Patents

Literature

73results about How to "Realize full closed-loop control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

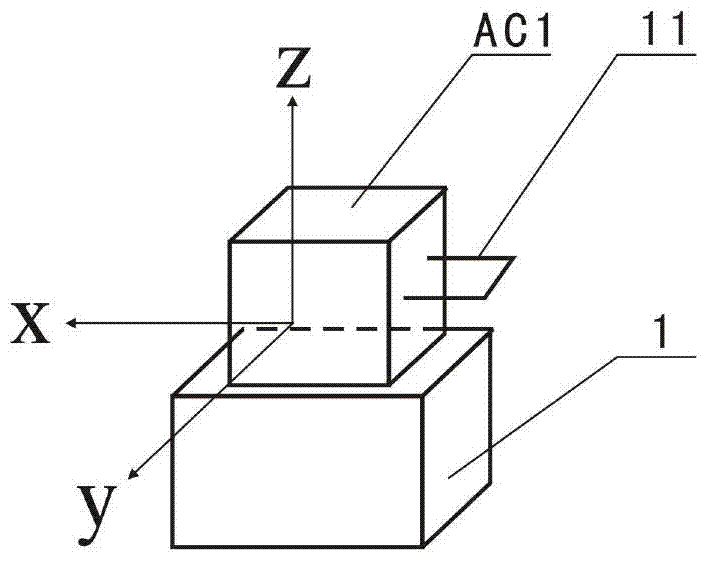

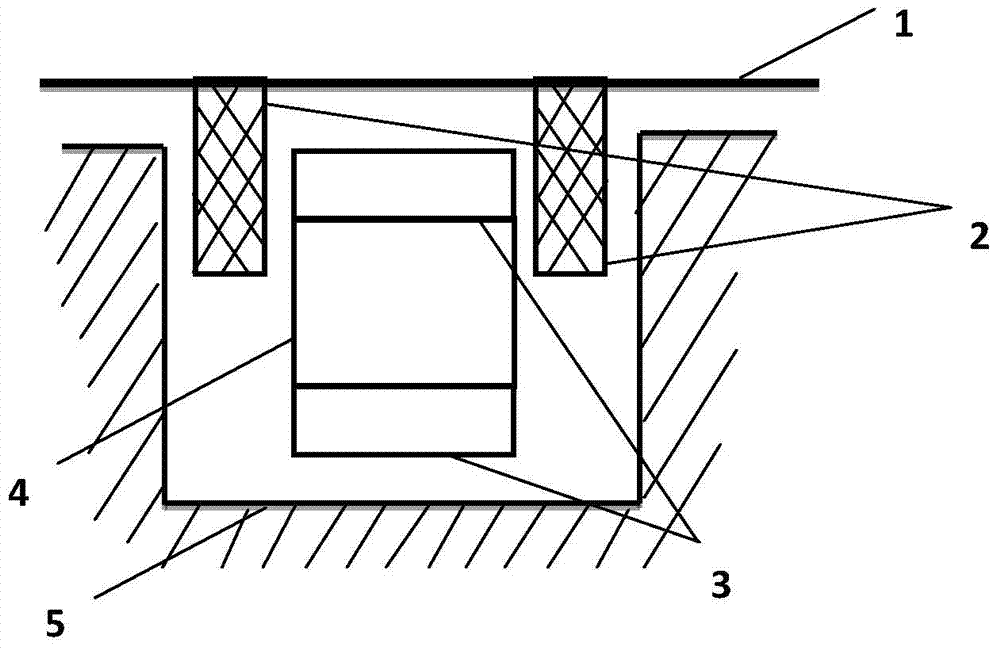

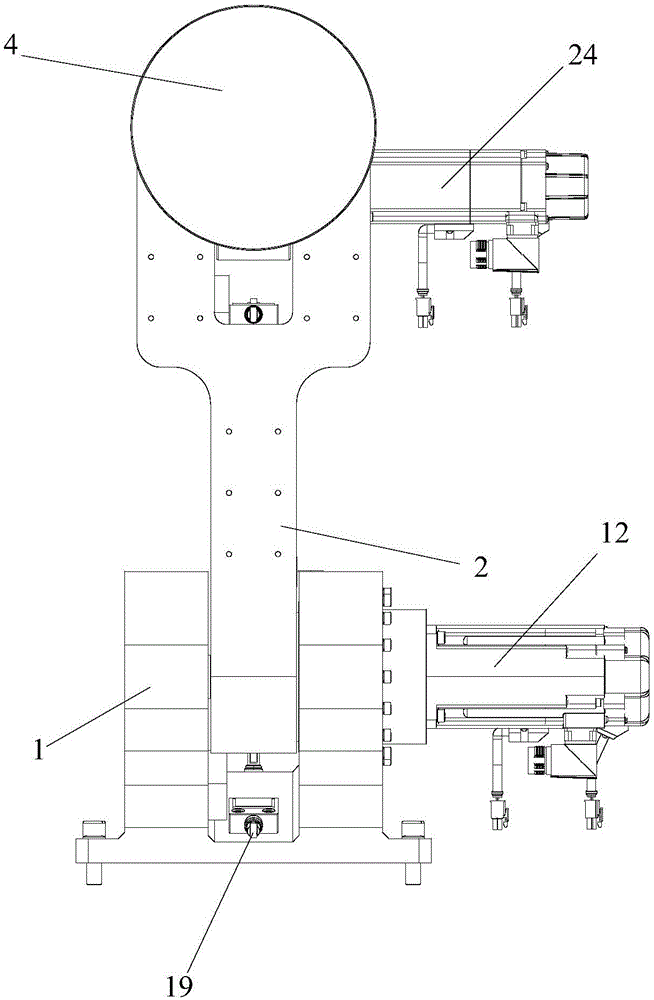

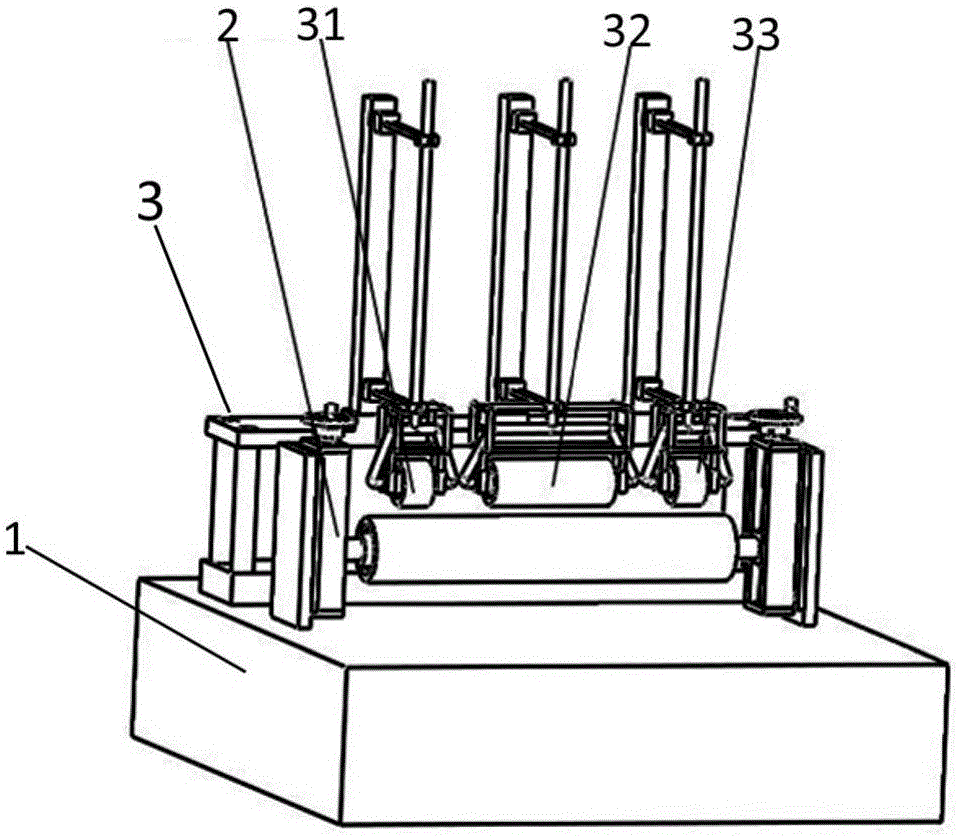

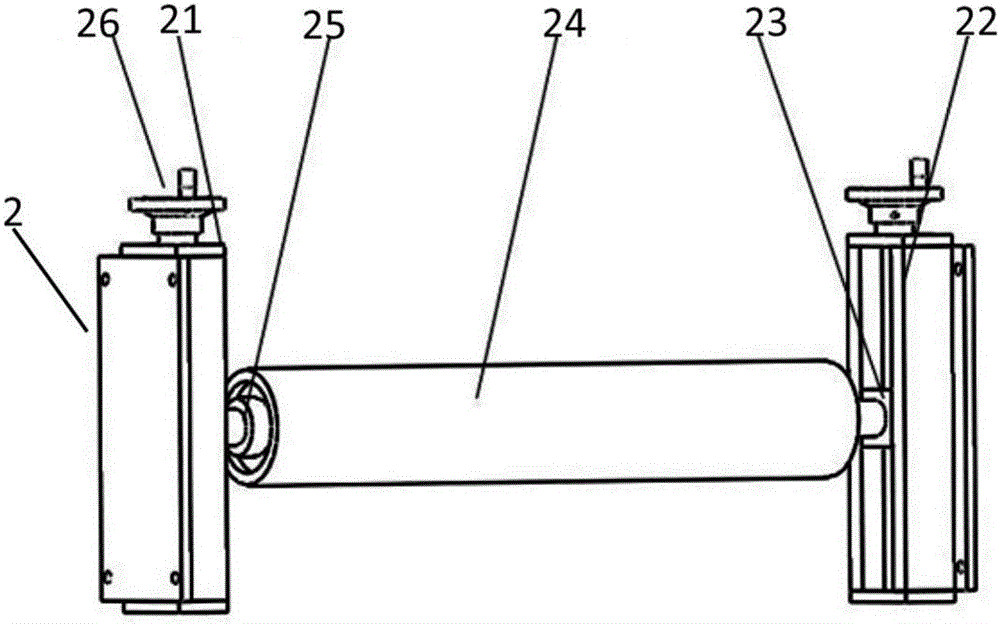

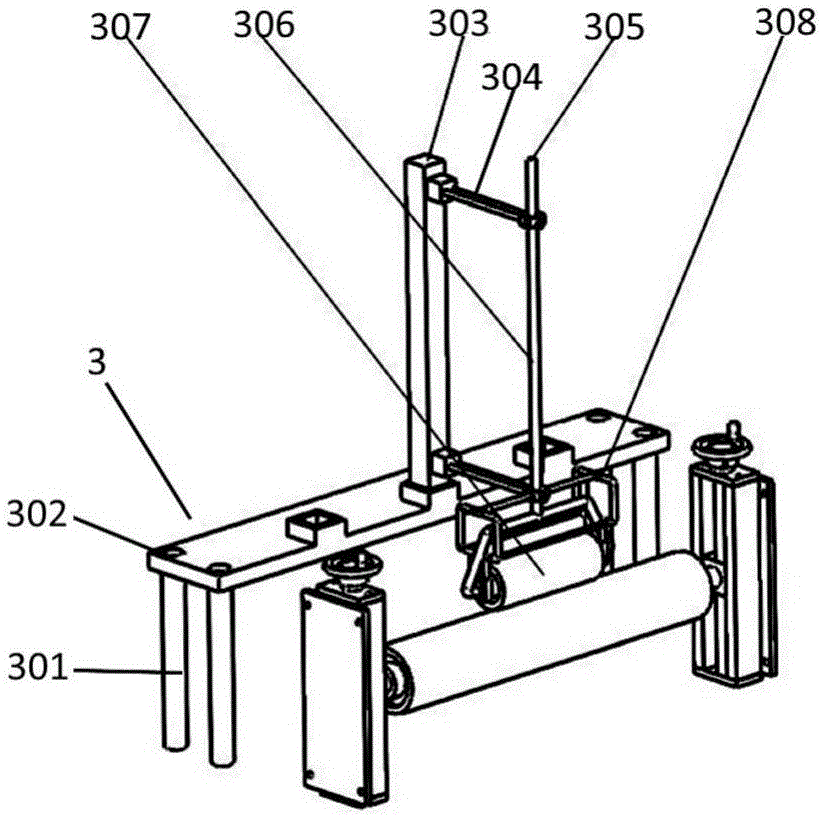

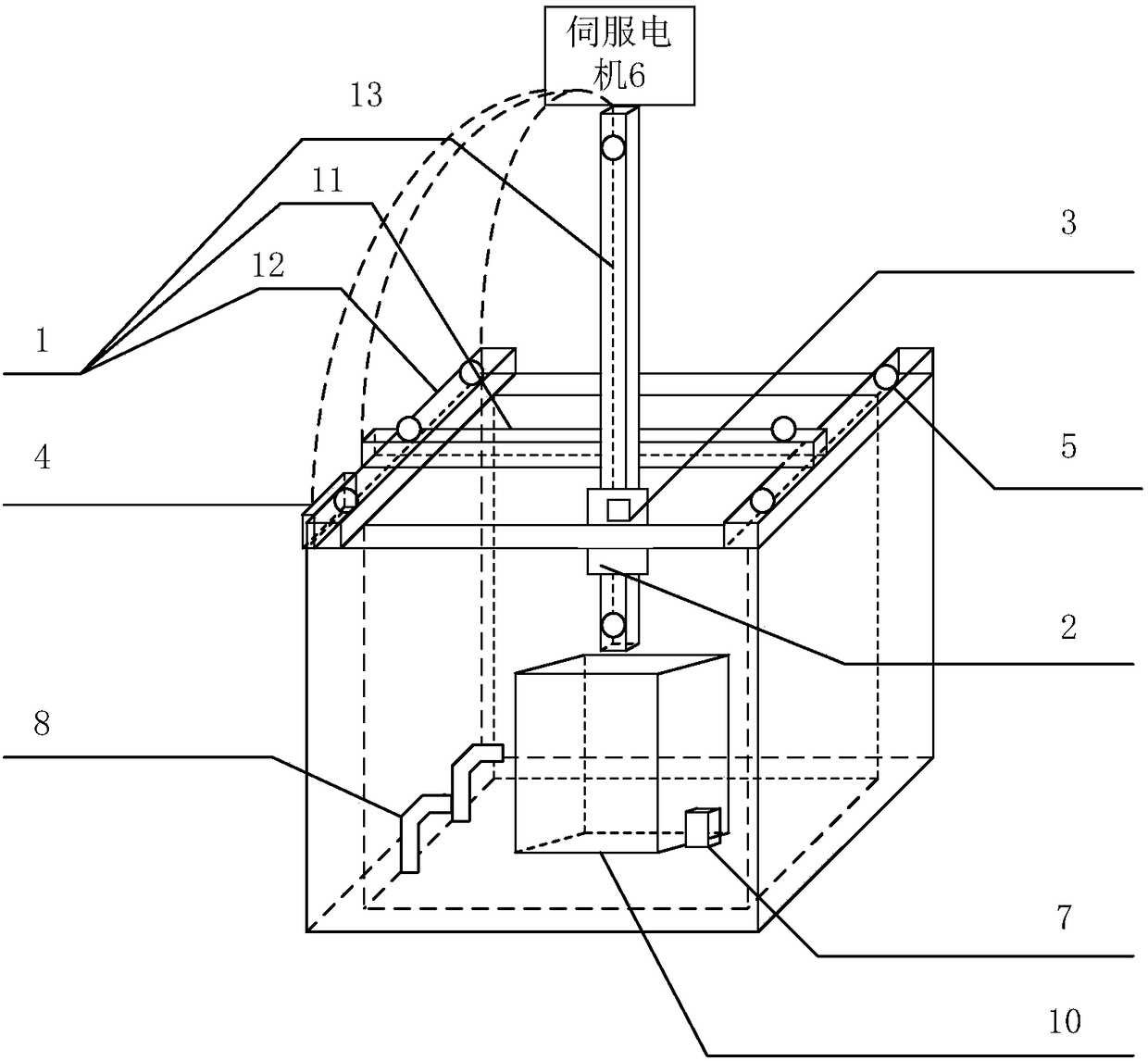

3D (three-dimensional) printing system structure

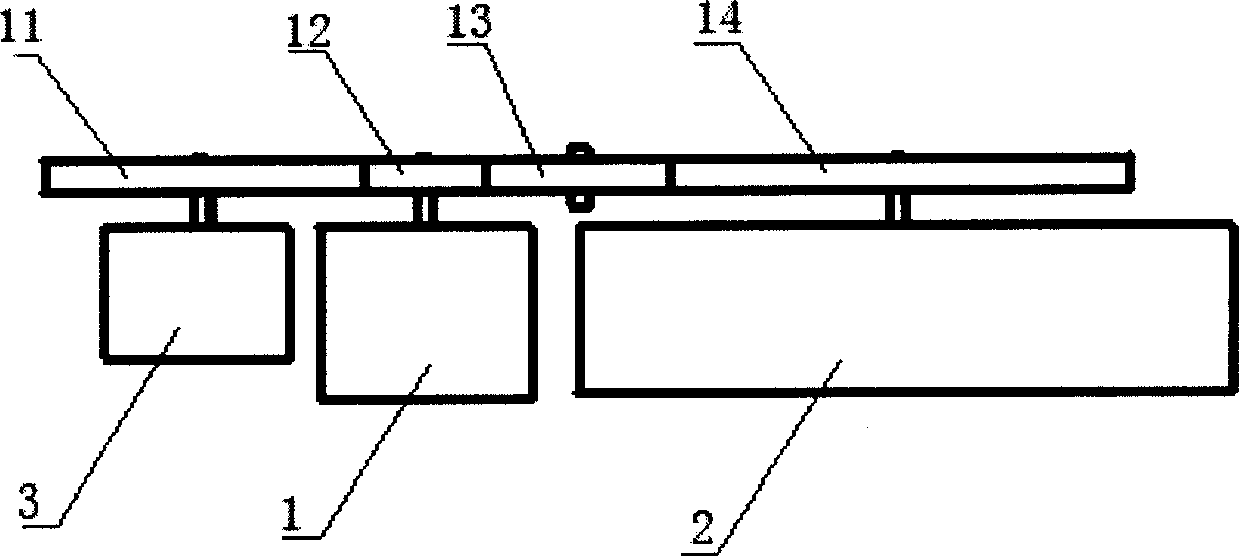

The invention relates to a 3D (three-dimensional) printing system structure. The 3D (three-dimensional) printing system structure comprises a lifting printing platform, a dual-screw dual-optical-axis Z-shaft driving mechanism, an X-shaft drive mechanism, a Y-shaft drive mechanism as well as a stationary object carrying platform, wherein the printing platform is provided with an X-shaft drive motor and a Y-shaft drive motor; the two motors are respectively connected to a pair of driven bearings by synchronous belts at two ends of the driving shaft; double slide shafts in the X direction and the Y direction are both provided with slide seats; two pairs of slide seats are respectively connected by an X cross beam and a Y cross beam, and the two cross beams respectively penetrate through a 3D printer head; a driving motor of the dual-screw dual-optical-axis driving mechanism and the driving shaft are connected by the synchronous belt; the position of the driving motor can be adjusted randomly. The X-shaft drive mechanism, the Y-shaft drive mechanism and the driving shaft operate individually, so that the motion modulation is reduced; the dual-screw dual-optical-axis driving mechanism has favorable stability, so that the printing platform is stressed in a balance manner; the driving in each direction is stable; the 3D printing precision is improved.

Owner:UNIV OF SCI & TECH OF CHINA

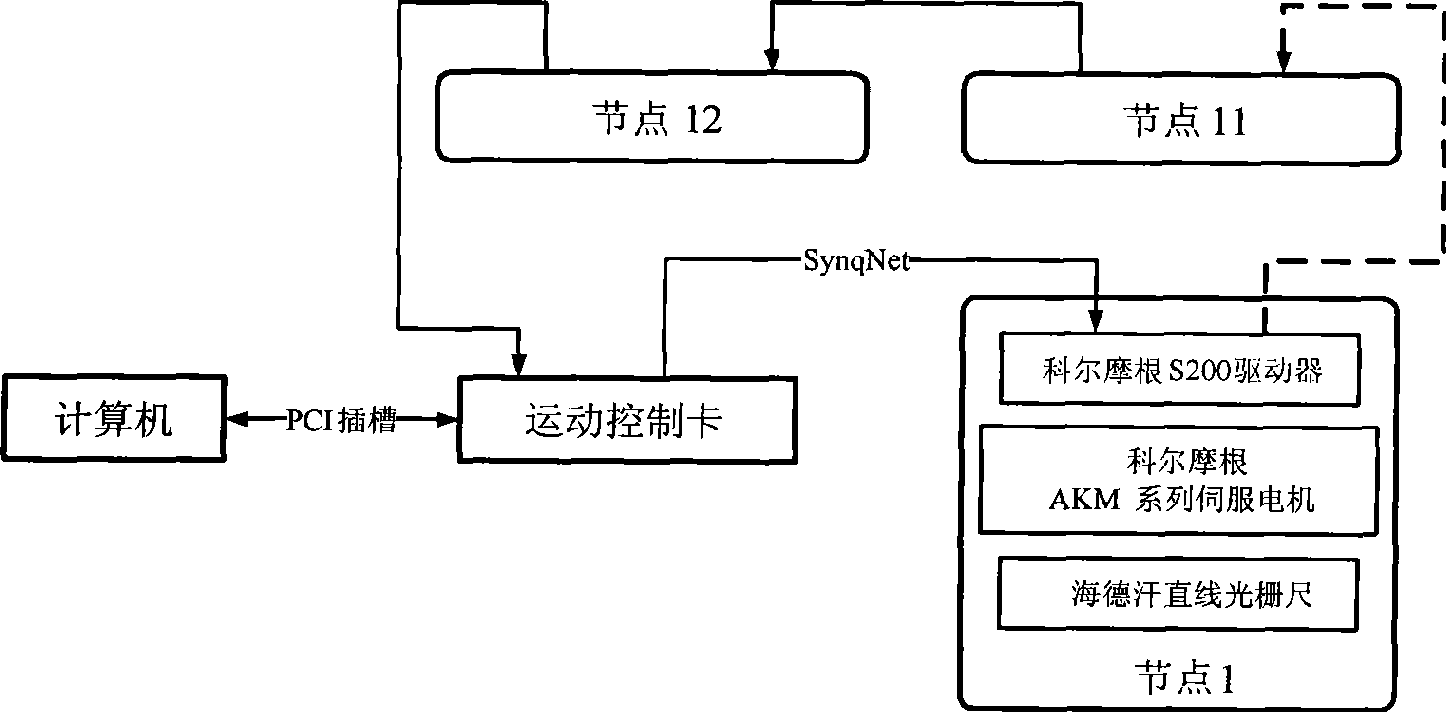

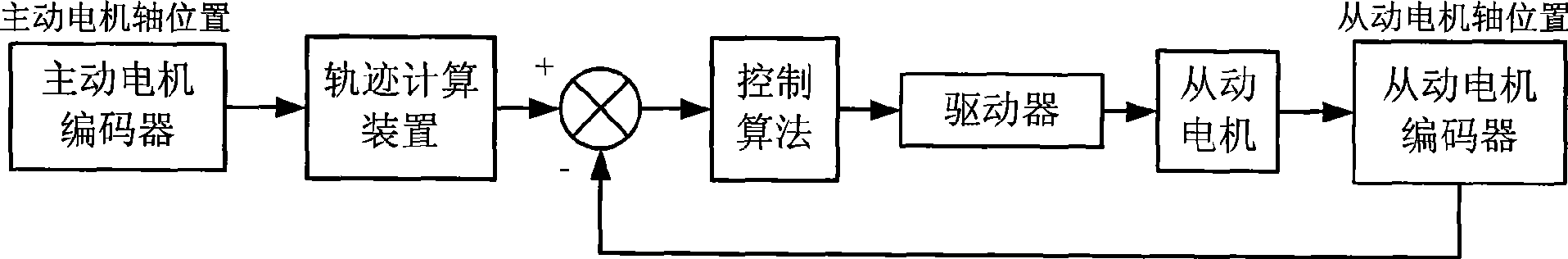

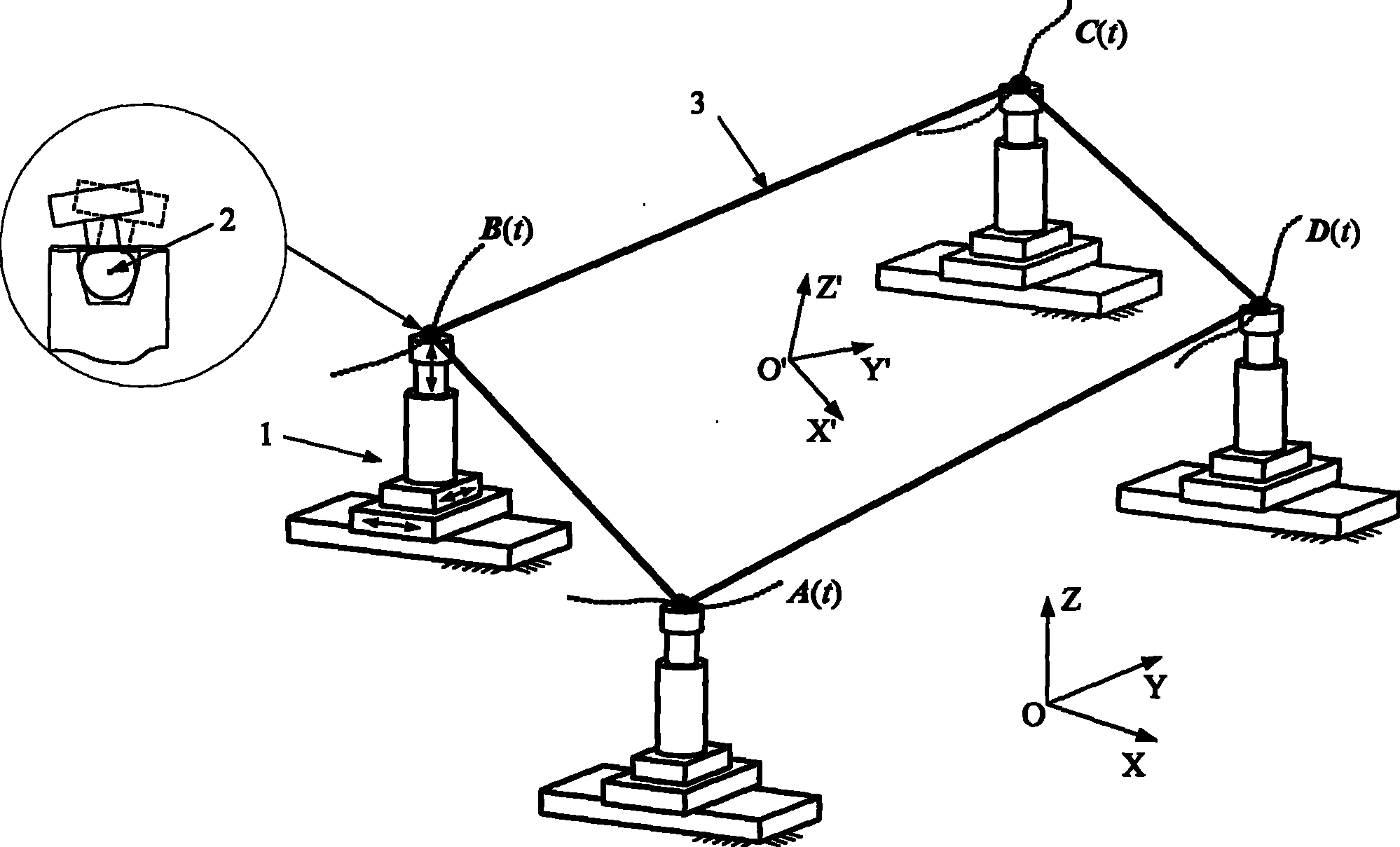

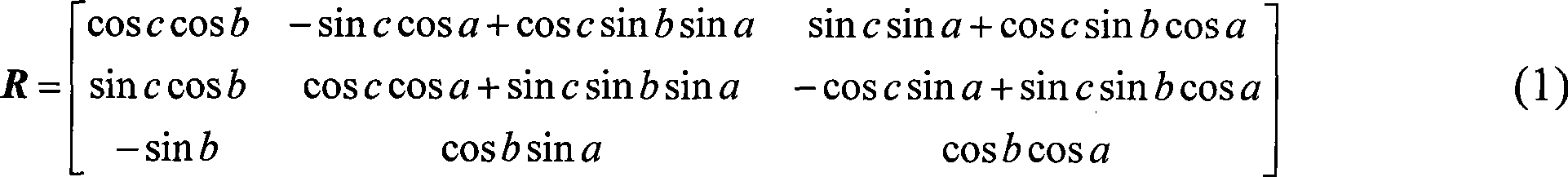

Synergetic control method of aircraft part pose alignment based on four locater

The invention discloses a method for adjusting and synergetically controlling the position and pose of an aircraft component based on four locators. The method comprises the following steps: firstly, a global coordinate system OXYZ is established, and the current position and pose and the target position and pose of the aircraft component are calculated under the global coordinate system; secondly, the automatic adjusting path and the inch adjusting path of the aircraft component are formed; thirdly, the track of the sphere pivot wiring point between the locator and the aircraft component is planed according to the automatic adjusting path and the inch adjusting path; fourthly, the track of the sphere pivot wiring point is inverted into the driving parameter of a 12 motor axle synchronous control network; fifthly, the 12 motor axle synchronous control network is built based on a SynqNet bus, and the position servo of single motor axle adopts the full-closed loop digit controlling; and sixthly, two locators are selected, and the collocated relation between the locators is the master-slave motion mode. The method has the following advantages: firstly, the path for adjusting the position and pose of the aircraft component can be planed; secondly, the full-closed loop controlling of the single axle motion of the locator can be realized; and thirdly, the 12 axle synchronous motion of the position and pose adjusting system can be realized.

