Assembly process of blind hole tool with high precision requirement

An assembly process and high-precision technology, applied in the field of mechanical processing, can solve the problems of inability to meet hole accuracy and surface roughness, high dependence on the level of workers' assembly skills, and difficulty in meeting assembly requirements, so as to improve manufacturing processability and assembly. Qualified rate, quality stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

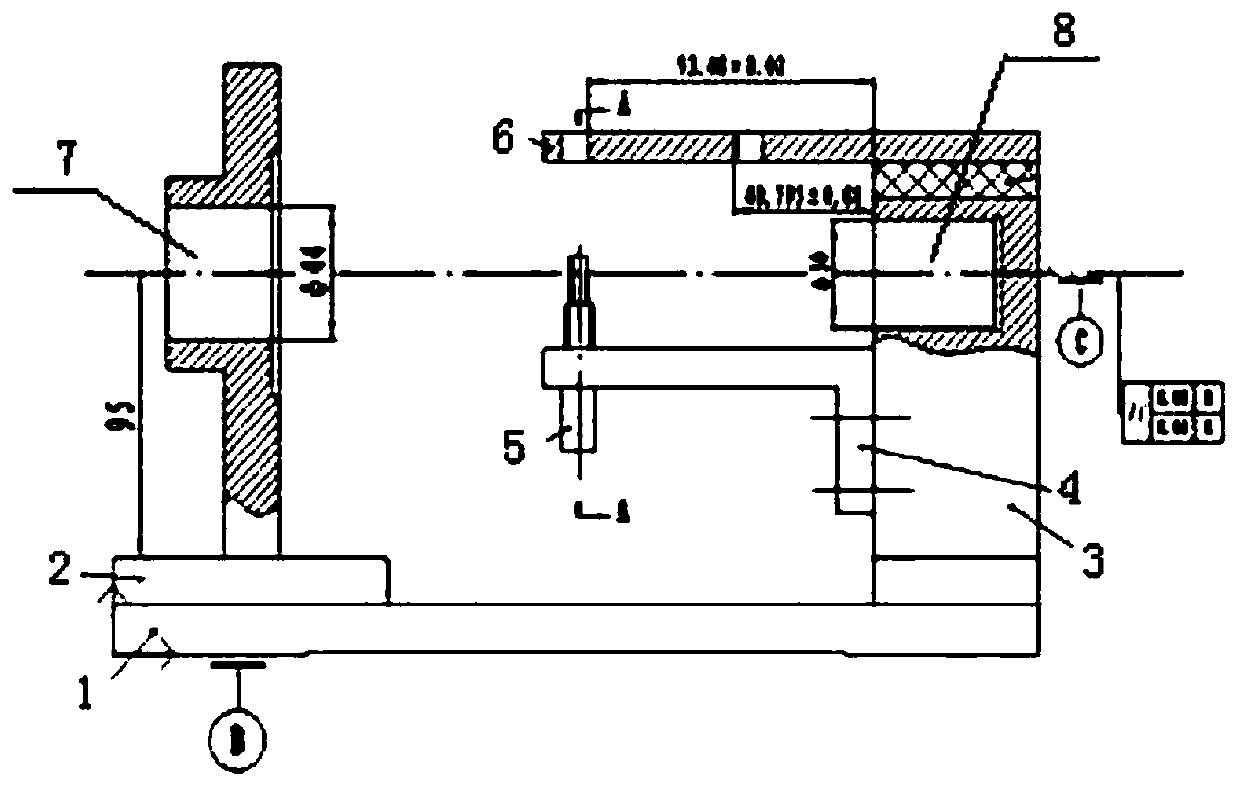

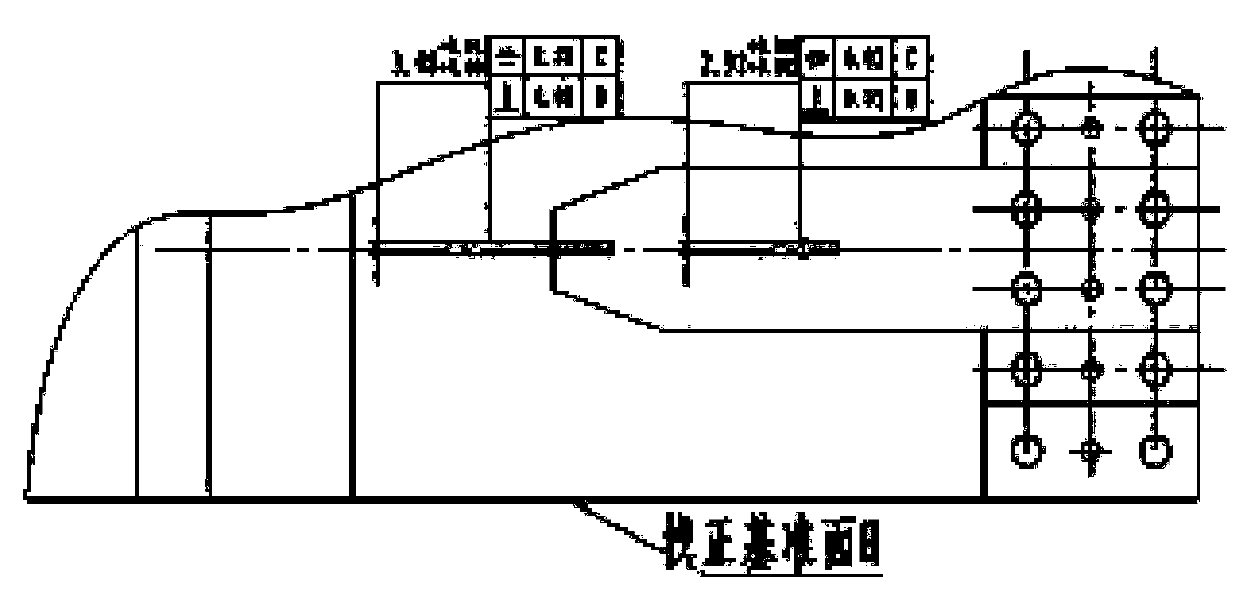

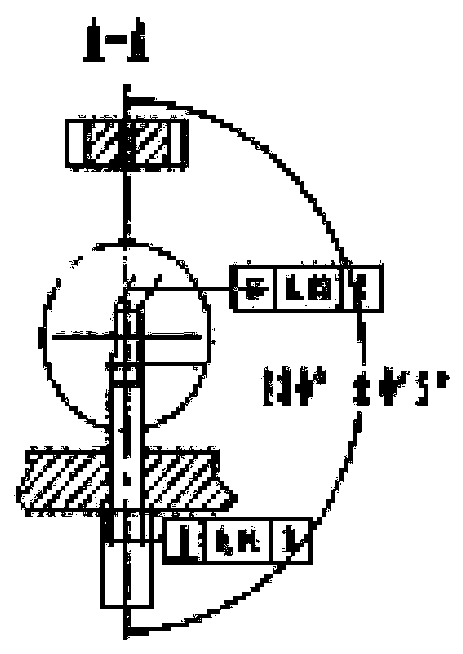

[0055] The invention provides an assembly process of blind hole tooling with high precision requirements, which specifically includes the following steps:

[0056] 1) The base 1 blank is provided in the form of No. 45 steel sheet. When rough machining, leave 0.5-0.6mm allowance in the thickness direction (board size 17×124×336), and leave 0.3mm grinding allowance for the front side, and normalize the material. After quenching, cleaning, aging heat treatment, rough grinding, fine grinding on both sides of the thickness and alignment, to fully eliminate the deformation after heat treatment, to ensure that the parallelism of the two sides of the thickness is within 0.01mm, and the perpendicularity to the alignment reference plane is within 0.005mm;

[0057] 2) The blank of the support plate 2 is provided in the form of No. 45 steel forgings. During rough machining, the full shape is milled, leaving 0.4-0.5mm allowance in the thickness direction, and 0.3mm allowance on the bottom s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com