with a high precision requirement. The assembly process comprises the following steps of 1) processing a base, and ensuring the parallelism of two surfaces of the thickness of the base and the perpendicularity with an alignment reference surface; 2) processing a support plate, and ensuring theparallelism of the two surfaces of the thickness of the support plate and the perpendicularity with the bottom surface; 3) processing a support, and ensuring the parallelism of the two of the thickness of the support and the perpendicularity with the bottom surface; 4) processing a positioning plate; 5) processing a guide plate; 6) assembling the base, the support and the positioning plate into anintegral structure, fixing the integral structure on a workbench of the coordinate boring machine, machining a blind hole in the support by adopting a boring cutter, axially lifting the boring cutter, assembling the support plate on the base, replacing the boring cutter, and machining a through hole in the support plate on the support plate; and 7) assembling the guide plate on the support by anadjusting assembly method. According to the assembly process of the blind hole tool with the high precision requirement, the requirement for the assembly form and location tolerance is met, dependenceon the skill level of workers is reduced, and the assembly qualification rate can be greatly increased.

Owner:XIAN AERO ENGINE CONTROLS

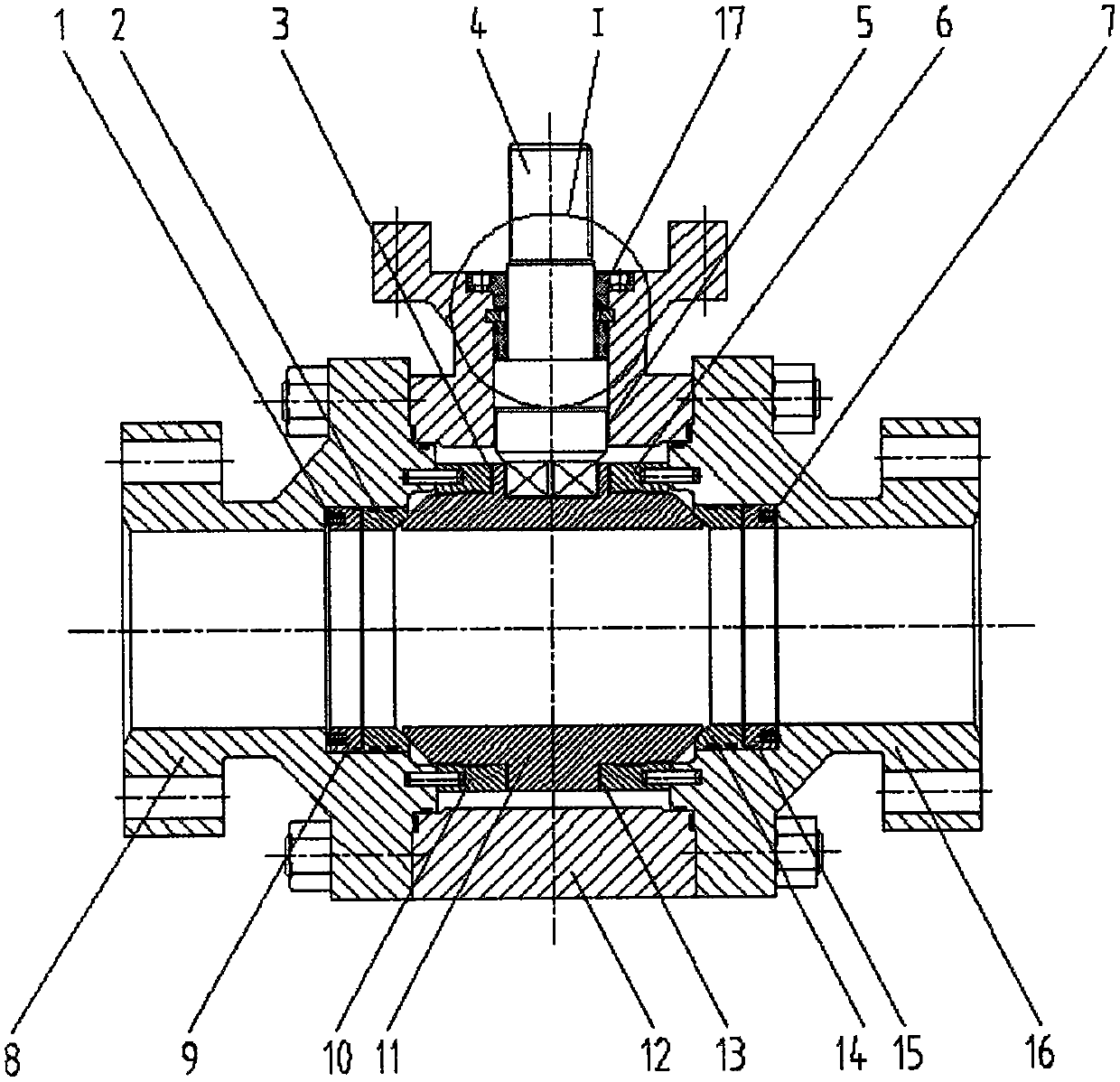

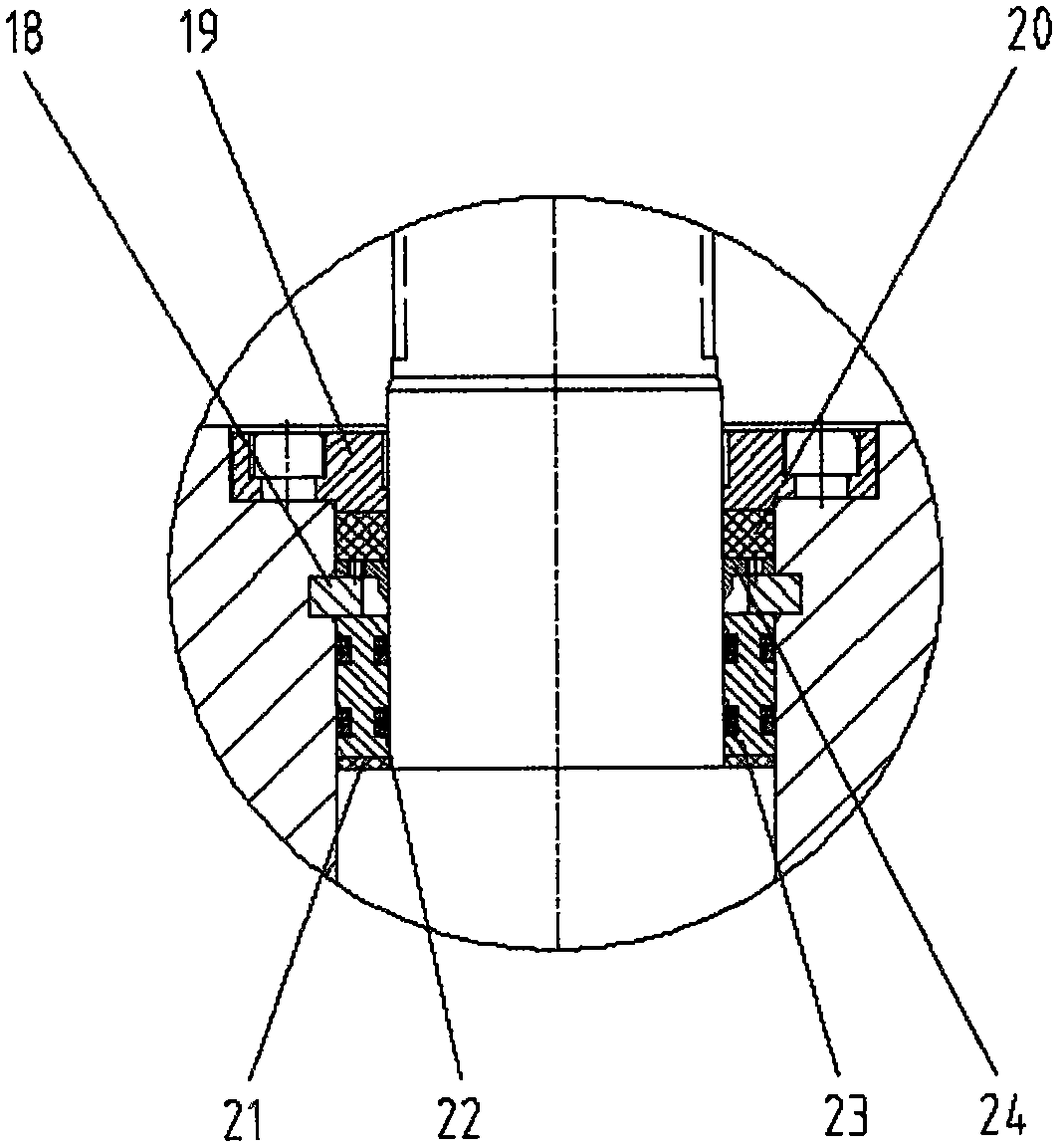

Hard-sealing fast ball valve

InactiveCN105370911AGuaranteed sealing performanceEliminate assembly errorsSpindle sealingsPlug valvesEngineeringHigh pressure

The invention belongs to the field of wind tunnel experiments and discloses a hard-sealing fast ball valve. The hard-sealing fast ball valve structurally comprises a valve body, a left valve deck, a right valve deck, a ball core, a left valve seat, a right valve seat, a valve rod, an upper supporting plate, a lower supporting plate, a left loading spring, a right loading spring, a left pressing ring, a right pressing ring, an upper sliding bearing, a lower sliding bearing, a valve rod sliding bearing and an upper sealing structure. Hardened layers are sprayed onto the ball core, the left valve seat and the right valve seat. The ball core, the valve rod and a valve seat base body are made of precipitation-hardening stainless steel. The integral upper sealing structure and a valve rod anti-blowing-out safety structure are adopted by the valve. According to the hard-sealing fast ball valve, the supporting plates and a fixed ball structure are adopted, and assembling errors are eliminated to the greatest extent; the ball core, the valve rod, a left valve seat base body and a right valve seat base body are made of the precipitation-hardening stainless steel, and meanwhile the hardened layers are sprayed onto the ball core, the left valve seat and the right valve seat so that high pressure difference and strong impact caused by large flow can be borne; the valve rod and the ball core are connected in a square mode, so that the load at the end of the valve rod is more uniform.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

