Magnetic material temperature feature testing method

A magnetic material and testing method technology, applied in the direction of magnetic performance measurement, etc., can solve the problems of low test accuracy, few structural elements of the magnetic flux test method, and unsuitable test requirements, etc., and achieve high test accuracy, high-precision closed-loop test, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] A kind of embodiment step of the test method of magnetic material temperature characteristic of the present invention is as follows:

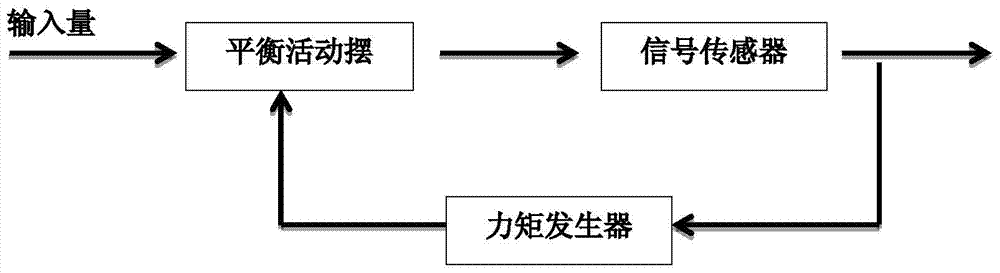

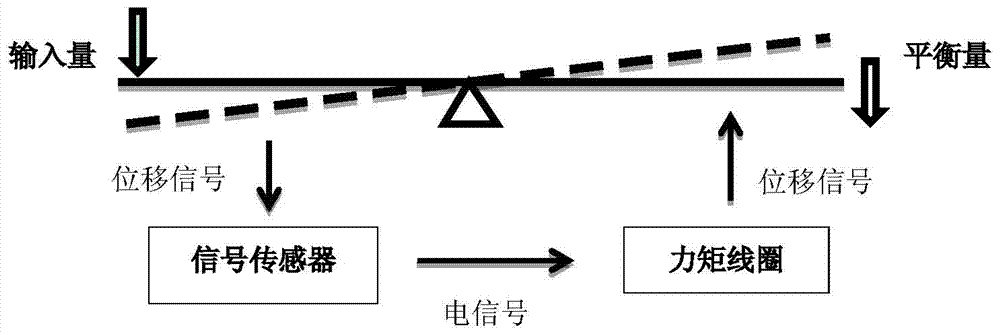

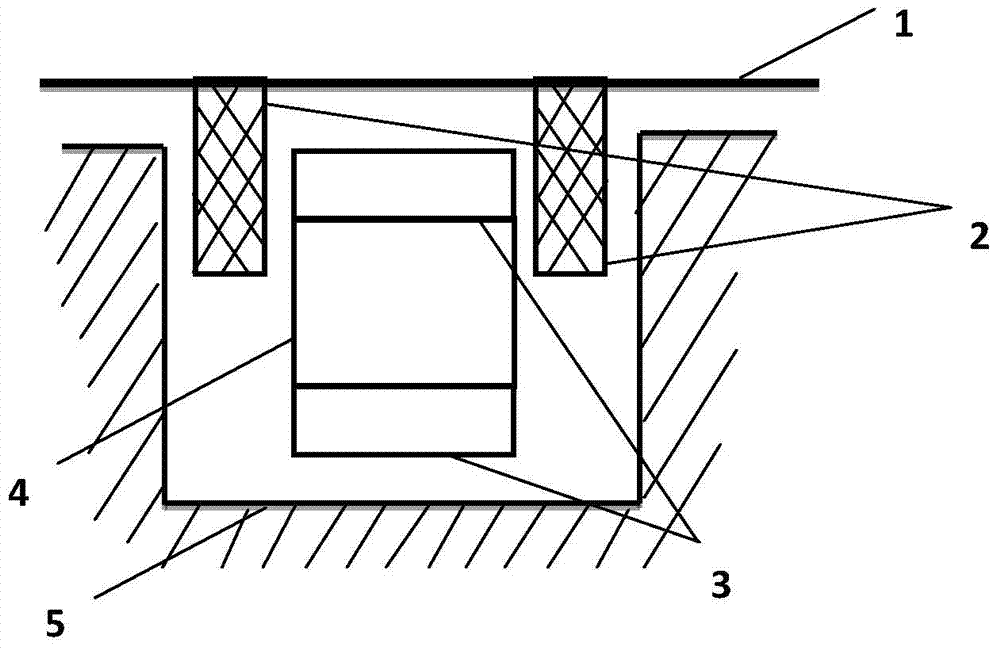

[0021] Step 1, build a special test device: the special test device is a force balance device, including a balance pendulum, one end of the balance pendulum is the input end, and the other end is the balance end. The working principle of the device is that the input quantity is applied to the balance The input end of the pendulum makes it deflect, and the balance end will generate a balance amount equal to the input amount to pull back the position of the pendulum to keep it in balance, see figure 1 , and the balance quantity will change with the change of the input quantity. In this force balance device, the balance end is a torque generator, which is composed of a measured magnetic material 4, a mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com