Pin roller linear guide rail

A roller linear guide, guide rail technology, applied in the direction of linear motion bearings, shafts and bearings, bearings, etc., can solve the problems of poor integrity of the circulation system and bearing system, increased slider assembly time, processing and assembly errors, etc. The effect of shortening assembly time, increasing service life and eliminating assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

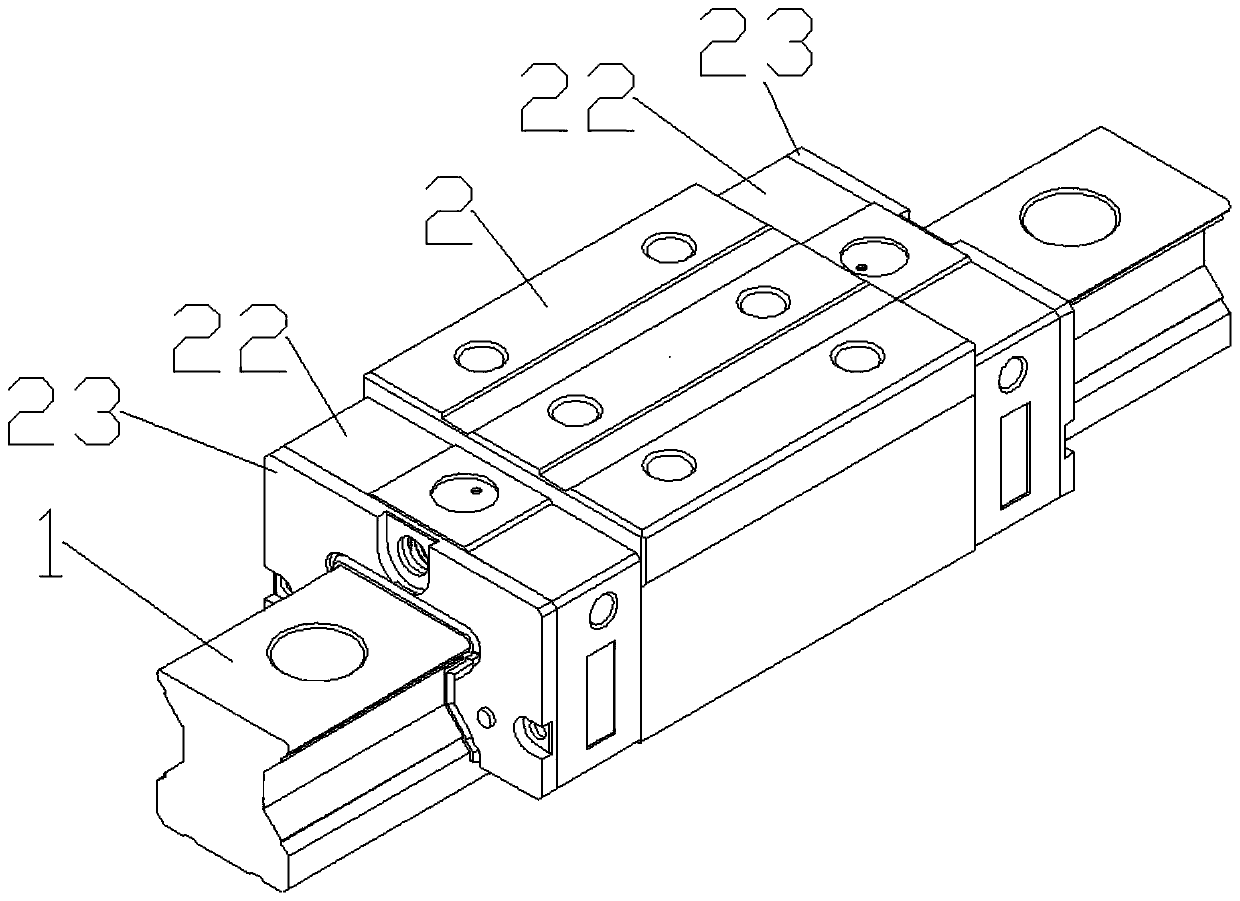

