COB camera module and packaging method thereof

A camera module and packaging method technology, which is applied to the assembly of printed circuits with electrical components, image communication, television, etc., can solve problems such as optical axis deviation, achieve the effects of improving yield rate, improving fault tolerance, and eliminating assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

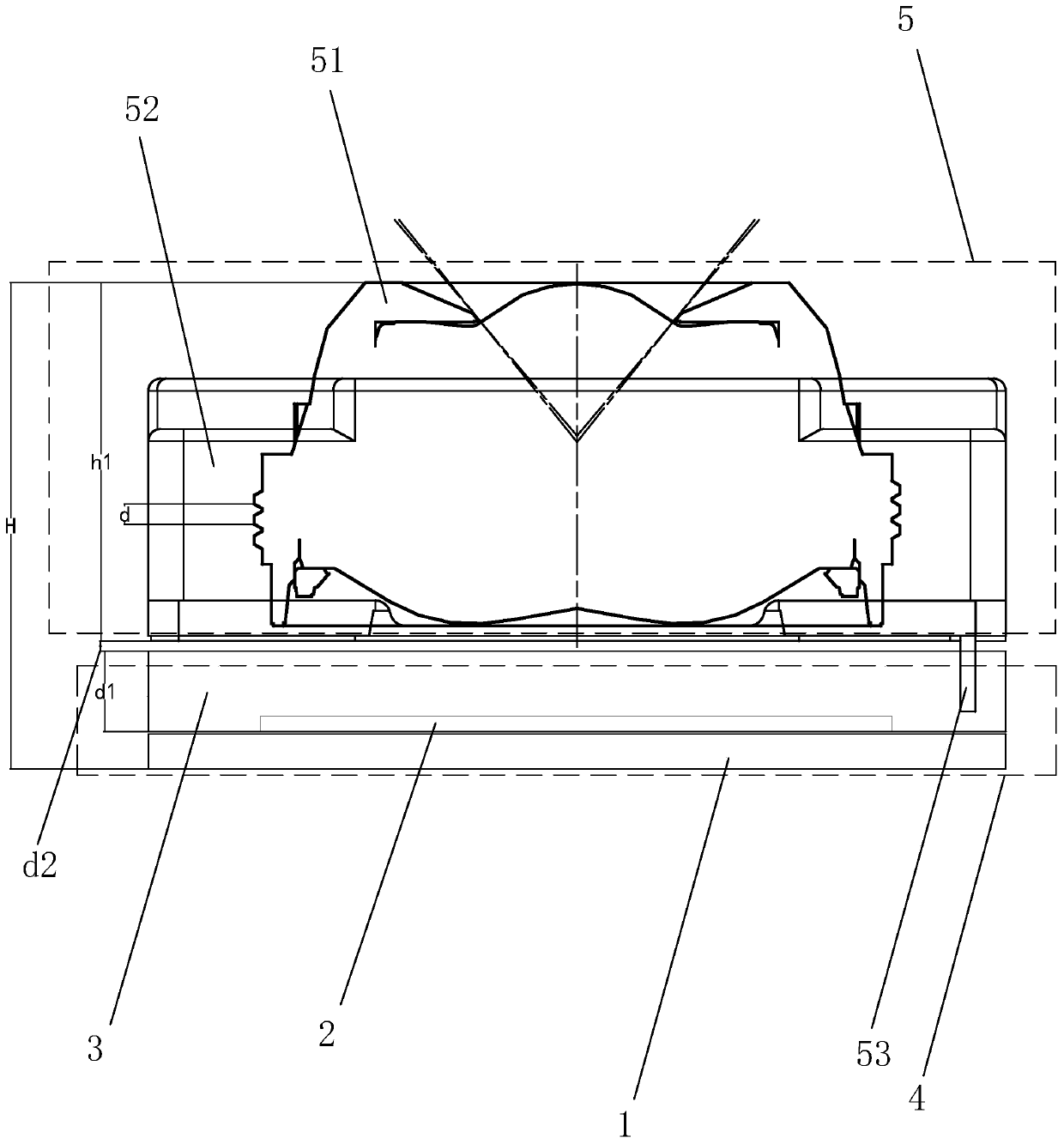

[0037] Such as figure 1 Shown, a kind of packaging method of COB camera module comprises the following steps:

[0038] S1. Cleaning and drying the circuit board 1, the chip 2 and the filter assembly 3;

[0039] S2. Attach the chip 2 on the circuit board 1 and perform pressure welding, and clean and dry the wire after welding;