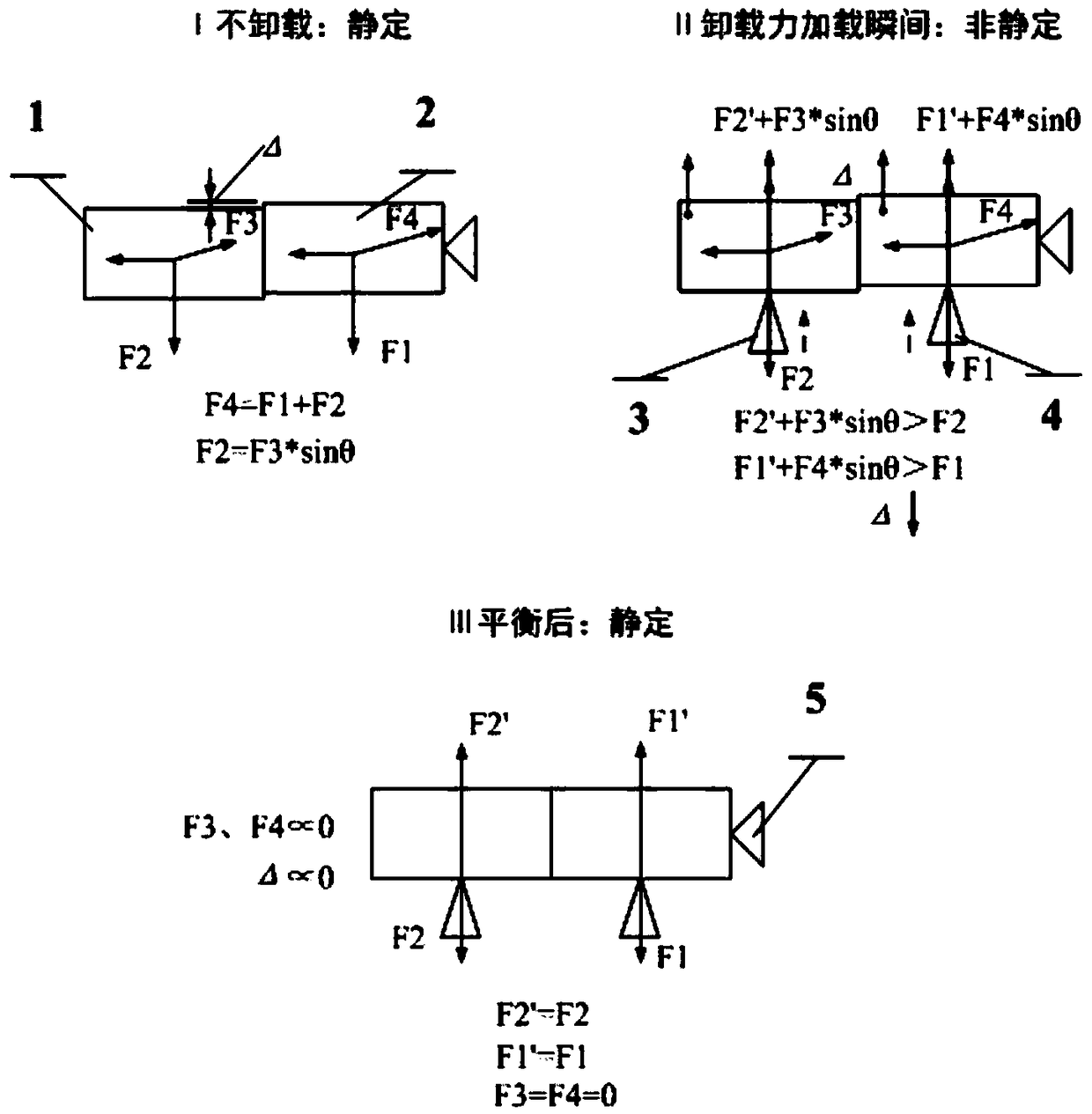

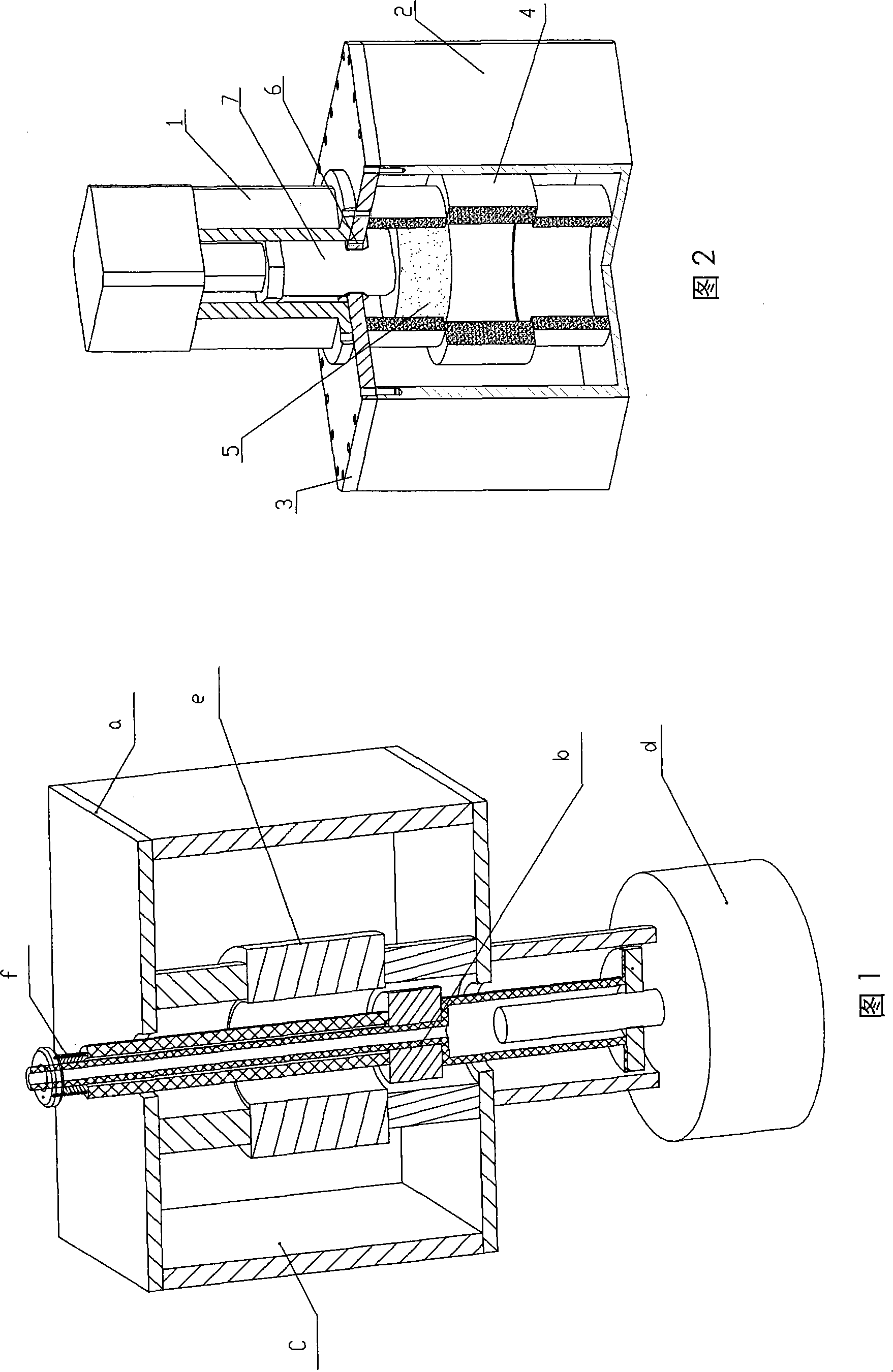

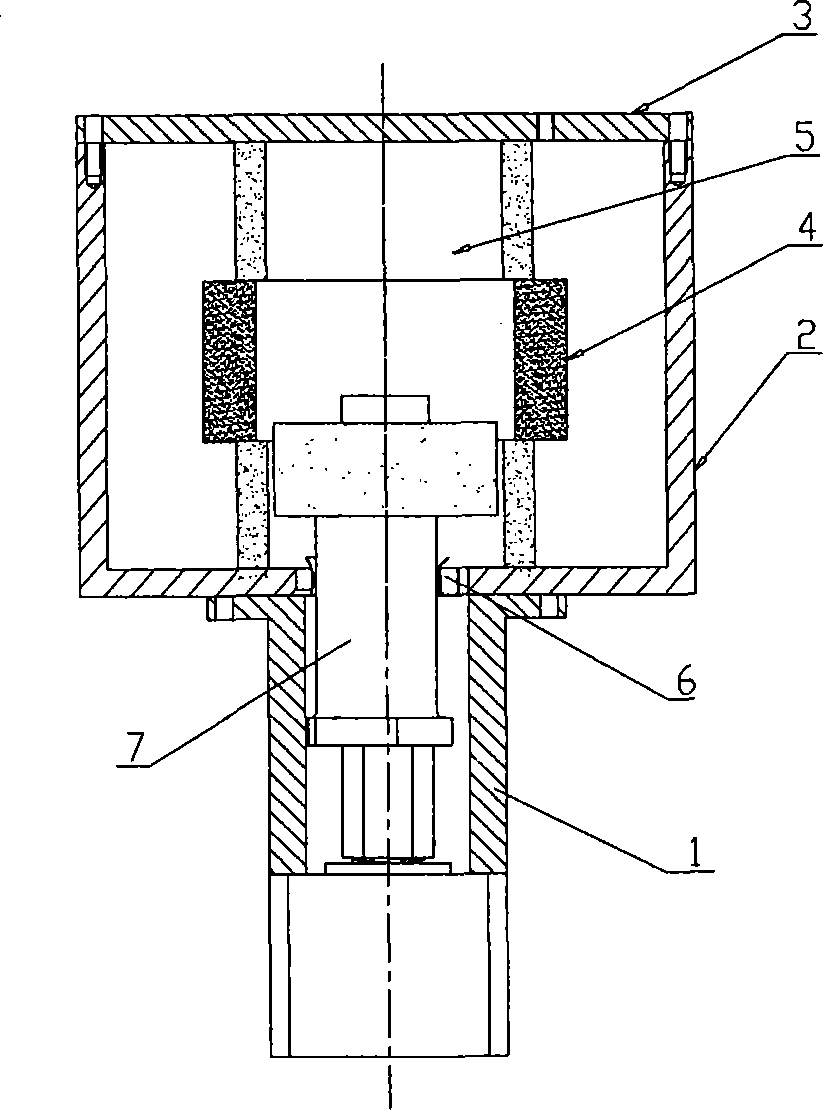

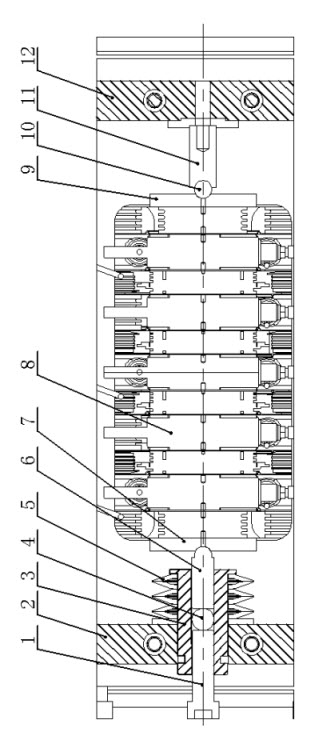

Mechanical press mounting structure of group large-power flat-plate power electronic device

ActiveCN101794767AEasy to controlImprove toleranceSemiconductor/solid-state device detailsSolid-state devicesMachine partsEngineering

The invention relates to a mechanical press mounting structure of a group large-power flat-plate power electronic device, which is technically characterized in that firstly, a left ejector pin is coaxially installed in a spring mandrel in a sliding mode, the spring mandrel is installed on a left support plate through a key pin which is mounted along the radial direction of the spring mandrel, a set of disk springs is mounted on the spring mandrel at the right end of the support plate, an annular groove is radially manufactured on the spring mandrel at the right end of the support plate, and a limiting chuck is mounted in the annular groove; secondly, a press mounting screw is coaxially engaged in the spring mandrel at the left side of the left ejector pin; and thirdly, the right end of the left ejector pin and a left pressure plate are in spherical pair installation, and the left end of the a right ejector pin and a right pressure plate are in spherical pair installation. In the mechanical press mounting structure, the disk springs are adopted as driving elements, the compression stroke of the disk springs are accurately controlled through machining parts and has nothing to do with the assembly precision; the mechanical pressing force is accurately controlled with constant pressure; and the structure has large latitude for the assembly length of power device series, eliminates the assembling clearance, has self-adaption for the length of the power device series in a certain range, and has high press mounting precision.

