Planetary reduction motor capable of achieving full closed-loop control and articulated robot

A planetary reducer, planetary deceleration technology, applied in the direction of controlling mechanical energy, program control manipulator, manipulator, etc., can solve the large assembly error of the reducer and the drive motor, the transmission accuracy and torsional deformation of the reducer, the backlash cannot be effectively detected and Compensation, inability to meet normal use requirements, etc., to avoid transmission errors, reduce axial dimensions, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with embodiment the present invention is described in detail:

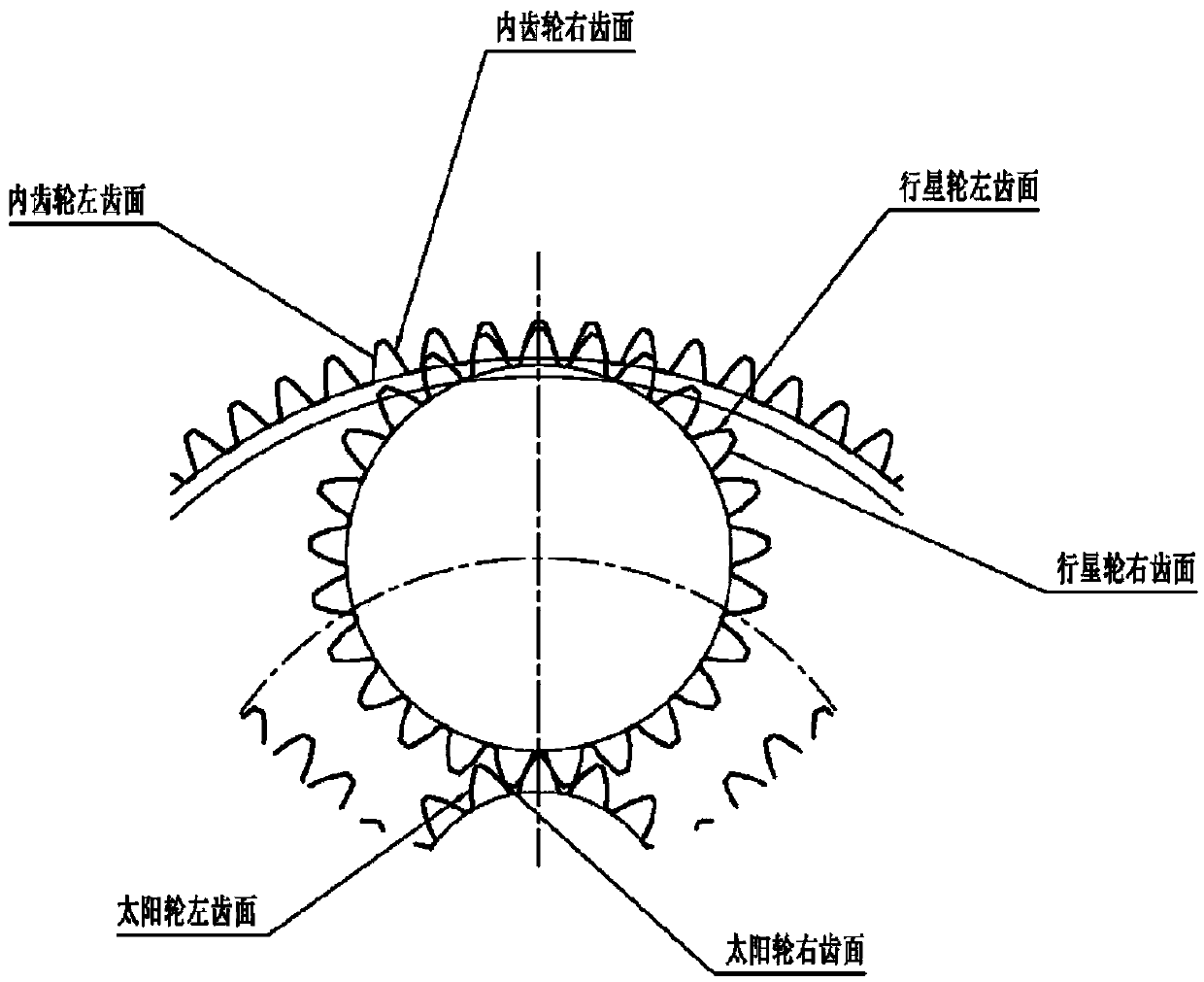

[0056] The planetary geared motor in the embodiment eliminates the backlash of the planetary geared motor, and designs a full-closed-loop control device that can improve the precision of the planetary geared motor. At the same time, the planetary geared motor is also larger than the existing planetary geared motor in terms of axial size. shortened.

