Side-mounted precision angular displacement self-detecting system

A detection system and angular displacement technology, used in general control systems, control/regulation systems, program control, etc., can solve the problems of not very high accuracy, can not achieve accurate measurement and measurement, and achieve small size and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

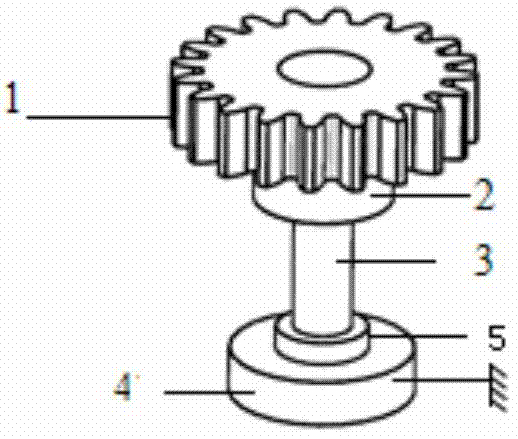

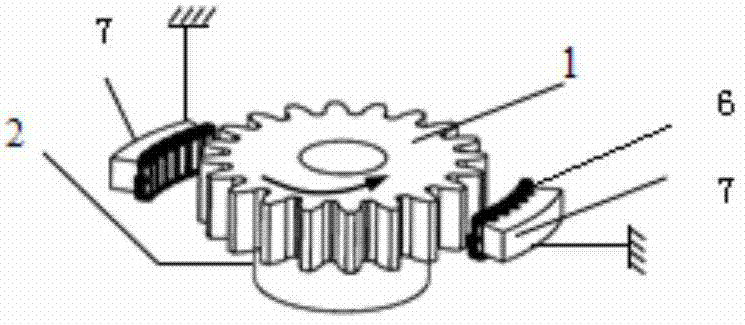

[0049] Design idea and specific structure of the present invention are further described in detail below in conjunction with accompanying drawing:

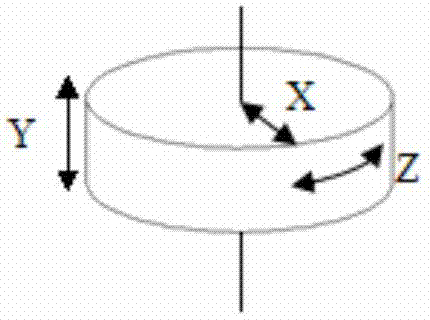

[0050]The invention proposes a system for automatically performing precise angular displacement detection and outputting the displacement information of the moving metal tooth-shaped body with the feature of mechanically dividing along the circumference. The invention adopts the principle of electromagnetic induction to make a group of electromagnetic induction probes including signal excitation coil, signal induction coil and signal compensation coil, and place one or more sets of the probes next to the moving metal body to be tested. Together with the microprocessor system, it can accurately obtain its movement displacement information in a non-contact manner. The excitation, induction and processing of the probe adopt some well-known electromagnetic sensor technologies, and one of the characteristics is that the probe adds equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com