Owner:TIANJIN RES INST OF ELECTRIC SCI +1

Laser wafer cutting equipment

PendingCN113500288AAvoid offsetAvoid DifficultyLaser beam welding apparatusElectric machineEngineering

The invention relates to laser wafer cutting equipment which comprises a marble platform, an air floating platform, an X-axis movement mechanism, a Y-axis movement mechanism, a Z-axis linear motor, a support, a sliding table, a laser, a mounting plate, a 45-degree mirror light path assembly, a light splitting system, a 45-degree mirror light path assembly, a cutting head and a cutting head support. The marble platform comprises a first-stage platform and a second-stage platform arranged on the first-stage platform. According to the invention, the linear motors are mounted in the X-axis direction, the Y-axis direction and the Z-axis direction, so that operation can be guaranteed to be carried out at the micrometer precision. The support is mounted on the second-stage platform of the marble platform; the sliding table is mounted on the support; fine adjustment in the x direction can be implemented through the sliding table so as to ensure that a light path is accurate. The second-stage platform is integrally machined, and the overall rigidity is good, so that light path deviation caused by support deformation is avoided, and the situation that the light path is difficult to adjust due to flatness errors is avoided. up-and-down movement can be carried out in the Z-axis direction to adjust and position, thereby eliminating assembly errors in the optical path height.

Owner:SHANGHAI INST OF LASER TECH

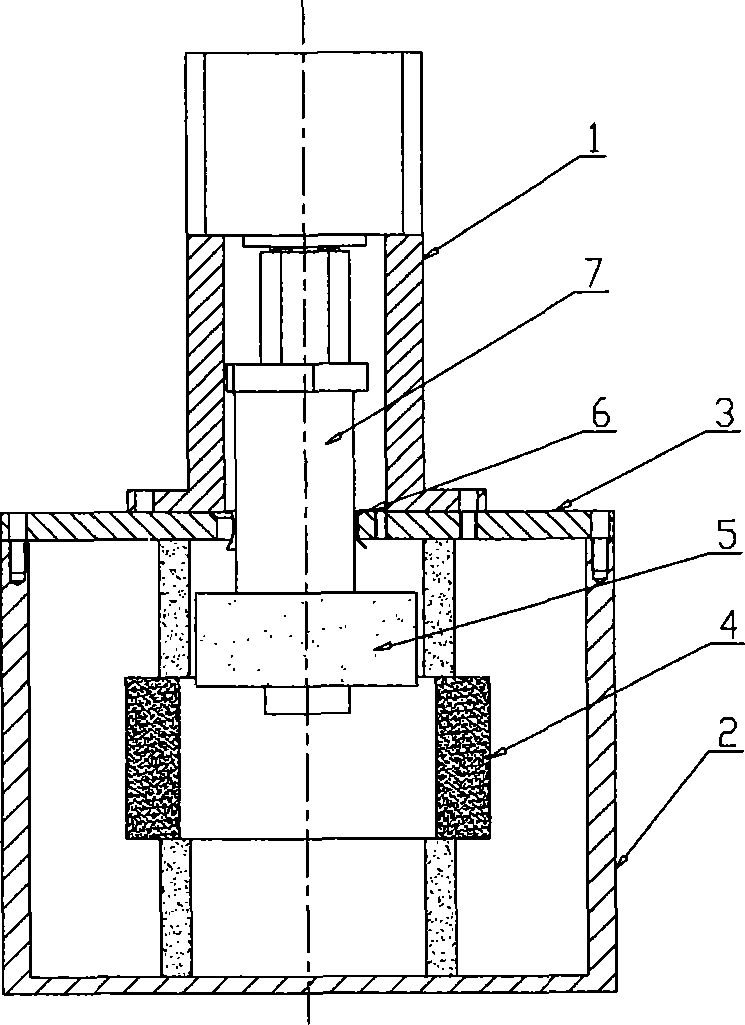

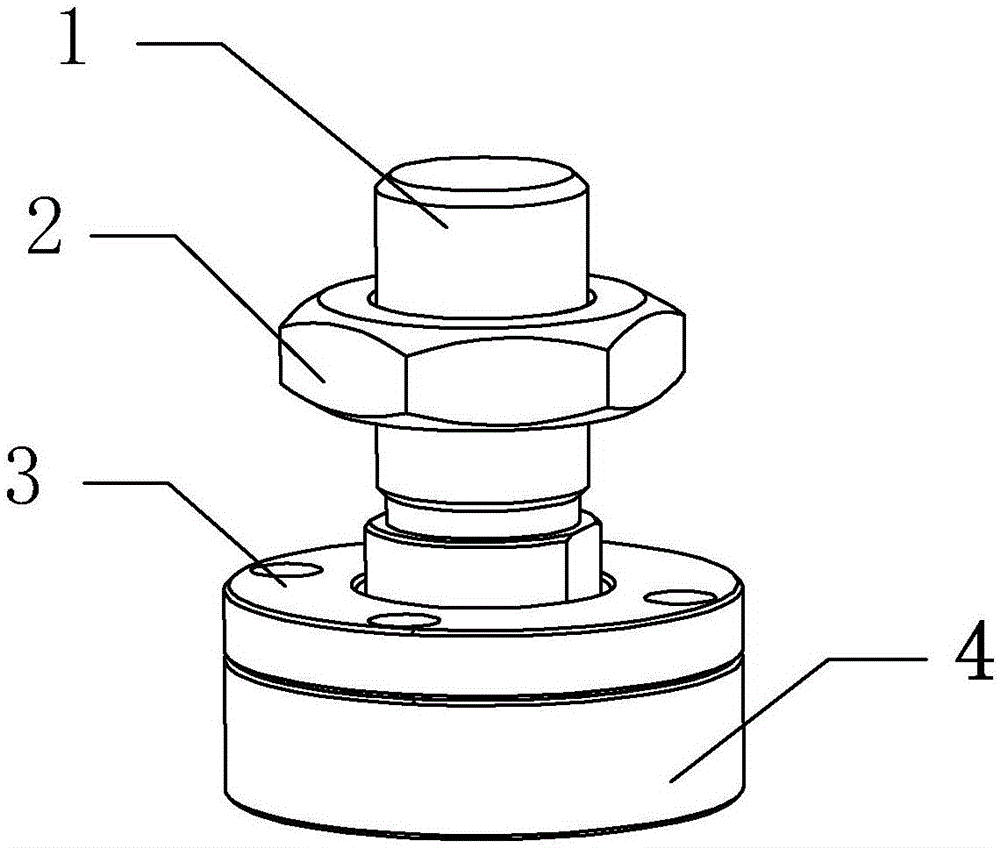

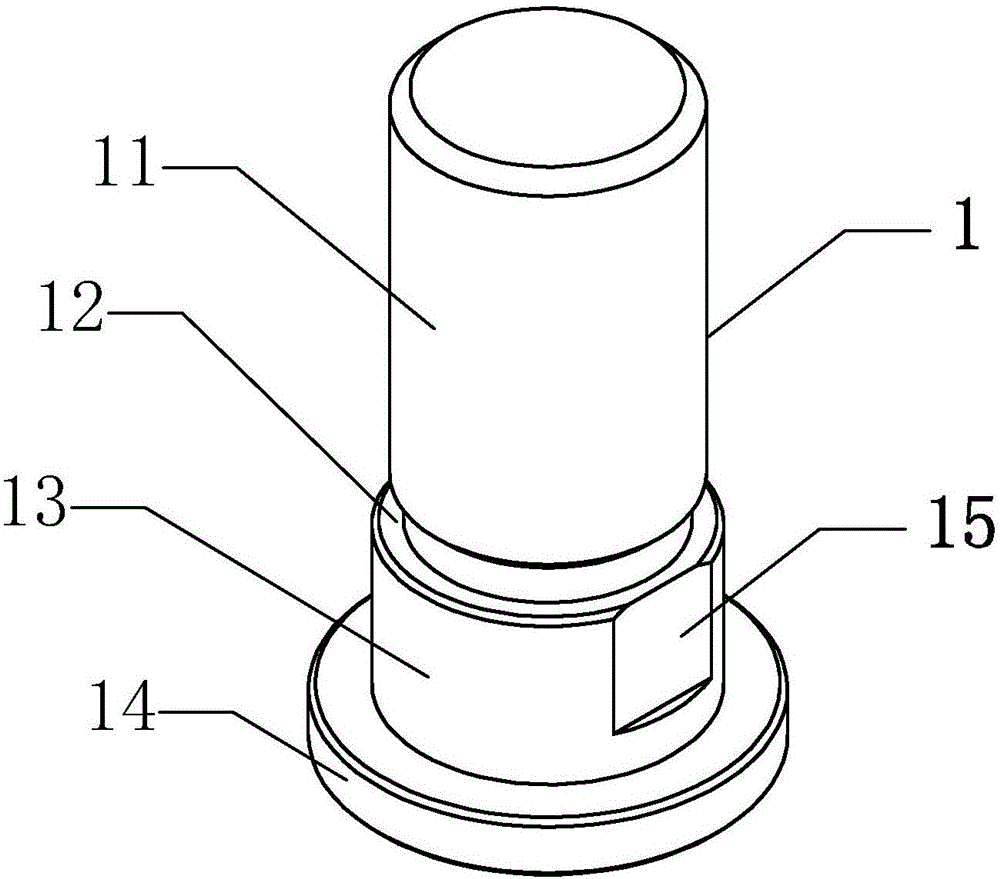

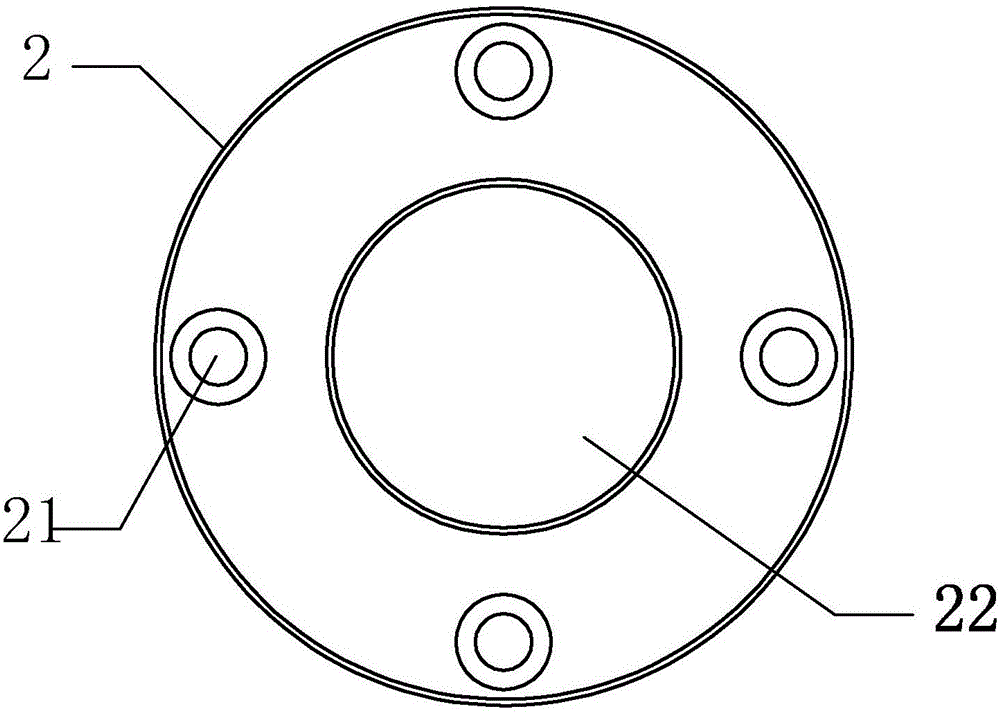

Floating joint and punch applying floating joint

The invention discloses a floating joint and a punch applying the floating joint. The floating joint comprises a male joint, a female joint and a cover plate, wherein the upper end of the male joint is a connecting end; the lower end of the male joint is fixedly clamped in a cavity formed by connecting the cover plate and the female joint; the lower end of the female joint is provided with a connecting structure. The floating joint is reasonable in structure; punching and necking are performed on components, so that high accuracy and easiness in machining can be realized easily, radial errors, axial errors and angular errors within certain ranges can be corrected, the axial length can be adjusted, and high adaptability is achieved. The characteristic of the presence of a bearing, a spring or other elastic structures in the conventional floating joint is abandoned; a novel flexible connecting structure is adopted, so that assembly errors are eliminated, and higher pressure can be borne at the same time; the floating joint has the advantages of little wear, long service life, reliable structure, high tensile strength, high compression resistance and the like.

