Optical fiber connector

An optical fiber connector and optical fiber technology, which is applied in the coupling of optical waveguides and other directions, can solve the problems of long time curing, time-consuming production, and many assembly process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

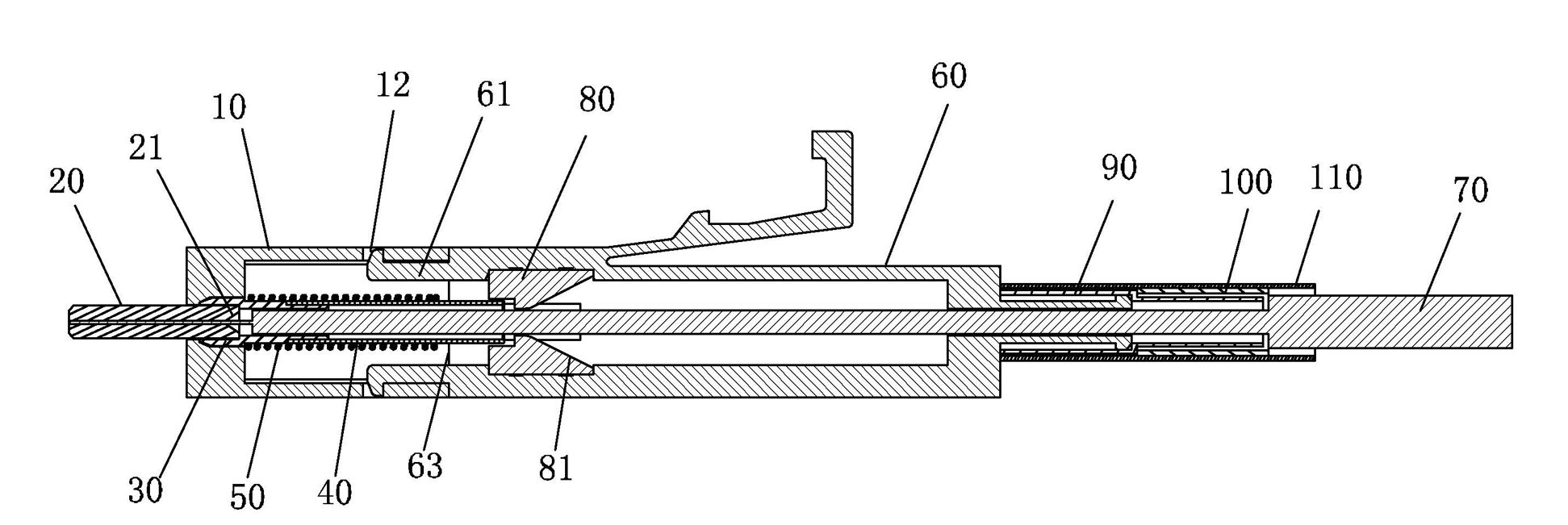

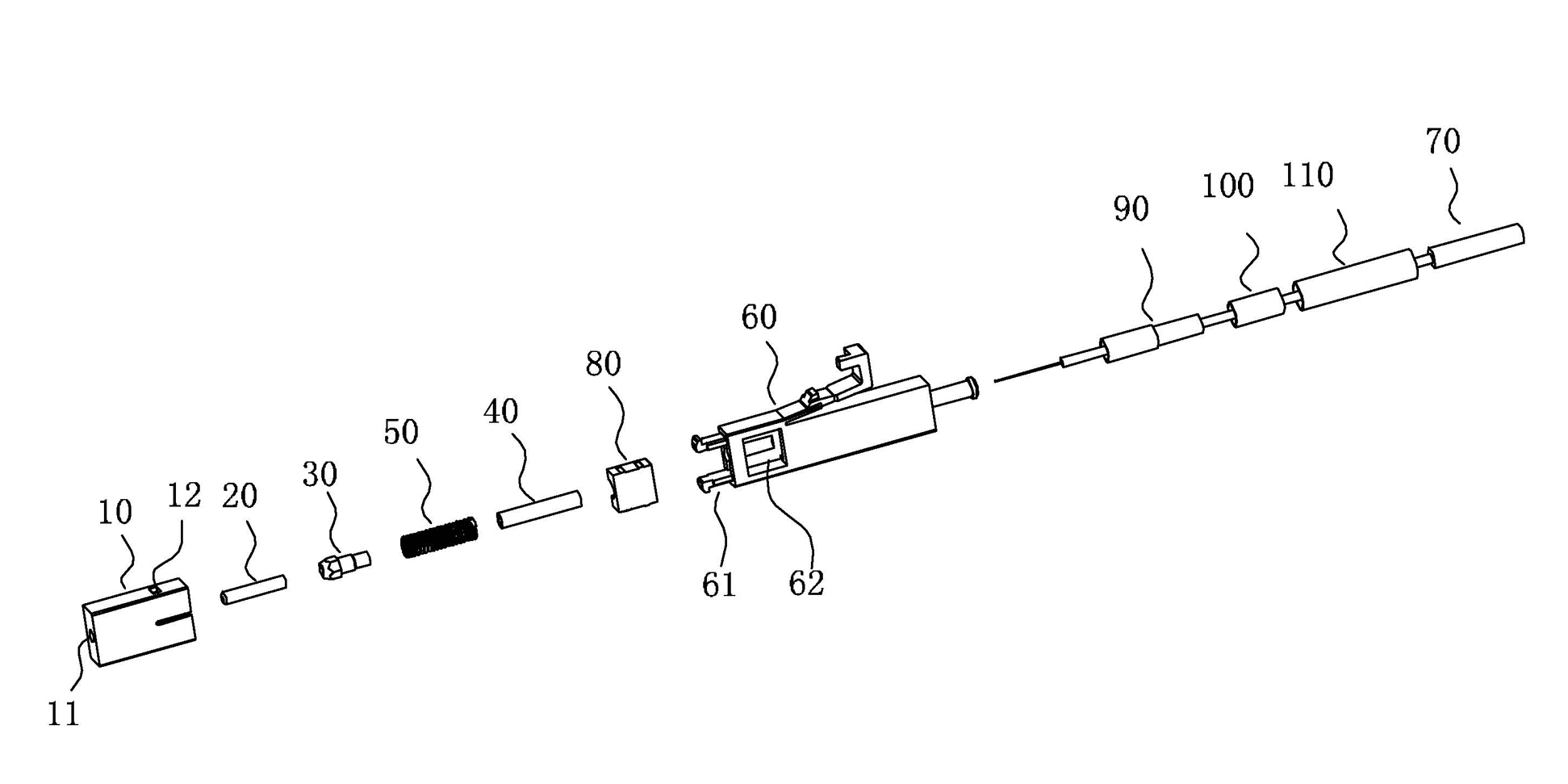

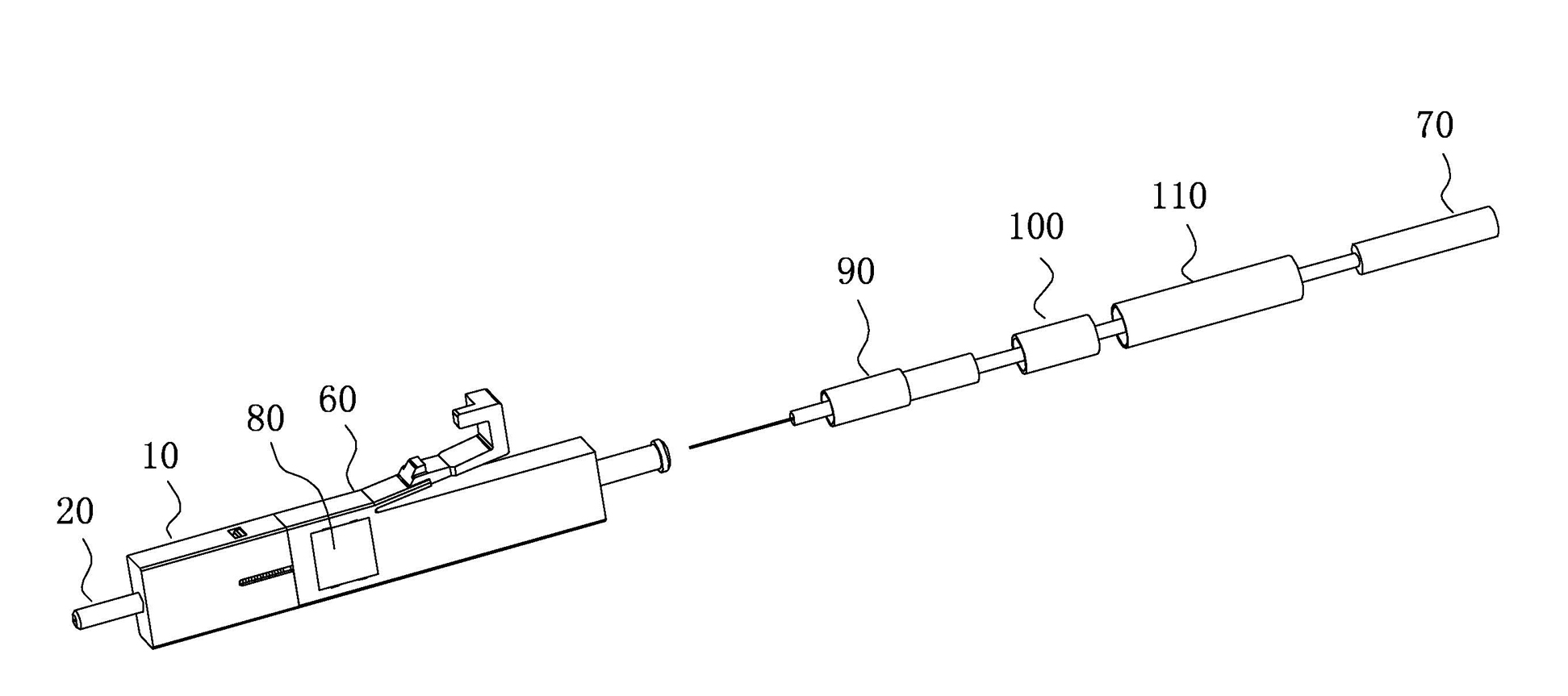

[0015] Figure 1-4 As shown, the optical fiber connector of the present invention includes: a ceramic ferrule housing 10, a ceramic ferrule 20, a spring 50, and a housing body 60; when assembling, a fixing glue is dropped into the core hole of the ceramic ferrule 20, After the ceramic ferrule housing 10 and the housing body 60 are snap-connected to each other, after the processed optical fiber 70 passes through the housing body 60 in turn, the core of the front end of the optical fiber 70 is inserted into the core hole in the ceramic ferrule 20 Inside.

[0016] Such as Figure 1-3 In the first embodiment of the optical fiber connector shown, a cavity is opened inside the ceramic ferrule housing 10, the rear end of the ceramic ferrule housing 10 is opened, and the front end of the ceramic ferrule housing 10 is opened for the ceramic ferrule 20 to pass through. Set the through hole 11; one end of the ceramic ferrule 20 is inserted and fixed to the front port of the ceramic ferrule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com