Trigger resistance providing method, trigger structure and game device

A game device and trigger technology, applied in the field of trigger resistance, trigger structure and game device, can solve the problems of limited assembly space, inconvenient operation, space occupation, etc., meet the requirements of reducing assembly space, simple and convenient assembly process, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

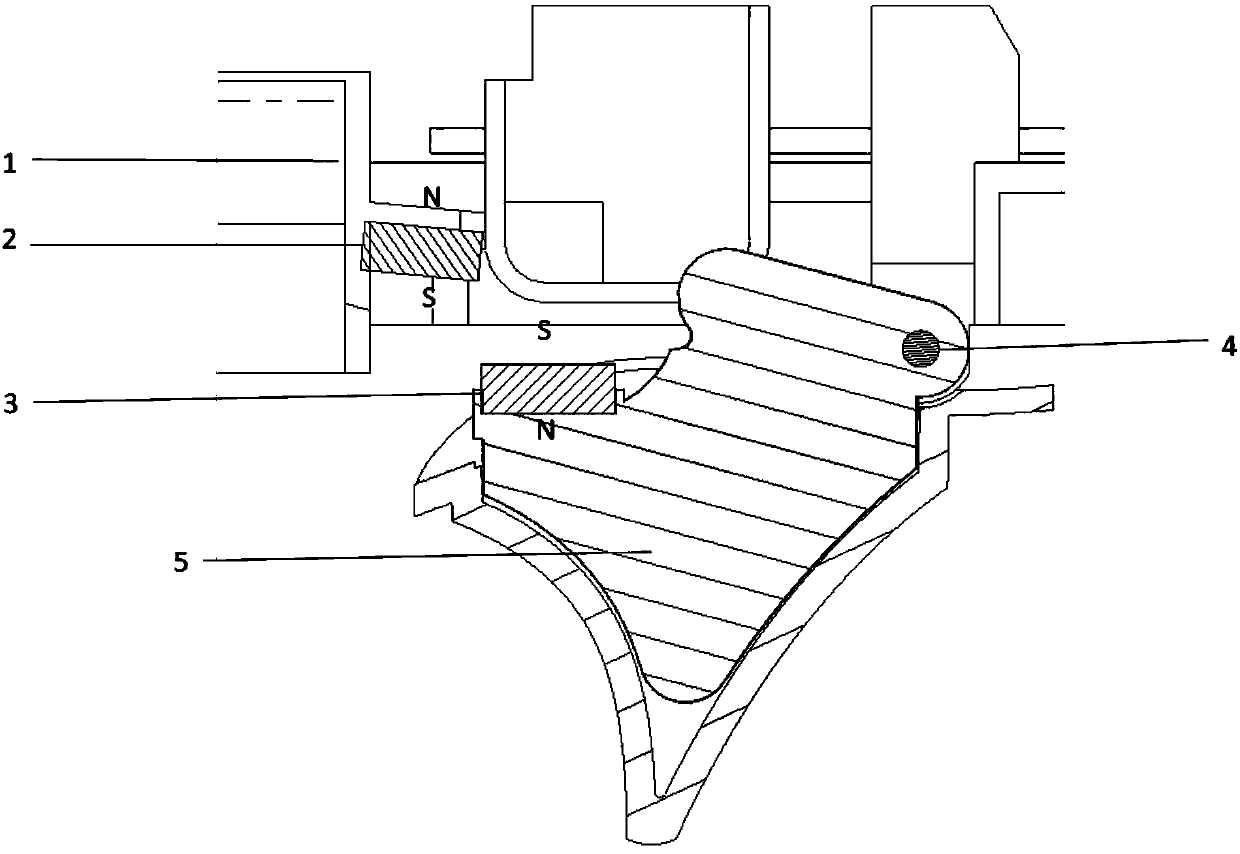

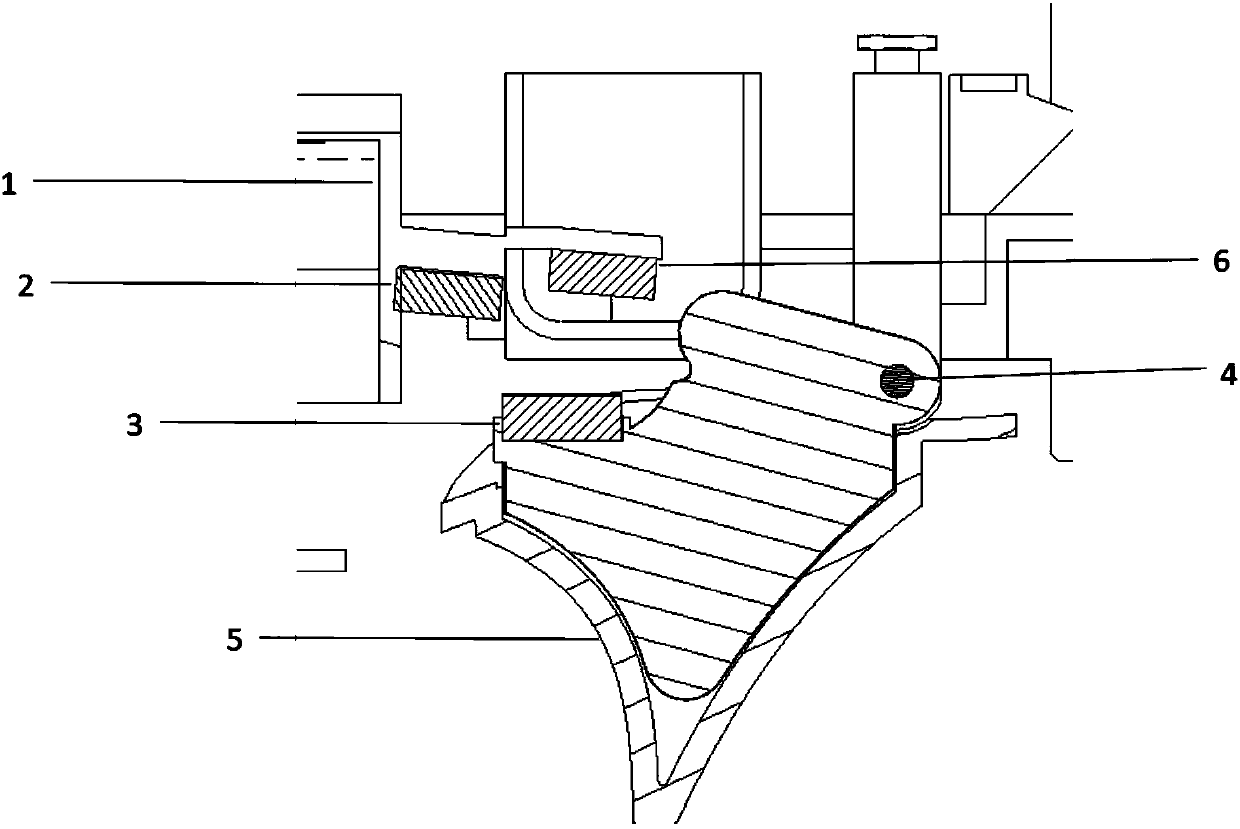

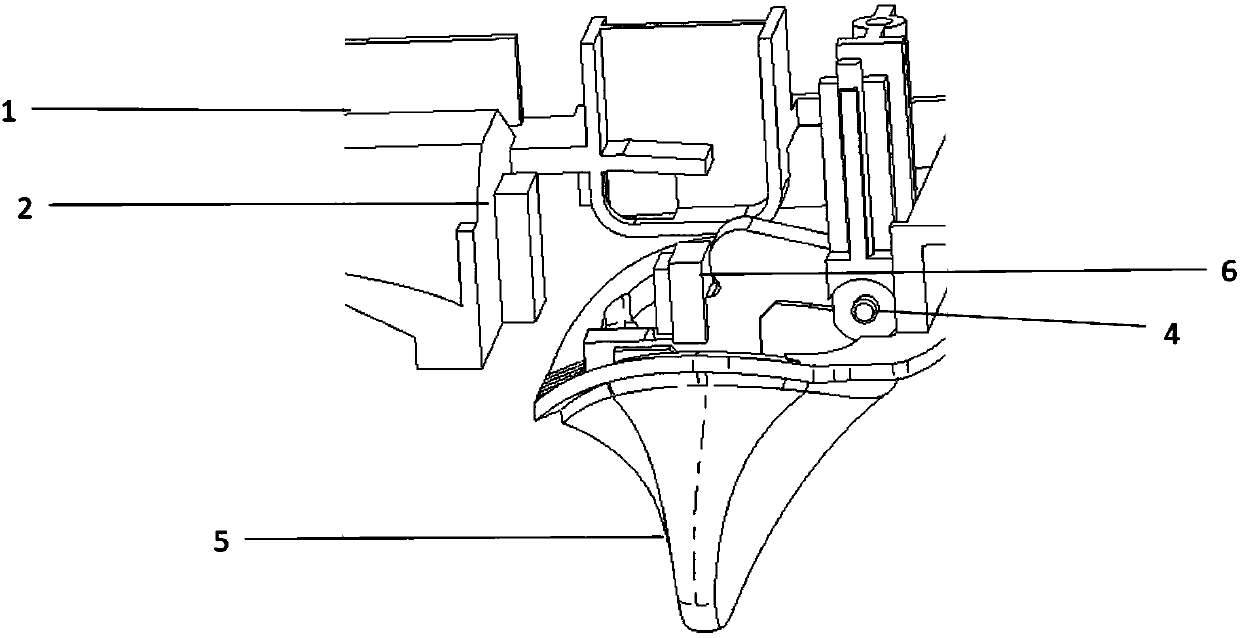

[0026] figure 1 It is a schematic diagram of a trigger structure of an embodiment of the present invention, such as figure 1 As shown, the trigger structure includes a main bracket 1, a trigger assembly 5 and a trigger shaft 4, and the trigger structure claimed in this application also includes a first magnet group 2 and a second magnet group 3;

