Gear-selecting and gear-shifting executive mechanism for automatic transmission

A technology for automatic transmissions and actuators, applied to mechanical equipment, transmission parts, components with teeth, etc., can solve the problems of complex structure, vibration and impact, and high precision requirements for upper and lower valve plates, so as to achieve high transmission efficiency, High reliability and good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

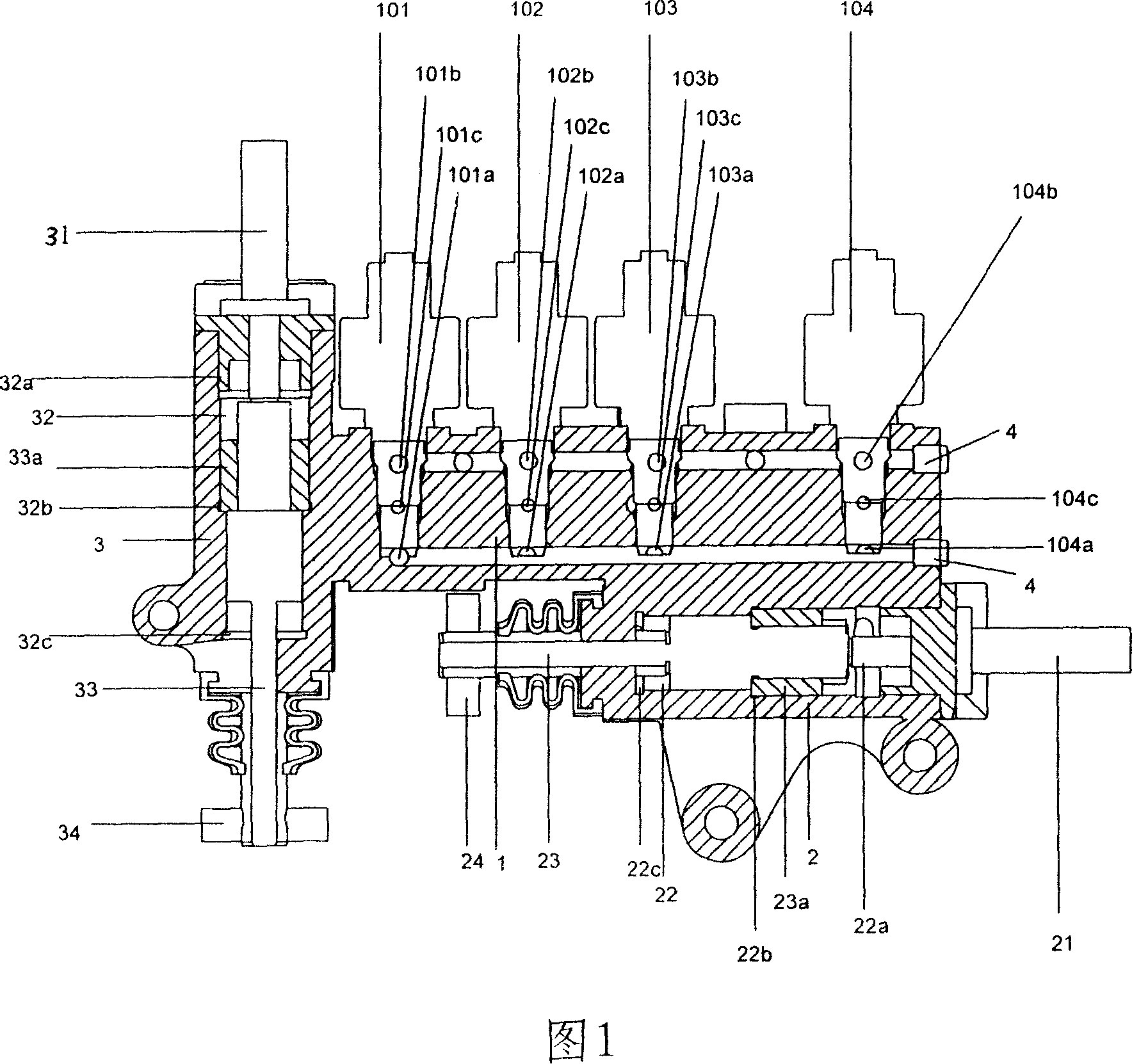

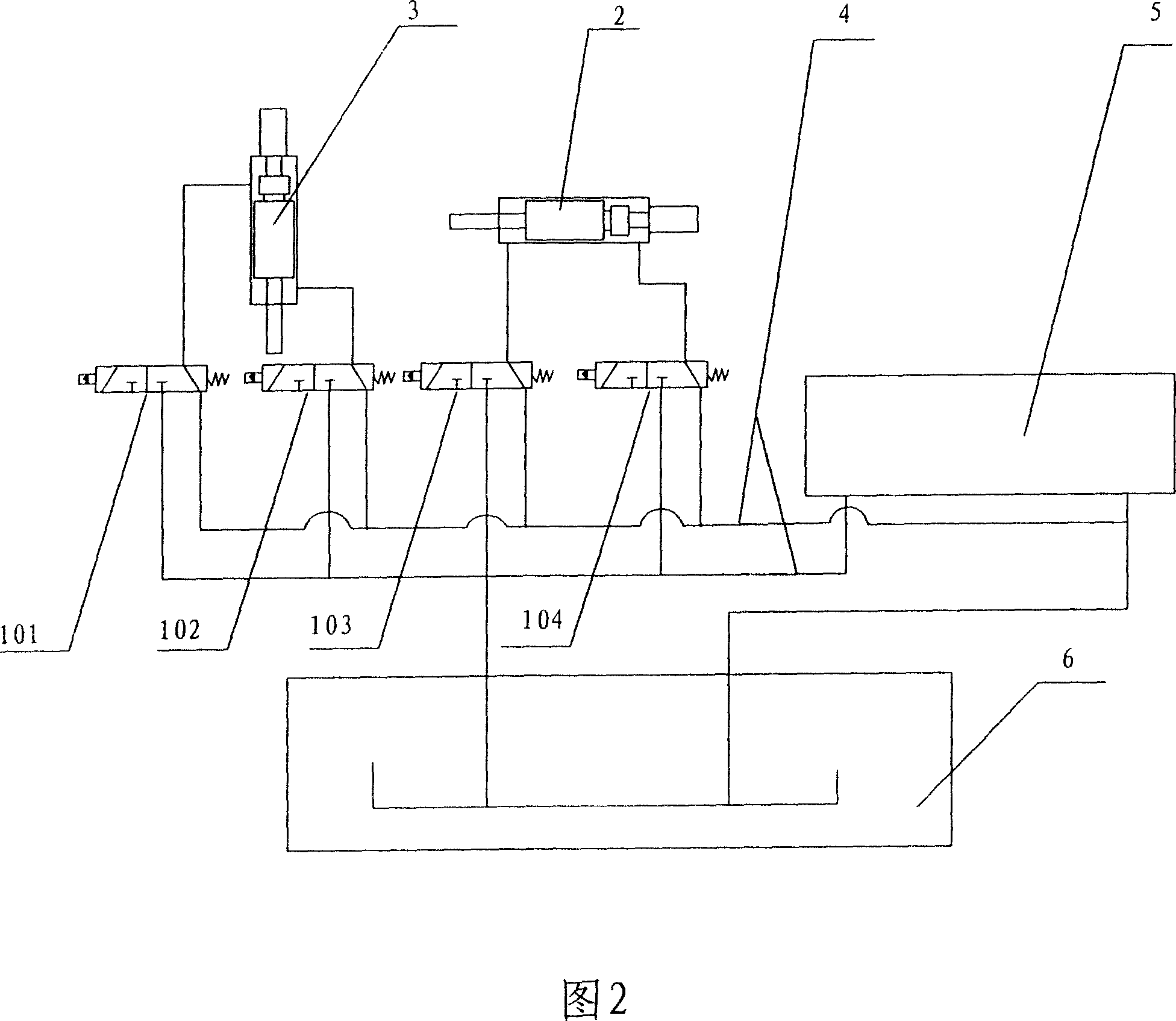

[0018] Referring to Fig. 1 and Fig. 2, the present invention is used for a gear selection and shift actuator of an automatic transmission, including a body 1, a gear selection device 2, a gear shift device 3, and a control valve block. The gear cylinder 22 is arranged orthogonally to the gear cylinder 32 of the gear shift device 3, and the gear selector 2, the gear shift device 3, and the control valve block are integrated on the body 1 to form an integral part. It communicates with the clutch actuator 5 and the power source 6 through the system oil passage 4 .

[0019] The gear selection device 2 includes: a gear selection displacement sensor 21, a gear selection cylinder 22, a gear selection plunger 23, and a gear selection rocker arm 24, wherein the sliding part of the gear selection displacement sensor 21 is connected to the gear selection column. The plug 23 is rigidly connected, and the gear selection displacement sensor 21 is fixedly connected to the rear end of the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com