High-speed board thickness measuring and retaining device

A thickness measurement and holding device technology, applied in length measuring devices, rolling mill control devices, metal rolling, etc., can solve the problems of low accuracy, difficult installation and maintenance, and high equipment costs, to ensure certainty and overcome high costs. , the effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

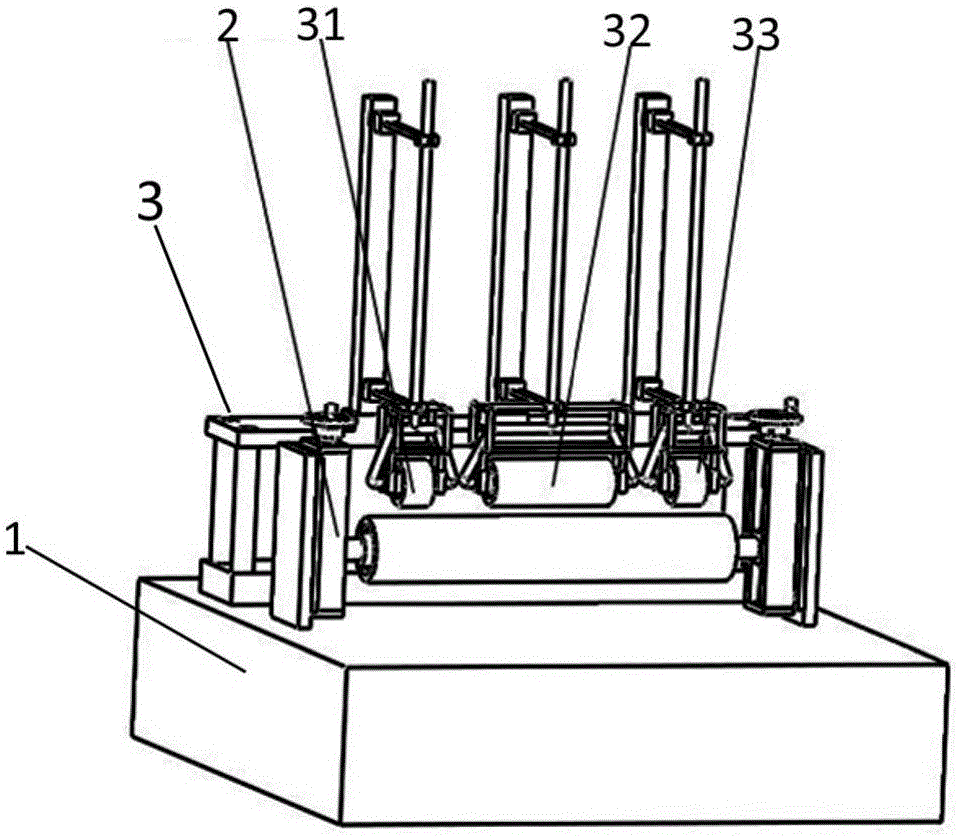

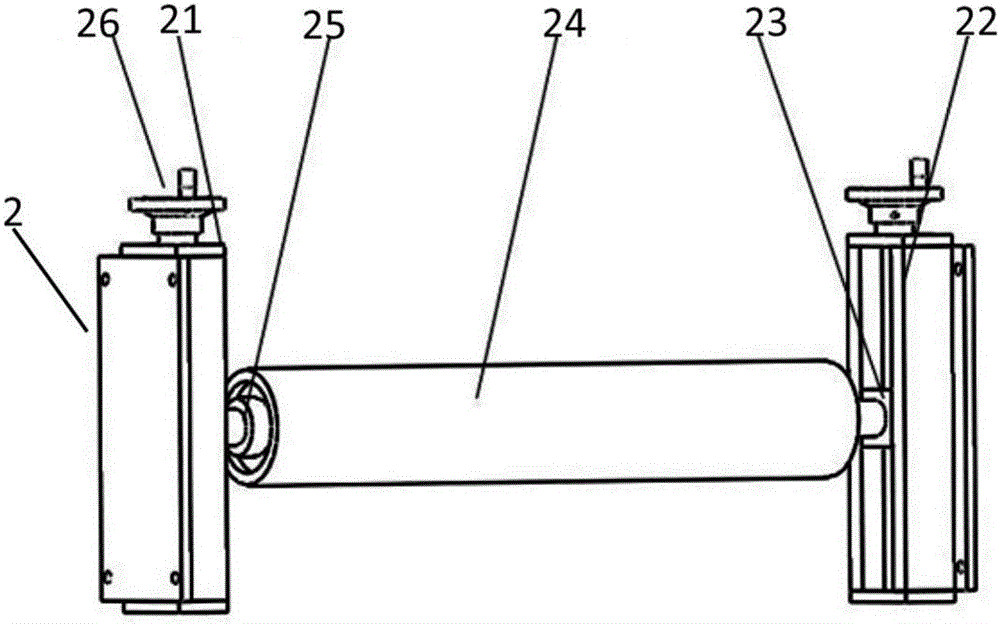

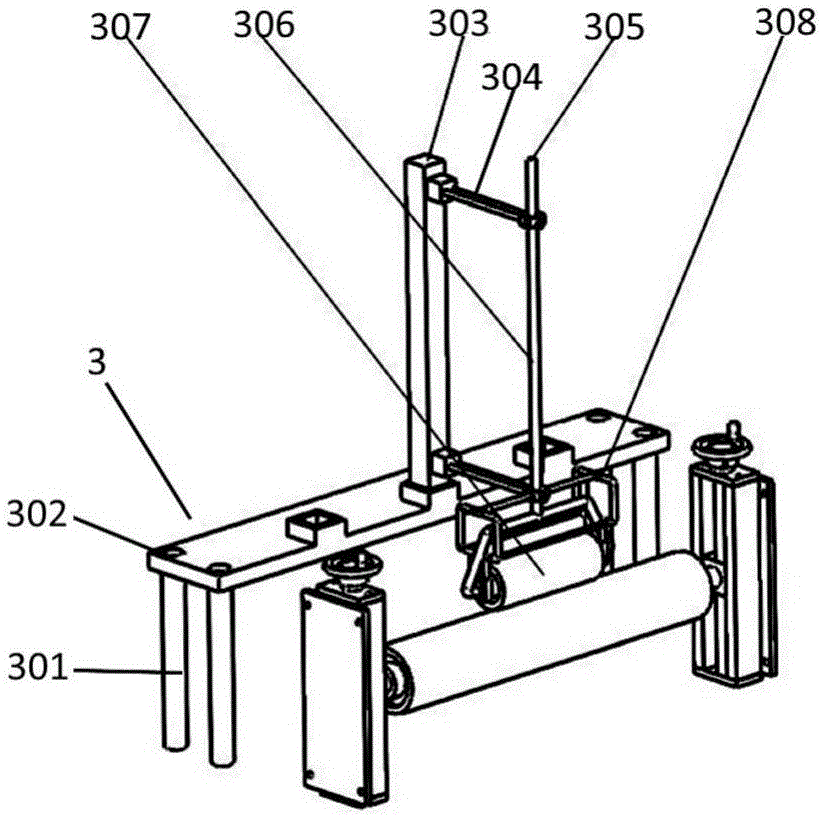

[0018] figure 1 It is the overall structure of the device of the present invention. The device is mainly composed of two modules installed on the base 1, which are respectively the guiding mechanism 2 and the thickness measuring mechanism. In this embodiment, the thickness measuring mechanism includes a first thickness measuring mechanism 31 , a second thickness measuring mechanism 32 and a third thickness measuring mechanism 33 . Among them, the guide mechanism is responsible for the import and export of the plate to ensure the directionality of the plate transmission. The thickness measurement mechanism is installed above the guide mechanism to ensure that the sensor mechanism and the undulation of the plate are kept in sync when the plate is uneven in thickness, ensuring co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com