Owner:CHANGSHA JINGHUA ELECTRONICS TECH

Chokes for high temperature gas-cooled reactors

ActiveCN109830319BImprove environmental adaptabilityPromote circulationNuclear energy generationReactor fuel elementsThermal dilatationThermodynamics

The invention relates to the technical field of reactor auxiliary equipment, and discloses a flow blocker for a high temperature gas cooled reactor. The flow blocker comprises a casing and a rotor component. A cavity is formed in the casing, and a feed inlet and a discharge outlet both communicated with the cavity are arranged on the casing. The rotor component comprises a rotating shaft and a rotating disc. The rotating shaft is rotatably mounted in the cavity around the axis. The rotating disc is coaxially arranged on the rotating shaft. The outer peripheral surface of the rotating disc is in clearance fit with the curved surface of the cavity. The outer peripheral surface of the rotating disc is provided with a plurality of positioning grooves and at least one receiving cup for accommodating materials. The receiving cups are located between every two adjacent positioning grooves. An elastic block is embedded in each positioning groove. The outer surface of each elastic block is abutted against the curved surface of the cavity to stop gas circulation between the feed inlet and the discharge outlet. The flow blocker has the advantages that the elastic blocks are provided to achieve buffering through the elastic force, normal circulation, loading and unloading of spherical elements can be maintained, the stability in long-term operation is high, and high-temperature thermal expansion compensation and mechanical wear compensation can be realized.

Owner:TSINGHUA UNIV

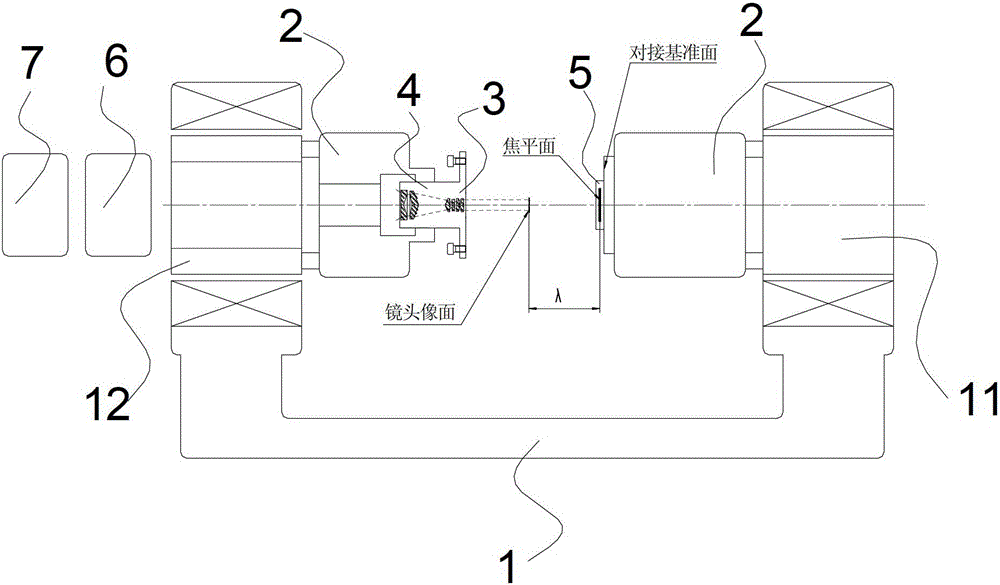

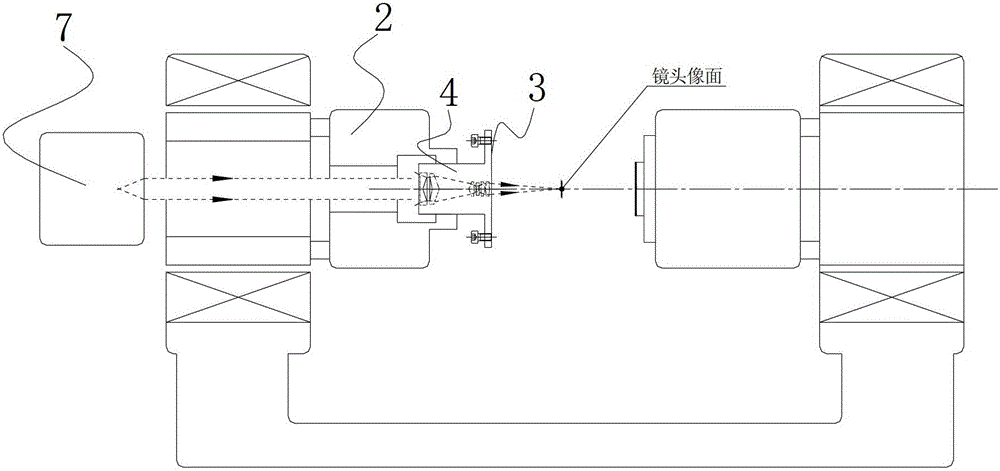

Combined adjustment and docking method and mechanism of high-precision visible light imaging system

ActiveCN103402114BGuaranteed parallelismEliminate assembly errorsTelevision systemsCamera lensTarget surface

The invention provides a combined adjusting and jointing method and a combined adjusting and jointing mechanism for a visible light imaging system and an imaging focal plane. The problem that the accuracy of perpendicularity between an optical axis of an optical imaging system and the imaging focal plane, the accuracy of an overlap ratio between the optical axis of the optical imaging system and the central normal of the target surface of the imaging focal plane and the accuracy of an overlap ratio between the image plane of the optical imaging system and the imaging focal plane in the conventional image plane jointing process cannot be ensured is mainly solved. By once clamping of a high-accuracy double-shaft lathe, a set regulation aim is fulfilled, the set regulation accuracy is achieved, and meanwhile, the jointing reference surface of a focal plane component and the end face of an optical lens mounting flange are turned, so that the parallelism between two planes is ensured, and an assembly error, which is caused by a previous assembly link, of the focal plane component and an optical lens is completely eliminated.

Owner:西安中科飞图光电科技有限公司

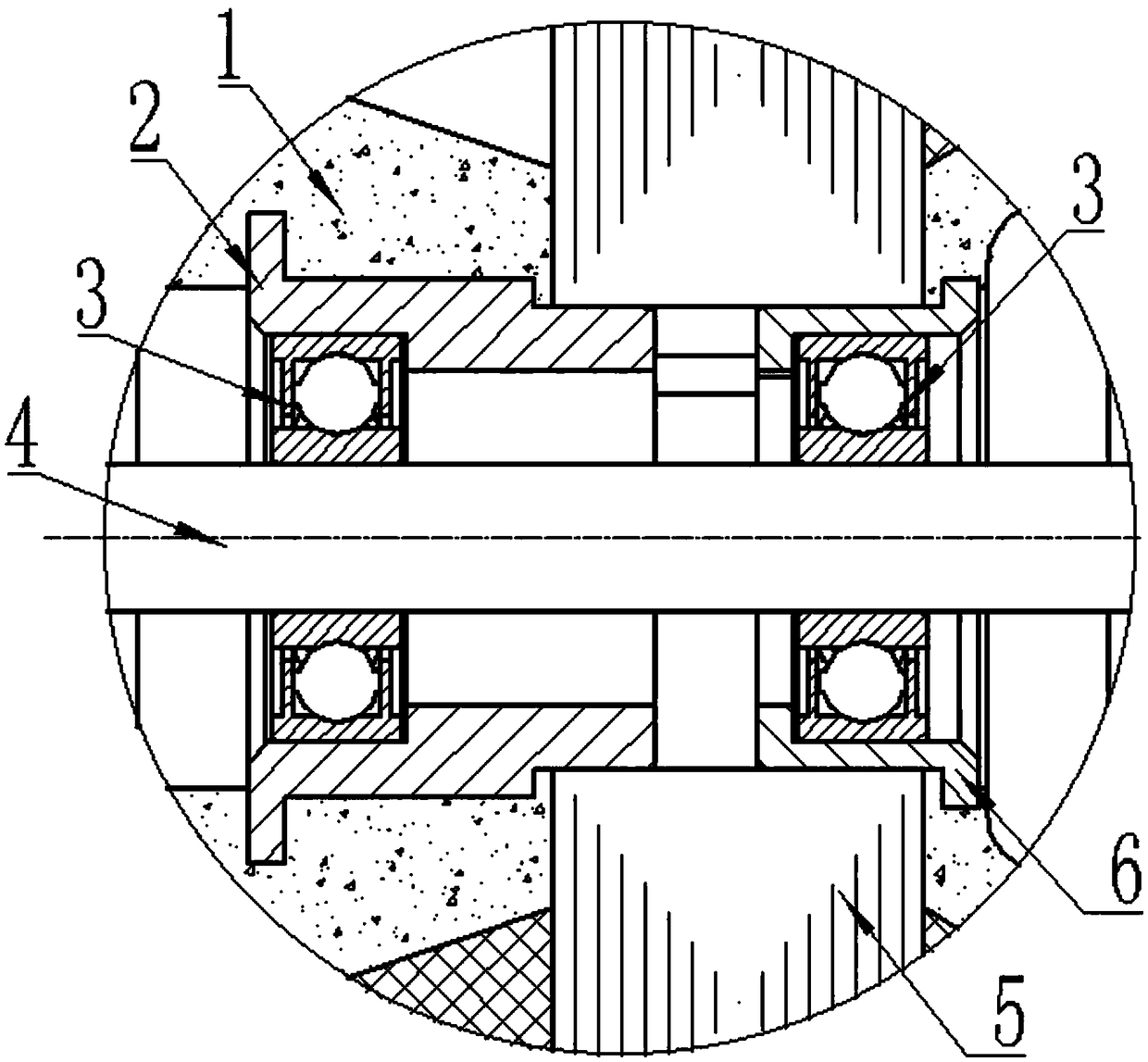

Bearing bracket structure for outer rotor motor

InactiveCN108768051AExtended service lifeAddressing the effects of lifespan damageMagnetic circuit stationary partsSupports/enclosures/casingsEngineeringMechanical engineering

The invention relates to the technical field of the outer rotor motor, especially a bearing bracket structure for the outer rotor motor. The bearing bracket structure comprises a stator iron core anda rotating shaft; a first bearing bracket is arranged at one side of the stator iron core, a first bracket limiting end is arranged at one end of the first bearing bracket, and the first bracket limiting end is coaxially fixed in the stator iron core; a second bearing bracket is arranged at the other side of the stator iron core, a second bracket limiting end is arranged at one end of the second bearing bracket, and the second bracket limiting end is coaxially fixed in the stator iron core; a second bearing chamber is arranged in the second bearing bracket, a bearing is arranged in the secondbearing chamber, and the rotating shaft penetrates two bearings; the external of each of the first bearing bracket, the bearing, the rotating shaft, the stator iron core, and the second bearing bracket is plastic-packaged to form the stator plastic-packaged body. The bearing bracket structure disclosed by the invention effectively solves the influence of damaging the bearing life in the operationof the rotating shaft, solves the defect of circle run-out when the bearing and the rotating shaft are in operation, and effectively prolongs the service life of the motor.

