Laser wafer cutting equipment

A technology for cutting equipment and wafers, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as parts installation and assembly errors, pollution of cutting head optical lenses, and affecting cutting accuracy, so as to eliminate assembly errors, The effect of avoiding optical path deviation and reducing production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

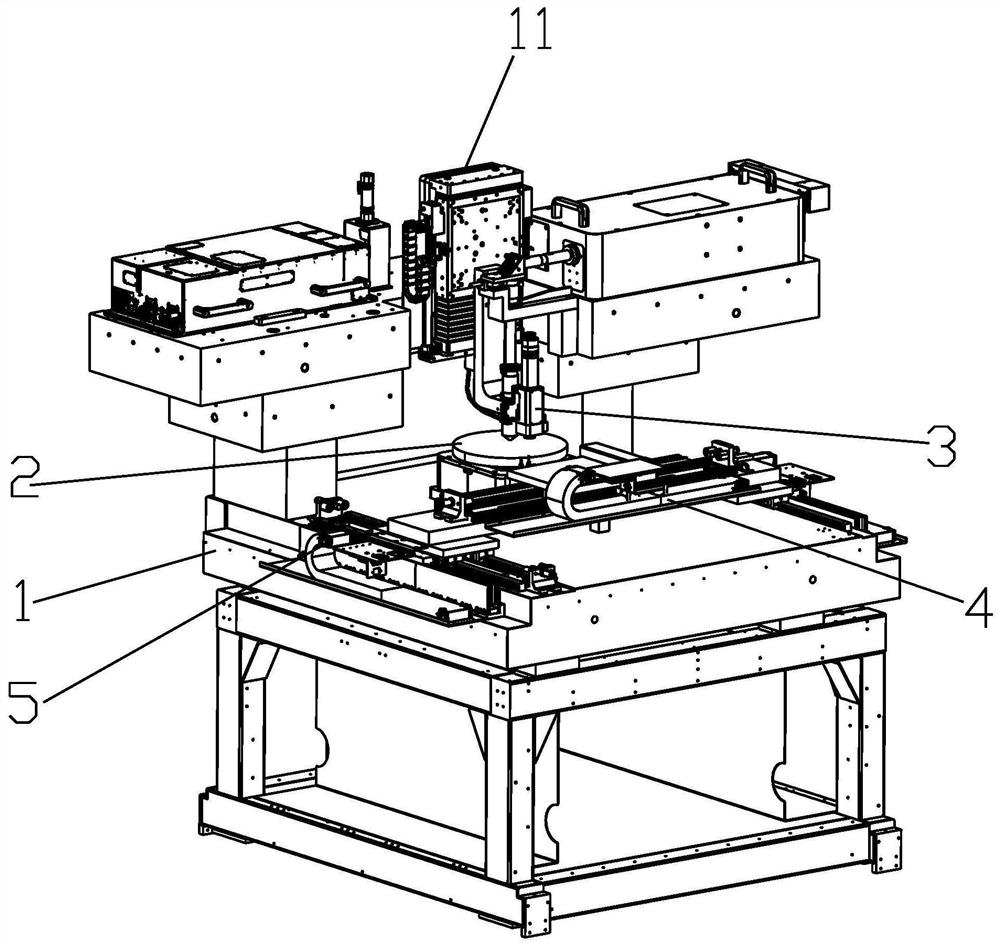

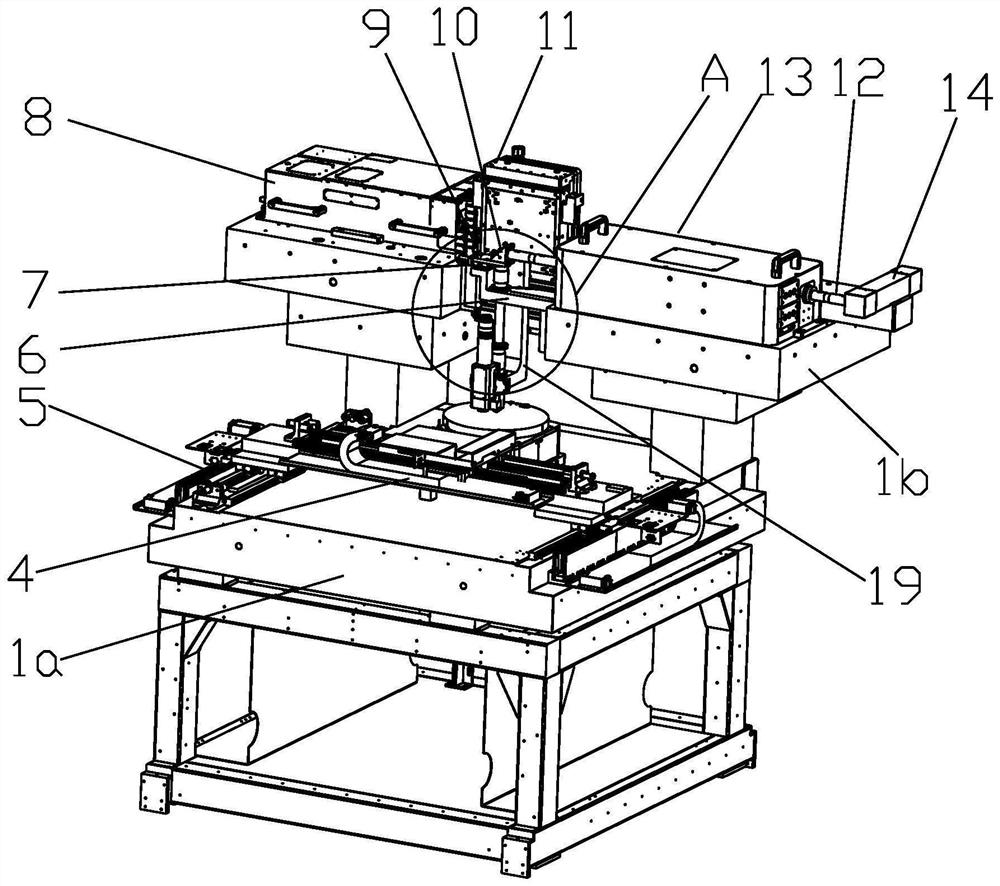

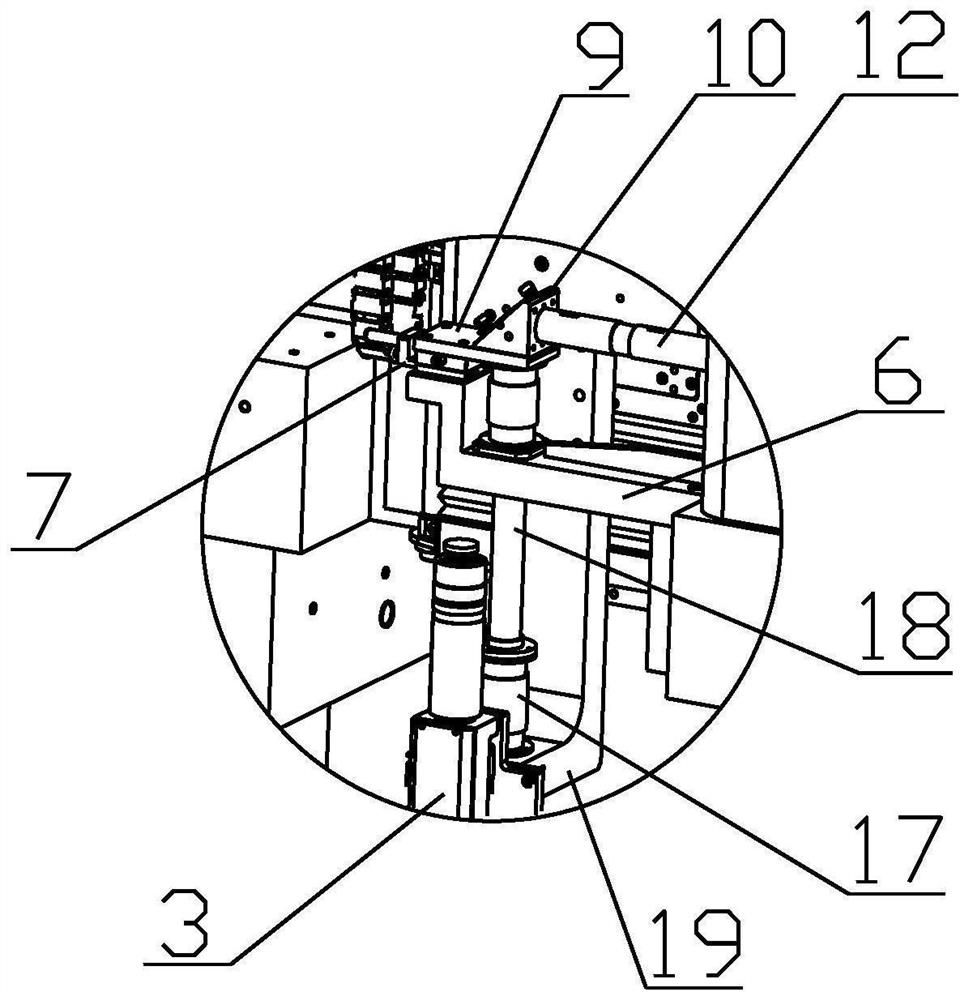

[0027] combine figure 1 , figure 2 As shown, a laser wafer cutting equipment includes a marble platform 1, an air flotation platform 2, an X-axis motion mechanism 4, a Y-axis motion mechanism 5, a Z-axis linear motor 11, a bracket 6, a slide table 7, a laser 8, and an installation Board 9, 45-degree mirror optical path assembly 10, beam splitting system 13, 45-degree mirror optical path assembly 14, cutting head 16 and cutting head support 19. The marble platform 1 includes a primary platform 1a and a secondary platform 1b arranged on the primary platform 1a. Please combine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com