Device for checking meshing clearance of central transmission bevel gear

A bevel gear, central technology, applied in the field of aero-engine assembly, can solve the problems of cumbersome and inefficient adjustment of the loading force, and achieve the effects of precise controllable axial loading force of bevel gears, good repeatability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

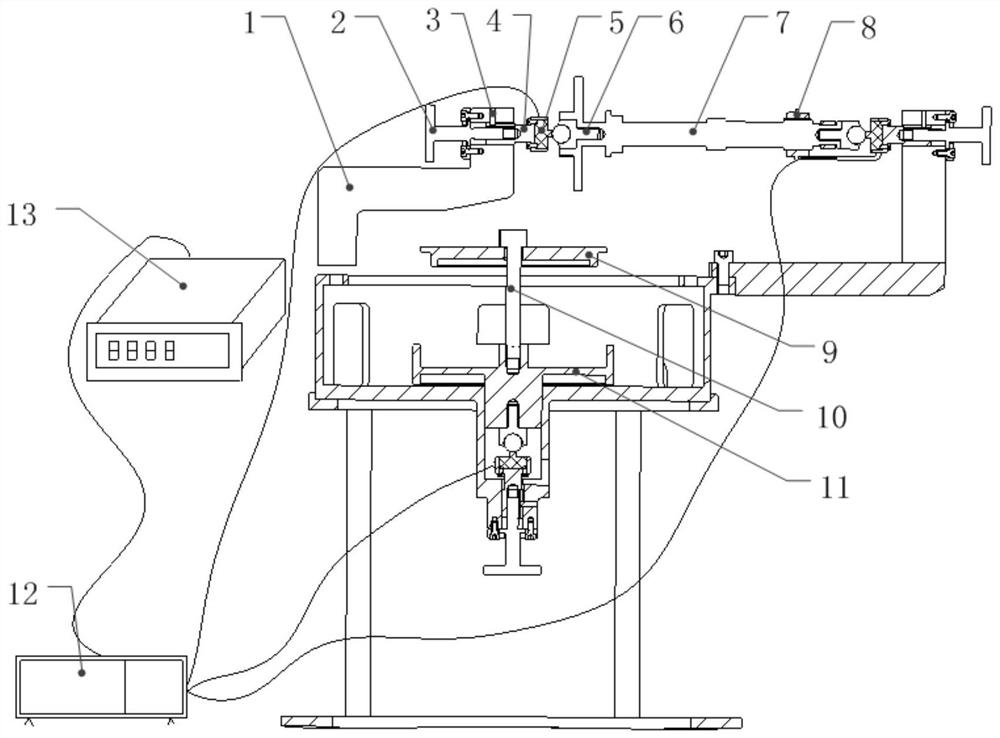

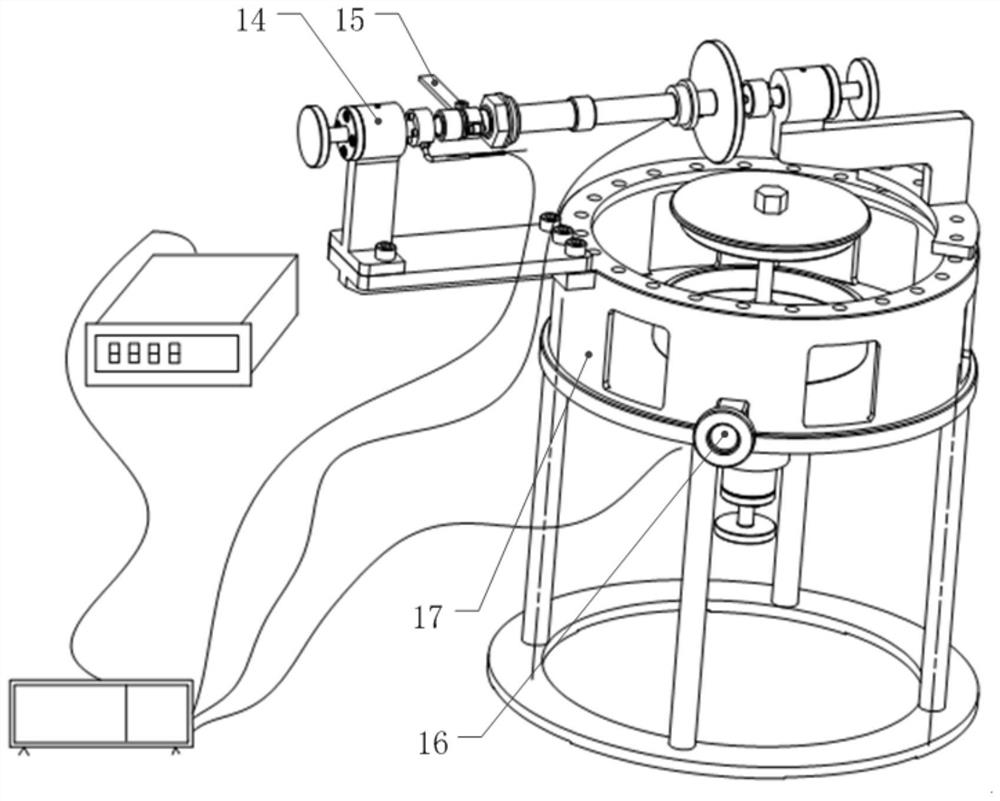

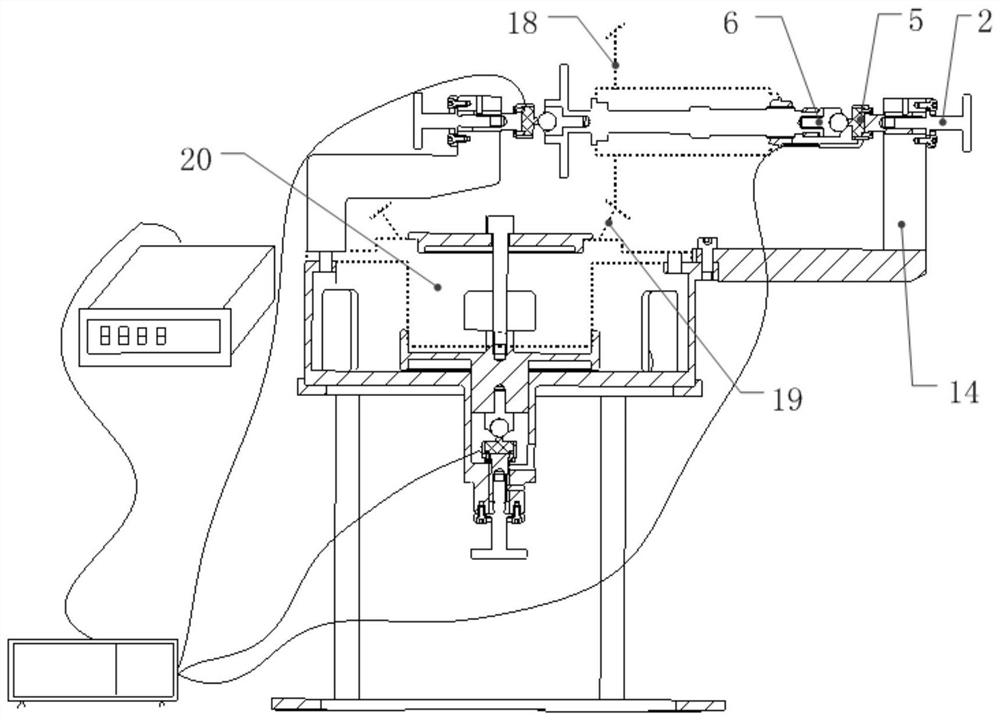

[0022] The central transmission device is the main transmission device for power extraction of the jet aircraft engine. It is usually installed on the front journal of the compressor. It has the characteristics of high power transmission, high speed, and large impact load. The meshing clearance value of the central transmission bevel gear is unreasonable or Bad meshing marks will directly lead to incorrect meshing of bevel gears, which will damage or break the teeth when the engine is started or working.

[0023] At present, in the practice of aero-engine assembly, the coloring inspection of spiral bevel gears is the only way to ensure that the tooth surface contact marks of the gear pair under the rated load are distributed symmetrically along the pitch line along the entire length of the tooth width with the expected coloring marks. The central transmission bevel gear meshing clearance inspection device generally has engineering problems such as complex structure, poor repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com