Owner:合肥市通得力电气制造有限公司 +1

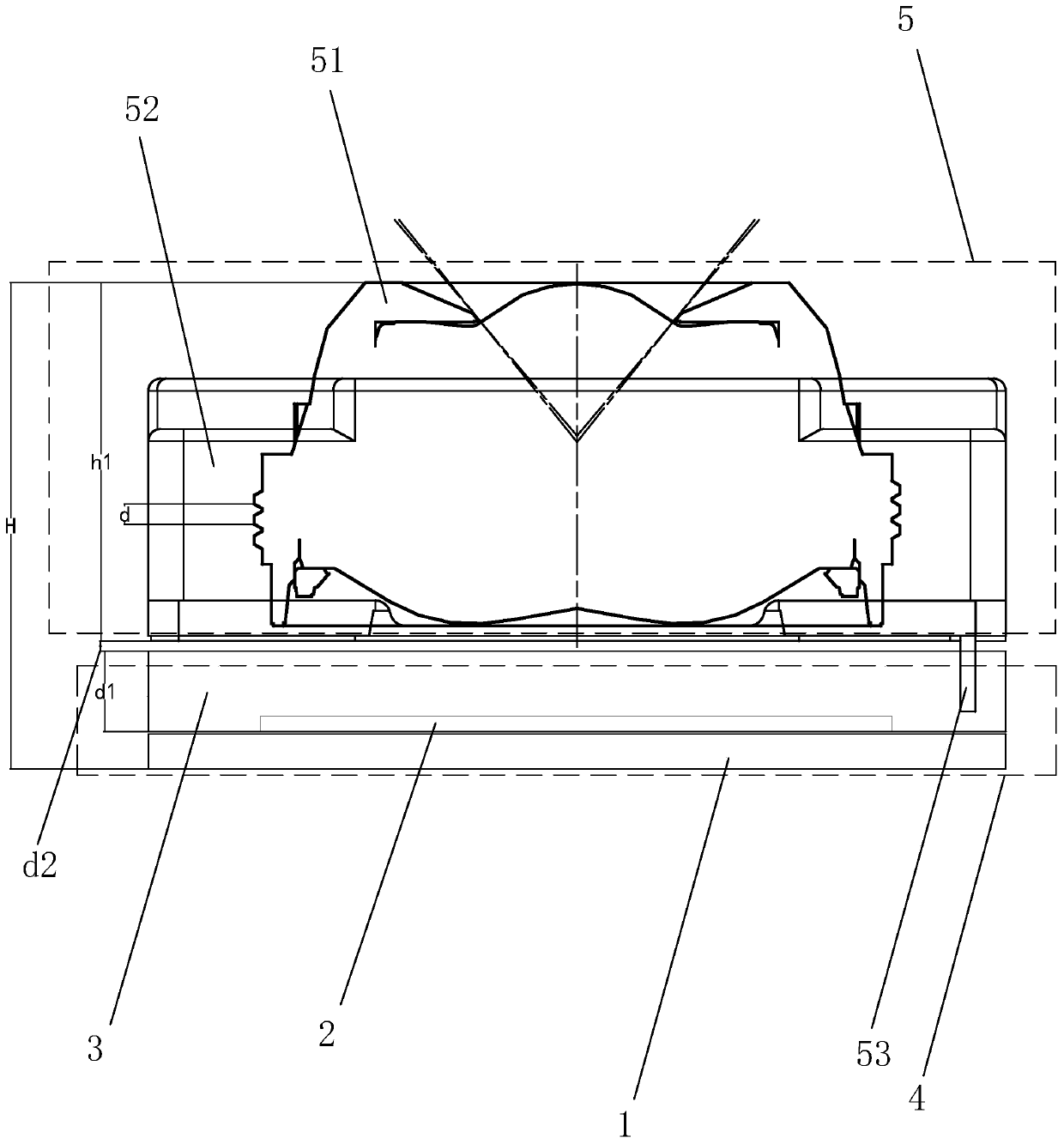

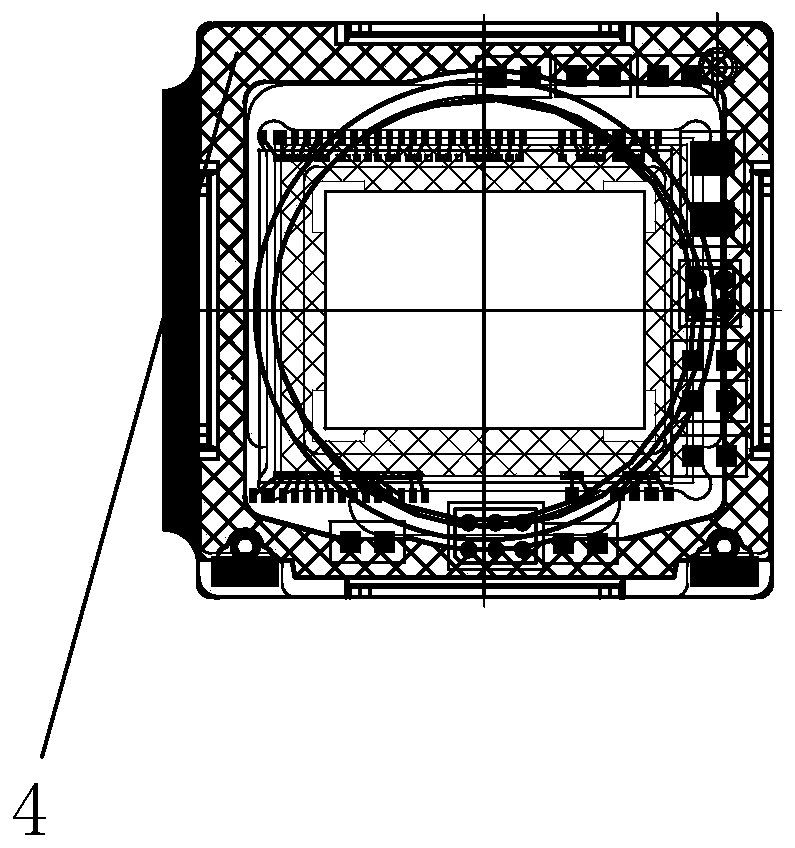

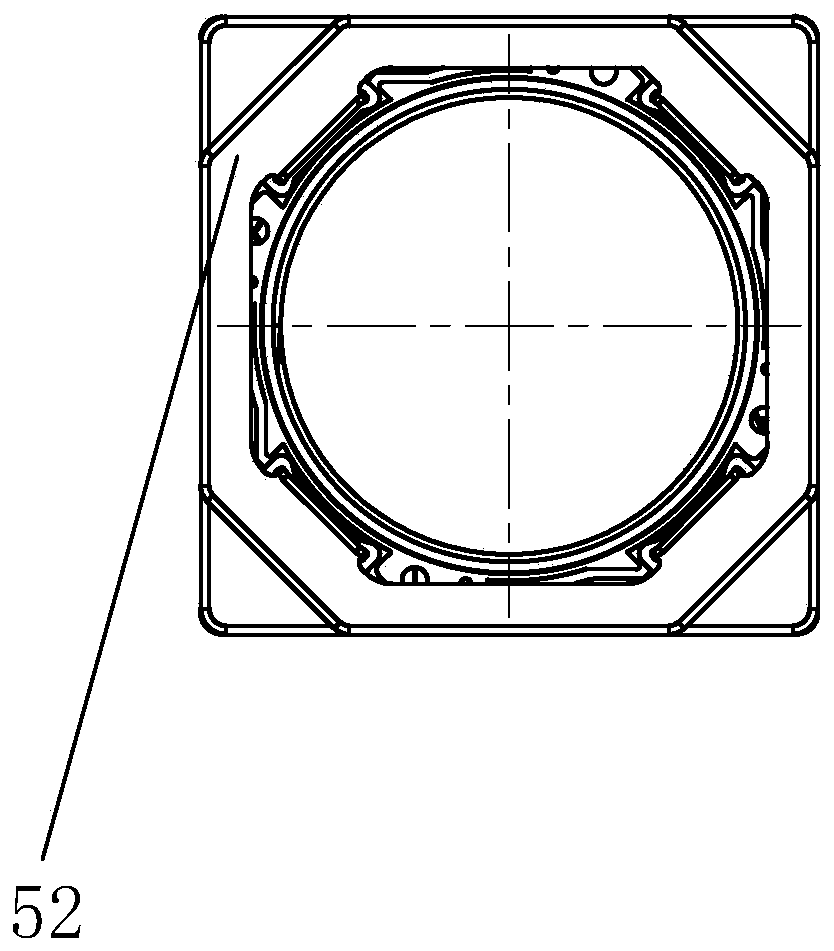

COB camera module and packaging method thereof

ActiveCN111371971AEliminate Assembly ErrorsImprove autofocus accuracyPrinted circuit assemblingTelevision system detailsEngineeringLight filter

The invention discloses a COB camera module and a packaging method thereof. The voice coil motor comprises a circuit board, a chip attached to the circuit board, a light filtering assembly attached tothe chip, a motor and a lens locked inside the motor, the motor is glued to the light filtering assembly, the locking height of the lens on the motor is h1, and the distance between the voice coil motor and the light filtering assembly is h2. The camera module is packaged by adopting two specific sizes of h1 and h2, and is matched with compensation type optical axis correction, so that the automatic focusing accuracy of the camera module and the optical axis overlap ratio between modules can be improved to the greatest extent. The automatic focusing accuracy of the COB camera module is improved by adopting two specific sizes of h1 and h2; defective products are accurately discriminated through compensation type optical axis correction, and meanwhile, the fault tolerance of optical axis correction is improved, so that the yield is improved; grading of the COB camera module can be completed in the packaging process through primary optical axis correction and compensation type secondarycorrection of the camera active focusing equipment.