[0027] The first magnet group 2 is arranged on the main bracket 1, and the second magnet group 3 is arranged on the trigger assembly 5;

[0028] When the trigger assembly 5 rotates around the trigger shaft 4, the distance between the first magnet group 2 and the second magnet group 3 changes, and the repulsive force between the first magnet group 2 and the second magnet group 3 also changes accordingly. The change in repulsive force provides trigger resistance.

[0029] It should be noted that when the trigger assembly 5 rotates to the maximum stroke (that is, the trigger rotates to the lowest point), the distance between the first...

Embodiment 2

[0040] Figure 4 is a schematic diagram of a game device according to an embodiment of the present invention, such as Figure 4 as shown,

[0041] game devices include figure 1 or figure 2 or image 3 Trigger structure shown.

[0042] In one embodiment of the invention, the gaming device may be a joystick.

Embodiment 3

[0044] Figure 5 is a flowchart of a method for providing trigger resistance in an embodiment of the present invention, such as Figure 5 as shown,

[0045] In step S110, a first magnet group is set on the main bracket of the trigger, and a second magnet group is set on the trigger assembly of the trigger;

[0046] In step S120, when the trigger assembly rotates around the trigger shaft, the distance between the first magnet group and the second magnet group changes, and the repulsive force between the first magnet group and the second magnet group also changes accordingly. The change in force provides trigger resistance.

[0047] In one embodiment of the present invention, the centers of the first magnet group and the second magnet group are arranged in the same vertical plane.

[0048] In one embodiment of the present invention, the magnetic properties of the first magnet group and the second magnet group are set so that when the trigger assembly is in the initial positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com