Intelligent computerized numerical control (CNC) spring machine

A spring machine, computer-controlled technology, applied in the direction of manufacturing springs, other household appliances, household appliances, etc. from wires, can solve the problems of low efficiency, spring shape limitation, and complicated adjustment of computer numerical control spring machines, achieving simple operation and reducing The effect of high scrap rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the drawings.

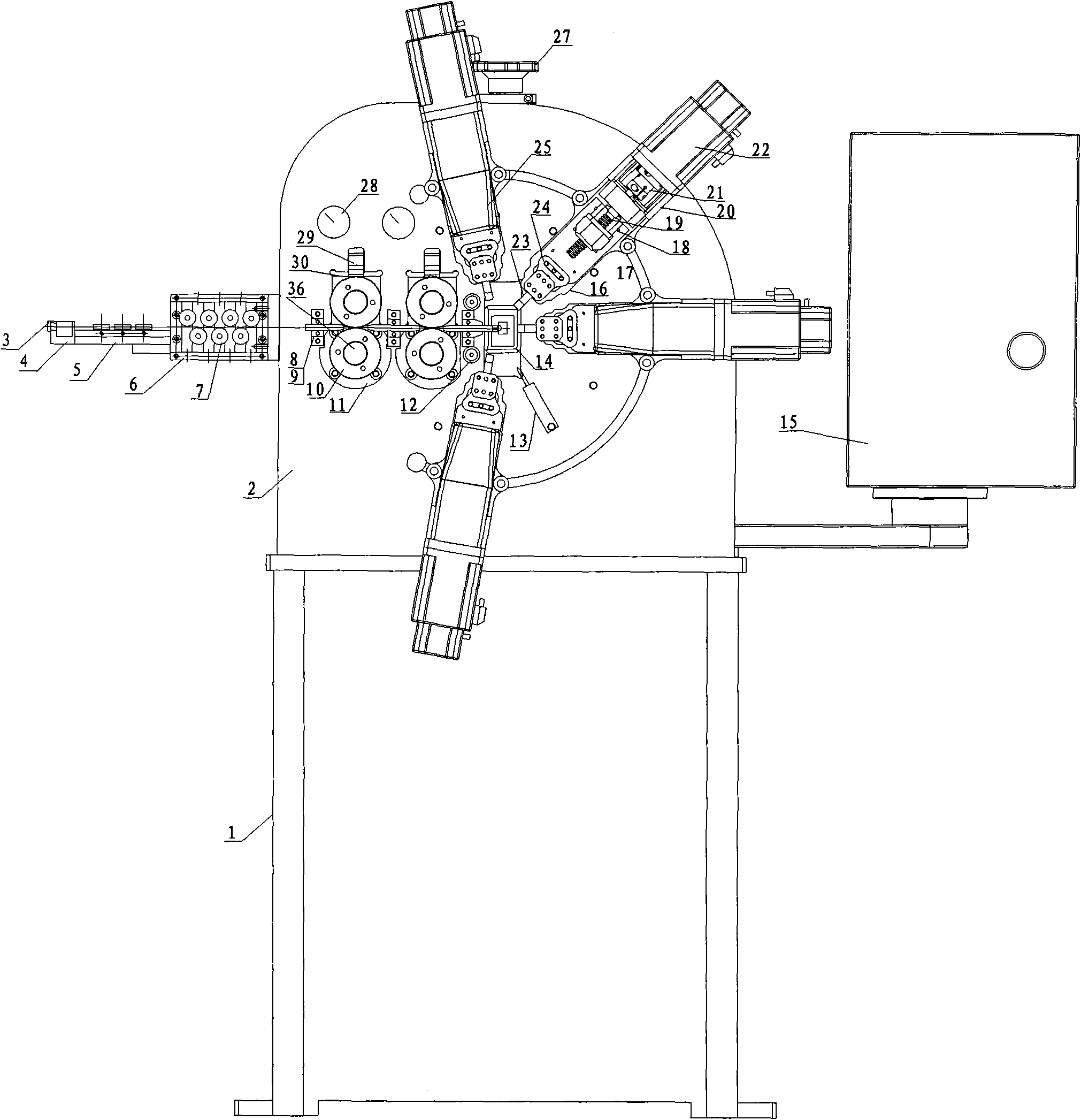

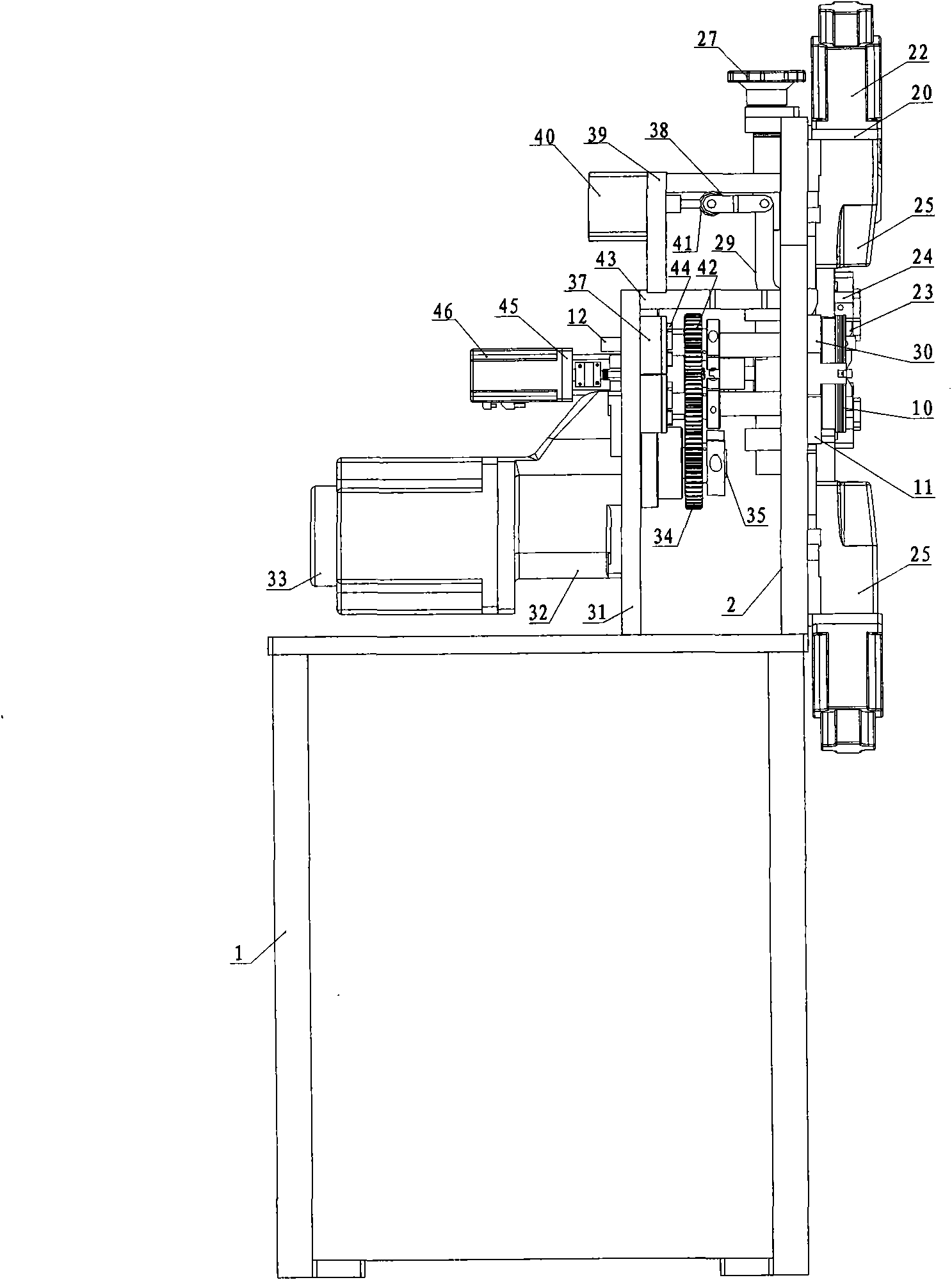

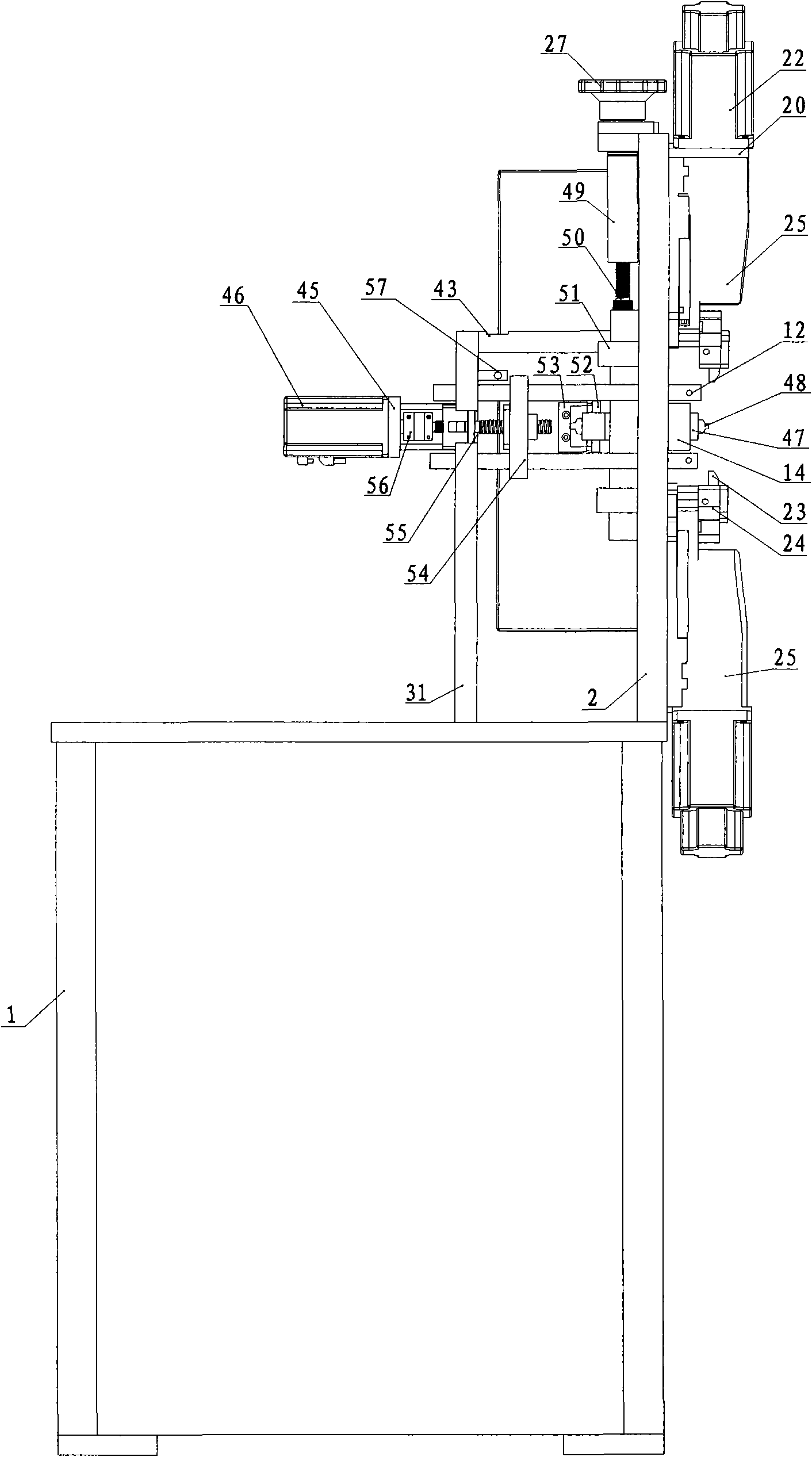

[0019] Such as figure 1 As shown, the present invention includes a base 1, a straightening mechanism, a wire feeding mechanism, a pitch mechanism, a core seat mechanism, a knife seat mechanism and a computer control system.

[0020] The base 1 is fixedly provided with front and rear wall panels 2, 31 parallel to each other, and the straightening mechanism and the wire feeding mechanism are sequentially arranged on the front surface of the front wall panel 2 along the advance direction of the steel wire to be processed.

[0021] The front end of the straightening mechanism is fixed with a cleaning sleeve 3 and a cleaning box 4 in sequence. The cleaning box 4 is filled with oil cotton to clean and lubricate the spring steel wire. The spring steel wire enters the cleaning box 4 through the cleaning sleeve 3 and passes from the cleaning box. 4 After output, enter the straightening mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com