PC-based numerical control machine tool full closed-loop control system

A control system and CNC machine tool technology, applied in the field of machinery, can solve the problems of incompetent software expansion function, unfavorable to play the automatic control of CNC machine tools, efficient processing, etc., to achieve the effect of full closed-loop control and improve the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

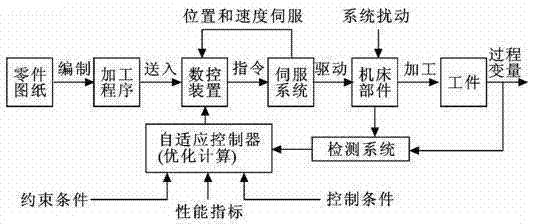

[0018] Such as figure 1 , the full-closed-loop servo control is based on the online monitoring and real-time control of the actual processing state variables to adjust the processing parameters (cutting speed, feed rate, etc.). In this way, the influence of machine tool state changes and external disturbances during the machining process can be eliminated to optimize the machining process, improve production efficiency and product quality.

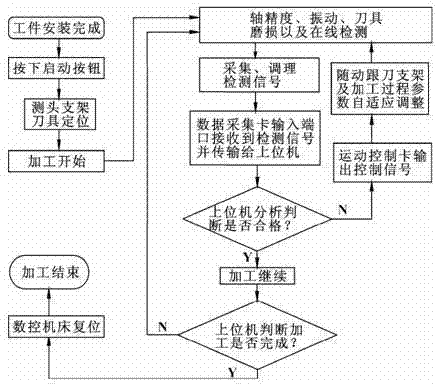

[0019] Such as figure 2 , the control system adopts the self-adaptive full-closed-loop servo control technology of the machine tool, and transmits the online detection quantity to the CNC system through the signal acquisition and processing unit. Automatically adjust processing parameters to reduce processing errors.

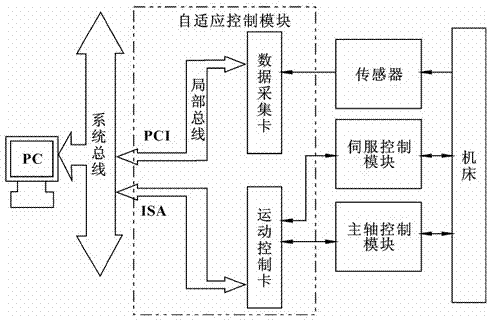

[0020] Such as image 3 , "PC + adaptive control module" constitutes an open structure. The control system ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com