Combined switch control system and control method

A combination switch and control system technology, which is applied in the direction of electric switches, vehicle maintenance, electrical components, etc., can solve the problems of complex wiring harness of combination switches, which is not conducive to cost saving and reliability, high temperature of switch contact points, etc., and achieves the improvement of assembly process performance, improved reliability and usability, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution, and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings.

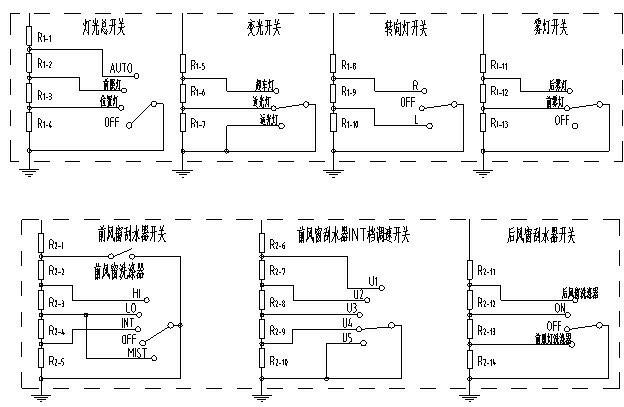

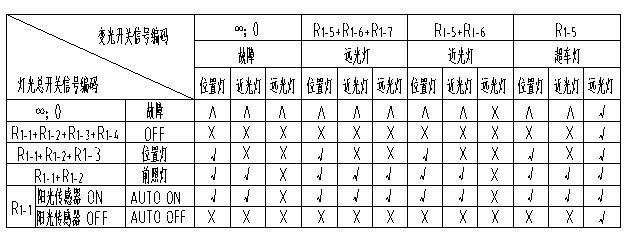

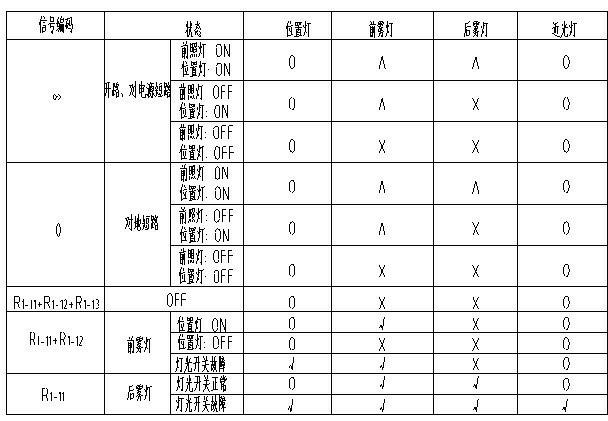

[0030] figure 1 It is a structural schematic diagram of the control system of the present invention. It can be seen from the figure that the combination switch control system includes a combination switch, BCM and controlled components. The output end of the combination switch is connected to the signal input end of the BCM, the combination switch receives the driver's control command and transmits the control command to the BCM in the form of a coded signal, the output end of the BCM is connected to the input end of the controlled component through the data bus, The BCM decodes the received encoded signal and edits it into a message and sends it to the data bus. The controlled component receives the message sent by the BCM from the data bus and performs correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com