Method for determining assembly-oriented rectangular plane shape error evaluation parameters

A technology for evaluating parameters and plane shapes, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., and can solve the problems of many characterization parameters and difficult parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

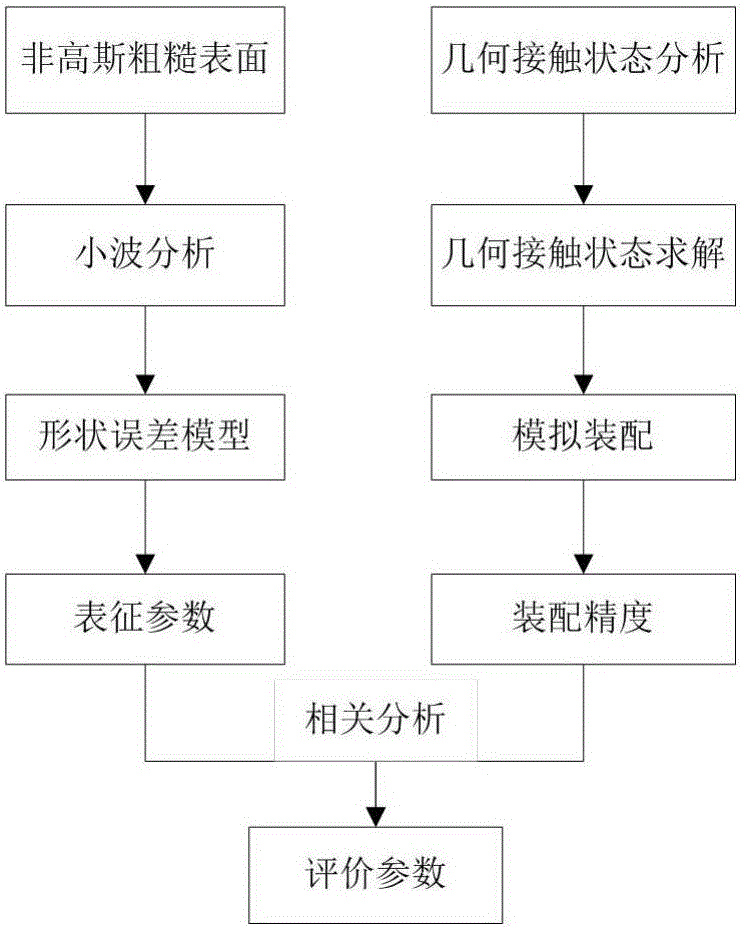

[0052] An assembly-oriented method for determining the evaluation parameters of rectangular planar shape errors, such as image 3 As shown, the specific steps are as follows:

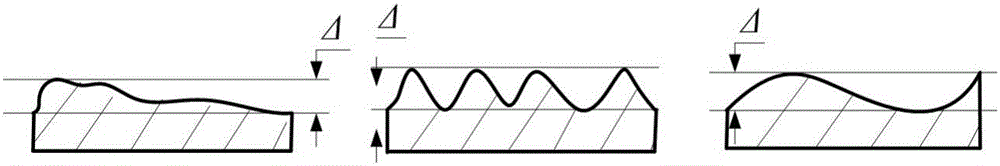

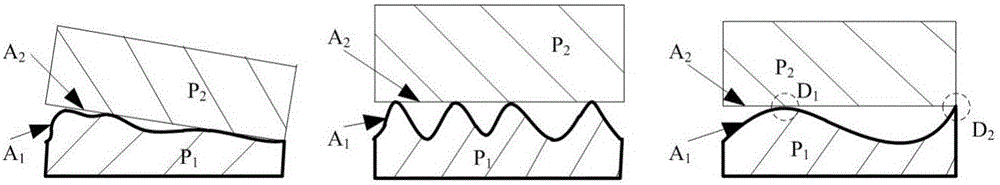

[0053] Step 1. The shape error of the part surface is obtained by the following method. The cutting surface is generated by the non-Gaussian plane simulation method, and the autocorrelation function R or the power spectral density function G of the given plane is used. z (ω x ,ω y ), get the system transfer function H(ω x ,ω y ), using the Johnson transformation system to obtain a random column η′ of non-Gaussian distribution with a certain skew and kurtosis, and using a computer to generate a non-Gaussian rough plane. Afterwards, the shape error surface is obtained by wavelet filtering; wavelet analysis is used, and the basis function Bior6.8 is used as the decomposed wavelet basis function to perform multi-scale separation of the feature information of the part's plane shape, and the shape error p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com