LRM (Line Replaceable Module) module locking and plugging device

A locking and sliding block technology, applied in elastic/clamping device, component plug-in combination, circuit layout on support structure, etc. Reliable performance, eliminate machining and assembly errors, and automatically adjust the effect of tightening distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

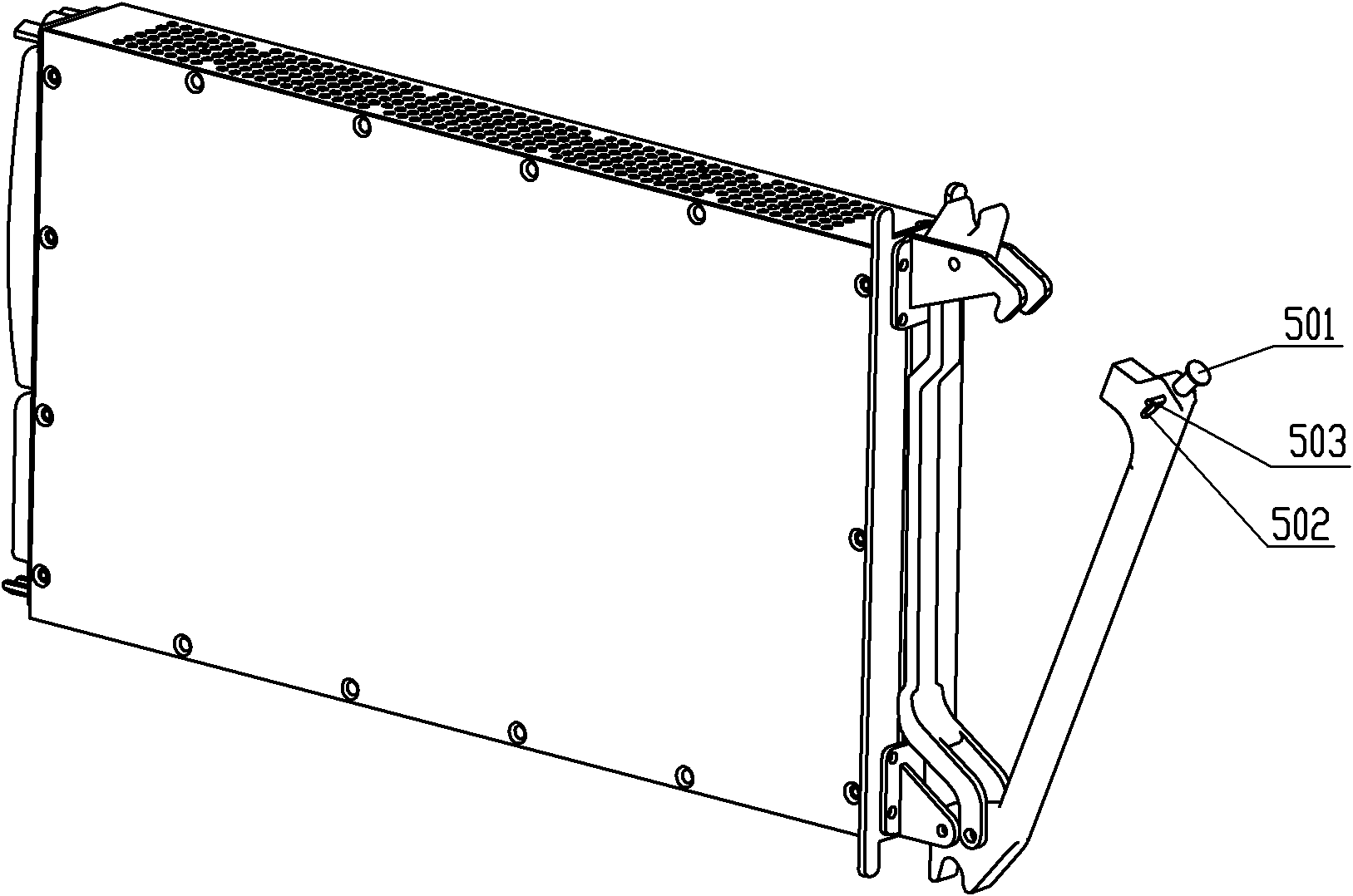

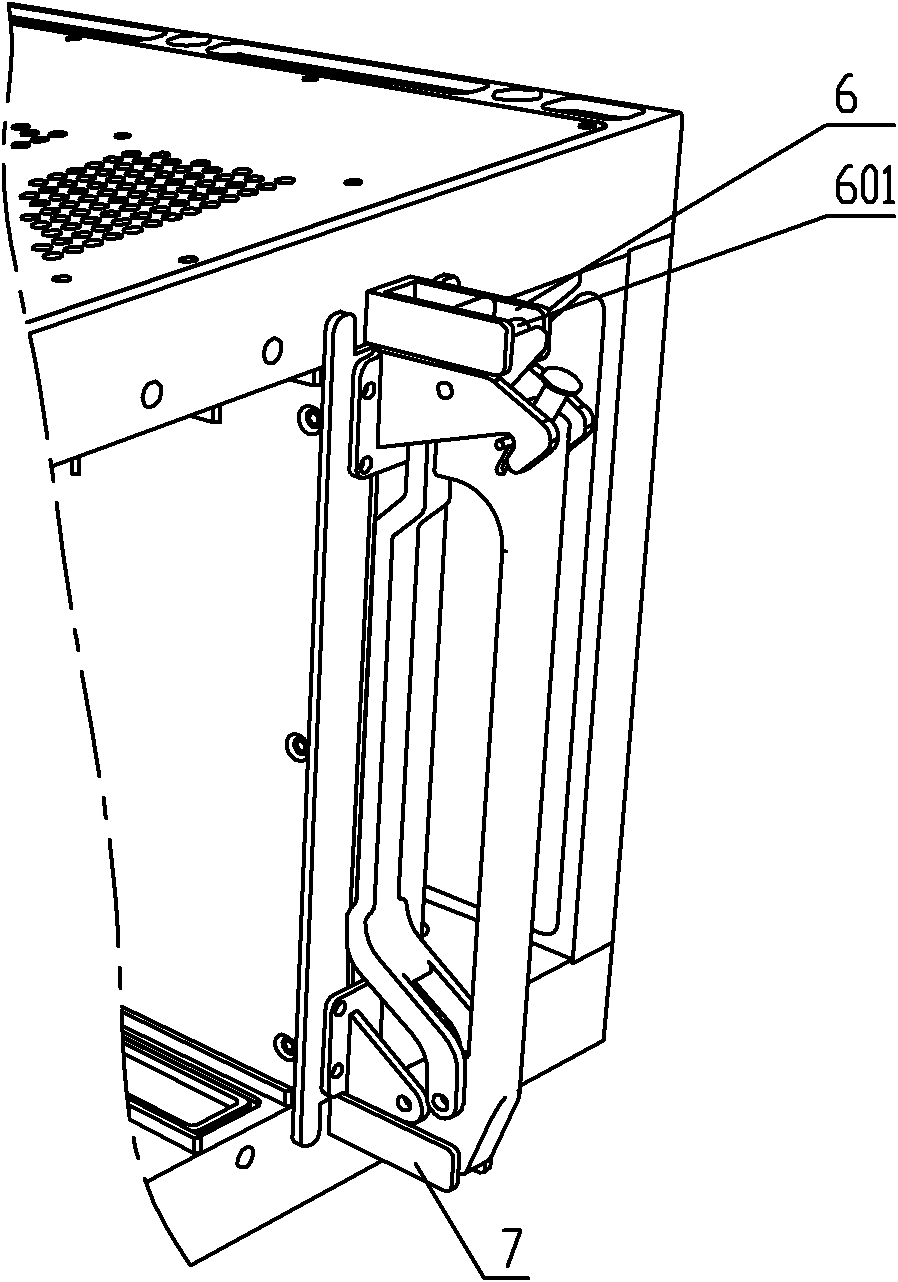

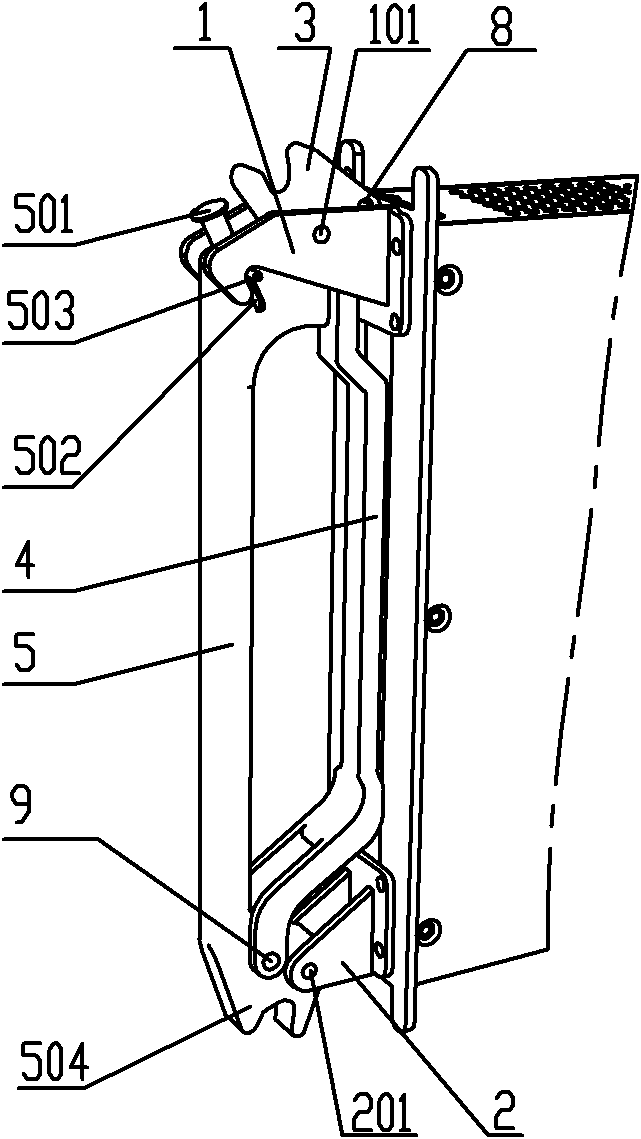

[0024] The invention is mainly applied to the integrated rack and LRM module of airborne electronic equipment, provides reliable and fast structural interconnection function for airborne electronic equipment, and provides structural guarantee for quick replacement and installation of products in the field.

[0025] A locking and plugging device for an LRM module, which is composed of a fork assembly fixed on the frame and a plug assembly fixed on the LRM module; It is composed of the lower end fork bar, and the upper and lower fork mouths are respectively rigidly connected with the first pin and the second pin along the horizontal direction; the plug-in assembly includes an upper hook, a concave wheel part, a lower hook, an inner connecting rod and The push rod is fixed on the LRM module through the back of the upper hook and the lower hook; the upper hook and the lower hook are connected horizontally with the first pin shaft and the second pin shaft respectively, and the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com