Owner:ZHEJIANG UNIV +1

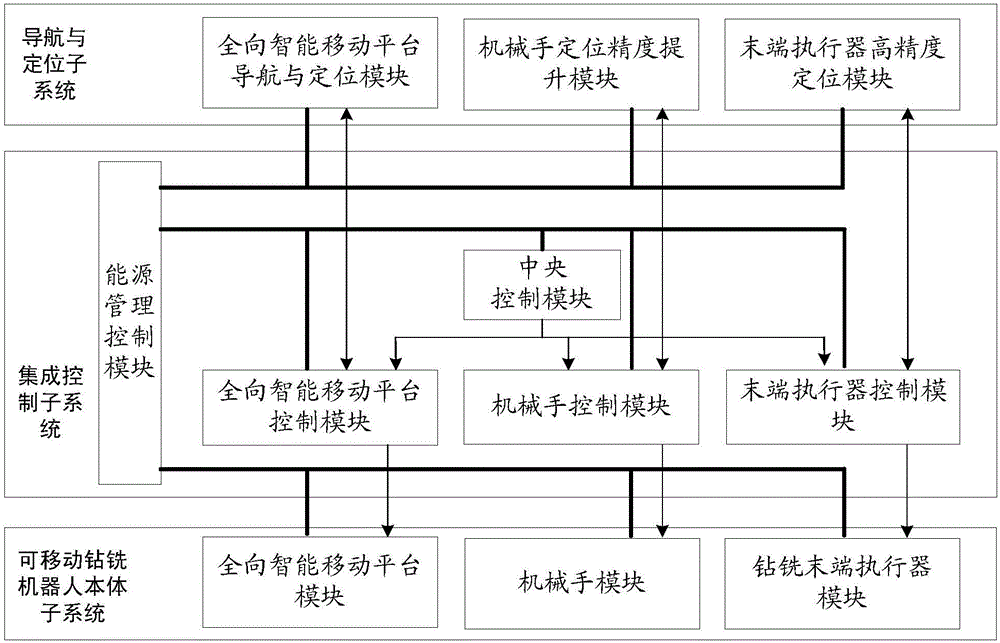

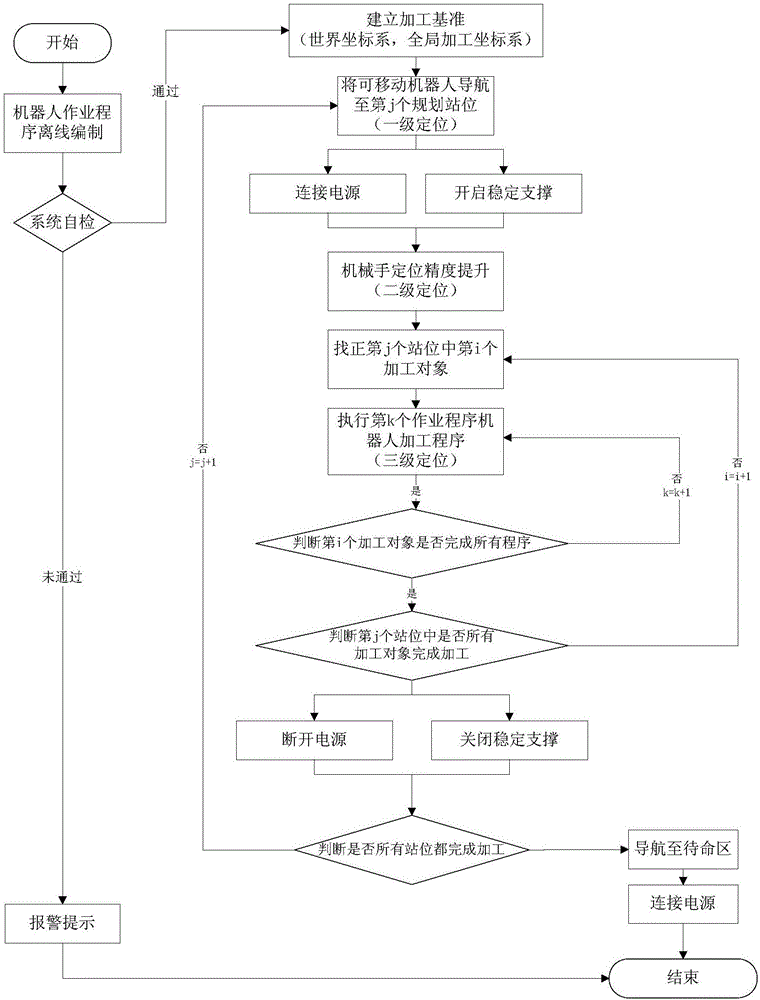

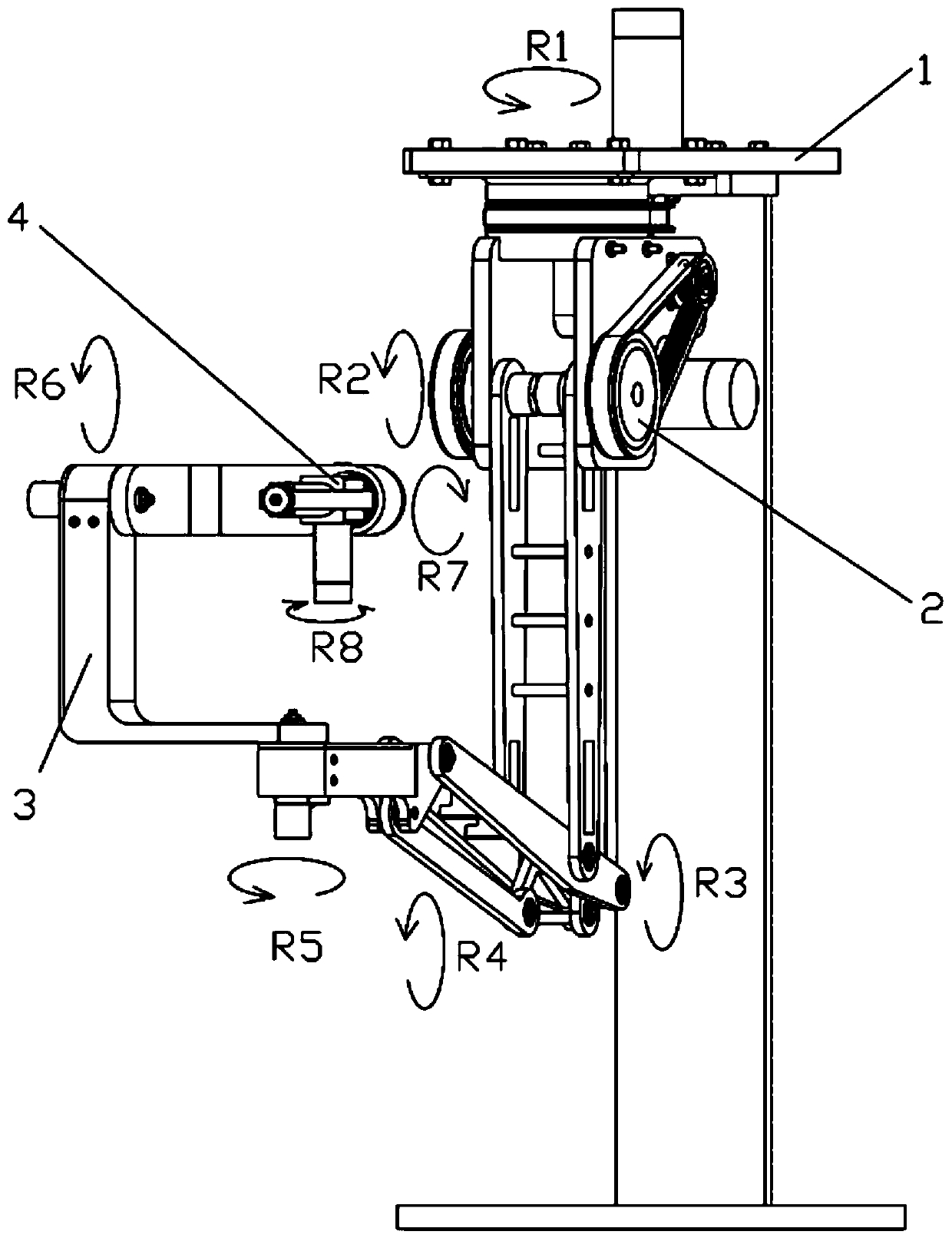

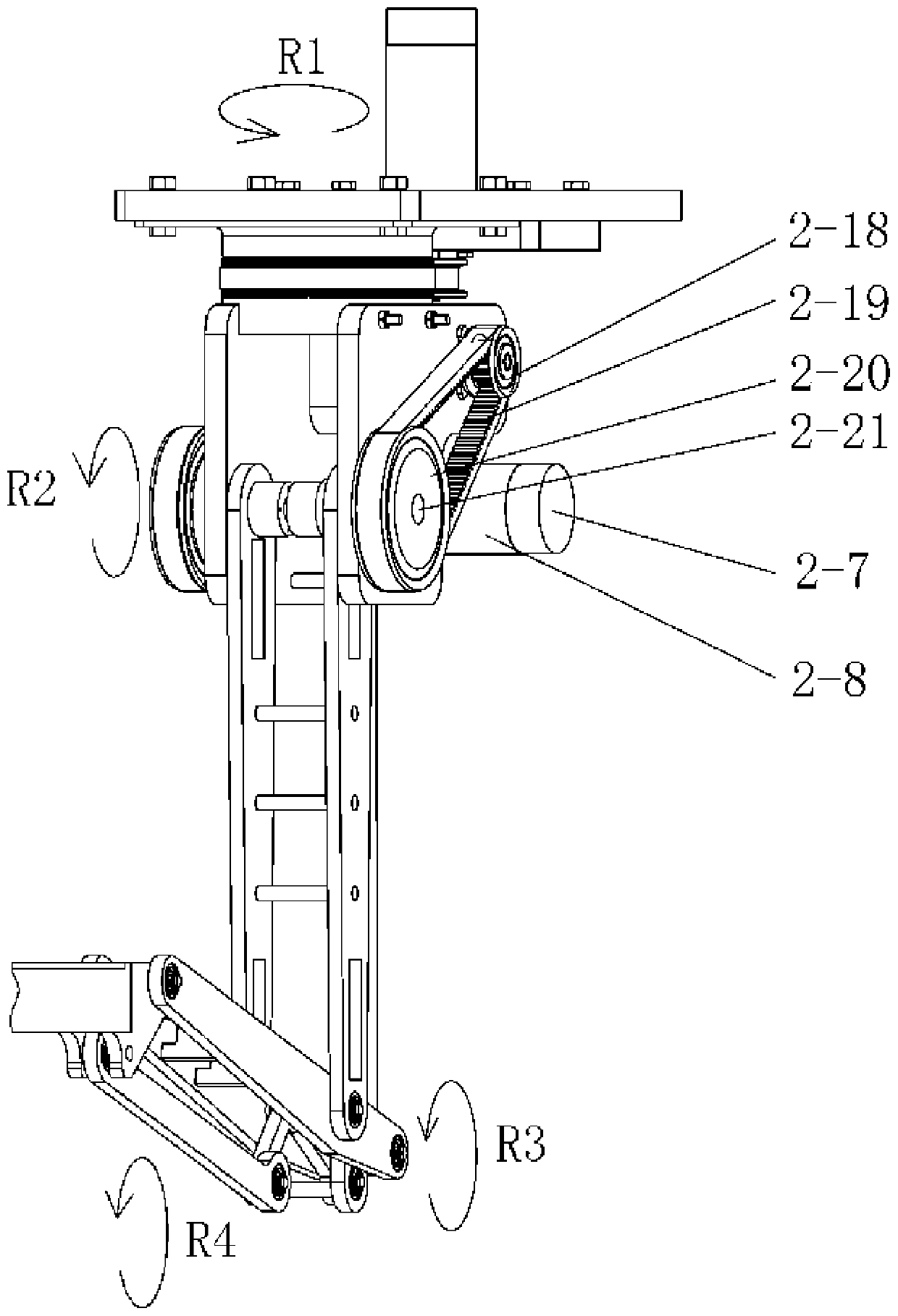

Movable drilling and milling robot system achieving automatic addressing

ActiveCN106625665ASave time and costIncrease flexibilityProgramme-controlled manipulatorOther manufacturing equipments/toolsRobotic controlRobotic systems

The invention discloses a movable drilling and milling robot system achieving automatic addressing. The movable drilling and milling robot system comprises a movable drilling and milling robot body subsystem, an integrated control subsystem and a navigating and positioning subsystem; the movable drilling and milling robot body subsystem comprises an omni-directional intelligent moving platform module, a manipulator module and a drilling and milling end executer module; the navigating and positioning subsystem comprises an omni-directional intelligent moving platform navigating and positioning module, a manipulator positioning precision improving module and a high-precision end executer positioning module; the integrated control subsystem comprises a central control module, an omni-directional intelligent moving platform control module, a manipulator control module, an end executer control module and an energy management control module. The system can rapidly adjust the layout according to changes of manufacturing tasks or production environments, is suitable for multi-variety and middle-small-batch production and overcomes the processing technological difficulties of an overlarge structure.

Owner:BEIJING SATELLITE MFG FACTORY

Apparatus and method for detecting electronic declination angle of communication antenna

InactiveCN1734227AOmit the self-test calibration processSimple structureUsing electrical meansAntennasElectricityControl theory

This invention relates to a device and method of detecting the angle of communication antenna downdiping, which comprises the following parts: motor driver (1), phase shifter (2), potentiometer (3). The moving end of potentiometer (3) connects the mobile portion of phase shifter (2) mechanically. The motor driver (1) synchronizes the motion of the phase shifter (2) and potentiometer (3).

Owner:GCI SCI & TECH

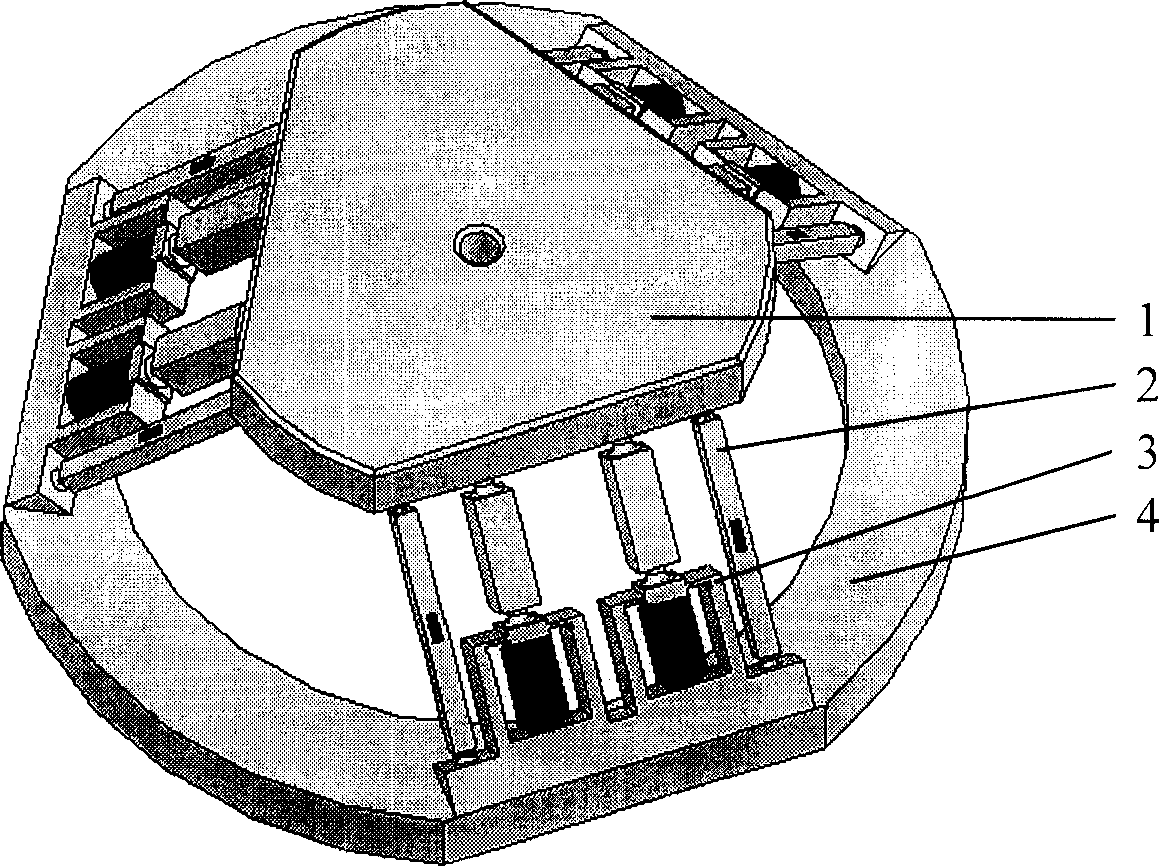

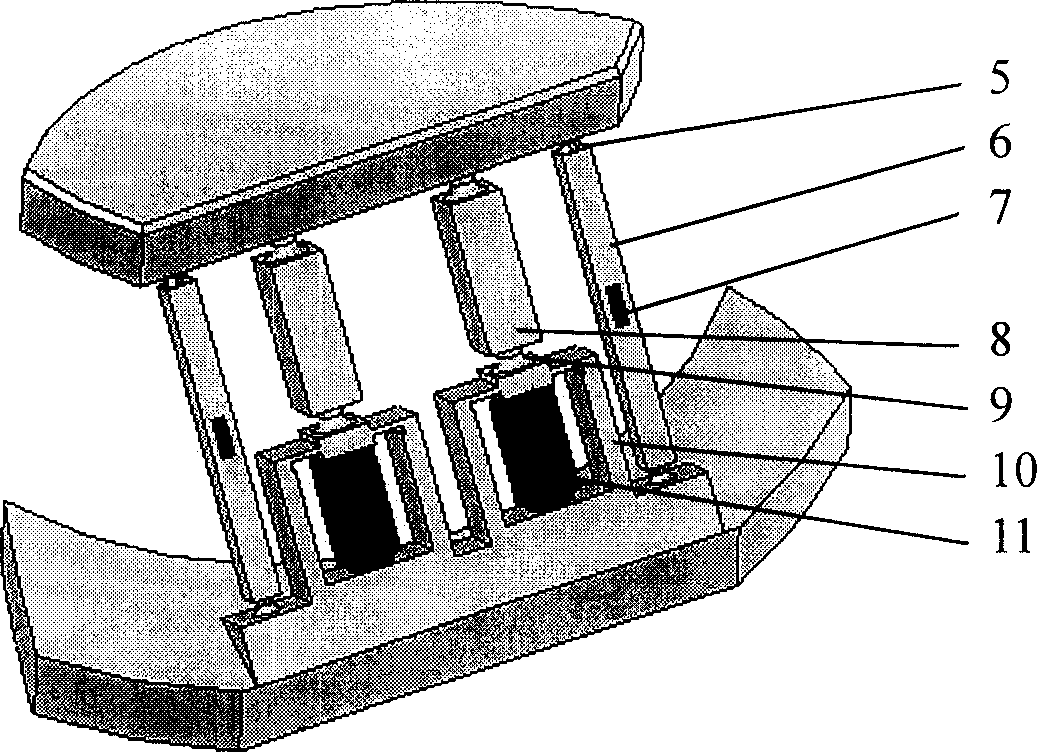

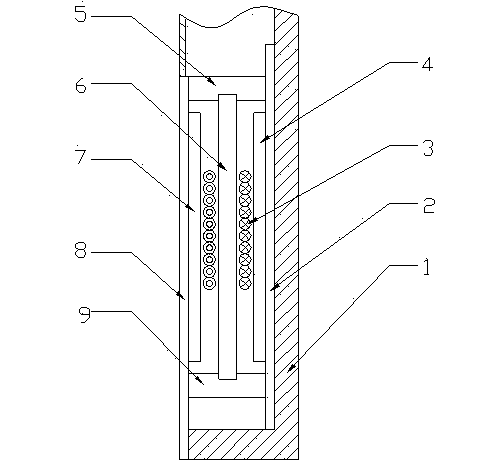

Six-freedom micro operation robot with complete position and posture feedback

InactiveCN1846948ARealize full closed-loop controlProgramme-controlled manipulatorMicro-operationParallel plate

The six-freedom micro operation robot with complete position a posture feedback features that the bench and the pedestal are connected through 12 kinematic link branches, including 6 feedback branches comprising a feedback branch pillar with flexible hinges on two ends and a strain gauge each, and 6 driving branches comprising a driving branch pillar with flexible hinges on two ends, parallel plate elastic shift pair and piezoelectric ceramic displacement unit each. The 12 kinematic link branches are separated into 3 groups including 2 feedback branches and 2 driving branches each. The main body of the six-freedom micro operation robot is one integral part machined through once machining. The present invention has simple structure, small size, low manufacture cost and other advantages, can realize micro complete closed-loop control with no friction, no interval and high resolution, and may be used widely.

Owner:YANSHAN UNIV

Linear rotary servo motor with two degrees of freedom

InactiveCN103427588AReduced mass and moment of inertia of the moverQuick responsePropulsion systemsRotary encoderTwo degrees of freedom

The invention relates provides a linear rotary servo motor with two degrees of freedom, and relates to the field of servo motors, wherein the linear rotary servo motor with two degrees of freedom can achieve two degrees of freedom of linear motion and rotary motion on one output shaft simultaneously, be used for mechanical equipment, simplify complexity of the equipment, and reduce production and maintenance cost. The linear motion is produced by Ampere force borne by a coil on a primary rotor in a magnetic field, and position feedback is conducted by using a grating ruler. The rotary motion is produced by a hollow cup coil, and position feedback is conducted by using a rotary encoder. Both a primary coil and a secondary coil are of a non-iron-core structure so that rotor mass and rotary inertia can be reduced greatly. The linear rotary servo motor with two degrees of freedom has high response speed. As a position feedback device is directly installed on the rotor, zero transmission and full-closed loop control are achieved, and motion accuracy is improved greatly. The linear rotary servo motor with two degrees of freedom is applicable to short-route, light-load, precision and high-speed movement occasions.

