Method for gathering ships by calculating frames, half widths and heights with three-dimensional coordinates

A three-dimensional coordinate and rib position technology, applied in the field of shipbuilding, can solve the problems of large error accumulation, low precision and labor, and achieve the effects of small error accumulation, high precision and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

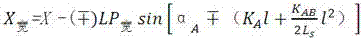

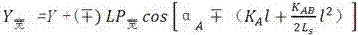

[0026] A method for closing a ship by calculating rib positions, half-widths and heights using three-dimensional coordinates, comprising the following steps:

[0027] (1) Coordinate system establishment:

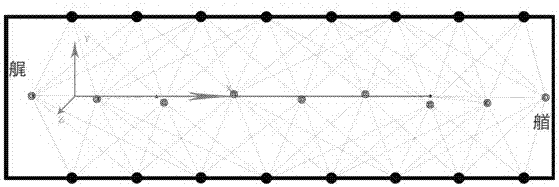

[0028] Establish the coordinate system of the stern axis of the ship according to the dock / sway, such as figure 1 shown.

[0029] A pair of control points are arranged every 30m on both sides of the dock / sway, and a certified total station (angle measurement accuracy ±0.5″, distance measurement accuracy ±0.6mm+1ppm) is used for field observation, and the measurement data is connected to the total station via Bluetooth. It is automatically recorded in the dock / sway stern axis coordinate system establishment software, and the observations are made according to the following technical indicators:

[0030] Ø The total station should have the functions of automatic collimation, automatic observation and automatic recording, and its nominal accuracy should meet: the direction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com