Method and device for checking the tyre seat on vehicle wheels

A wheel and tire technology, applied in vehicle testing, using optical devices, measuring devices, etc., can solve problems such as wheel imbalance, and achieve the effect of easy modification and saving of structural costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

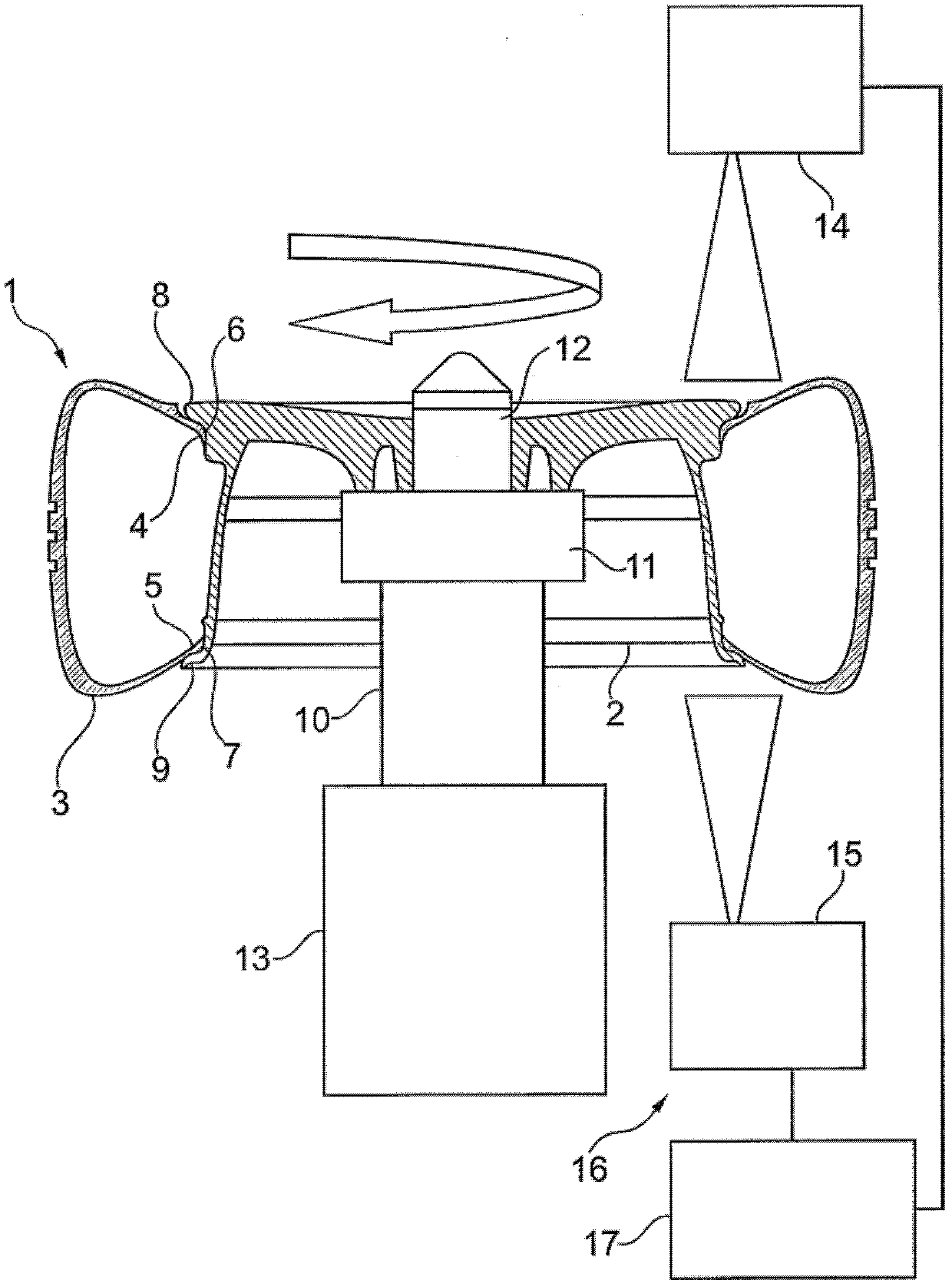

[0015] attached figure 1 A wheel 1 is shown in cross section, consisting of a rim 2 and a tubeless tire 3 . The tire 3 has two tire beads 4 , 5 surrounding the counter surfaces 6 , 7 on the outer circumference of the rim 2 . In the axial direction, the tire bead 4, 5 bears on the annular wall 8, 9 of the rim 2, which extends radially outwards adjacent to the mating face 6, 7 and with it towards the mating face 6, 9 The sides of 7 form the contact surfaces for the tire beads 4 , 5 .

[0016] The wheel 1 is mounted on a rotatable spindle 10 . For this purpose, the spindle 10 has a support 11 with a flat radial contact surface and a clamping device 12 which engages in the central bore of the rim 2 , by means of which the rim 2 is precisely centered and torsion-proof. fastened to the spindle 10. The spindle 10 is arranged on a drive motor 13 and can be driven by it.

[0017] Spaced apart from the axis of rotation of the spindle 10 , the sensors 14 , 15 of an optical distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com