Owner:贾莉莉

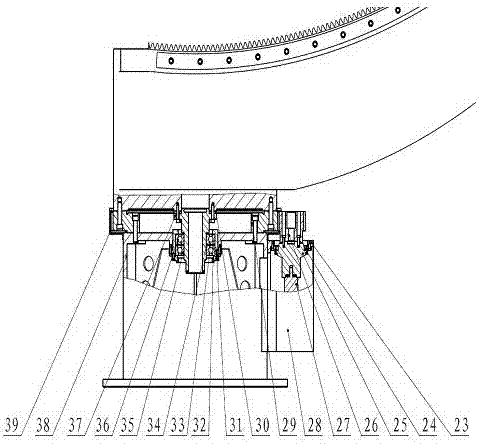

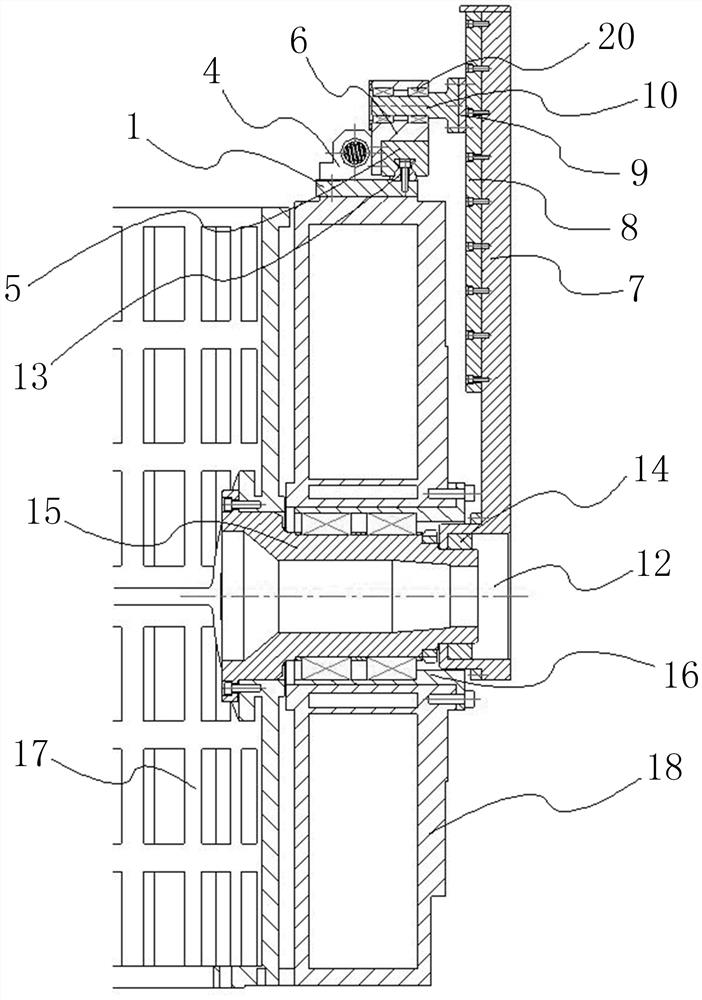

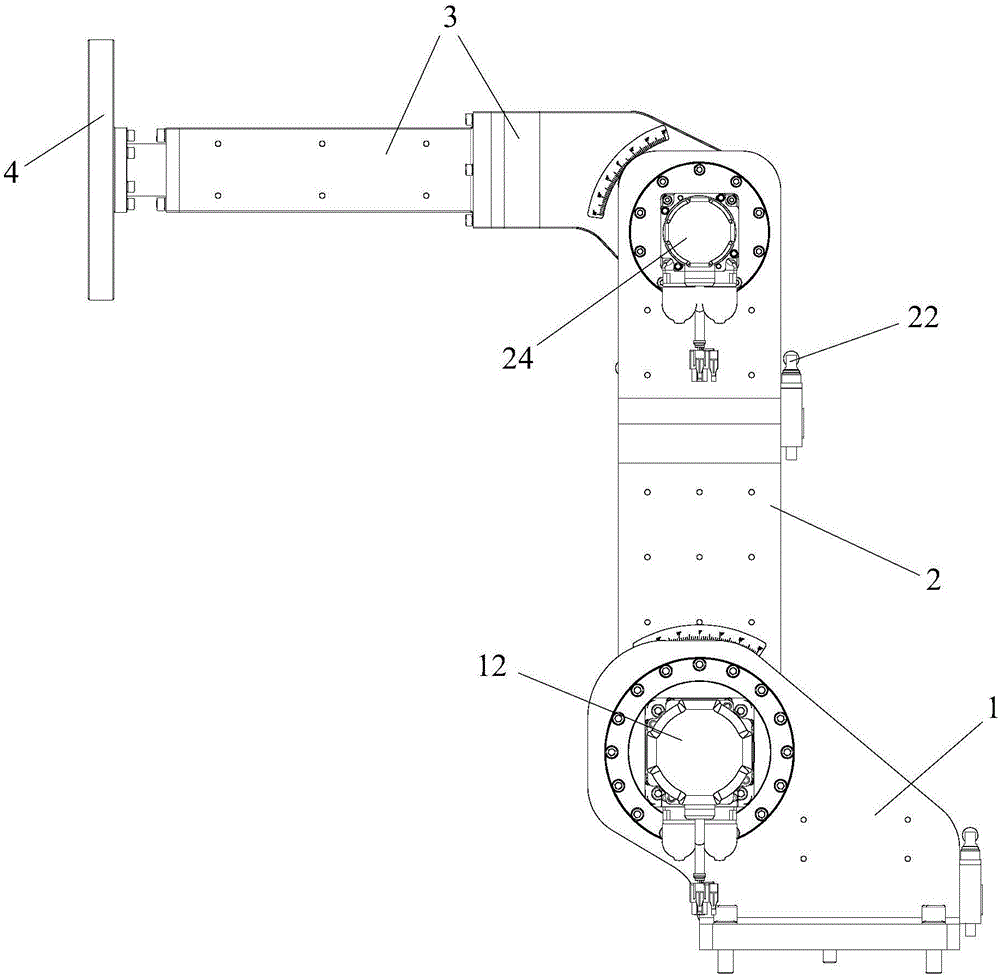

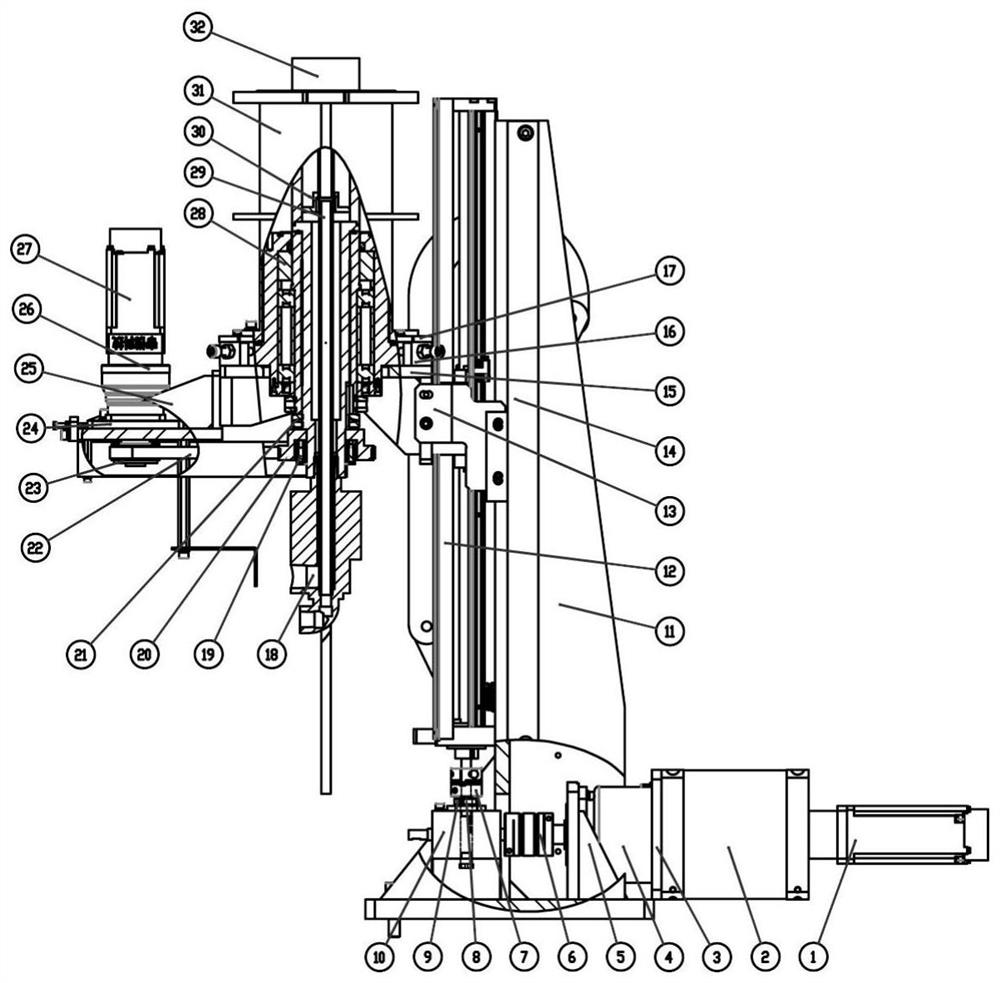

Three-axis antenna test turntable system with low reflection characteristic

PendingCN106970363AReduce electromagnetic interferenceImprove accuracyWave based measurement systemsAntenna radiation diagramsEngineeringMicrowave

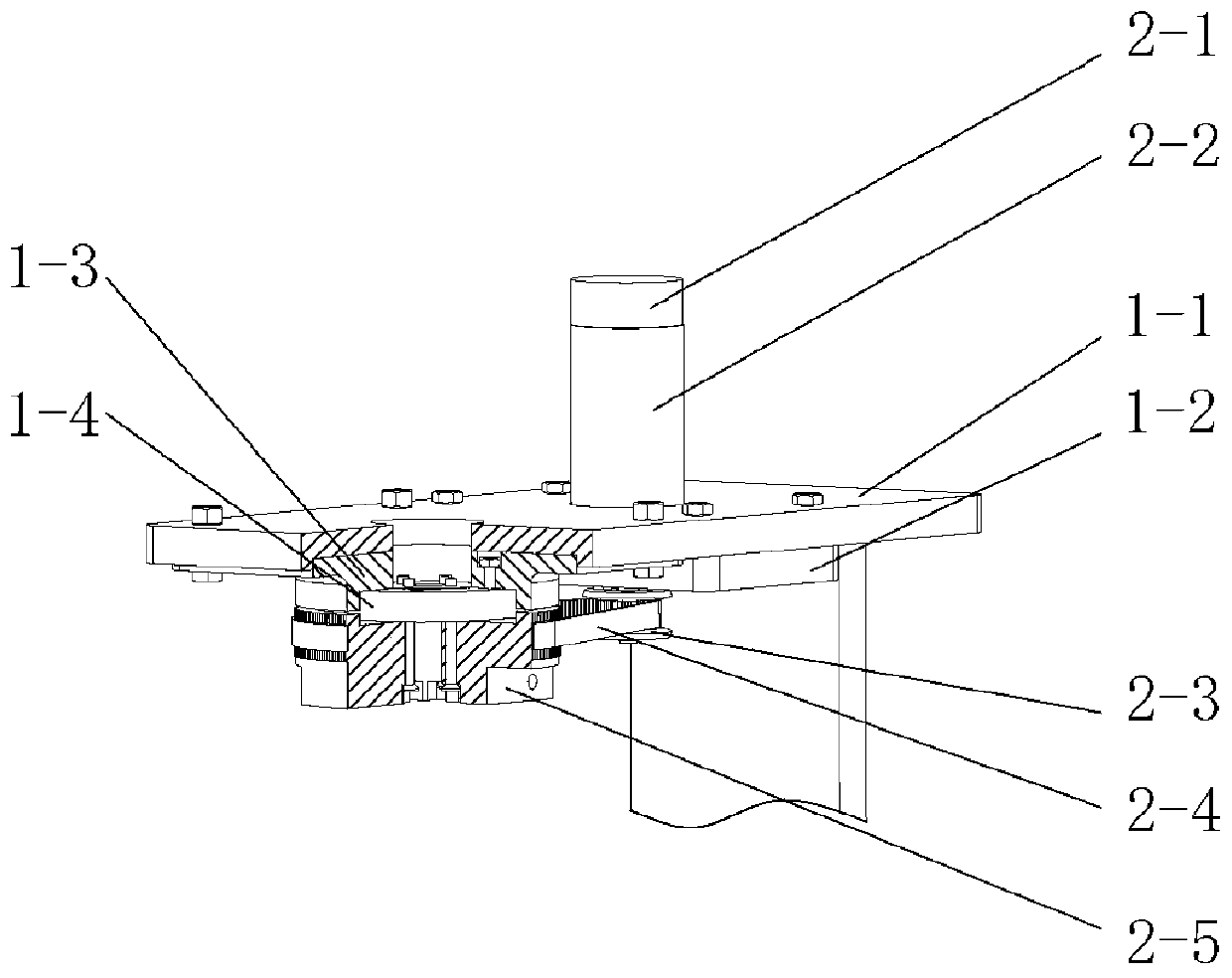

The invention discloses a three-axis antenna test turntable system with a low reflection characteristic, which is composed of three parts of a rolling shaft system assembly, a pitching shaft system assembly and an azimuth shaft system assembly, wherein the azimuth shaft system assembly is arranged on a microwave anechoic chamber ground through an azimuth base; the pitching shaft system assembly is fixedly connected with the outer ring of an azimuth four-point contact ball turntable bearing through a pitching frame lower flange face by using a screw; the rolling shaft system assembly is fixedly connected with the upper end face of a pitching upper support through a rolling frame lower flange face by using a screw; and a load is arranged on a rolling load mounting plate. Movement of three degrees of freedom rotation of rolling, pitching and azimuth can be realized, accurate positioning at a specified angle position can be realized, and the system of the invention has the advantages of practicality, stability and reliability.

Owner:JIUJIANG PRECISION MEASURING TECH RES INST

Force feedback main manipulator for minimally invasive surgery

ActiveCN110811843AReduce moment of inertiaMinus moment of inertiaDiagnosticsSurgical manipulatorsLess invasive surgeryEngineering

The invention discloses a force feedback main manipulator for minimally invasive surgery. The force feedback main manipulator comprises a first parallelogram structure, a second parallelogram structure, an attitude adjusting mechanism and a clamping mechanism; the first parallelogram structure and the second parallelogram structure are both formed by a plurality of rod pieces which are sequentially hinged end to end; a first hinging point of the first parallelogram structure is coaxial with a first hinging point of the second parallelogram structure; a second hinging point of the first parallelogram structure is connected with a second hinging point of the second parallelogram structure through a connecting rod; the tail end of the second parallelogram structure is a wrist part, wherein the wrist part can be keep horizontal under connection of the first parallelogram structure and the second parallelogram structure; the wrist part is hinged with the attitude adjusting mechanism; and the attitude adjusting mechanism is hinged with the clamping mechanism. The force feedback main manipulator provided by the invention can meet the requirements of minimally invasive surgery, conforms toergonomics, has a force feedback function and is low in cost.

Owner:SHANDONG UNIV

Control method for bar stock saw cutting self-adapting precision baiting

InactiveCN101135895AAccurately control the actual length accuracyRealize adaptive control of precision sawingProgramme control in sequence/logic controllersEngineeringSelf adaptive

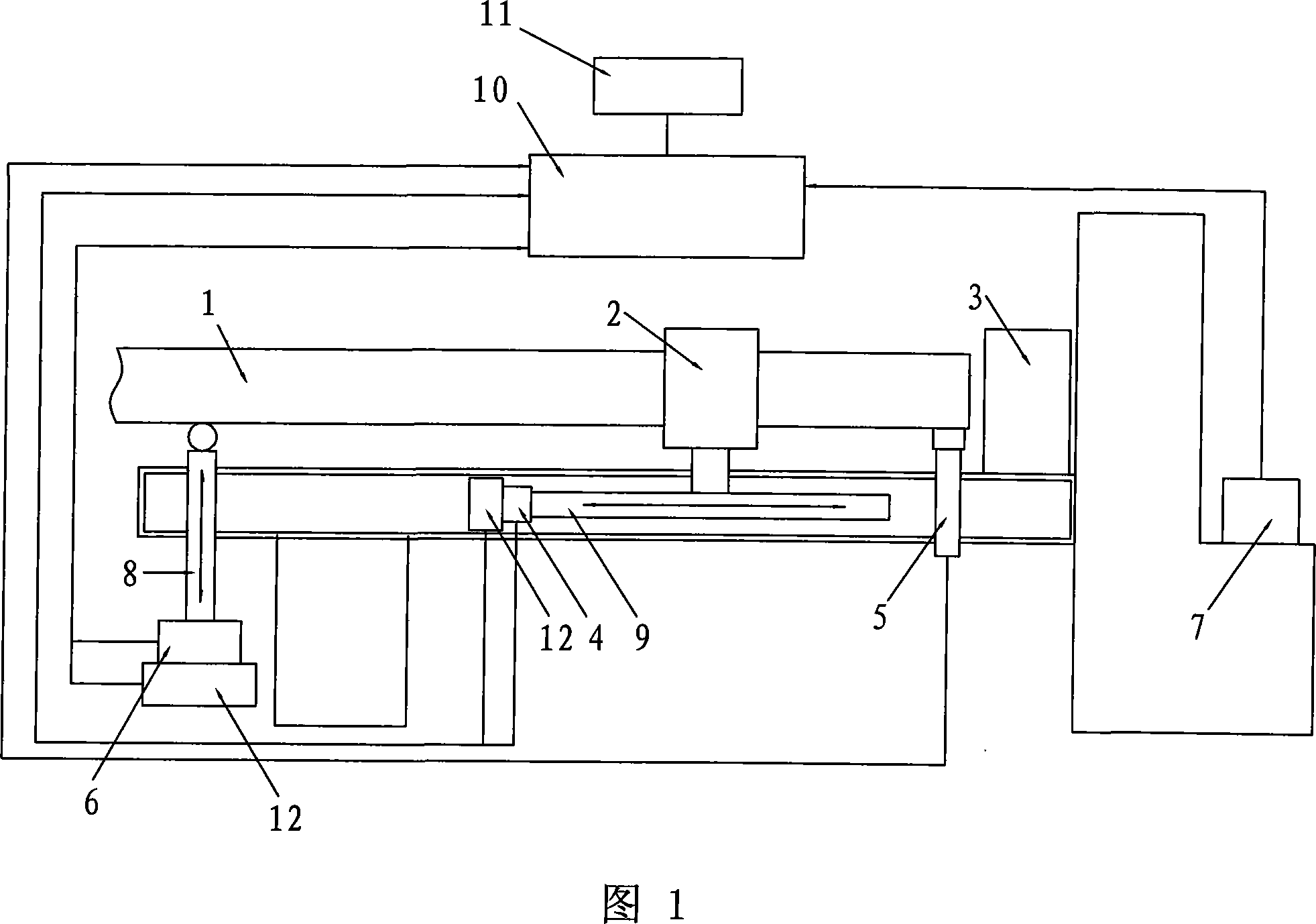

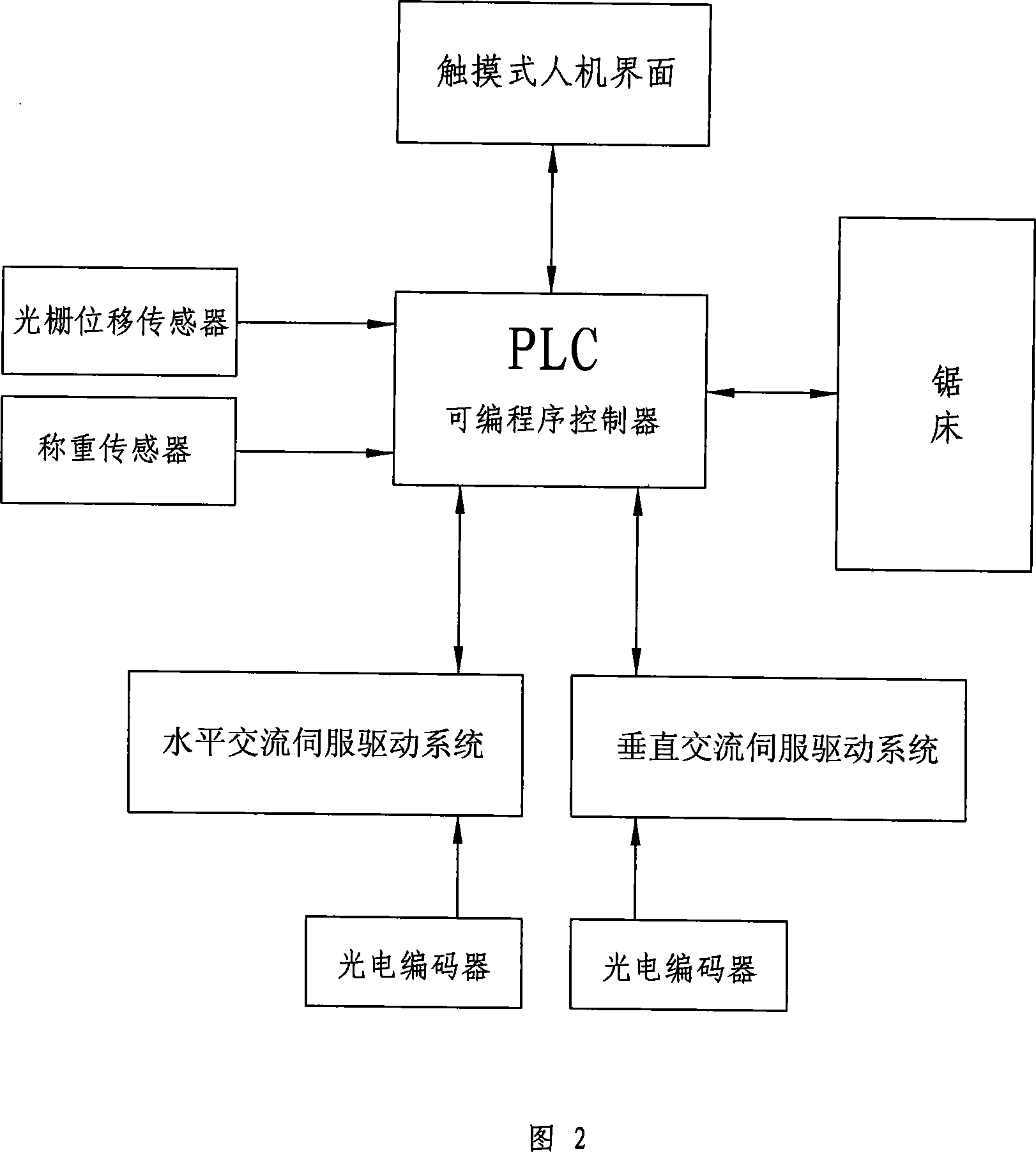

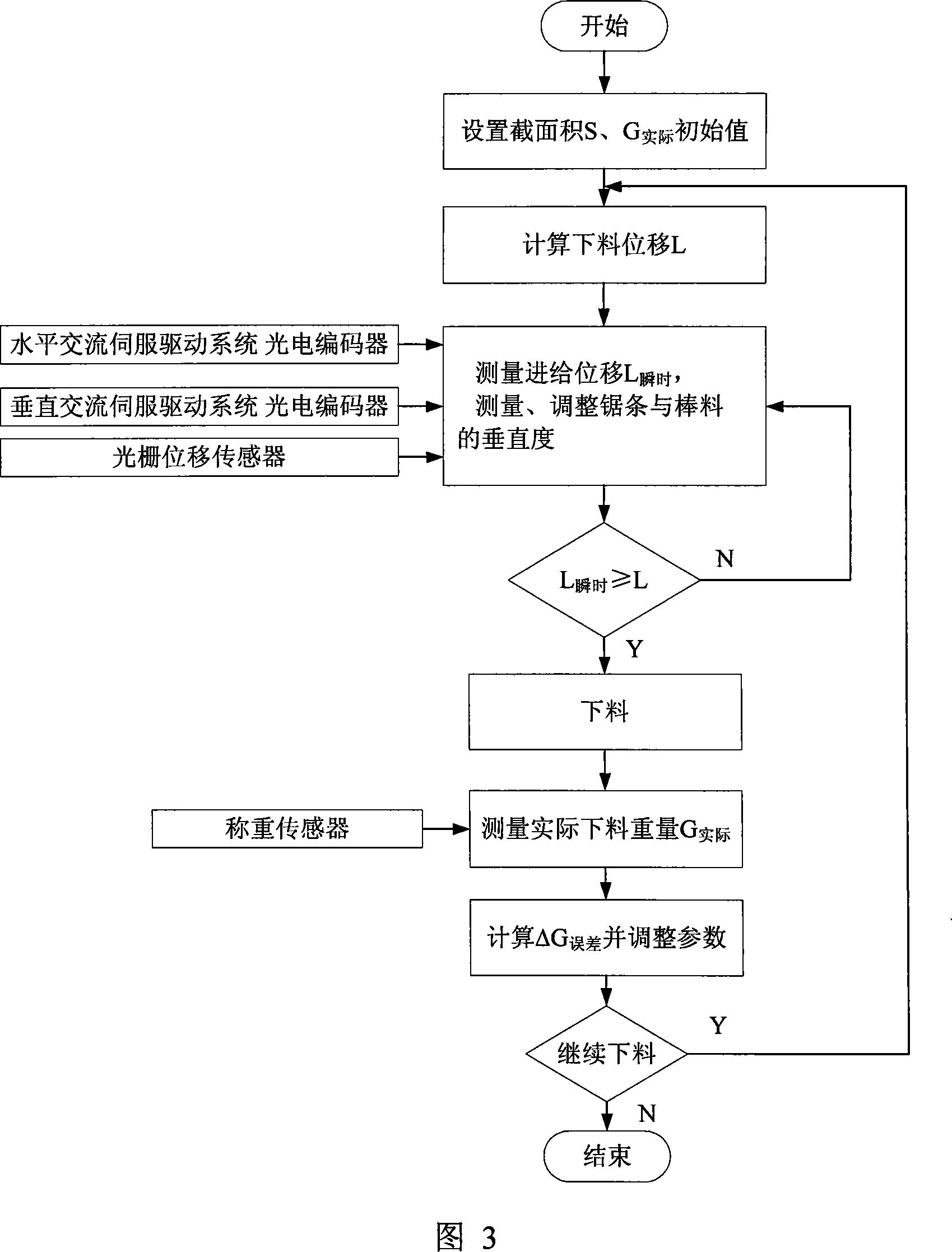

The method comprises: using a bar stock saw automatically-adaptive lay- off system. The method comprises: a horizontal AC servo drive system is used for realizing the rod feed; a highly-accurate photoelectric encoder is used to detect the amount of fed rod; a grating shifting sensor is used to detect the height value of front end of the rod; a vertical AC servo drive system is used to adjust the height of the rear end of the rod to keep the consistency between the front end and the rear end of the rod; a highly-accurate weight sensor is used to weigh the actual weight G of the rod and to compare the actual weight of rod with the reset value, and according to the difference Delta G to adjust the cutting length.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Planar parallel mechanism end tracking control system based on two-dimensional encoder and planar parallel mechanism end tracking control method thereof

ActiveCN106054806AImprove positioning accuracy and tracking accuracyGood real-time performanceProgramme controlComputer controlEmbedded systemMeasurement device

The invention provides a planar parallel mechanism end tracking control system based on a two-dimensional encoder and a planar parallel mechanism end tracking control method thereof. The system comprises a planar parallel mechanism, a two-dimensional encoder measurement device, a mechanism clearing device and a control device which are installed on a static platform. The control device is composed of a servo motor control module, a trigger photoelectric switch module, a parallel mechanism positioning control module and a parallel mechanism trace tracking control module. According to the whole system, firstly the end of the planar parallel mechanism is enabled to be located in the zero point through the mechanism clearing device, then the real-time position of the end of the planar parallel mechanism is measured through the two-dimensional encoder and then inputted to the control device, and the planar parallel mechanism is driven by the control device so that the end is enabled to be accurately positioned according to the preset traces. According to the control system and method, a data processing module involved can obtain the position of the end of the platform through simple resolving so that the real-time performance is great. Meanwhile, the end trace tracking precision of the planar parallel mechanism can also be enhanced so that the condition for realizing submicron level positioning precision is provided for the planar parallel mechanism.