Owner:横店集团东磁有限公司

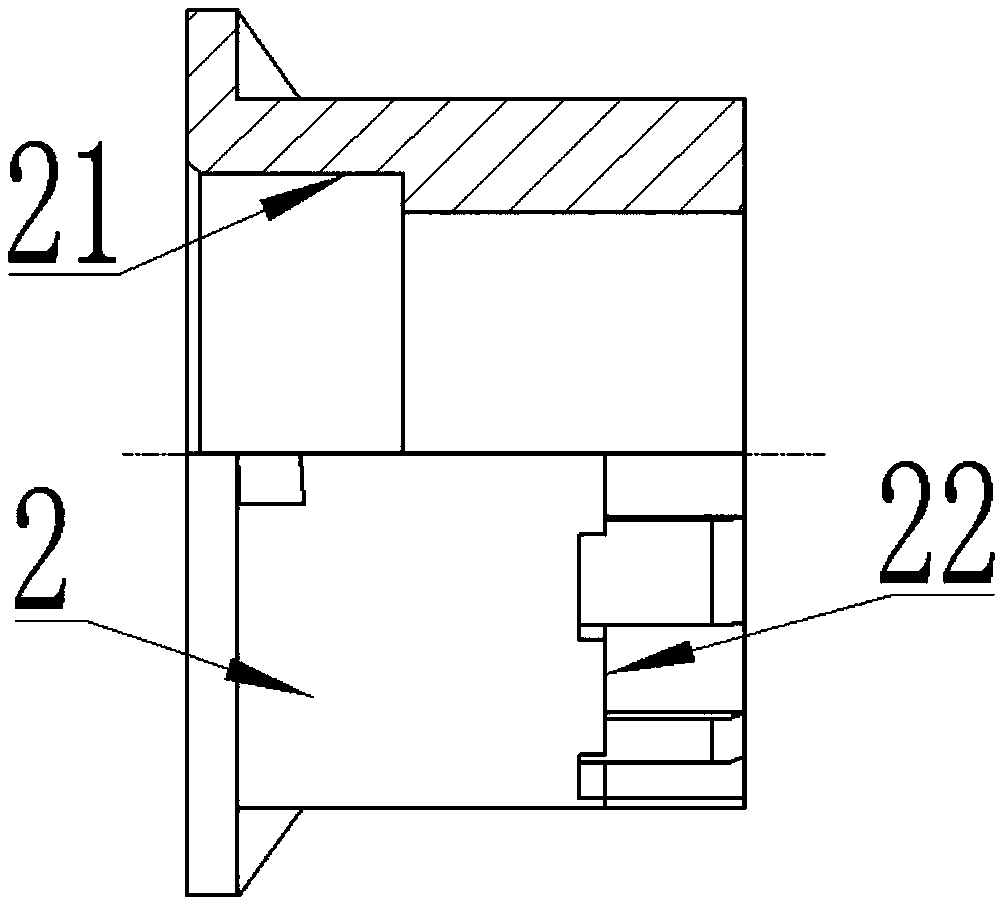

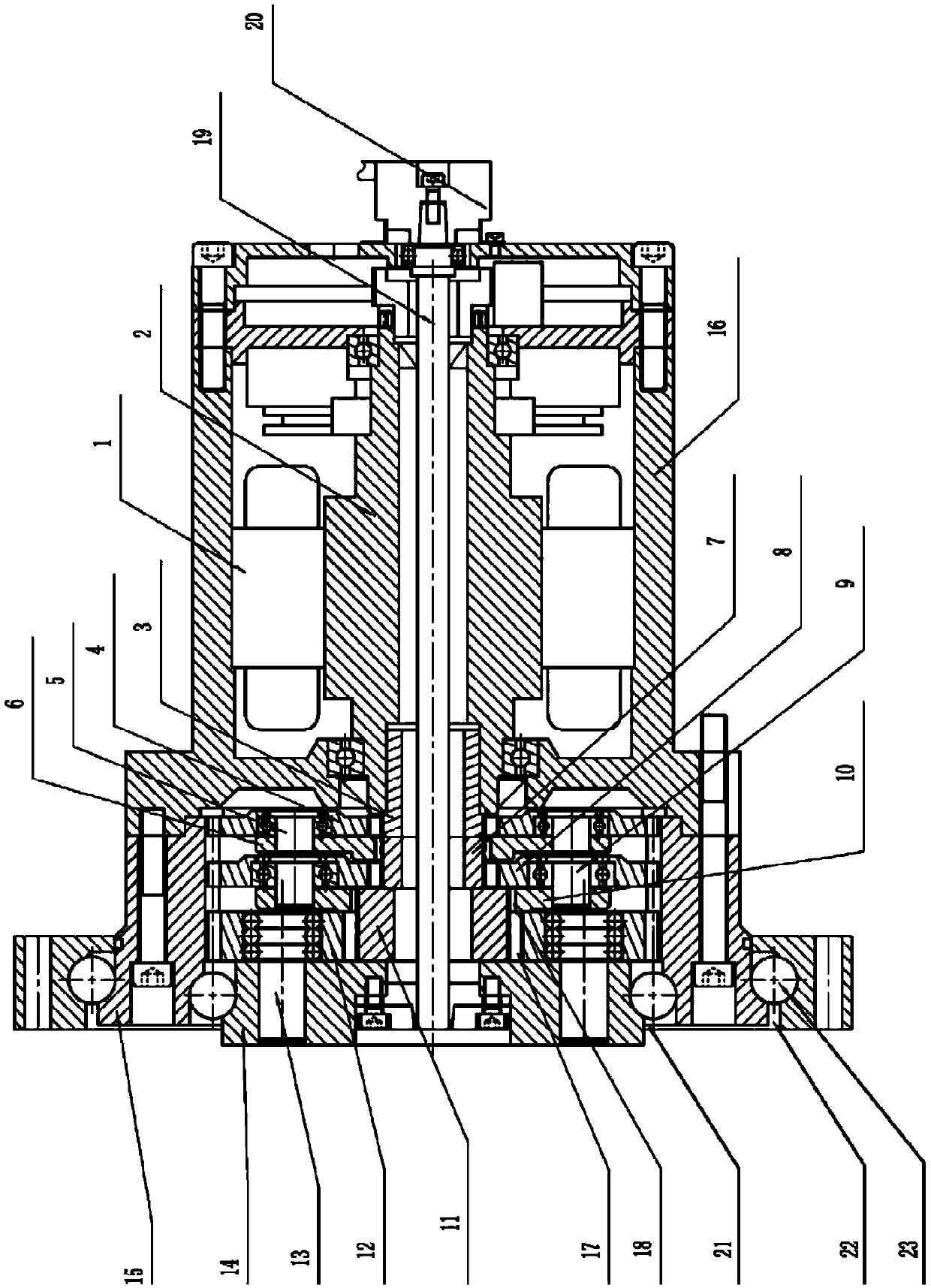

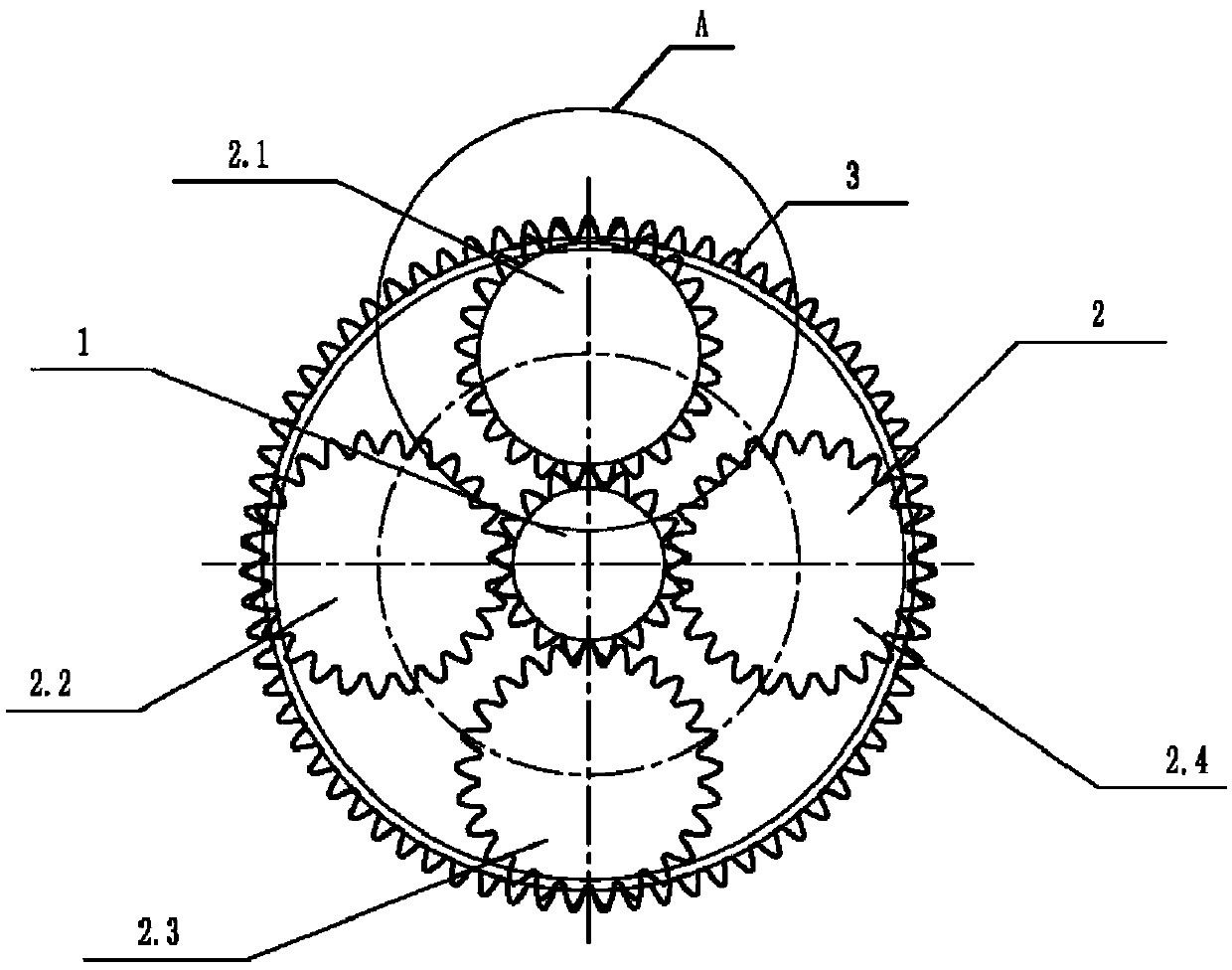

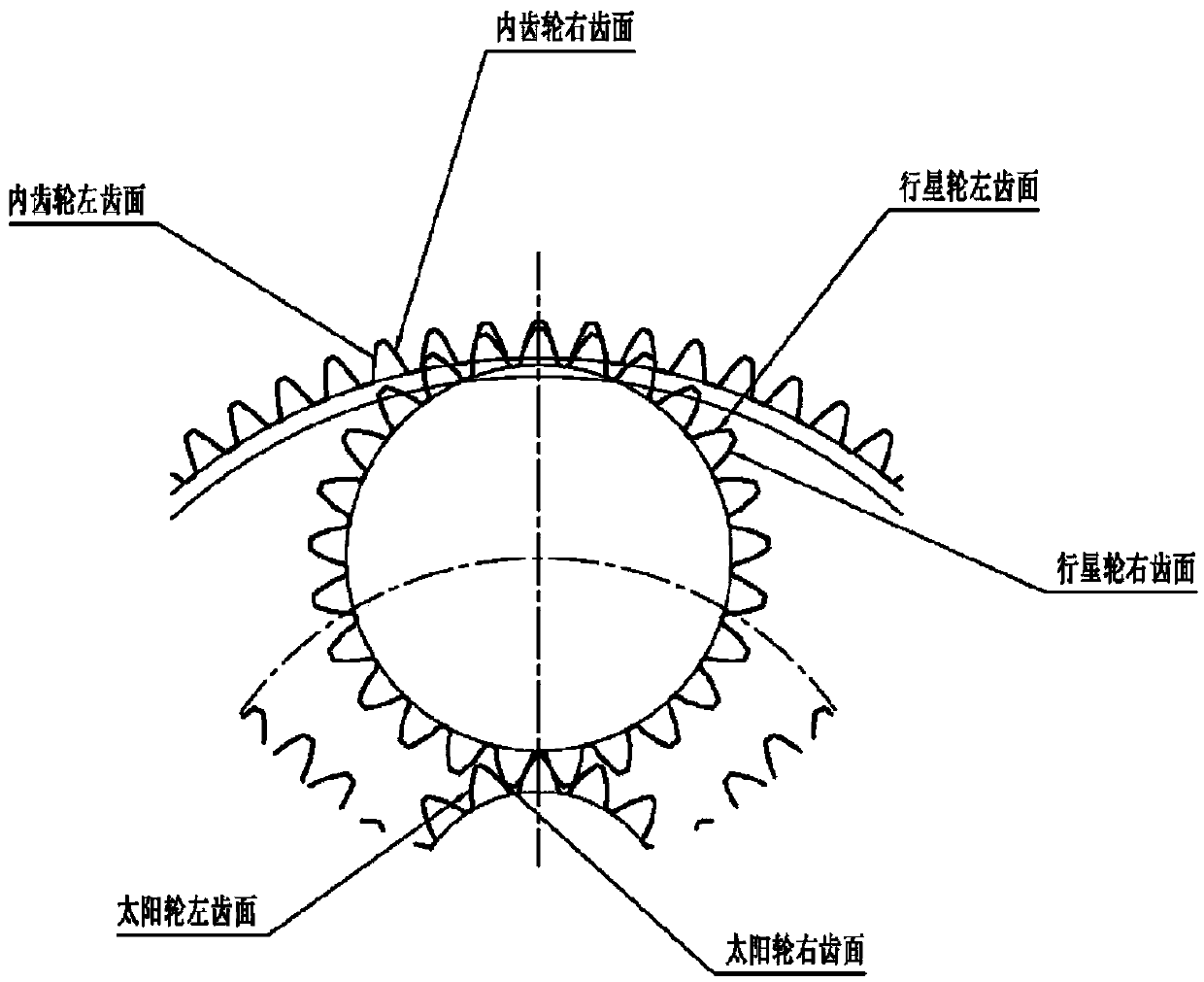

Planetary reduction motor capable of achieving full closed-loop control and articulated robot