[0057] When the above-mentioned high-precision planetary geared motor is applied to a joint robot, it can meet the use requirements of the joint robot.

[0058] The basic structure of the planetary geared motor in the embodiment

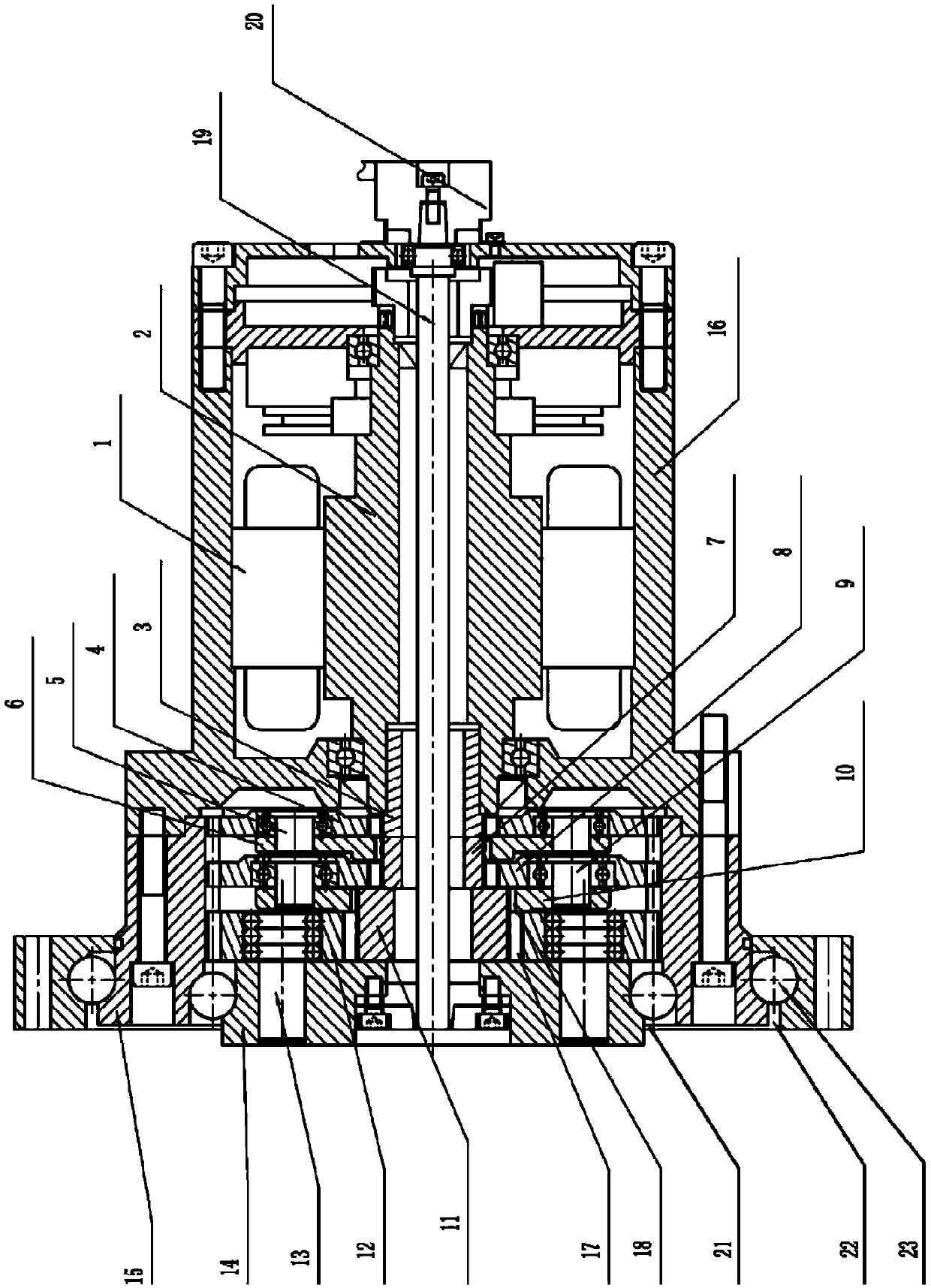

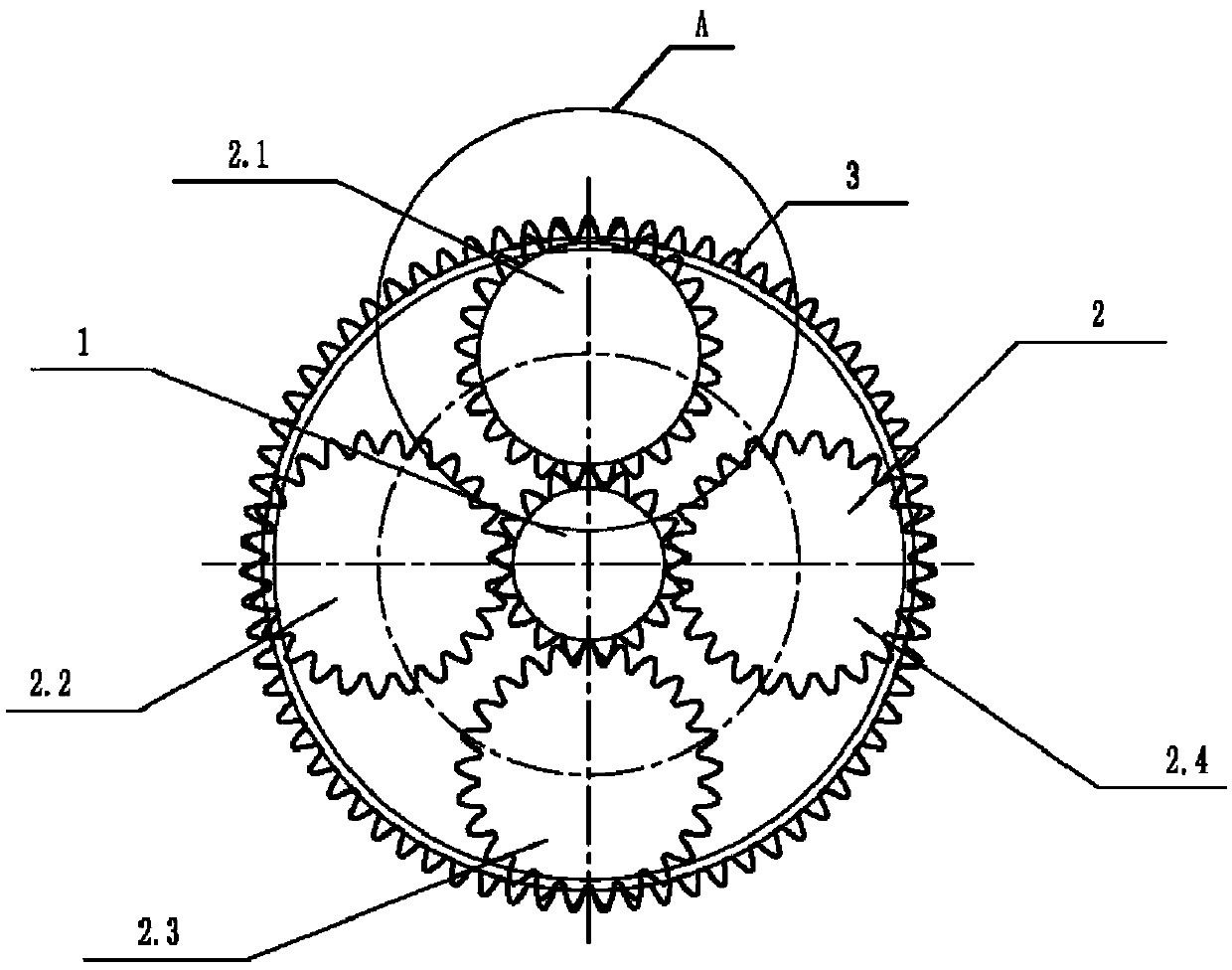

[0059] Such as figure 1 As shown, the contact structure of the planetary gear motor includes a planetary gear part and a motor part, the motor part includes a motor housing 16, and a stator 1 and a rotor 2 arranged in the motor housing 16; the planetary gear part includes an internal gear Housing 15, the S-leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com