Owner:SOUTH CHINA UNIV OF TECH

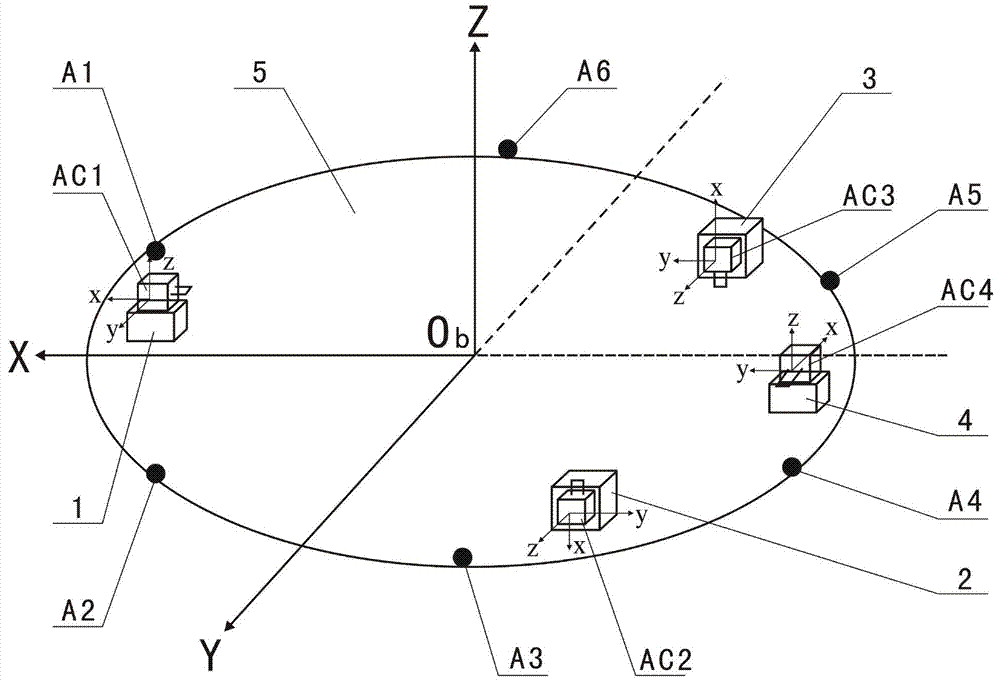

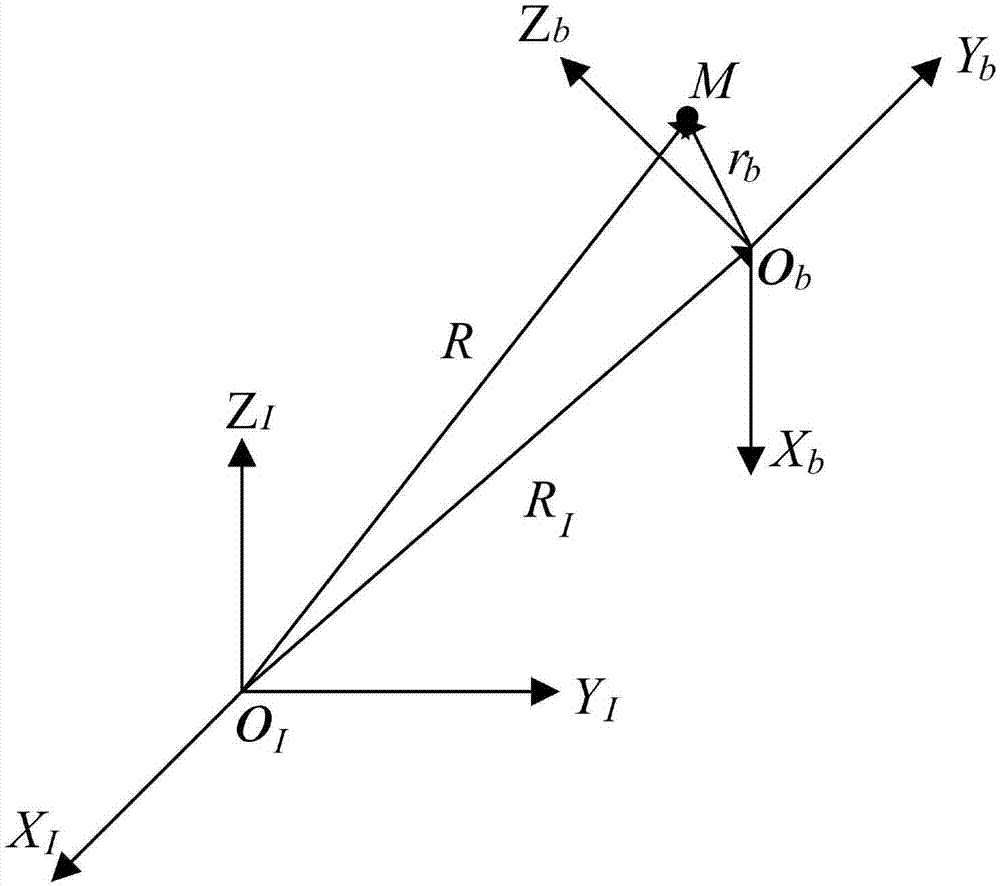

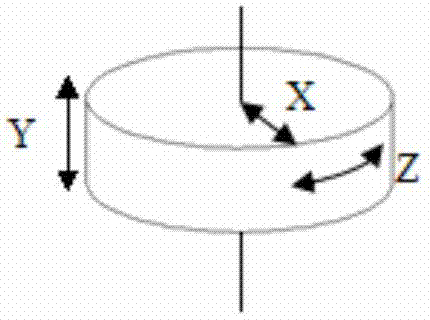

Stewart platform attitude measurement device and measurement method

ActiveCN104848818ARealize full closed-loop controlEasy to measureNavigation by speed/acceleration measurementsMeasurement deviceCushion

The invention discloses a Stewart platform attitude measurement device. Axial directions of three coordinate axes of a movable platform coordinate system are respectively X, Y and Z, four tri-axial acceleration sensors are installed on the movable platform of the Stewart platform through four cushion blocks, two tri-axial acceleration sensors are symmetric to each other by using a coordinate origin Ob of the movable platform coordinate system and respectively arranged at two sides of the X axis, another two tri-axial acceleration sensors are symmetrically installed by using the X axis as the symmetric axis. The invention further discloses a measurement method adopted by the Stewart platform attitude measurement device, the acceleration component of the coordinate origin Ob of the movable platform with respect to the coordinate origin OI of a fixed platform and a movable platform rotation angle speed are obtained through a formula, so that the position and attitude parameters of the movable platform coordinate system with respect to the fixed platform coordinate system can be obtained. Through the adoption of the measurement device and measurement method disclosed by the invention, the centroid coordinate, the rotation angle and the rotation direction parameter of the Stewart platform can be directly obtained without complex computation.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