ActiveCN110739798AEliminate assembly errorsRealize full closed-loop controlProgramme-controlled manipulatorJointsInterference fitLoop control

The invention relates to a planetary reduction motor capable of realizing full closed-loop control and an articulated robot using the reduction motor. According to the invention, the assembly accuracyis high, and high-precision full closed-loop control is realized. The main structure of the motor includes a planetary reducer part, a motor part and a full closed-loop control device. The full closed-loop control device includes a drive shaft and a grating encoder. The grating encoder is located outside the motor casing body and is arranged on the rear end surface of the motor casing body. A rotor and the sun gear of a first-stage planetary reduction mechanism in the planetary reducer are fixedly connected through interference fit. The front end of the motor casing body and the reducer casing body are directly fixed by screws. In each stage of the planetary reduction mechanism, at least two planetary holes in a planet carrier have a circumferential offset relative to the positions of planet wheels distributed in the circumferential direction, which is used to reduce backlash.

Owner:SIX RING DRIVE XIAN TECH CO LTD

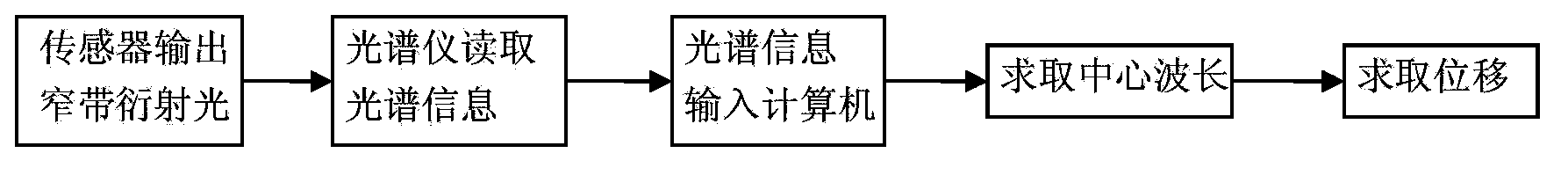

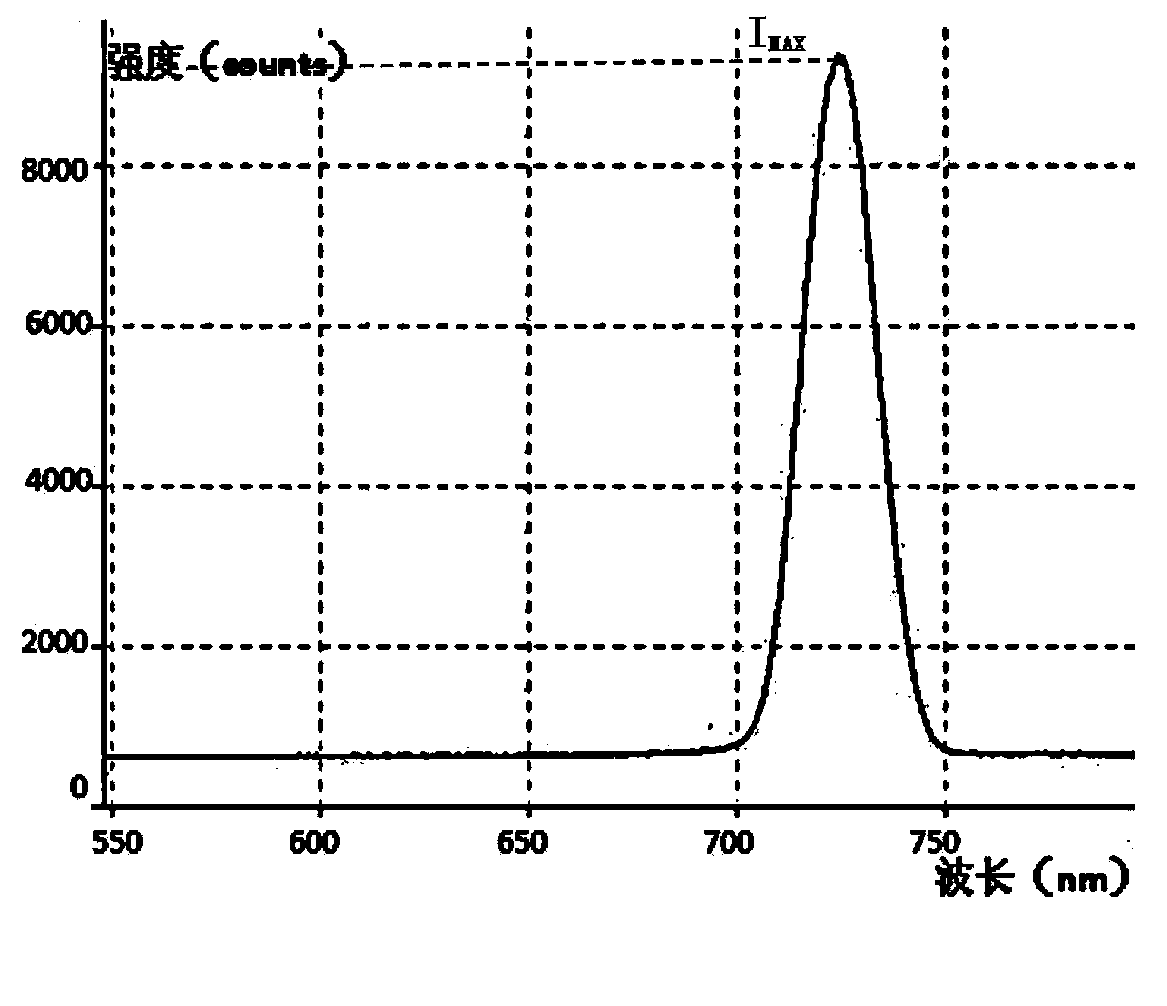

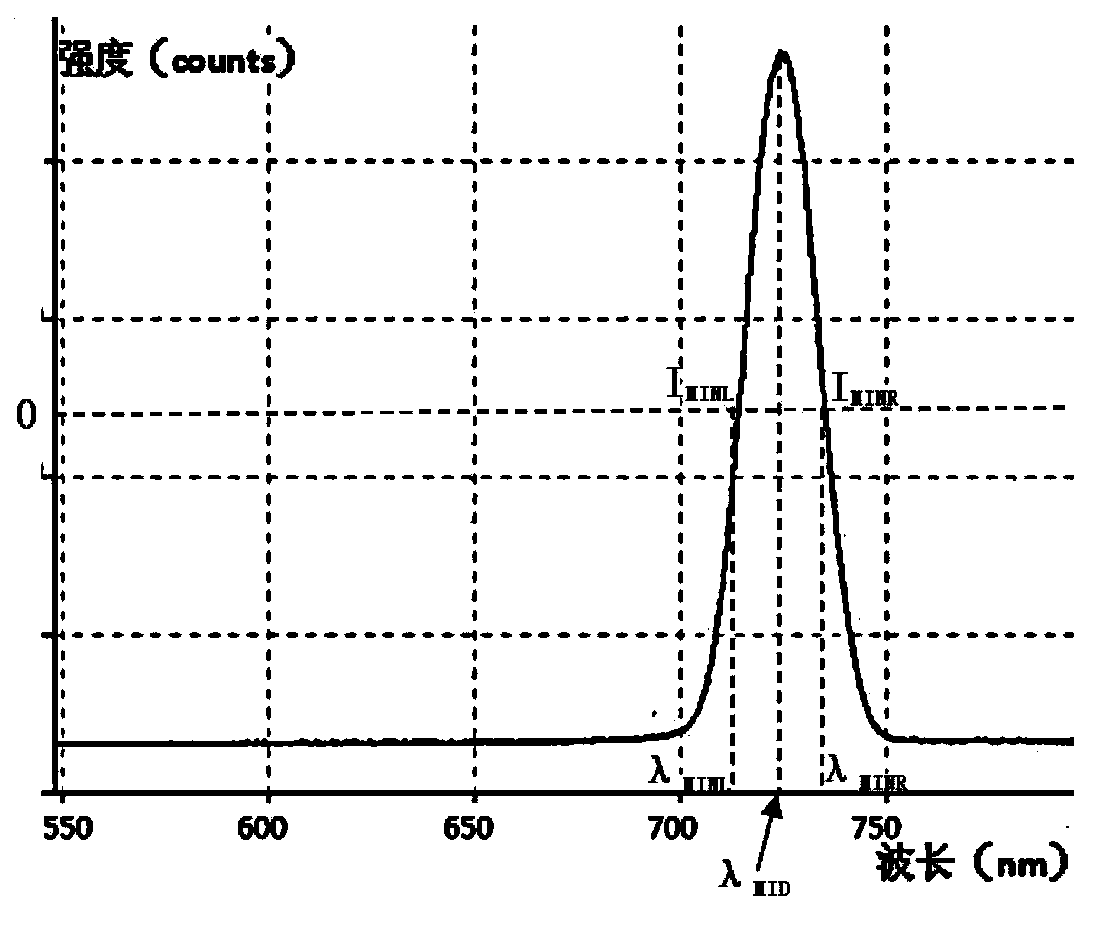

Spectrograph-based optical displacement sensor signal demodulation method

ActiveCN103808267AReduce data processing timeImprove calculation accuracyUsing optical meansComputational physicsVIT signals

The invention relates to a spectrograph-based optical displacement sensor signal demodulation method. According the scheme, a data processing process of a wavelength encoding type optical displacement sensor comprises (1) reading spectroscopic data of output diffraction light of the sensor through a spectrograph; (2) processing the data through a full width at half maximum peak searching algorithm to obtain central wavelength; (3) performing comprehensive regression interpolation on the central wavelength to obtain displacement information. The spectrograph-based optical displacement sensor signal demodulation method has the advantages of being rapid, not needing a gate code calculation process and shortening data processing time; being accurate, avoiding gate code equation fitting errors and improving the calculation accuracy; being independent, not being influenced by optical grating diffraction angle errors and eliminating machining and assembling errors due to the facts that a former process of obtaining the grate code through a diffraction formula is eliminated and the displacement is directly obtained through the central wavelength.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