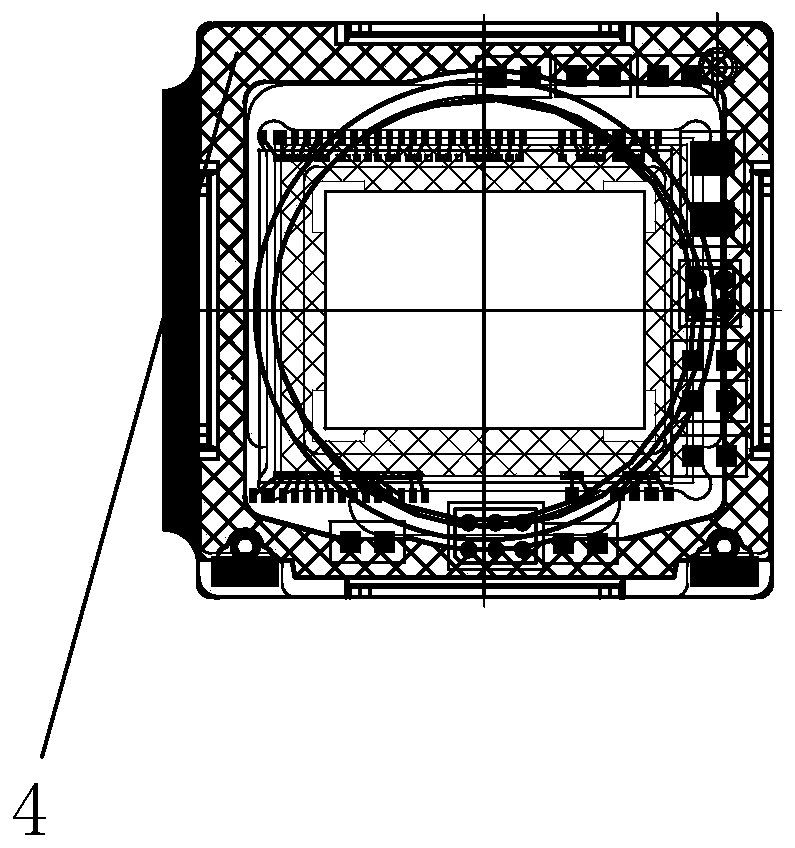

[0040] S3. Attach the filter assembly 3 on the chip 2 and dry it to obtain a module one 4;

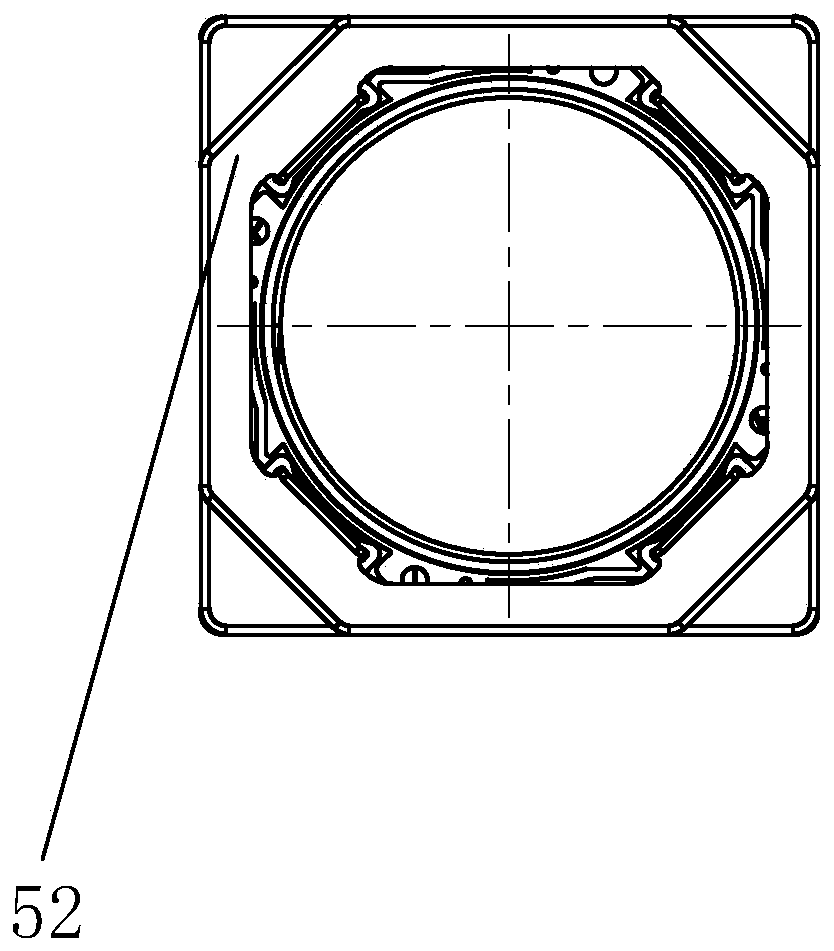

[0041] S4. Cleaning and drying the lens 51 and the motor 52 respectively;

[0042] S5. Lock the lens 51 into the motor 52 by a locking machine to obtain module 2 5. The size of the lens 51 higher than the motor 52 is a specific height h1 corresponding to the best focal length;

[0043] S6. Temporarily fix the position of module 2 5 and adjust its internal lens 51 to the highest position, use the camera active focusing device to detect the coincidence degree of the optical axis of module 1 4 and module 2 5 optical axis, and adjust it to the maximum within the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com