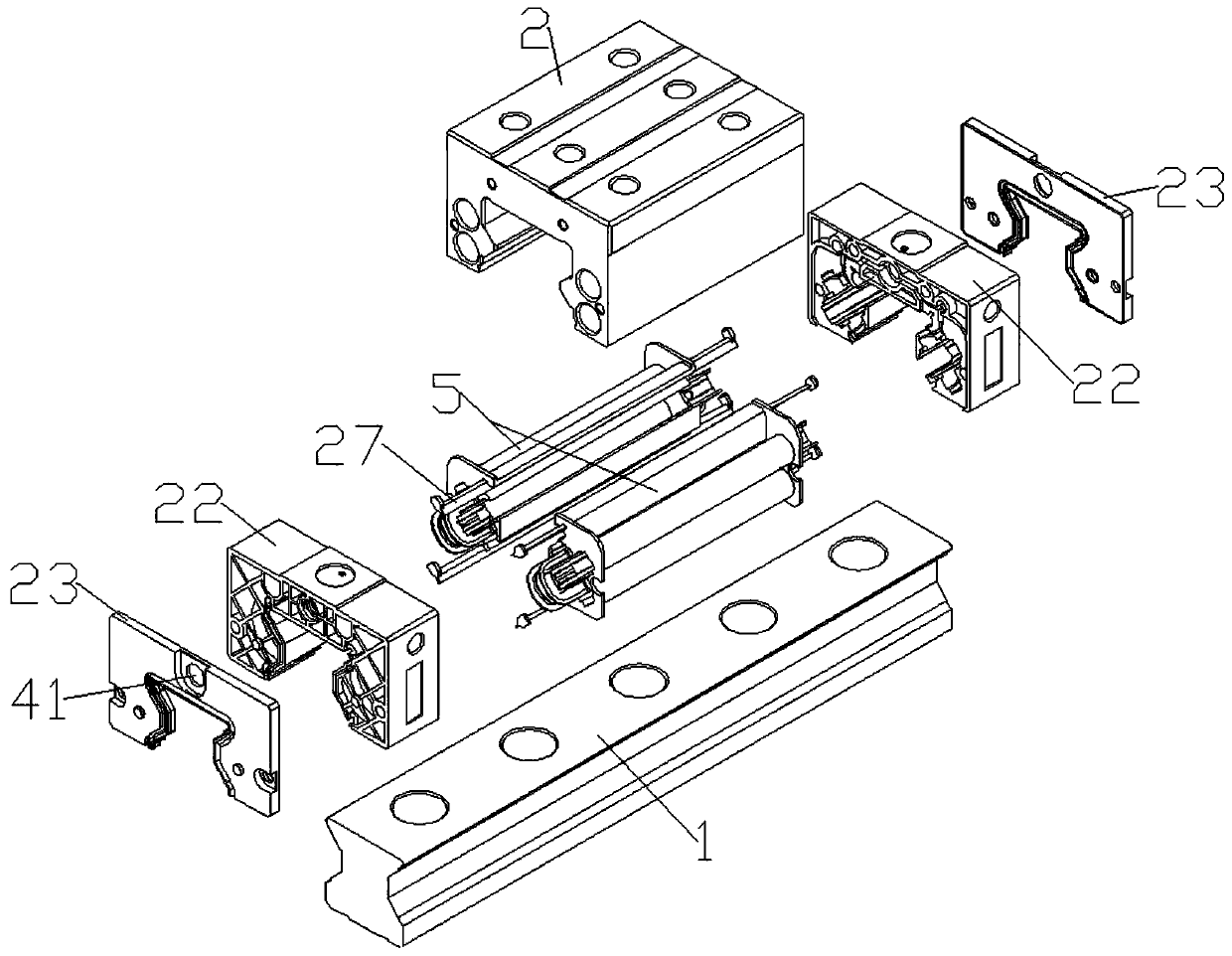

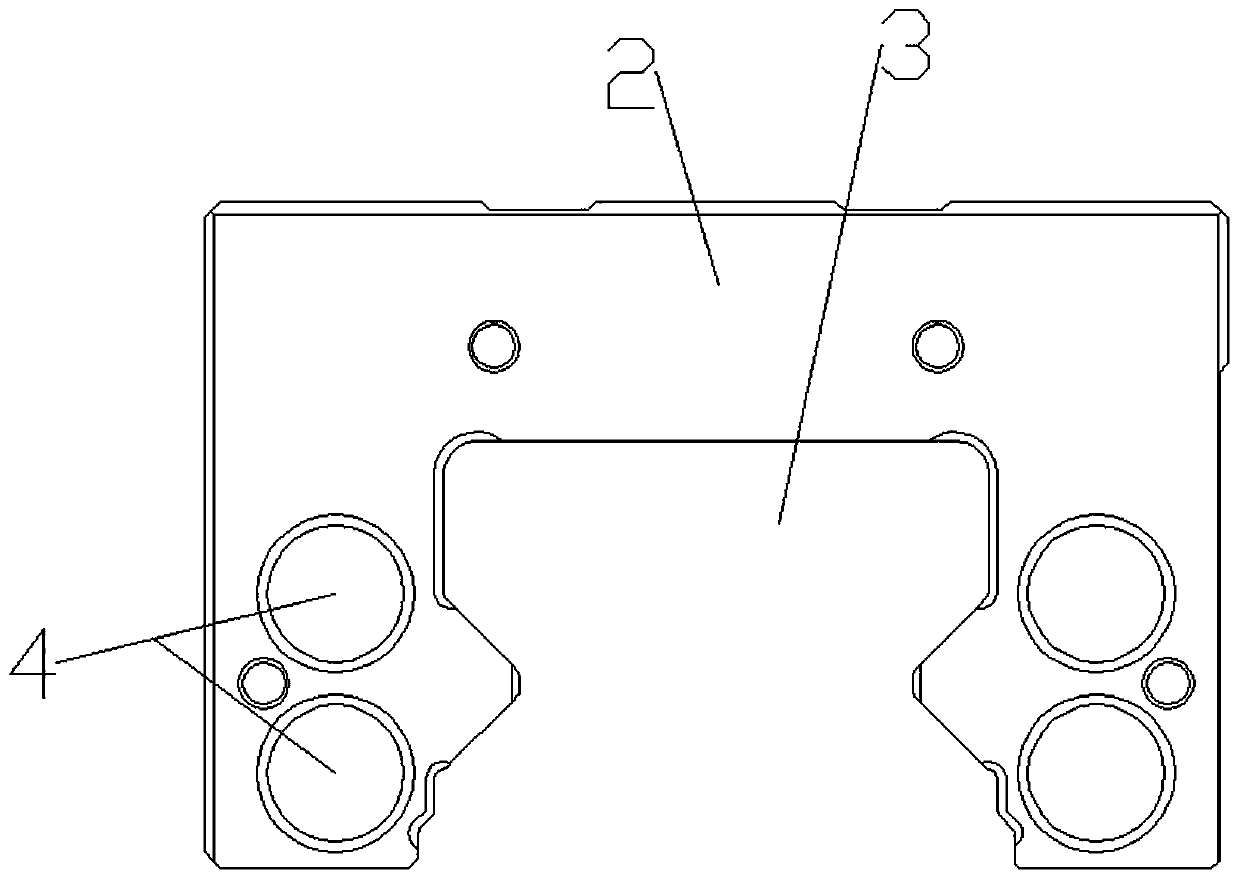

[0028] Refer to attached Figure 1-16: a kind of roller linear guide in the present embodiment, comprises guide rail 1, and described guide rail 1 upper end outer side is slidably connected with slider, and described slider comprises slider body 2, and the center position of described slider body 2 lower end is provided with installation Groove 3, the left and right sides of the installation groove 3 are respectively provided with two upper and lower circulation passages 4 opened on the inside of the slider body 2, and the left and right sides of the slider body 2 are provided with symmetrical holes about the center of the slider body 2. Circulation device 5, the circulation device 5 at the left end includes a return pipe 6 located inside the circulation channel 4, the front and rear ends of the return pipe 6 are provided with clamping plates 7 located at the front and rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com