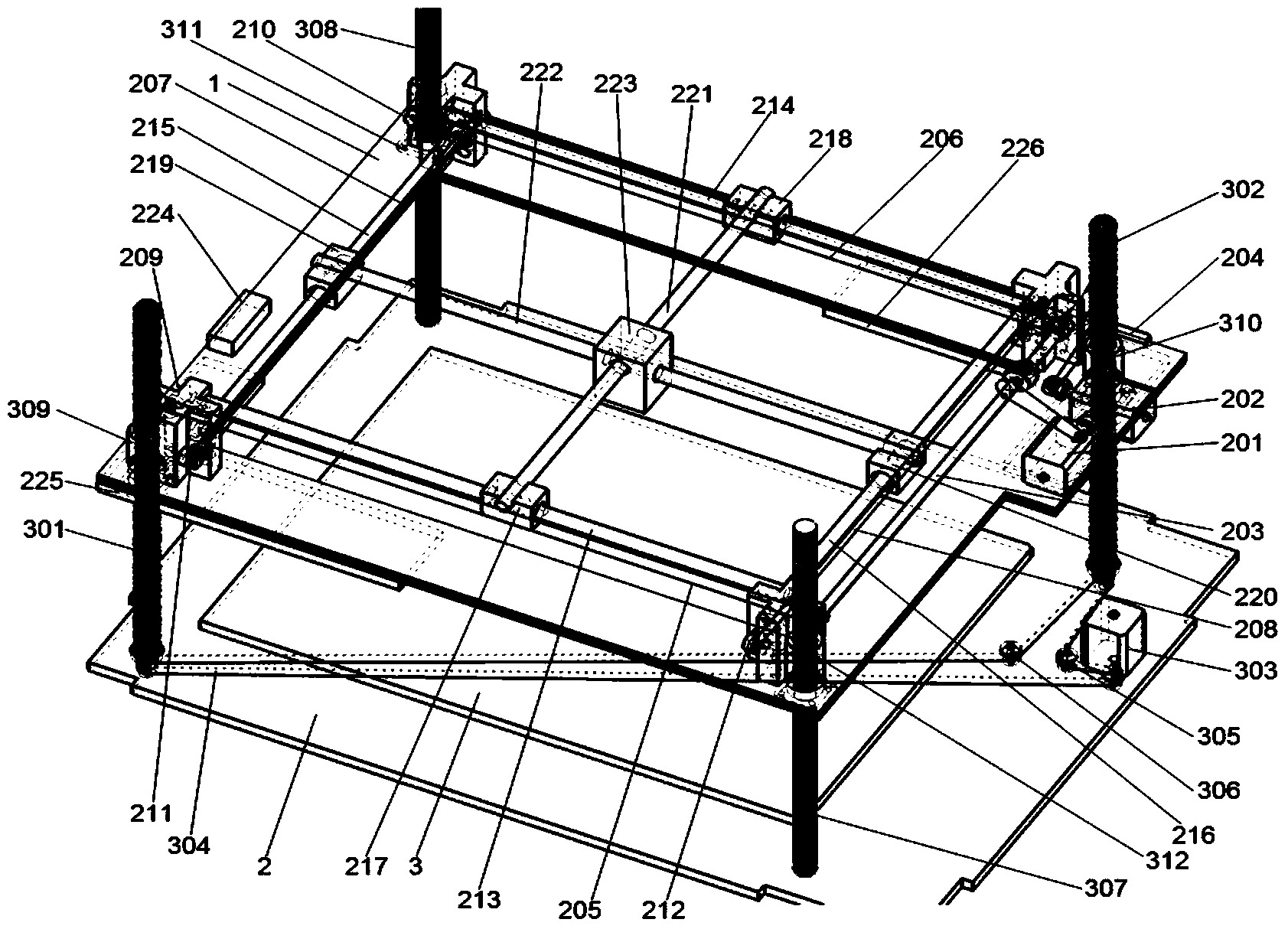

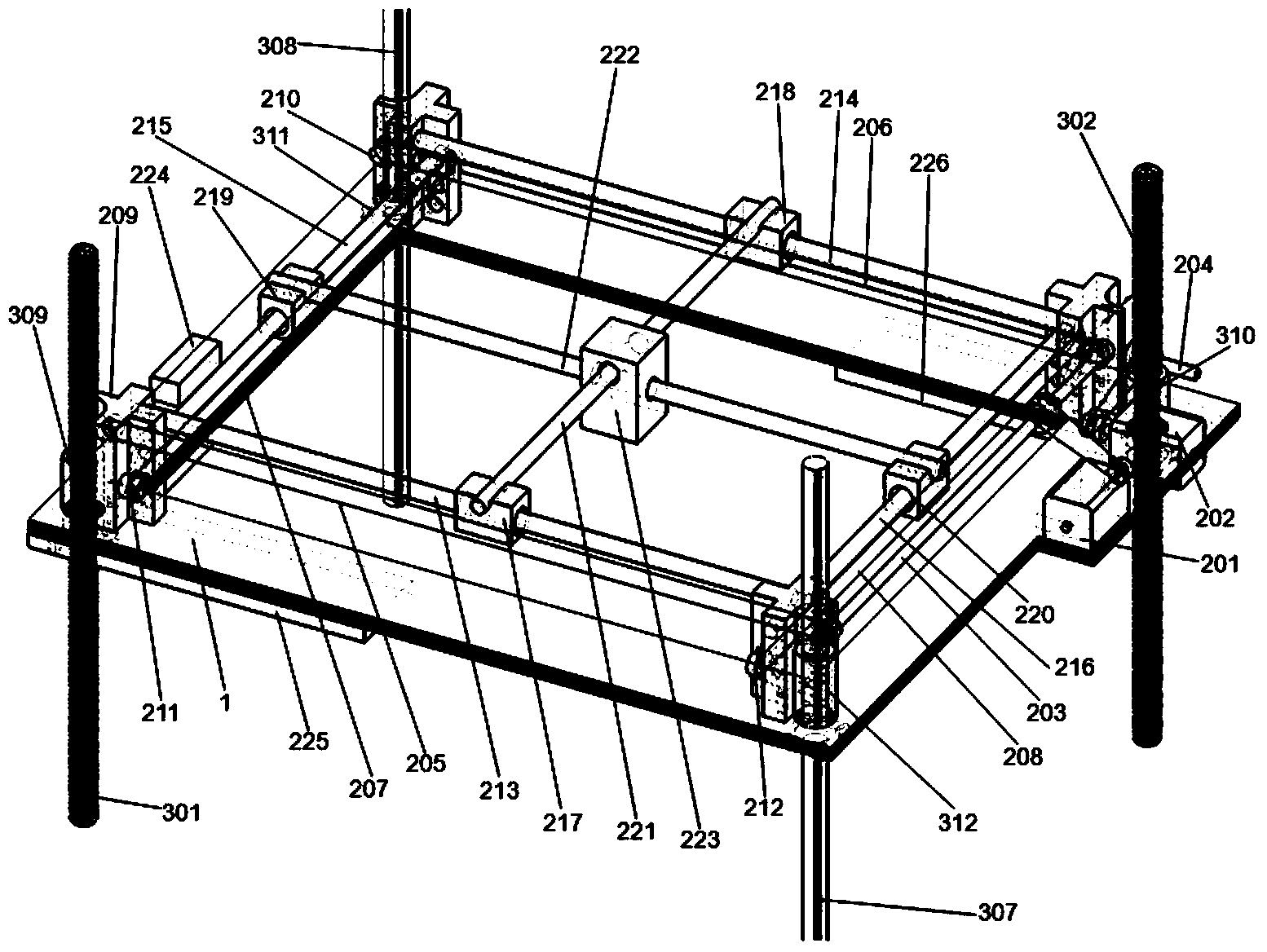

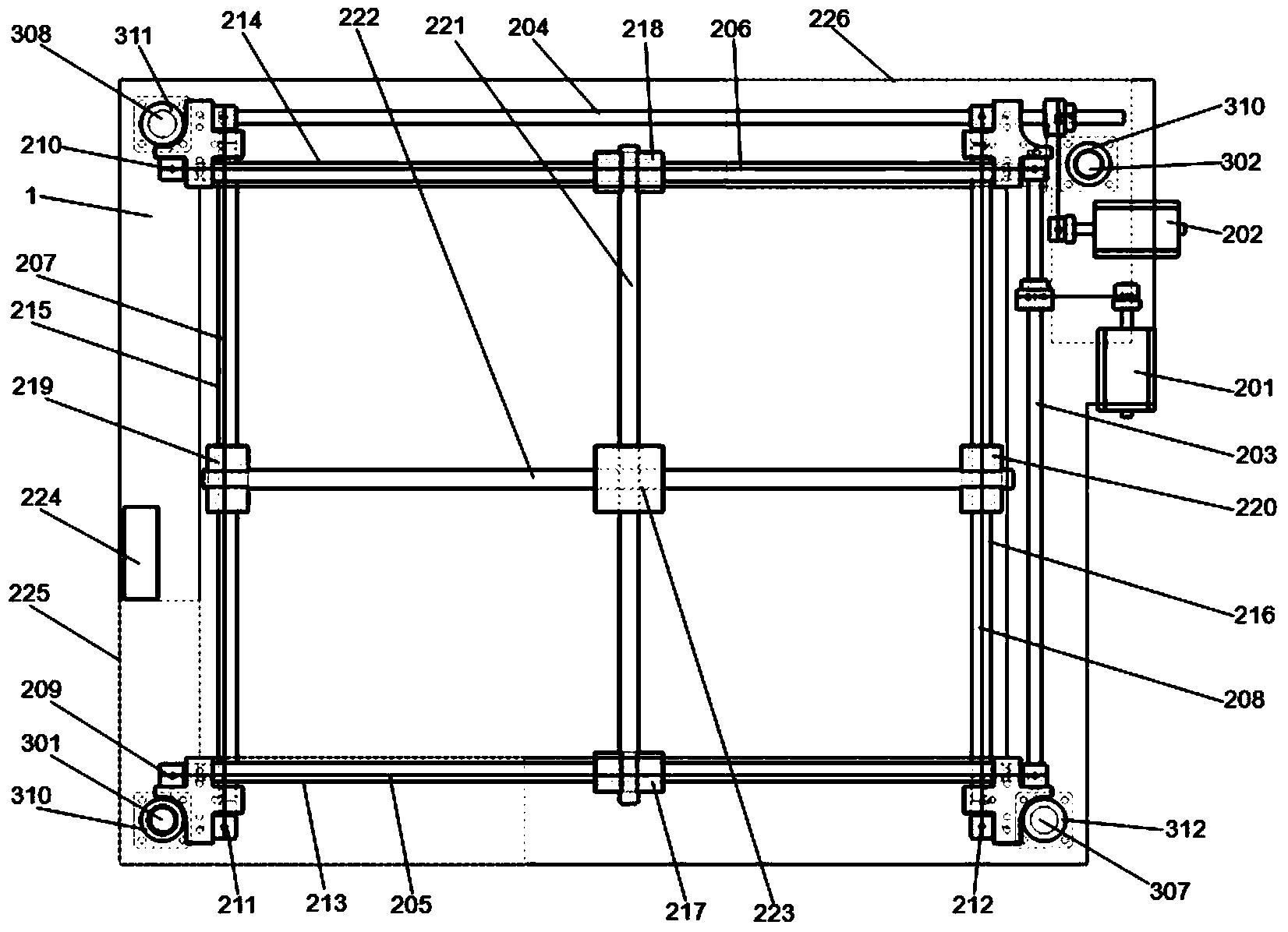

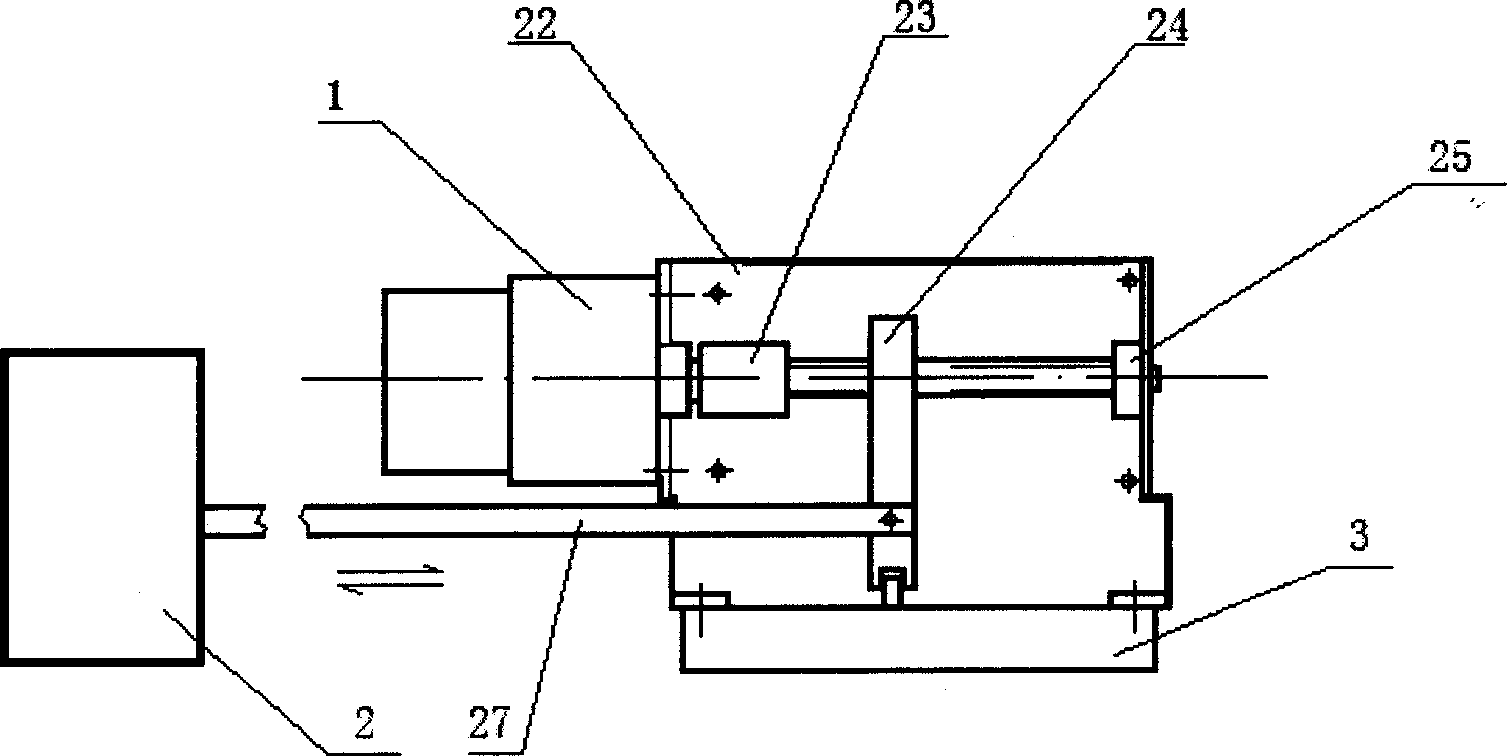

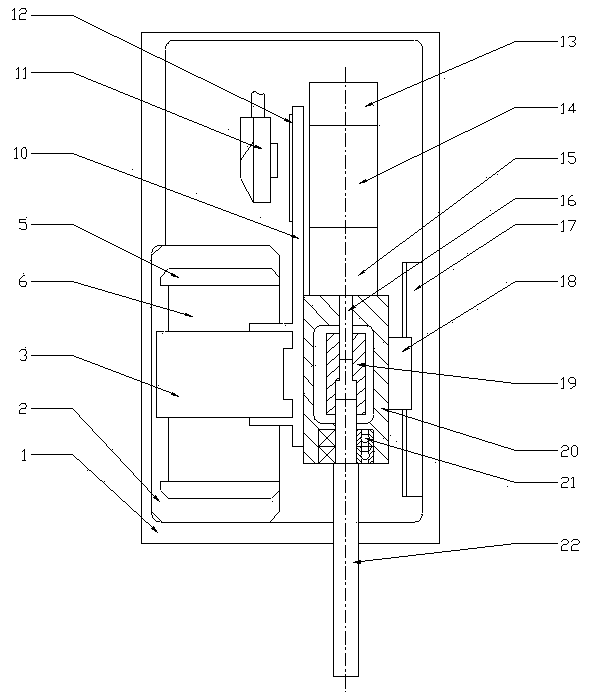

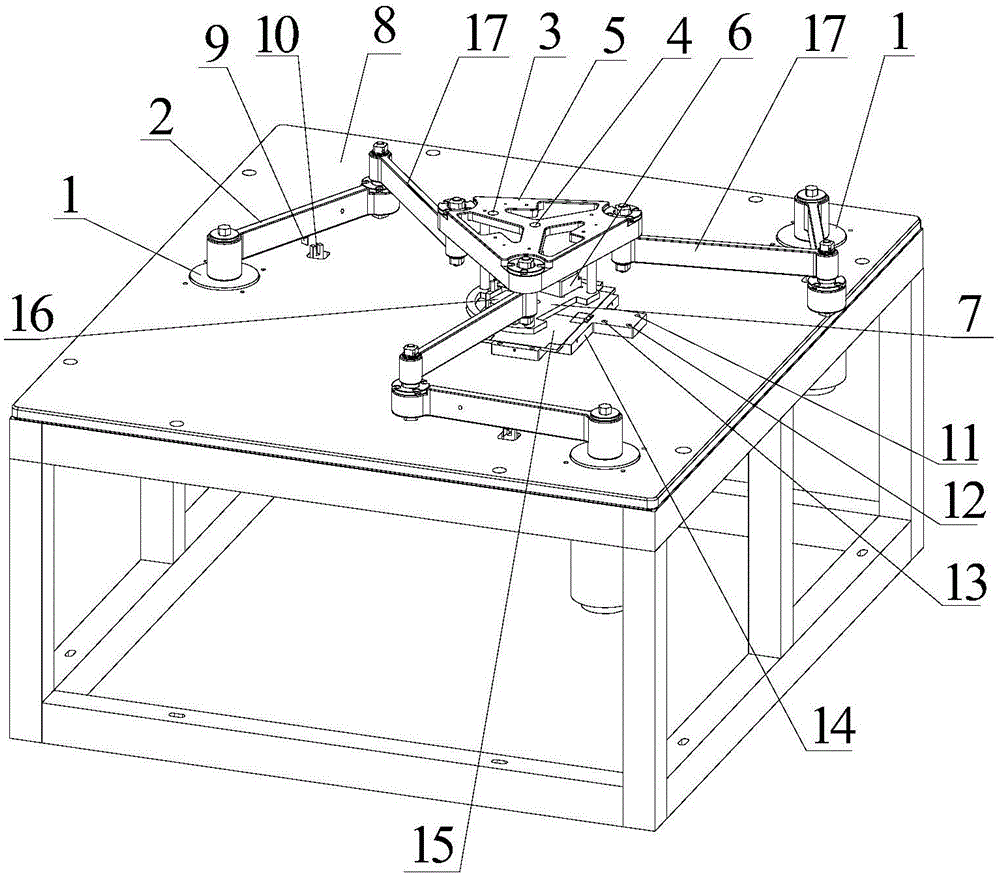

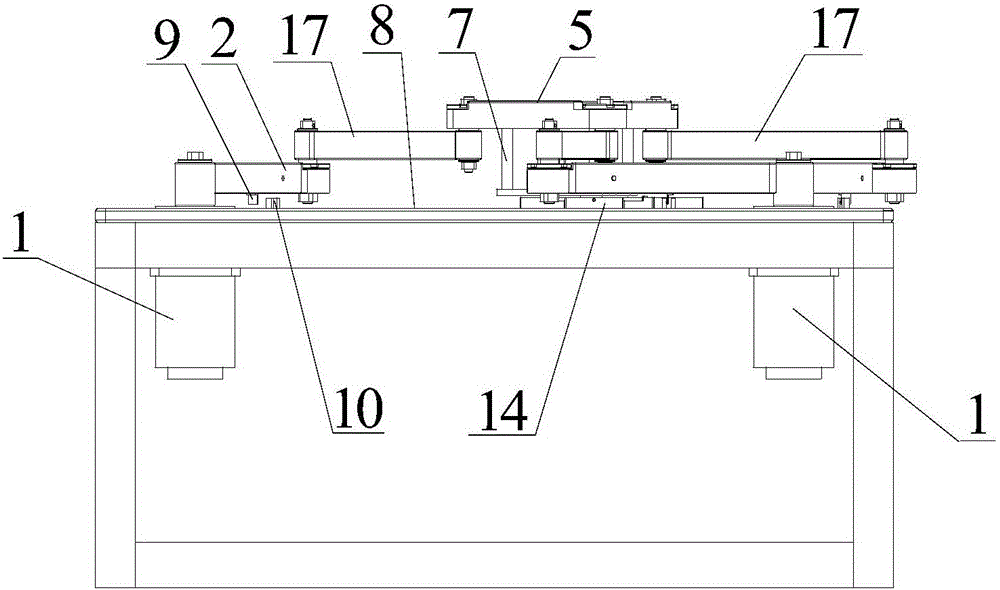

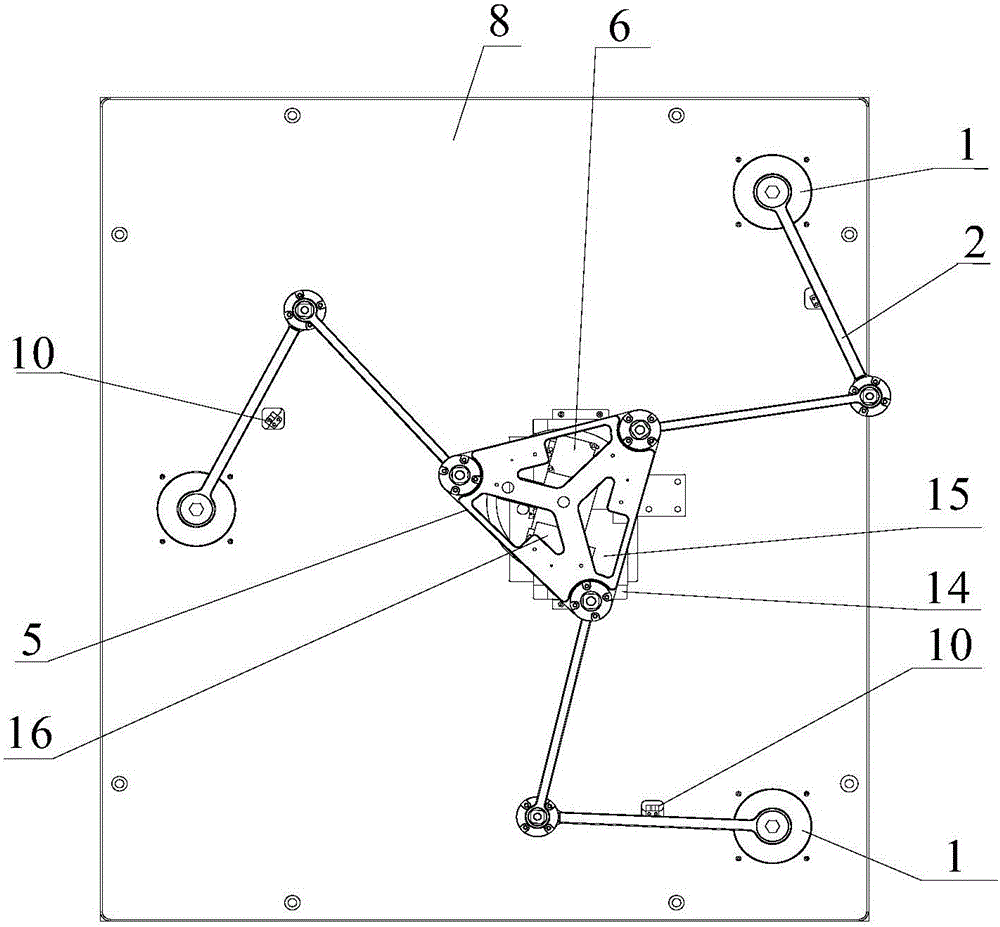

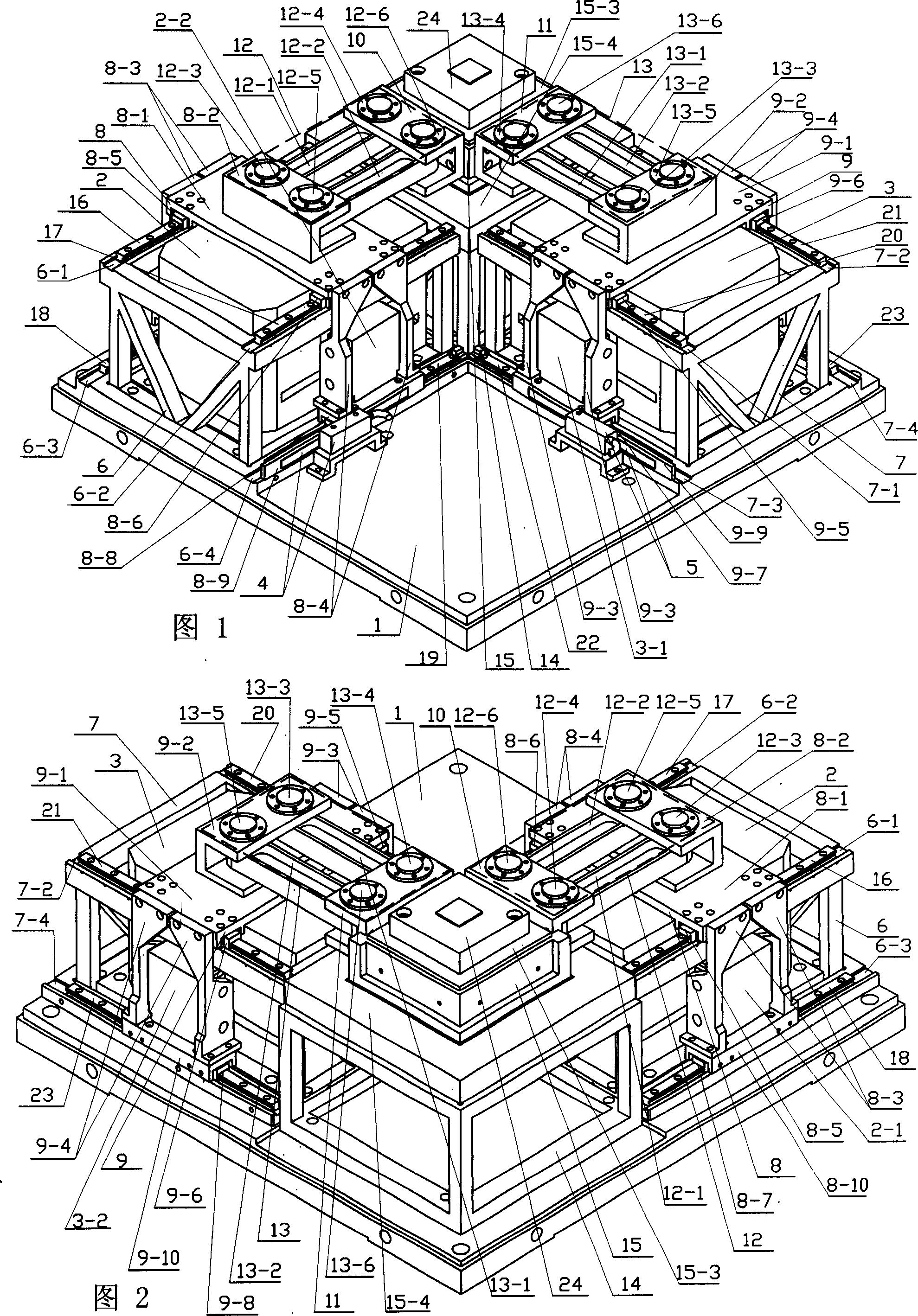

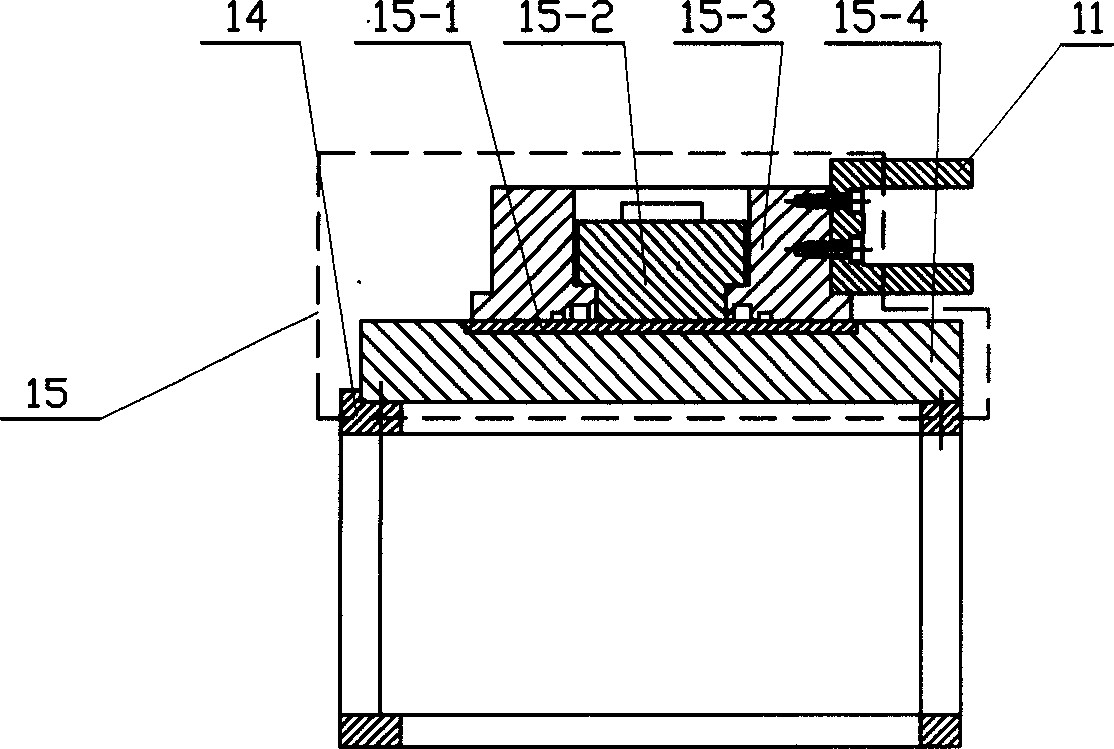

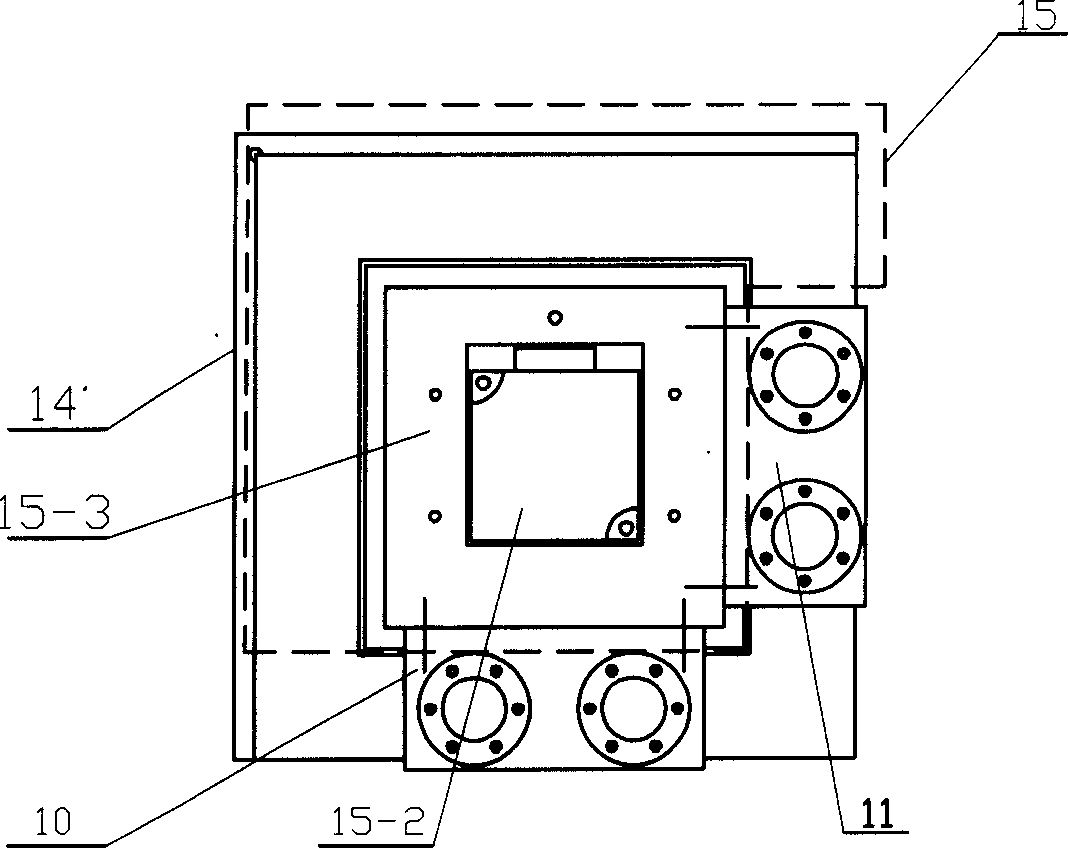

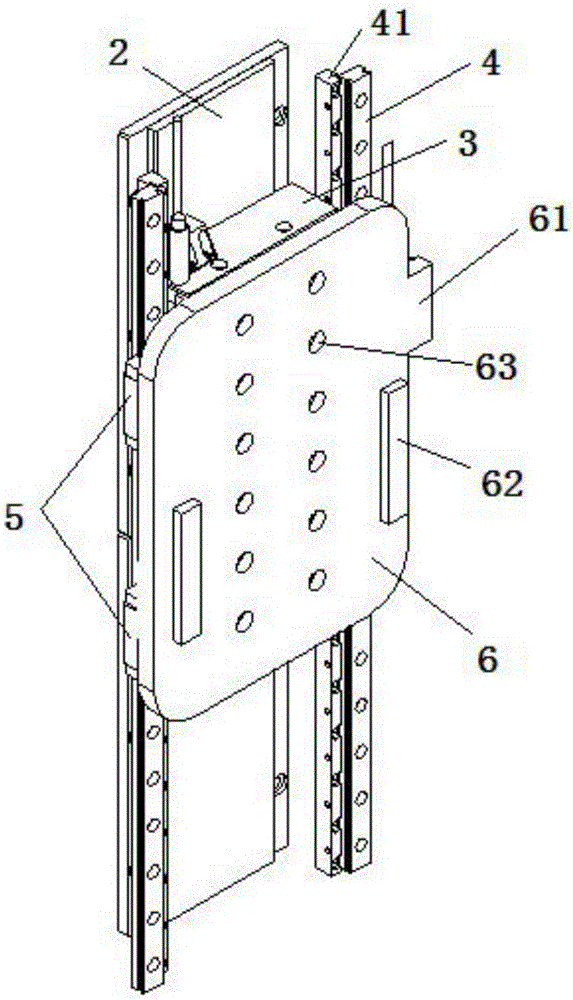

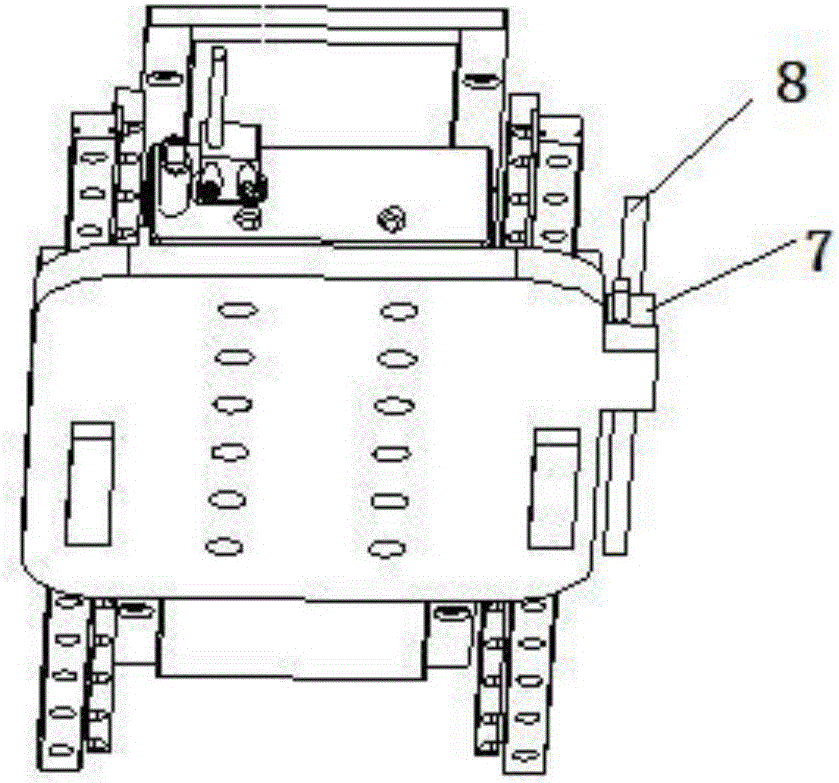

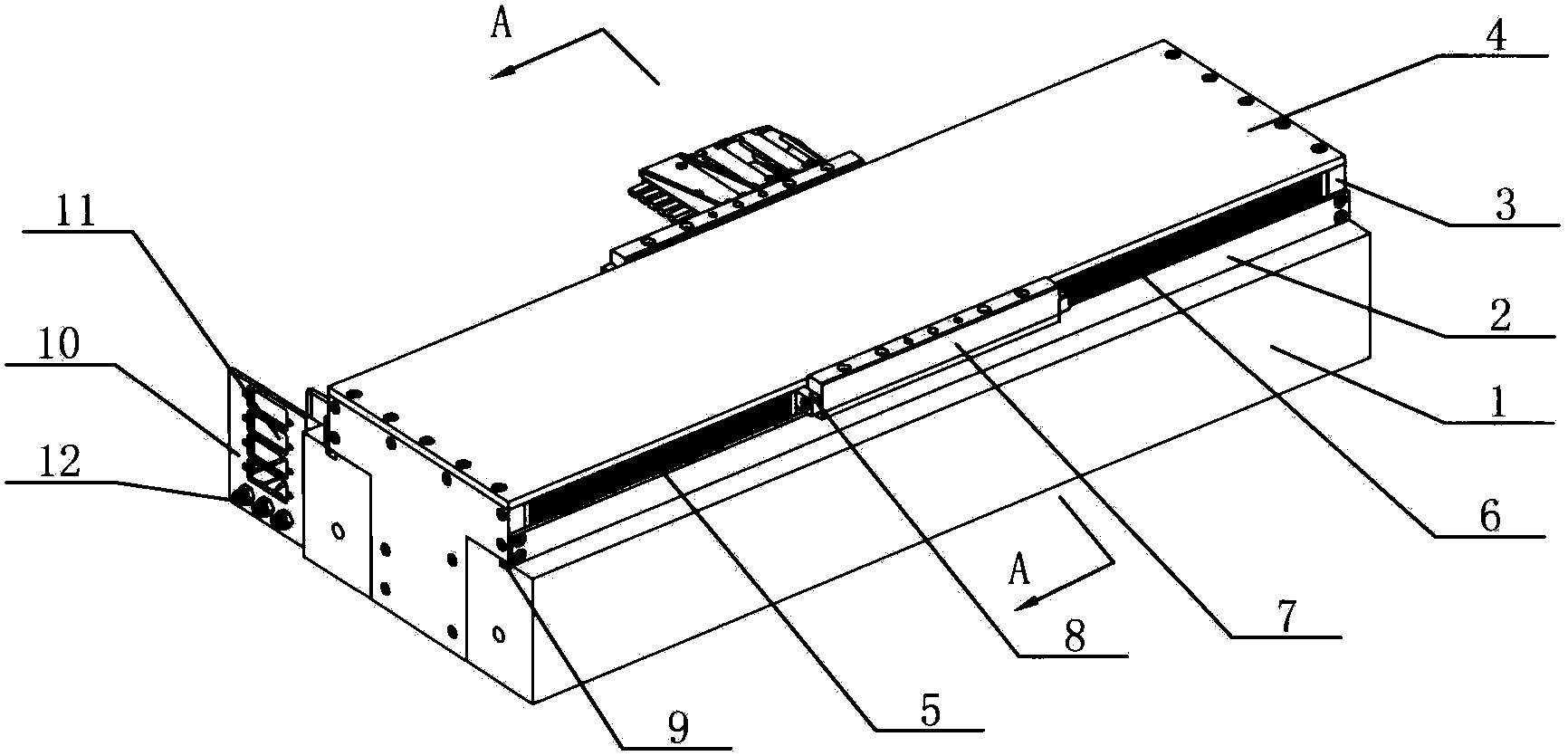

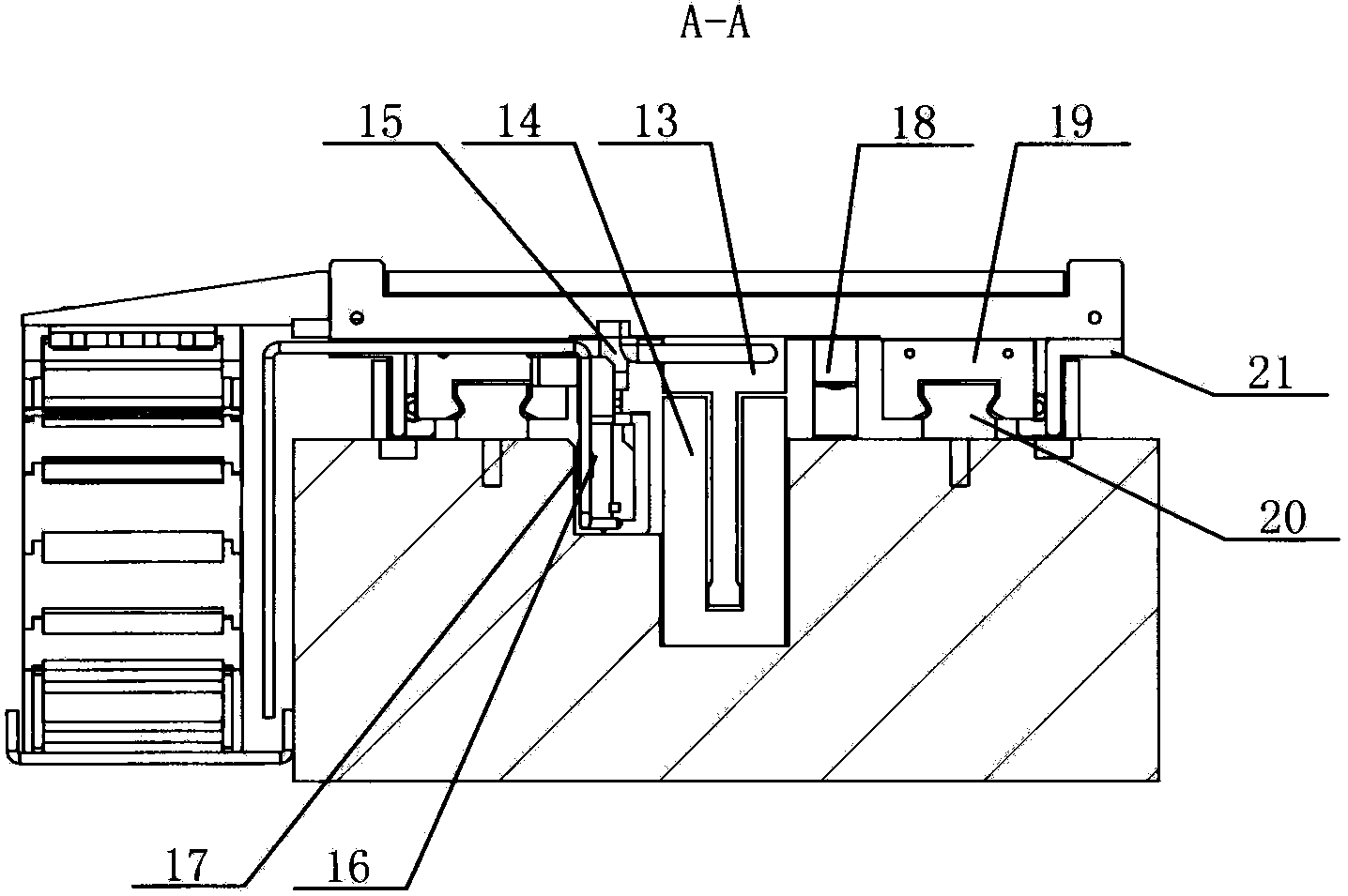

Macro/micro driven two-degree-of-freedom high-acceleration high-precision parallel positioning system