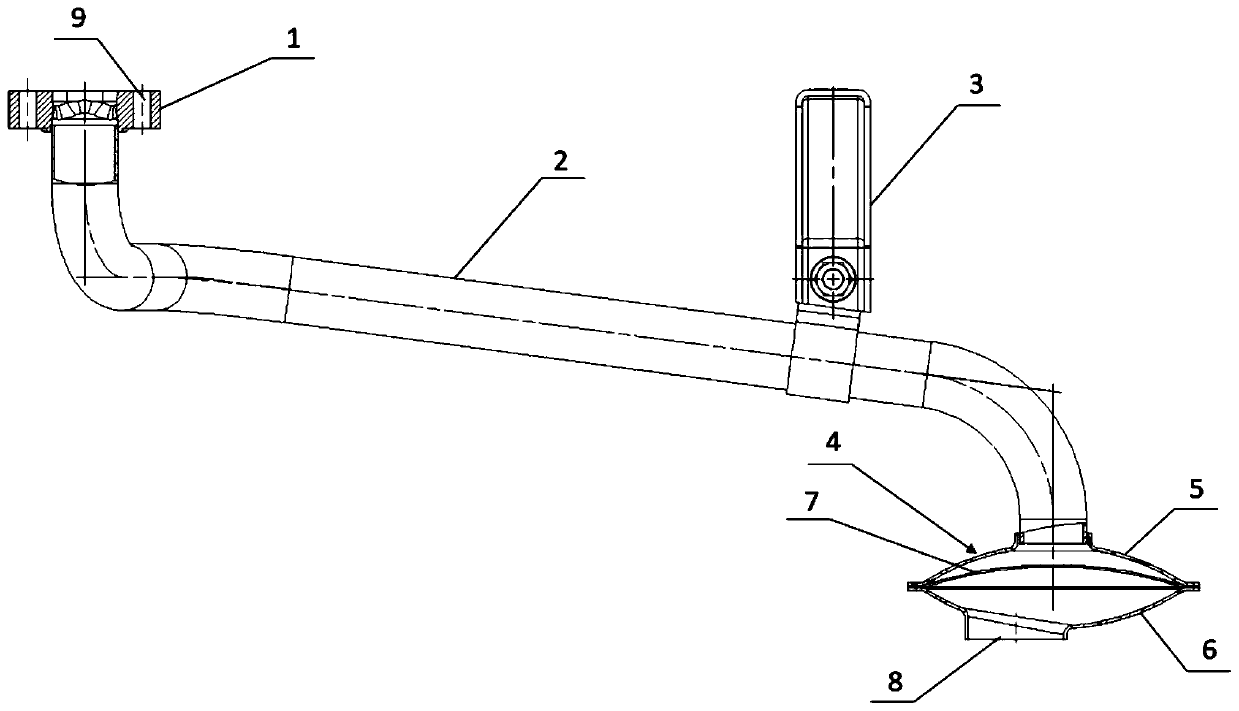

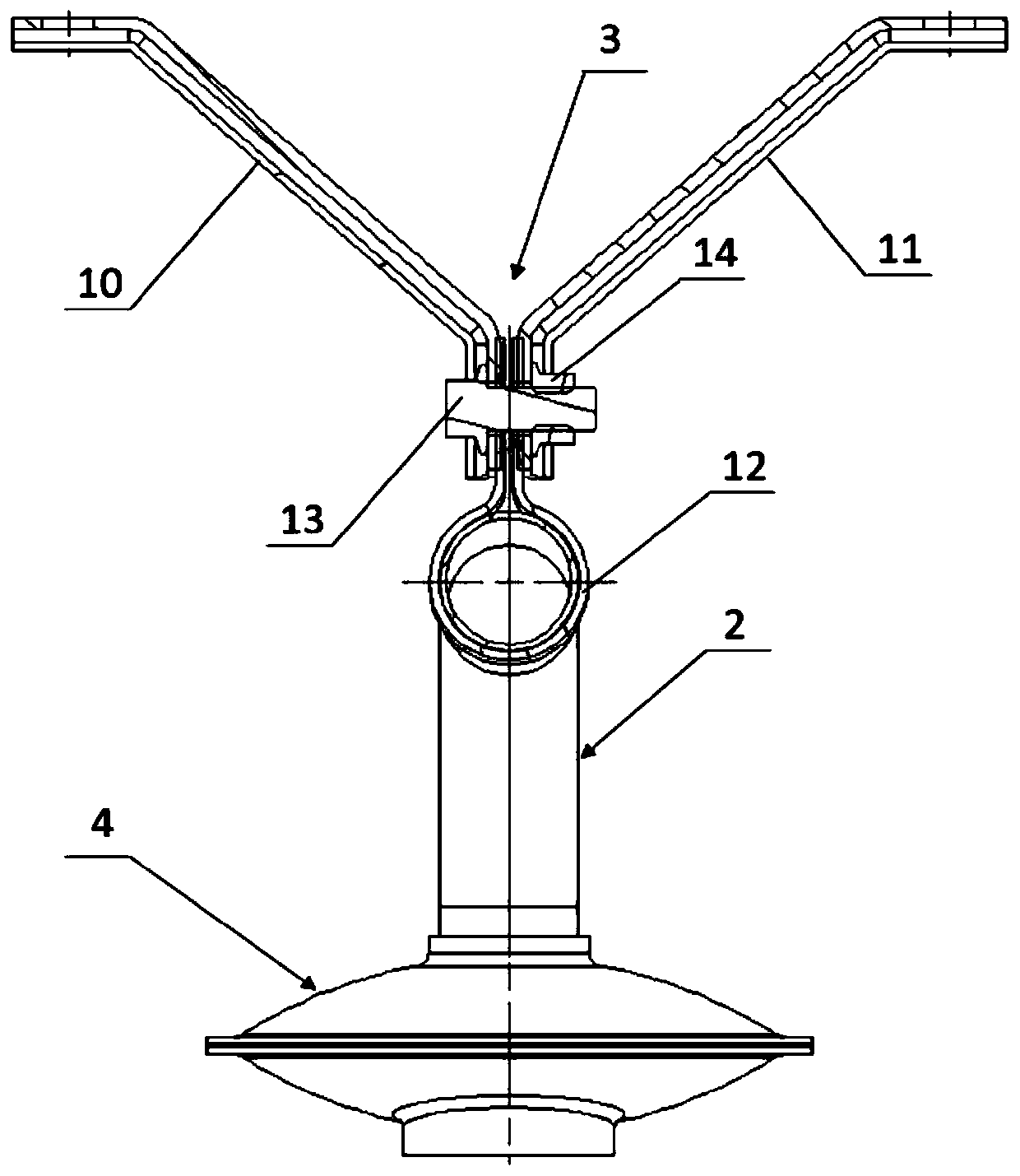

Oil suction pipe part

PendingCN111350562AEliminate assembly errorsReduce assembly stressLubricant conduit arrangementsPressure lubricationStructural engineeringMechanical engineering

The invention provides an oil suction pipe part, comprising a pipeline flange, an oil suction bent pipe, a fixing frame and an oil suction cover. The front end of the oil suction bent pipe and the oilsuction cover are solidified, the tail end of the oil suction bent pipe and the pipeline flange are solidified, and the fixing frame is arranged at the tail end of the oil suction bent pipe; and theoil suction cover comprises an arc-shaped upper cover, an arc-shaped lower cover and an arc-shaped filter net, the arc-shaped upper cover and the front end of the oil suction bent pipe communicate andare solidified, the arc-shaped upper cover and the arc-shaped lower cover are in clamping fit and solidified, the arc-shaped filter net is arranged between the arc-shaped upper cover and the arc-shaped lower cover, and an oil suction opening is further formed in the arc-shaped lower cover. According to the oil suction pipe part provided by the invention, an assembly-type oil suction pipe part isadopted as the fixing frame so that the assembly error within a certain range can be eliminated, assembly stress is reduced, reliability is improved, and a breakage failure caused by long-term usage is avoided.

Owner:GUANGXI YUCHAI MASCH CO LTD

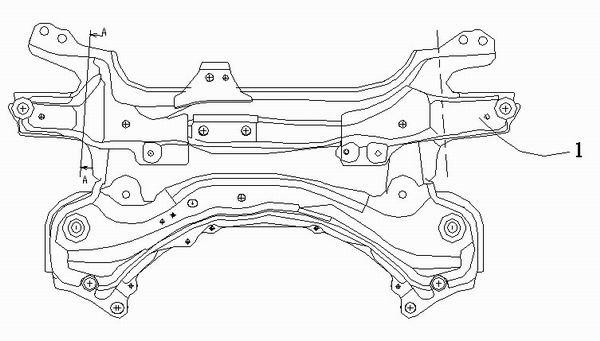

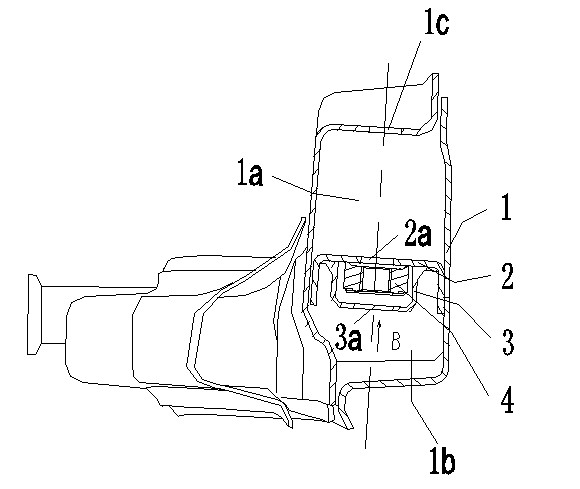

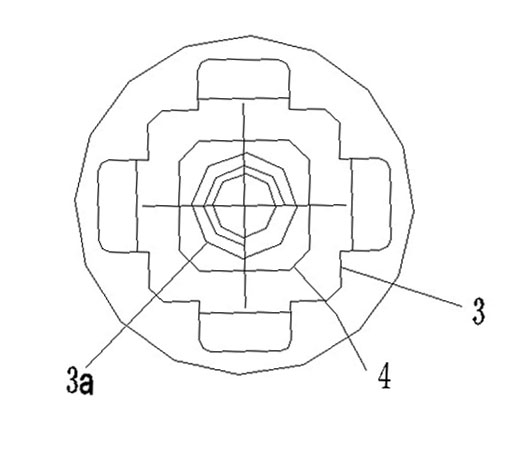

Cantilever installation structure of automotive auxiliary frame

InactiveCN102107678AEasy to operateNo assembly defects that cannot be adjustedUnderstructuresPivoted suspension armsVehicle frameEngineering

The invention discloses a cantilever installation structure of an automotive auxiliary frame. The left and right sides of the auxiliary frame (1) are symmetrically provided with cavities, mounting plates (2) are longitudinally arranged in the cavities, a rectangular cover (3) is welded on the mounting plates (2), movable nuts (4) are arranged in the rectangular cover (3), the axes of the movable nuts (4) are vertical to the mounting plates (2), and the movable nuts (4) can move in the radial direction in the rectangular cover (3). The structure is simple, an automotive cantilever can be installed on the auxiliary frame easily and quickly at one step, and the assembly defect of regulation incapability in the conventional projection welding nut connection modes is not caused.

Owner:力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com