Linear rotary servo motor with two degrees of freedom

A servo motor, degree of freedom technology, applied in the field of servo motors, can solve the problems of complex structure of the whole machine, high production and maintenance costs, and achieve the effects of improving motion accuracy, fast response speed, and light load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

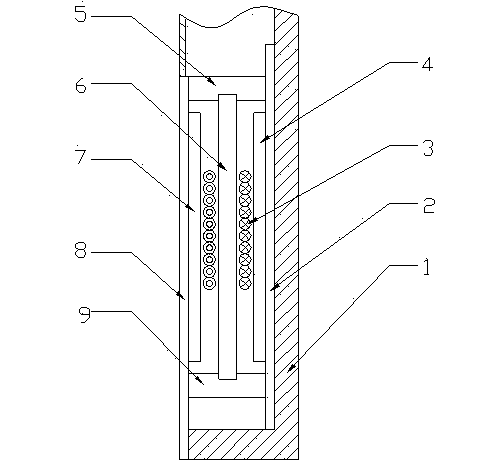

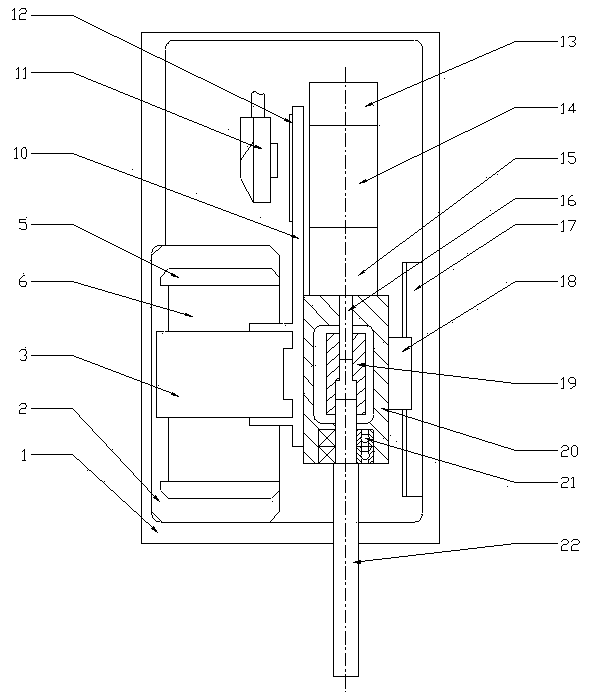

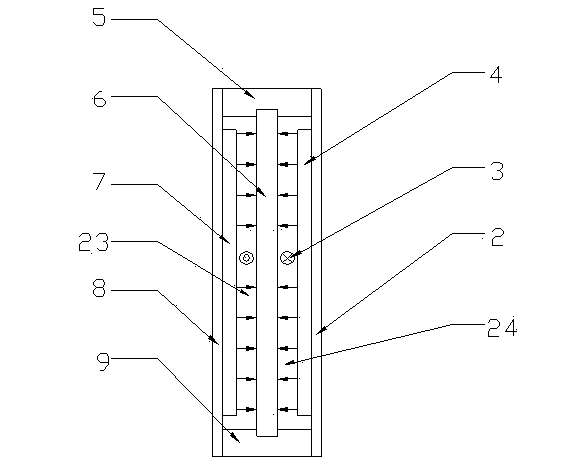

[0007] combine figure 1 as well as image 3 Explain the implementation mode of the primary mover movement. In this embodiment, it is composed of a base 1, a linear stator, and a primary coil 3; , the upper yoke 8; two permanent magnets are attached to the upper and lower yokes respectively, and the upper and lower yokes are connected to the middle yoke 6 through the magnetic yoke to form a complete magnetic field circuit; the permanent magnets attached to the upper magnetic plate 8 The magnet 7 forms a uniform magnetic field 23 whose direction is perpendicular to the middle magnetic yoke 6 on its right side, and the permanent magnet 4 attached to the lower magnetic plate 2 forms a uniform magnetic field 24 whose direction is perpendicular to the middle magnetic plate on its left side; the primary coil 3 penetrate into the uniform magnetic field 24, bypass the middle yoke 6, and pass through the uniform magnetic field 23. When there is a positive current in the primary coil 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com