ActiveCN1731082AIncrease stiffnessIncrease load capacityUsing optical meansMechanical measuring arrangementsTwo degrees of freedomLinkage concept

The invention relates to a parallel orientating system with two free degree, high acceleration, high precision and macro / micro dual driven. The mutually perpendicular X-shaft liner driven apparatus 2 and Y-shaft liner driven apparatus are fixed on the base 1; the X-shaft liner driven apparatus 2 is fastened with X-shaft moving platform assembly 8; the Y-shaft liner driven apparatus 3 is fastened with Y-shaft moving platform assembly 9; the X-shaft parallel linkage 12 is hinged between X-shaft moving platform assembly 8 and X-shaft end platform 10; the Y-shaft parallel linkage 13 is hinged between Y-shaft moving platform assembly 9 and Y-shaft end platform 11; the X-shaft end platform 10 and the Y-shaft end platform 11 are fastened with the end output platform 15.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

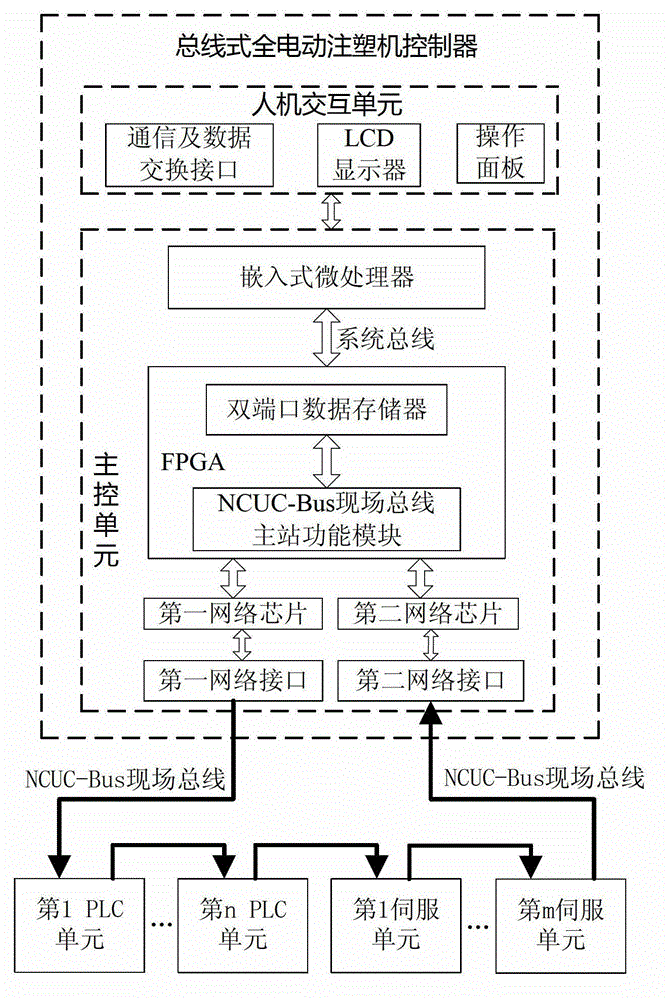

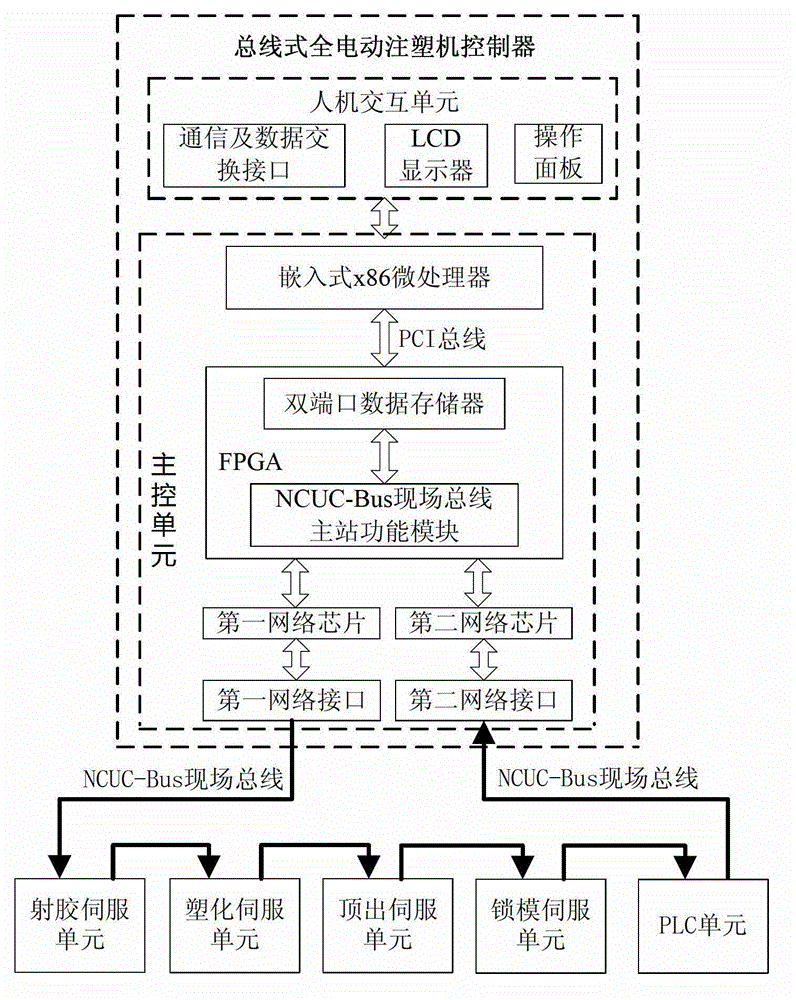

Controller for bus-type fully electric injection molding machine

The invention discloses a controller for a bus-type fully electric injection molding machine. The controller comprises a human-machine interaction unit and a main control unit; a field bus master station functional module reads instruction data written by an embedded microprocessor from a double-port data memory, packs the instruction data according to the format of a field bus protocol and then outputs the packed instruction data, and the packed instruction data pass through a first network chip and a first network interface and then are transmitted to a slave station; after the slave station processes the instruction data, feedback data are uploaded to the field bus master station functional module from a second network interface and a second network chip; the field bus master station functional module unpacks the uploaded feedback data, and writes the unpacked feedback data into the double-port data memory; and the embedded microprocessor reads the uploaded feedback data from the double-port data memory, submits the feedback data to the human-machine interaction unit for displaying, meanwhile, carries out various control calculations, and writes the calculated control instruction data into the double-port data memory.

Owner:WUHAN HUAZHONG NUMERICAL CONTROL +1

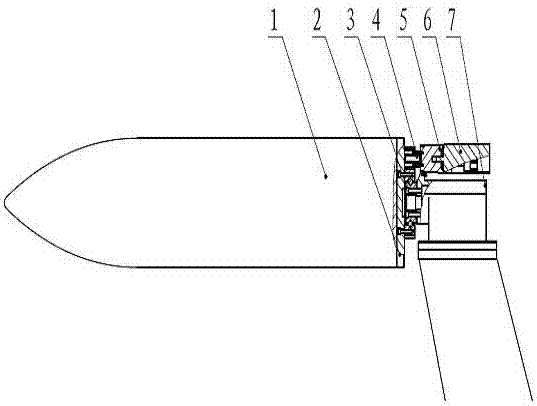

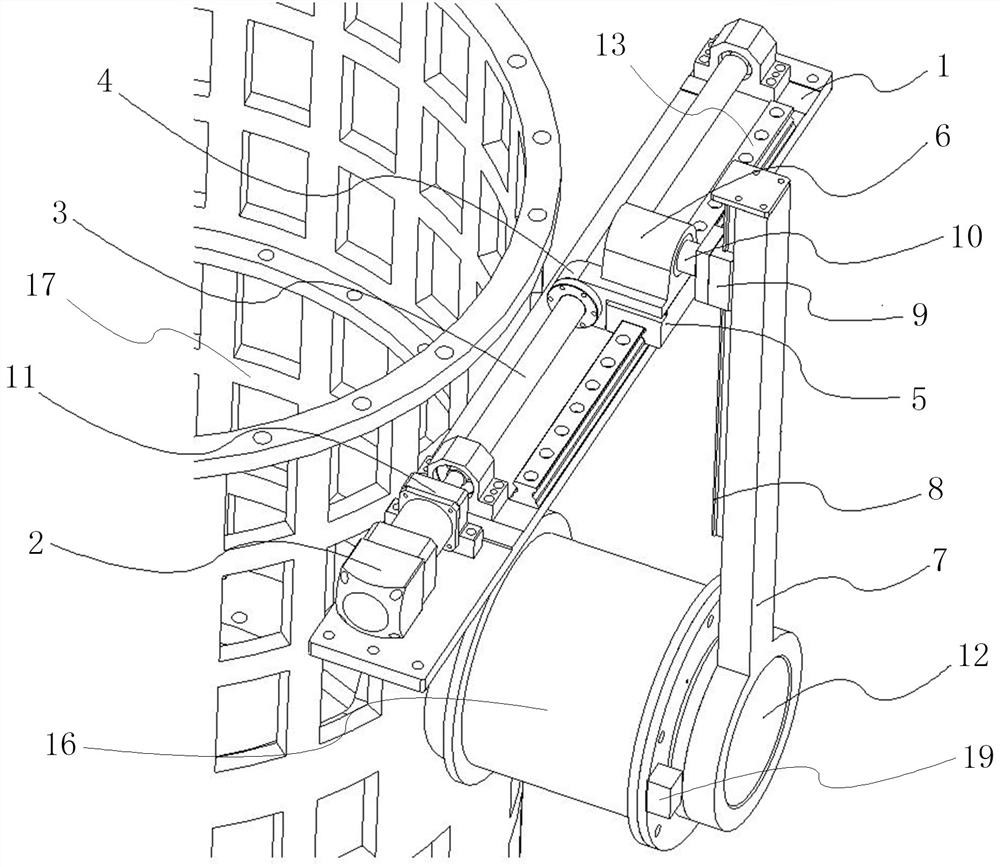

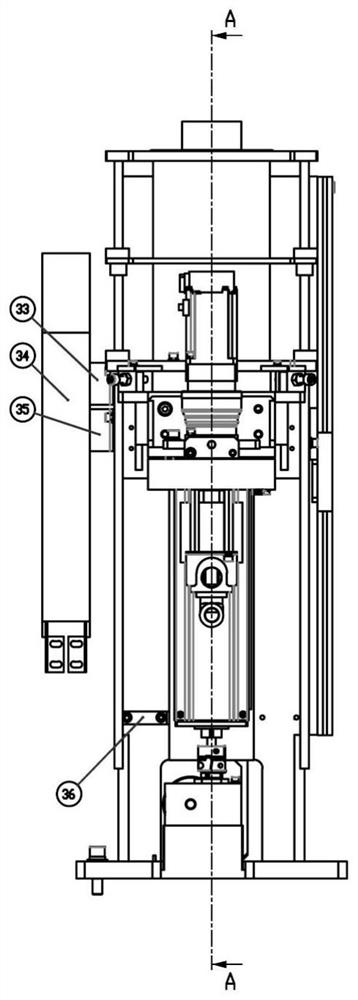

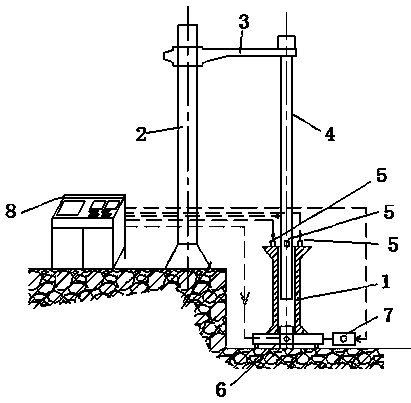

Test piece rotation driving device for centrifugal overload test of solid rocket engine

PendingCN111855216AMeet the test requirements of lateral overload at different anglesBalance eccentric momentEngine testingRotational axisLoop control

The invention relates to the field of centrifugal experiments. The invention particularly discloses a test piece rotation driving device for a centrifugal overload test of a solid rocket engine. The device comprises a mounting bottom plate and a driving motor, the output end of the driving motor is connected with a ball screw nut pair, a first guide rail is arranged on the mounting bottom plate along the ball screw nut pair, a first sliding block is arranged on the first guide rail, a screw nut of the ball screw nut pair is connected with the first sliding block, and a moving seat is arrangedon the first sliding block. The device further comprises a rocker arm, a second guide rail is arranged on the rocker arm along the rocker arm, a rotating seat is slidably arranged on the second guiderail, and a rotating shaft is arranged on the rotating seat and rotationally connected with the moving seat. The driving device has the advantages that a speed reducer, the screw nut pair, the rockerarm and the like in the driving device are of labor-saving structures, and large torque can be provided; the driving device is controlled by a servo motor, driven by the ball screw nut pair and guidedby a guide rail sliding block pair, and full-closed-loop control is realized by an encoder, so that the whole system has very high control precision.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

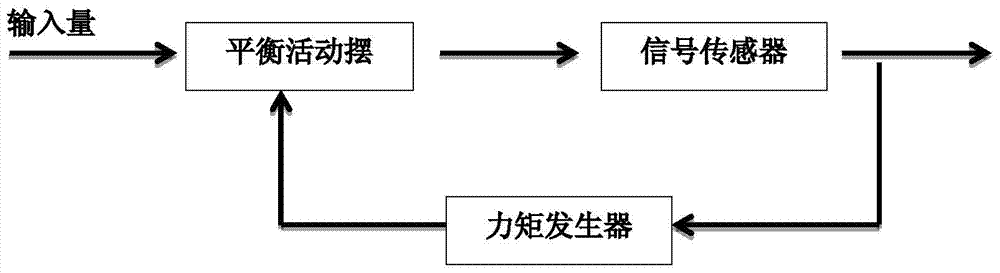

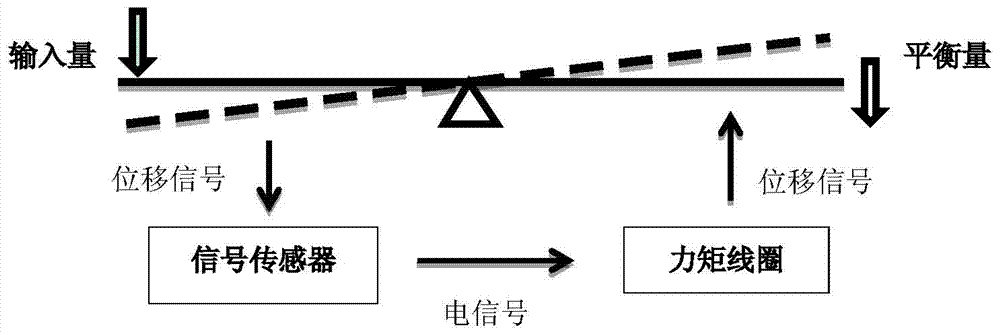

Magnetic material temperature feature testing method

ActiveCN104714196AImprove test accuracyRealize full closed-loop controlMagnetic property measurementsMaterials testingComputer science

The invention relates to a magnetic material temperature feature testing method, which belongs to the technical field of material testing. The method comprises the following steps: 1, a special testing device is built; 2, n temperature sampling points are selected, wherein n is a natural number no smaller than 2; 3, the special testing device with tested magnetic material is fixed on a rotating table, the temperature environment is the ith temperature sampling point Ti, the rotating table is rotated, a weight m fixed at the input end of a compensation wheel enables the compensation wheel to deflect under the effect of a gravitational acceleration g, current Ii is then generated in a current coil, and the value of the current Ii is measured, wherein i=1, 2, to n; and 4, at different temperature sampling points, the tested magnetic material has different magnetic induction intensities B, I passing through a torque coil is different, and thus temperature features of the tested magnetic material can be obtained. The method of the invention is high in testing precision and wide in application range.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

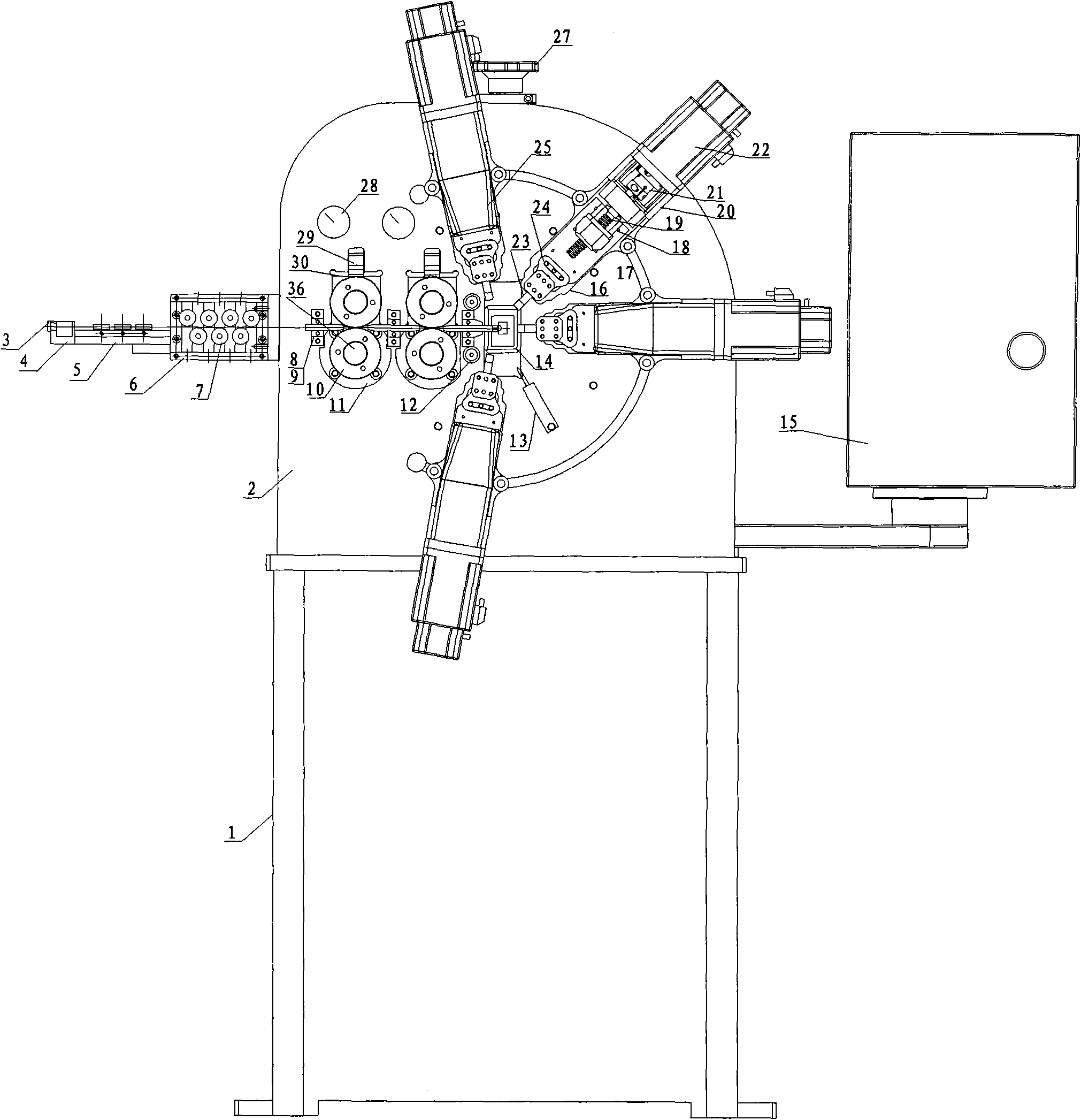

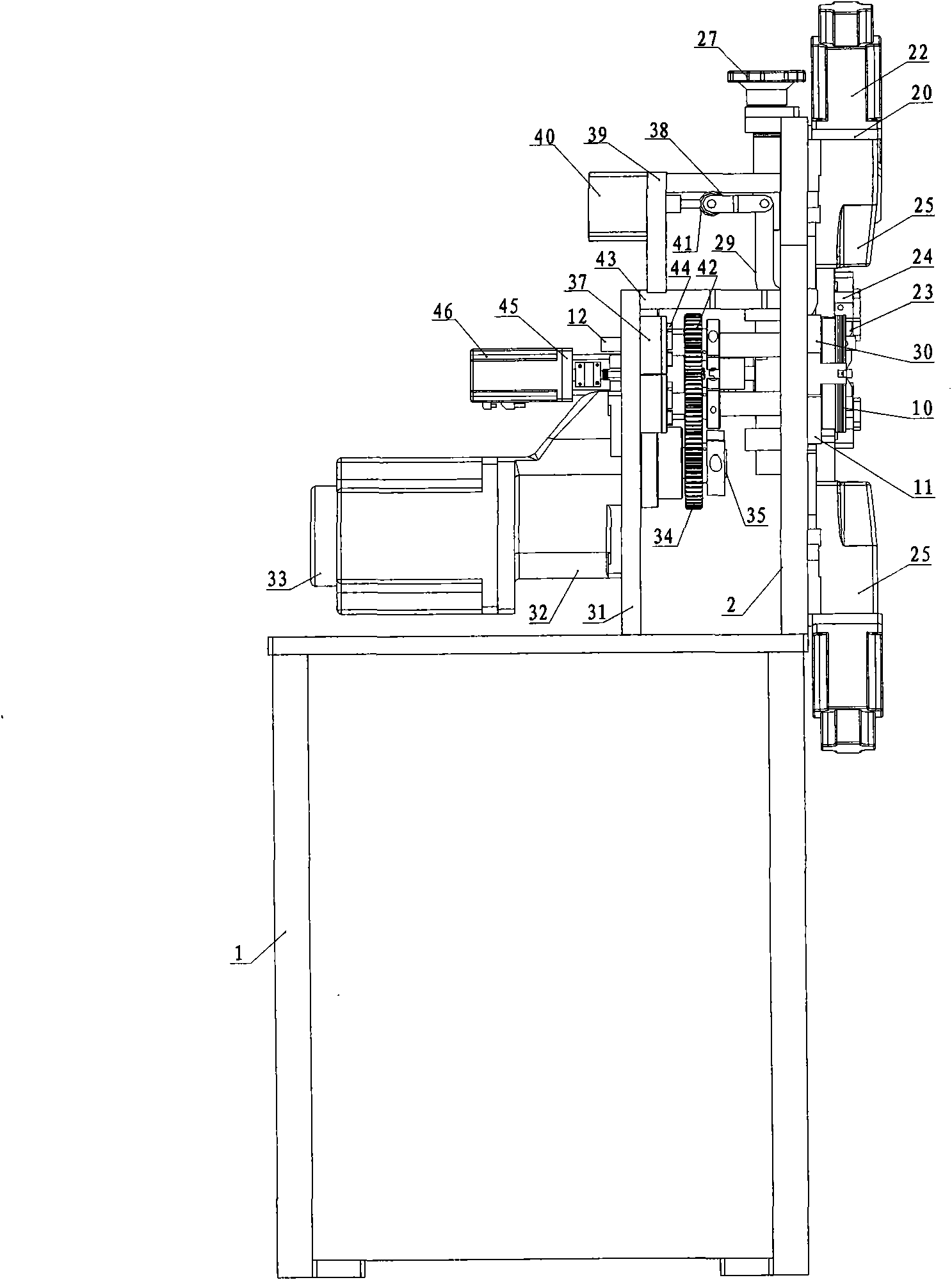

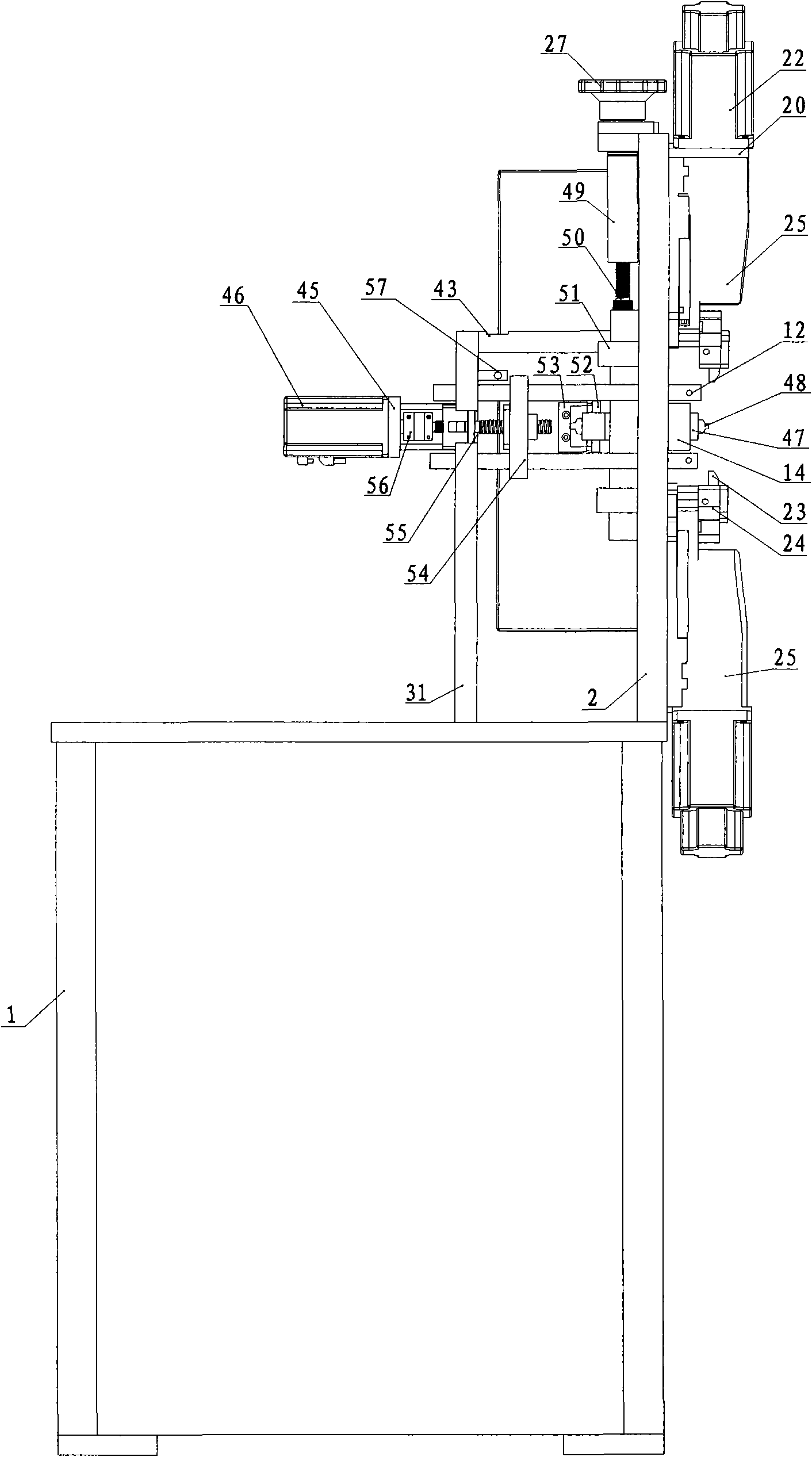

Intelligent computerized numerical control (CNC) spring machine

ActiveCN101559463BReduce scrap rateReasonable structural designWire springsComputer control systemNumerical control

The invention discloses an intelligent CNC spring machine used for processing extension springs, compression springs, torsion springs, spiral springs and the like. The intelligent CNC spring machine comprises a straightening mechanism, a wire feeding mechanism, a pitch mechanism, a core seat mechanism, a knife seat mechanism and a computer control system. The pitch mechanism comprises a pitch servo motor and a pitch ball screw pair driving a pitch shaft to move; the core seat mechanism comprises a core seat lifting mechanism and a core rod core-pulling mechanism; and the knife seat mechanism comprises a plurality of sliding knife seats and knife seat driving mechanisms and can move along an arc-shaped track in a radial direction. The spring machine is provided with five sections includinga straightening section, a wire feeding section, a pitch section, a core seat section and a knife seat section according to the principle of spring formation, and has reasonable structure design and is driven by a full servo and controlled by a computer so as to realize fully closed loop control and be capable of reducing the rejection rate of finished products. The intelligent CNC spring machinecan be widely applied to the production of various extension springs, compression springs, torsion springs, spiral springs and the like, with simple operation, high processing precision and high production efficiency.

Owner:湖北伟斯科技有限公司

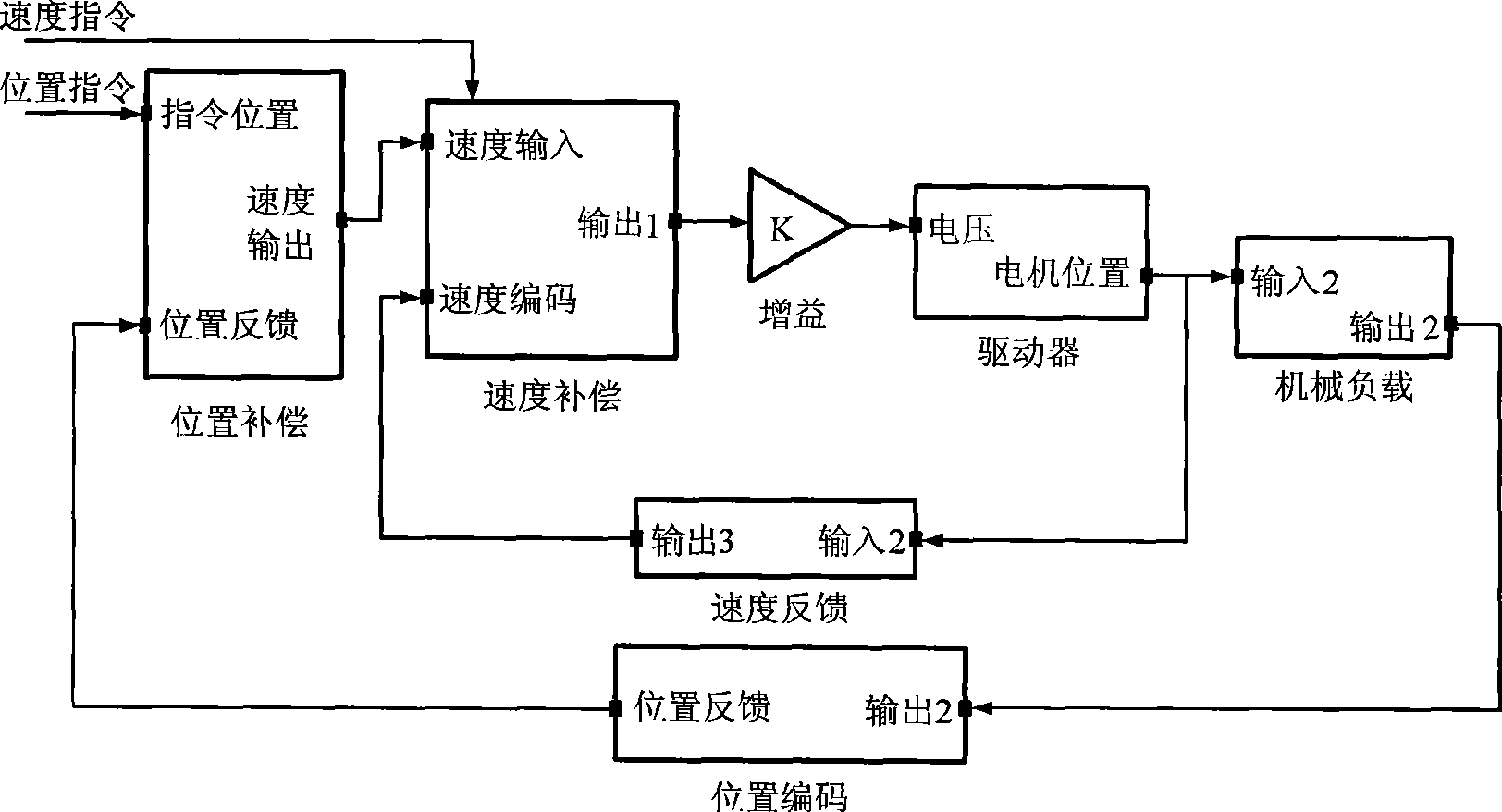

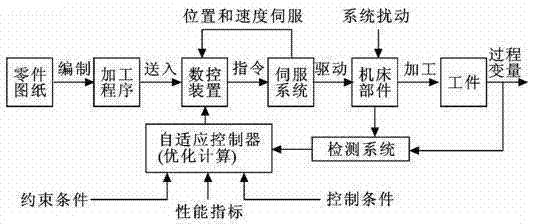

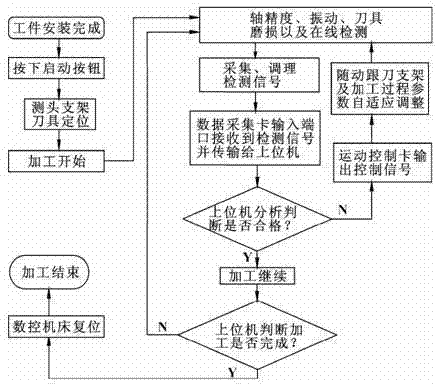

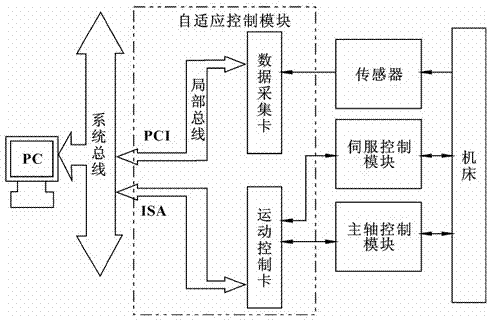

PC-based numerical control machine tool full closed-loop control system

InactiveCN106873524AHigh degree of automationRealize full closed-loop controlProgramme controlComputer controlControl systemClosed loop

A PC-based numerical control machine tool full closed-loop control system is provided. A machine tool adaptive full closed-loop servo control technology is used. An online detection quantity is transmitted, through a signal acquisition and processing unit, to a numerical control system. The numerical control system analyzes whether a real-time processing dimension error exceeds a tolerance value prescribed by a part accuracy index, and then automatically adjusts the processing parameters to reduce the processing error. The control system adopts an open computer numerical control system based on PC and suitable for the development trend of the current numerical control machine tool, completes the setting of functional units by software, improves the automation degree of the numerical control system and realizes the full closed loop control of processing precision.

Owner:申久祝

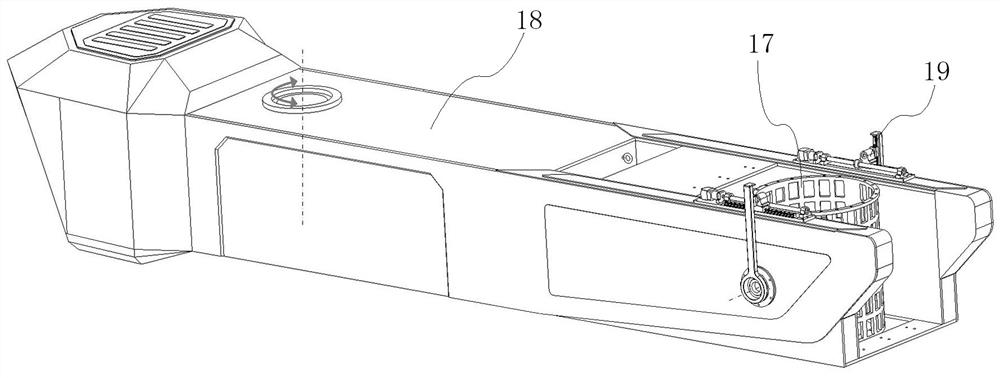

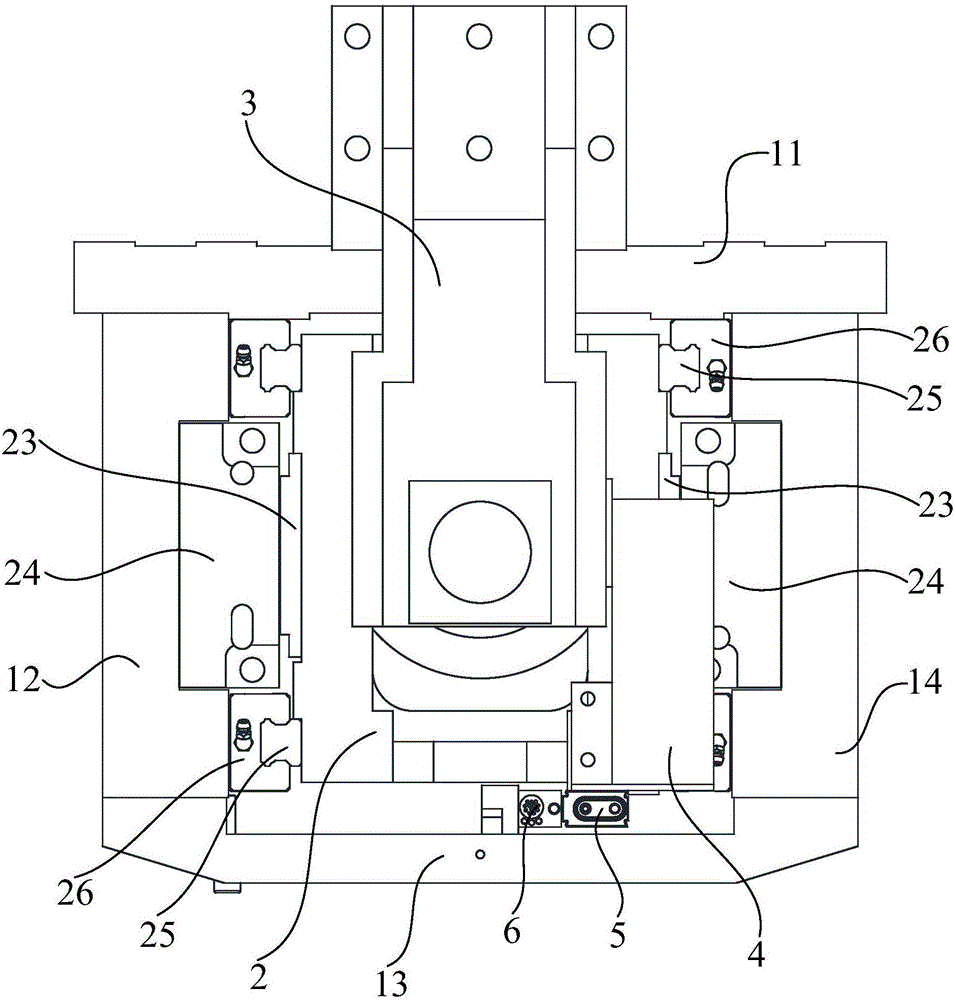

High-speed Z-axis machining device and machine tool including same

InactiveCN106624979AHigh positioning accuracyQuick responseFeeding apparatusMaintainance and safety accessoriesResponsivityMobile end

The invention discloses a high-speed Z-axis machining device and a machine tool including the same. The high-speed Z-axis machining device comprises a fixing part, a Z-axis part and a balance cylinder. The fixing part is provided with a through hole from top to bottom. The Z-axis part penetrates through the through hole and is slidably arranged on the fixing part. Two Z-axis linear motors are separately arranged between the two sides of the Z-axis part and the fixing part. The mobile end of the balance cylinder is connected to the top of the Z-axis part. The machine tool comprises the high-speed Z-axis machining device. According to the high-speed Z-axis machining device and the machine tool including the same, the double linear motors are adopted for double drive, and the drive force is larger; by adoption of a non-contact structure, no friction is generated, the structure has no abrasion, the service life is long, the precision retentivity is good, and long-term operation is table; and meanwhile, a gravity center drive effect is achieved, so that no inertia moment is generated during high-speed movement, and high positioning precision and responsivity and high-precision machining are achieved.

Owner:SHANGHAI LYNAC NUMERICAL CONTROL TECH CO LTD

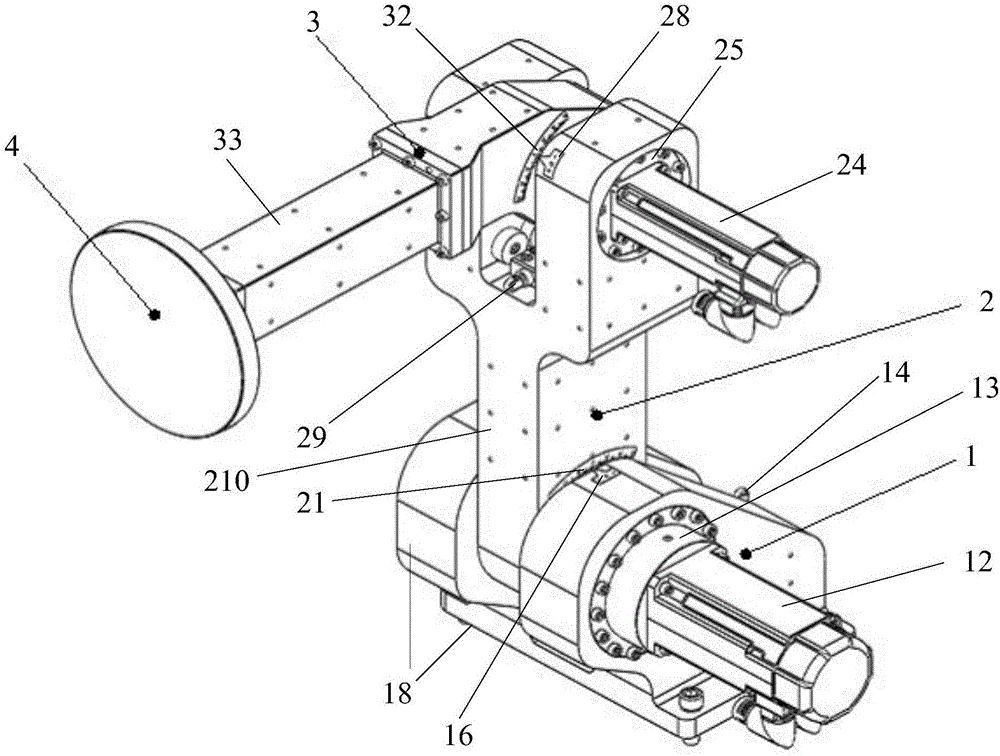

Precision robot

InactiveCN106239509AIncrease movement speedHigh movement precisionProgramme-controlled manipulatorControl systemClosed loop

The invention provides a precision robot. The robot comprises a base assembly, a big arm assembly, a forearm assembly and a control system; one end of the big arm assembly is rotationally arranged on the base assembly; a first angle encoder coaxially rotating with the big arm assembly is arranged on the base assembly; one end of the forearm assembly is rotationally arranged at the other end of the big arm assembly; a second angle encoder coaxially rotating with the forearm assembly is arranged at the other end of the big arm assembly; the other end of the forearm assembly is connected with a load; the first angle encoder and the second angle encoder are in signal connection with an input end of the control system; and the base assembly and the big arm assembly are in signal connection with an output end of the control system. With the precision robot, the position and the motion track of a mechanical arm can be detected by the control system online in real time, so that full-closed loop control on input and output is realized, and the motion speed and precision of the robot are greatly increased.

Owner:FOSHAN INST OF INTELLIGENT EQUIP TECH +1

High-speed board thickness measuring and retaining device

ActiveCN106513442AGuaranteed certaintyRealize full closed-loop controlRoll mill control devicesMeasuring devicesMeasurement precisionAccuracy and precision

Owner:SOUTHEAST UNIV

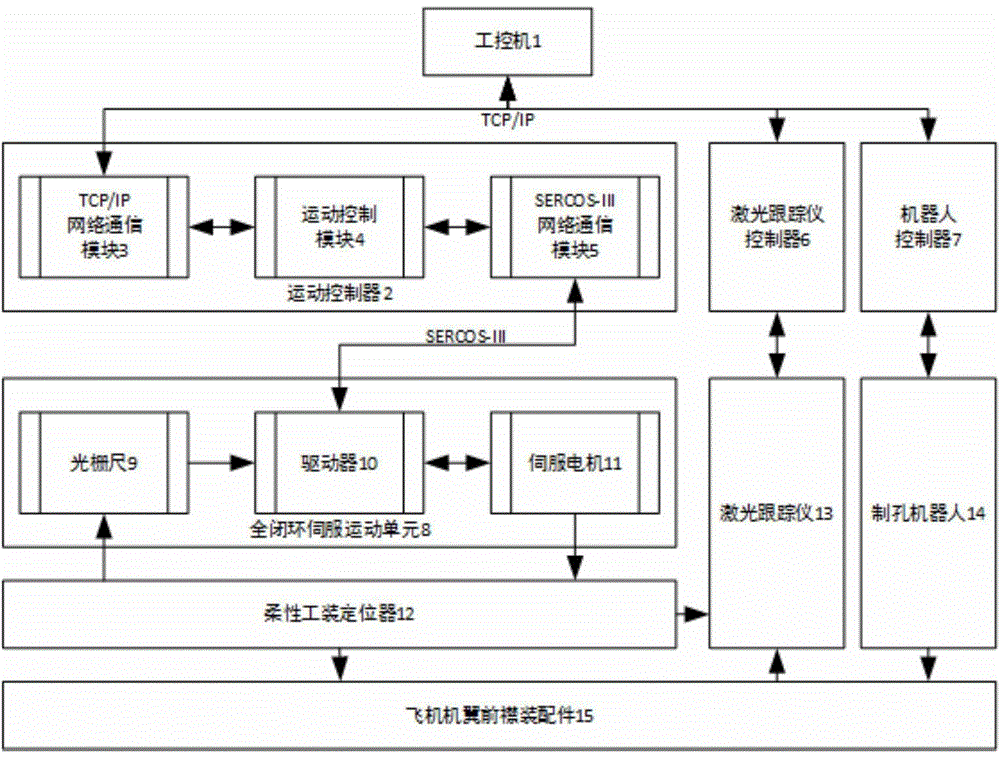

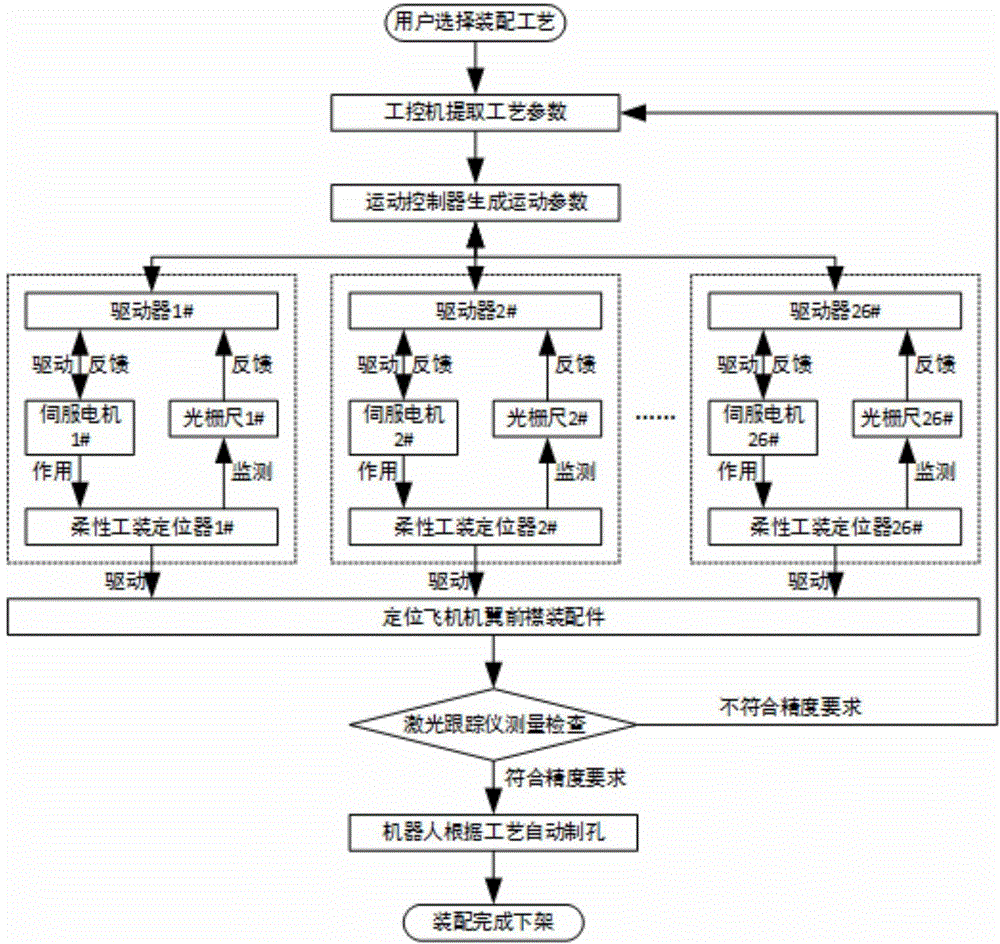

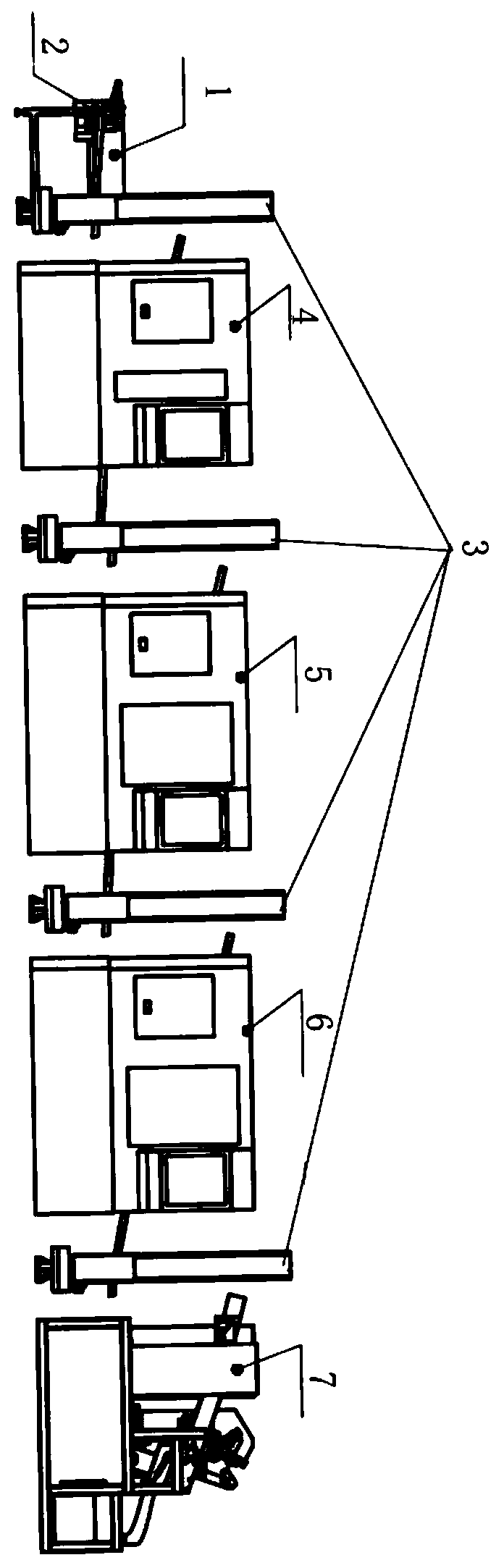

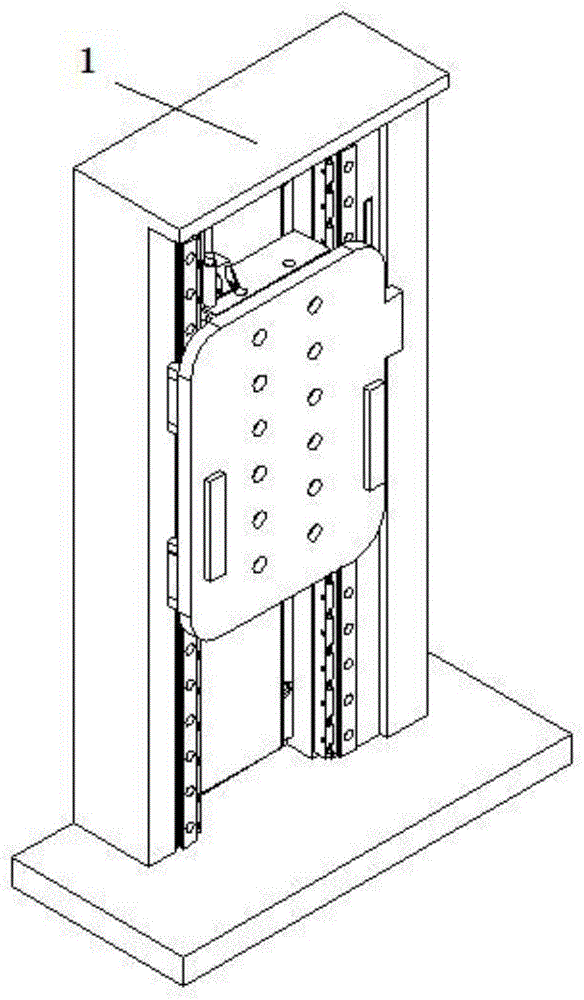

Control system for flexible tools for assembly of wing foreparts

InactiveCN104678900ARealize digital assemblyRealize full closed-loop controlNumerical controlGratingClosed loop

The invention discloses a control system for flexible tools for assembly of wing foreparts. A single-axis servo motor on an SERCOS-III (serial real time communication specification-III) bus node is controlled through a motion controller, and therefore the motion control of a complete set of flexible tools for the assembly of the wing foreparts is realized, and the digital assembly of the wing foreparts is performed. The control system comprises a digital flexible tool, a laser tracker, a robot drilling system integration interface and a software integration platform, and all systems run harmoniously; control command and status return information interaction is implemented between the controller and an actuator unit; distributed motion control is performed on all shafts of the digital flexible tool; control is performed on the shafts of the flexible tool by an IPC (Industrial Personal Computer), and single-point location control is realized on each shaft; each shaft is provided with a grating ruler, and an actual position signal is measured, and is fed back to the control system to realize full-closed loop control of all the shafts. By changing the digital assembly process for the wing foreparts, servo control of different actions can be performed to realize the assembly of the wing foreparts of different types.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Modular combined production process for automatic ball cage manufacturing

ActiveCN111571393AAddressing Batch Quality RisksRealize the automation of grinding processGrinding feed controlAbrasive surface conditioning devicesNumerical controlLoop control

The invention relates to a combined production process, in particular to a modular combined production process for automatic ball cage manufacturing. The method comprises the following steps of feeding machine operation, positive and negative recognition system operation, elevator operation, numerical control window grinding machine operation, numerical control cylindrical grinding machine operation, numerical control internal grinding machine operation and automatic online detection operation. The functions of automatic feeding, recognition, clamping, machining, automatic detection, sorting,diagnosis, alarming, protection, communication, calling and the like are configured, and full-closed-loop control over high-precision ball cage grinding automation and real-time efficient online detection is truly achieved.

Owner:杭州腾励传动科技股份有限公司

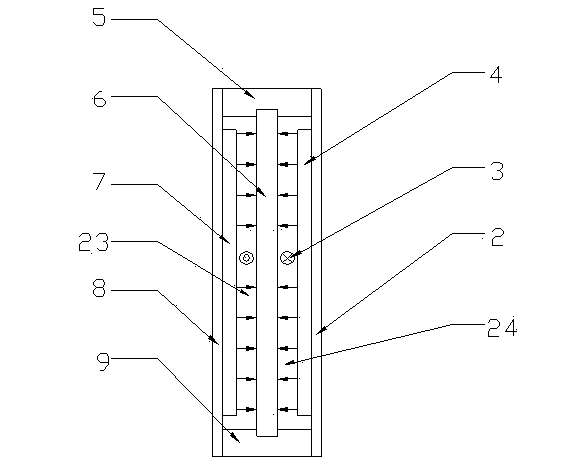

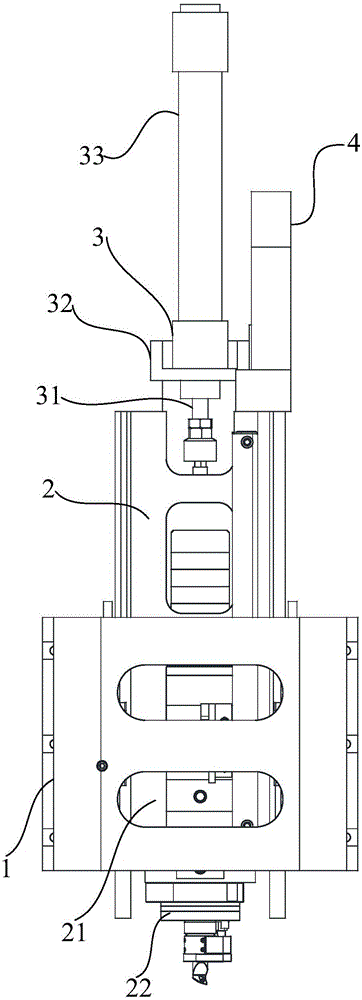

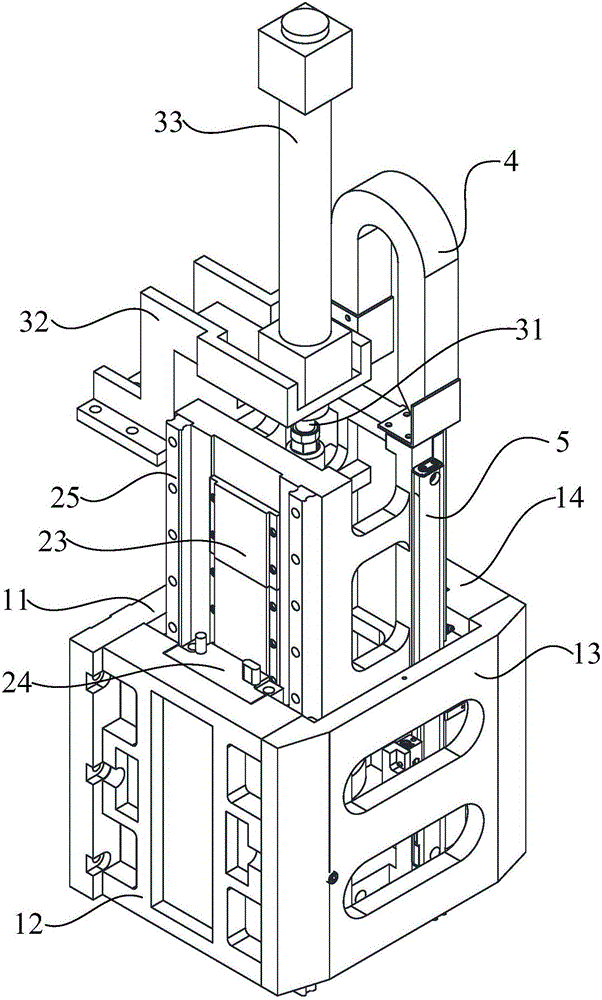

Vertical high-speed high-accuracy direct-driving mechanism

The invention relates to a vertical high-speed high-accuracy direct-driving mechanism. The mechanism comprises a vertically-placed base, vertically-placed sliding rails on the base, a primary linear motor and a secondary linear motor. The primary linear motor is installed on the base. The secondary linear motor is connected to a movable carrying plate, on which a sliding block is arranged. The sliding block is clamped on the sliding rails and move along the sliding rails. The primary linear motor and the secondary linear motor are arranged oppositely. The movable carrying plate is provided with a reading head. The base is further provided with a grating ruler used for sensing changes of the position of the reading head. The vertical high-speed high-accuracy direct-driving mechanism has following beneficial effects: by adoption of direct-driving technology of linear motors, extremely high acceleration and deceleration speed and motion speed are achieved; mechanical abrasion and opposite clearance are avoided; non-contact driving technology is utilized so that long service lifetime is realized; the base is made by large damping material so that value of amplitude for harmonic response of a lower-order mode is inhibited and vibration of the high-order mode is overcome; good dynamic response attribute is obtained; and by adoption of high-resolution position feedback device, full closed-loop control is achieved and the repeated accuracy is higher.

Owner:BOZHON PRECISION IND TECH CO LTD

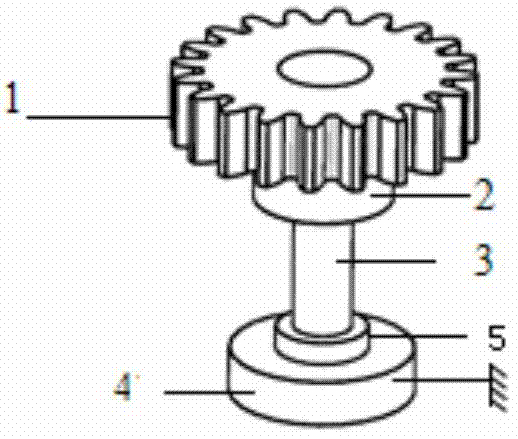

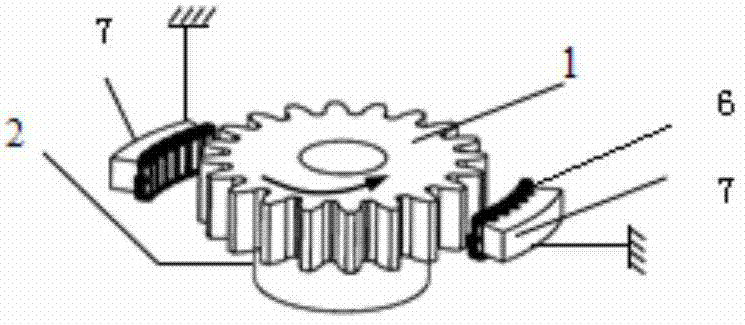

Side-mounted precision angular displacement self-detecting system

ActiveCN104298170ARealize full closed-loop controlCompact structureNumerical controlSystems designContact mode

The invention provides a system enabling a moving metal toothed body with circumferentially and mechanically halving characteristics to automatically perform precision angular displacement detection and output displacement information. The side-mounted precision angular displacement self-detection system designs a group of detection heads which comprise exciting, induction and compensation coils, arranged beside a moving metal body to be detected and work with a microprocessor system to accurately obtain motion displacement information of the moving metal body in a non-contact mode. The system is characterized in that the detection heads are additionally provided with axially-halved grooves, and a single coil is axially wound and tangentially connected in series to weaken magnetic field edge effects of the coil; tooth crests of metal winding bases of the detection heads are tangentially and axially machined into a particular arc respectively; the metal body to be detected and toothed portions of the detection heads comply with set distribution principles; the detection heads are provided with signal compensation coils with independently adjustable compensation power supplies; the metal body to be detected and the detection heads are regarded as an overall mechanical system with a sensing function, and an online or system error correction technology is used, so that the whole system can have the capability of self-detection and precision displacement information output.

Owner:重庆大族时栅科技有限公司

High-precision radiation field scanning device adapted to multiple water tanks

InactiveCN108132482AGuaranteed non-interferenceRealize full closed-loop controlDosimetersControl using feedbackGratingElectric machinery

The invention relates to a high-precision radiation field scanning device adapted to multiple water tanks. The scanning device comprises a 3D motion guide rail device, a clamping module, a detector and a magnetic grating scale; the 3D motion guide rail device is arranged over a detector placing side of the water tank, and comprises first, second and third guide rails; the clamping module is arranged on the 3D motion guide rail device, and drive by a servo motor of the 3D motion guide rail device; the detector is fixed by the clamping module and arranged in the water tank, moves correspondinglyin the water tank with movement of the clamping module, and detects rays input to the water tank via a ray incident plane of the water tank to determine a radiation dose; and the magnetic grating scale ensures that the detector reaches a predetermined work position accurately. Via the scanning device, the detector moves in multiple dimensions, different positions are detected, needed measurementdata is obtained, and a test result is more accurate and effective.

Owner:NAT INST OF METROLOGY CHINA

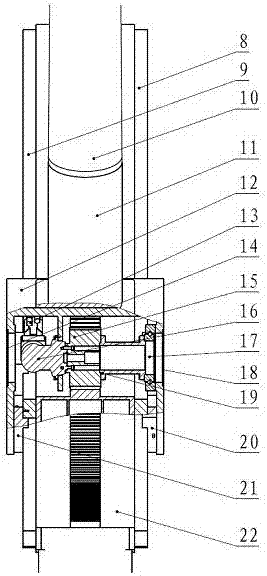

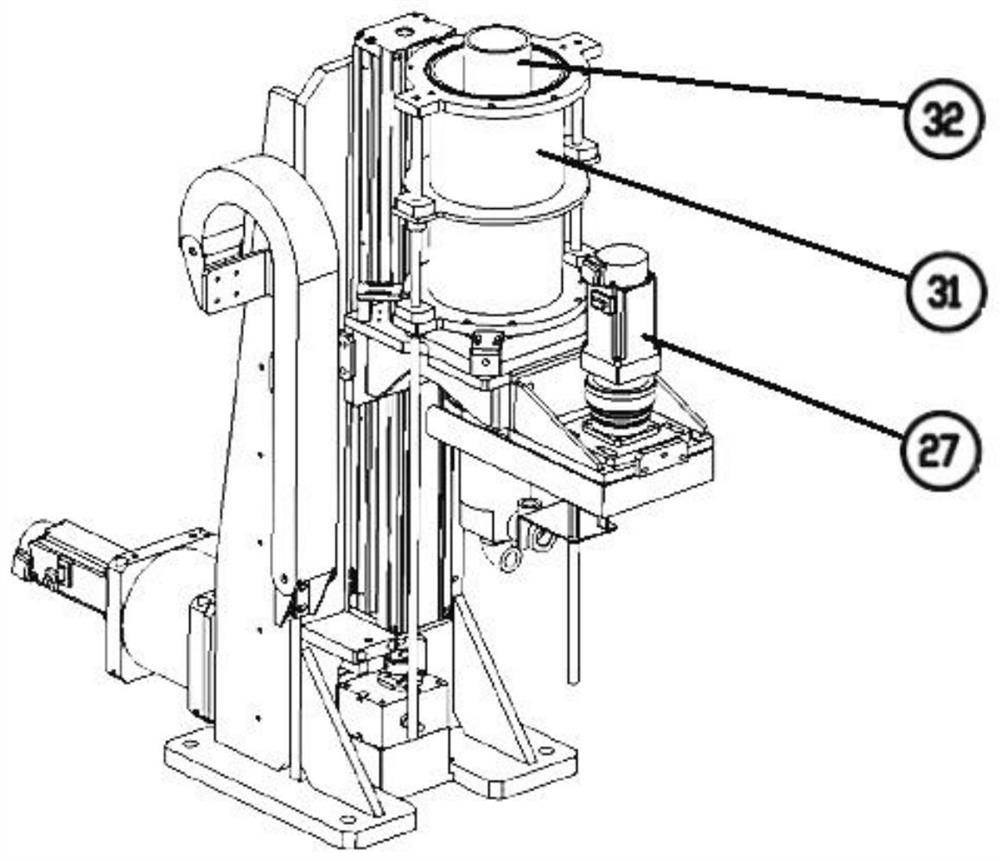

Crucible lifting and rotating mechanism special for silicon carbide furnace

PendingCN113758252AAchieve fine-tuningGuaranteed accuracyCrucible furnacesCarbide siliconRotational axis

The invention relates to the field of semiconductor equipment, in particular to a crucible lifting and rotating mechanism special for a silicon carbide furnace. The mechanism comprises a lifting mechanism, a rotating mechanism is installed on a lifting sliding table of the lifting mechanism, the rotating mechanism comprises a rotating shaft, and the rotating shaft is rotationally connected with the lifting sliding table through a magnetofluid rotary sealing piece; the periphery of the magnetofluid rotary sealing piece is connected with the lower end of a corrugated pipe device; the upper end of the corrugated pipe device is a corrugated pipe upper flange for connecting a silicon carbide furnace bottom cavity; the lower end of the rotating shaft is rotationally connected with a rotating joint which is provided with a water inlet and a water outlet; and a cooling loop is arranged in the rotating shaft, one end of the cooling loop is communicated with the water inlet, and the other end of the cooling loop is communicated with the water outlet. The magnetofluid rotary sealing piece is additionally arranged, so that the rotating effect and the high-vacuum sealing effect are achieved. High sealing performance between the rotating position and a silicon carbide furnace inner cavity is conveniently achieved, then the high vacuum degree of the silicon carbide furnace inner cavity can be guaranteed, and the mechanism is suitable for processing and production of third-generation semiconductor materials.

Owner:SHANGHAI HANHONG PRECISION MACHINERY

Smelting control method of metal electroslag remelting furnace

The invention discloses a smelting control method of a metal electroslag remelting furnace. The method is characterized by comprising the following steps: before smelting, firstly installing three position sensors used for detecting the position of an electrode in the metal electroslag remelting furnace; secondly before smelting and during smelting, detecting the position of the electrode by the position sensors, feeding the position of the electrode, detected by the position sensors, back to a data control processing system and then controlling executive devices to move a crystallizer to achieve automatic centering of the electrode under closed-loop control, wherein the three position sensors are arranged in a concentric circle along the axial lead of the crystallizer and are uniformly distributed and fixed on the upper surface of the crystallizer in a ring shape. The method has the advantages that the method can conduce to facilitating centering, reducing the phenomenon of failure of the crystallizer and prolonging the service life of the crystallizer.

Owner:宝武特冶航研科技有限公司

Precise linear shaft for cutter grinder

InactiveCN103846747ASatisfy processabilityFulfil requirementsOther manufacturing equipments/toolsGrinding/polishing safety devicesGratingEngineering

The invention provides a precise linear shaft for a cutter grinder and relates to the field of precise cutter machining equipment. The precise liner shaft comprises a base, a water retaining plate, an end plate, a protecting plate, a left dust cover, a right dust cover, a movable plate, a dust cover connecting plate, drainage grooves, an external-interface connecting plate, an electrical interface, an air pipe connector, a linear motor rotor, a linear motor stator, limiting blocks, a reading ruler, a grating ruler, hard limit, a slider, a guide rail and an inner water retaining plate. The technical problems existing in transmission cutter machining and the cutter grinder for grinding of old cutters can be solved; the cutter grinder set up by modularized design for the precise linear shaft can improve machining speed, the performance of a complete machine is improved to a certain degree, and an integrated optimization solution is provided for precise cutter maching.

Owner:KUNSHAN YUNCO PRECISION IND TECH

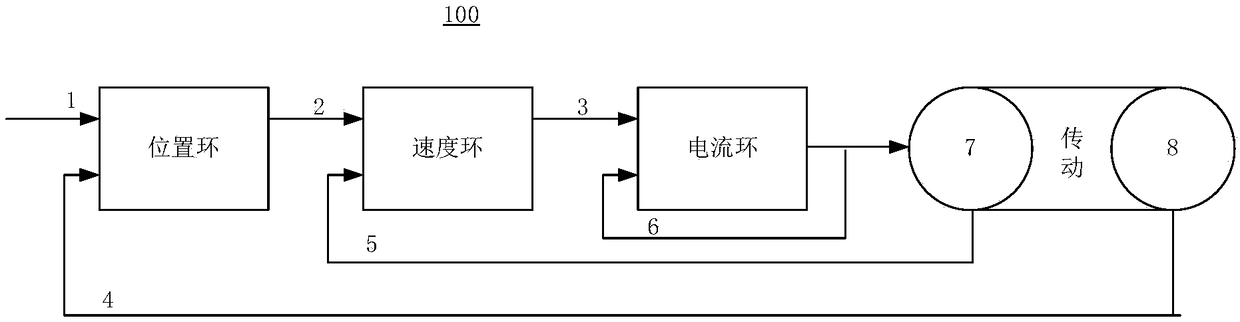

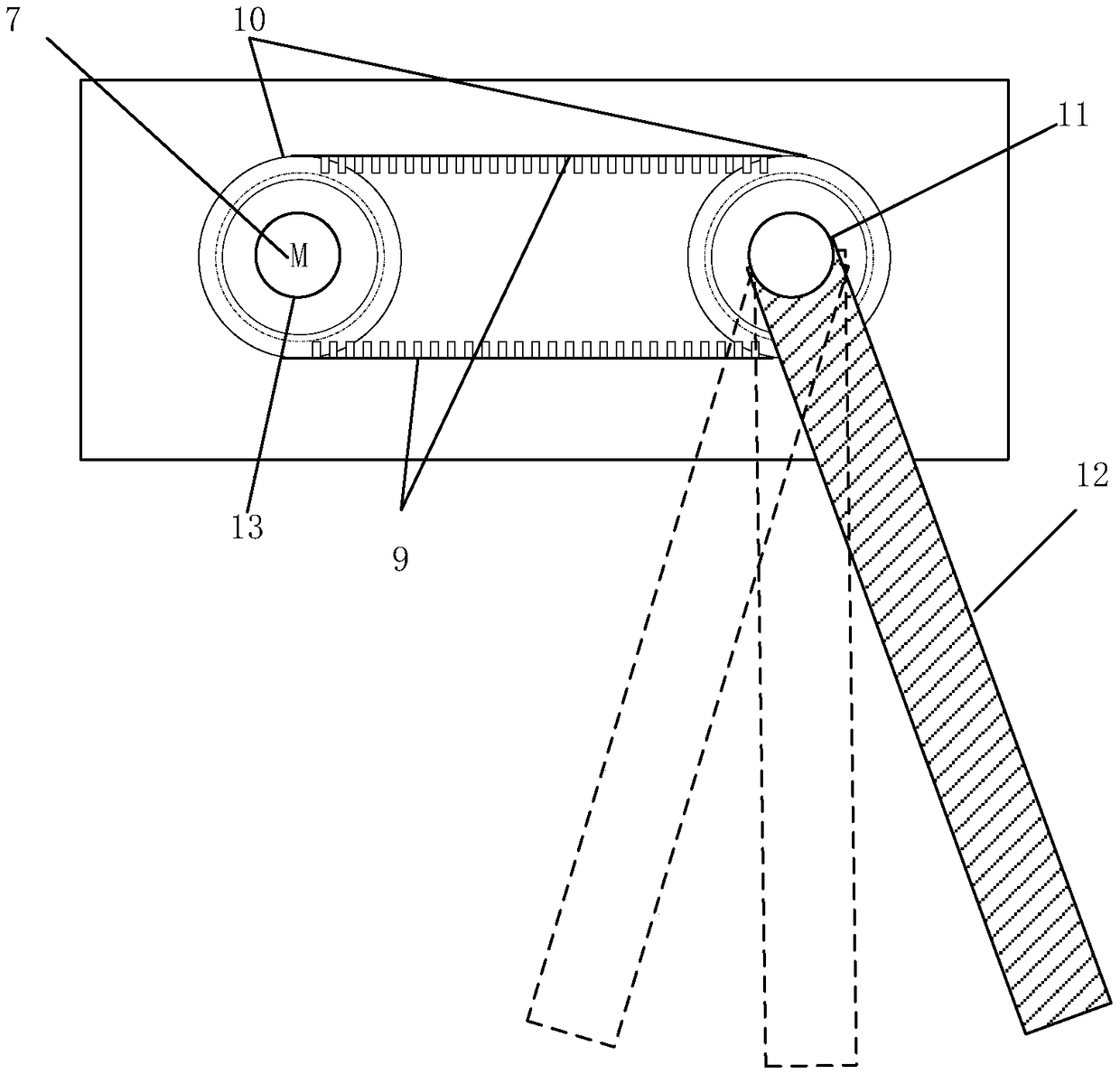

Double-code-disc motor control system

InactiveCN108123655ARealize full closed-loop controlEliminate the short-term "flying car" phenomenonElectric motor controlControl systemClosed loop

The invention discloses a double-code-disc motor control system which comprises a first code disc which is arranged on the motor and is used for calculating speed feedback of a speed ring, a second code disc which is arranged on an external execution mechanism and is used as position feedback of a motor control position ring. Three-ring control is used by the motor control system, and the positionring, the speed ring and a current ring are arranged from the outside to the inside. According to the double-code-disc motor control system provided by the invention, the double code discs are used to achieve the full-closed-loop control of a motor, when the execution mechanism has a problem of a transmission gap, elastic deformation or the like, a short-time 'galloping' phenomenon of the motor can be eliminated, and a vibration phenomenon of the motor in passing the transmission gap is greatly improved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Synergetic control method of aircraft part pose alignment based on four locater

InactiveCN101362511BRealize full closed-loop controlInstruments for road network navigationAircraft assemblySynchronous controlClosed loop

The invention discloses a method for adjusting and synergetically controlling the position and pose of an aircraft component based on four locators. The method comprises the following steps: firstly, a global coordinate system OXYZ is established, and the current position and pose and the target position and pose of the aircraft component are calculated under the global coordinate system; secondly, the automatic adjusting path and the inch adjusting path of the aircraft component are formed; thirdly, the track of the sphere pivot wiring point between the locator and the aircraft component is planed according to the automatic adjusting path and the inch adjusting path; fourthly, the track of the sphere pivot wiring point is inverted into the driving parameter of a 12 motor axle synchronouscontrol network; fifthly, the 12 motor axle synchronous control network is built based on a SynqNet bus, and the position servo of single motor axle adopts the full-closed loop digit controlling; andsixthly, two locators are selected, and the collocated relation between the locators is the master-slave motion mode. The method has the following advantages: firstly, the path for adjusting the position and pose of the aircraft component can be planed; secondly, the full-closed loop controlling of the single axle motion of the locator can be realized; and thirdly, the 12 axle synchronous motion of the position and pose adjusting system can be realized.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com