High-precision combined calibration and butt-joint method and mechanism for infrared imaging system

A technology of infrared imaging system and docking mechanism, which is applied in the direction of optical components, optics, instruments, etc., can solve the problem that the optical axis of the optical imaging system and the center of the imaging focal plane cannot guarantee the perpendicularity precision of the optical axis of the optical imaging system and the target surface of the imaging focal plane The coincidence accuracy of the normal line coincides with the accuracy of the image plane of the optical imaging system and the imaging focal plane to achieve the effect of eliminating assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

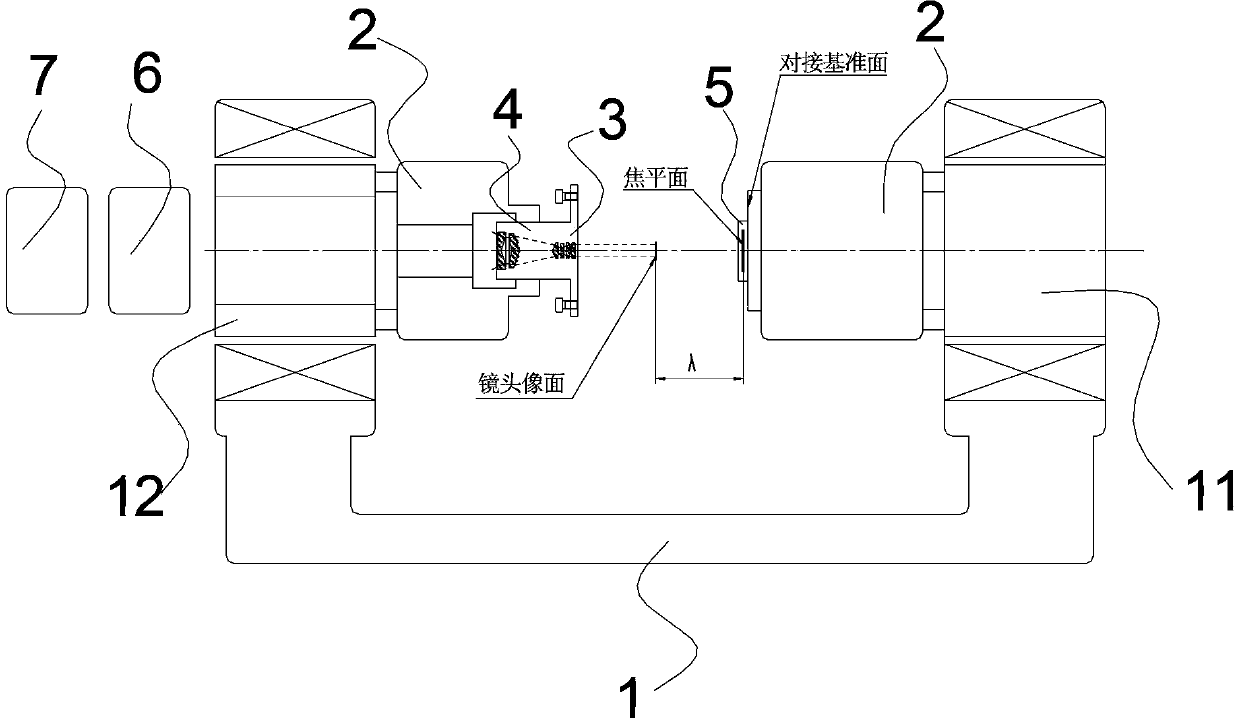

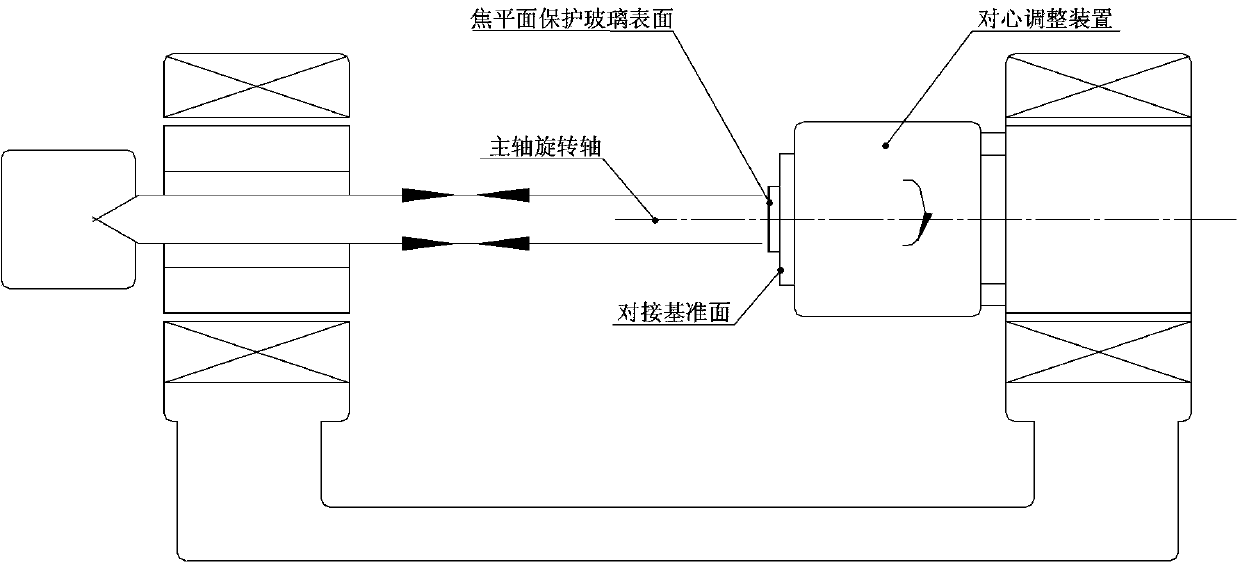

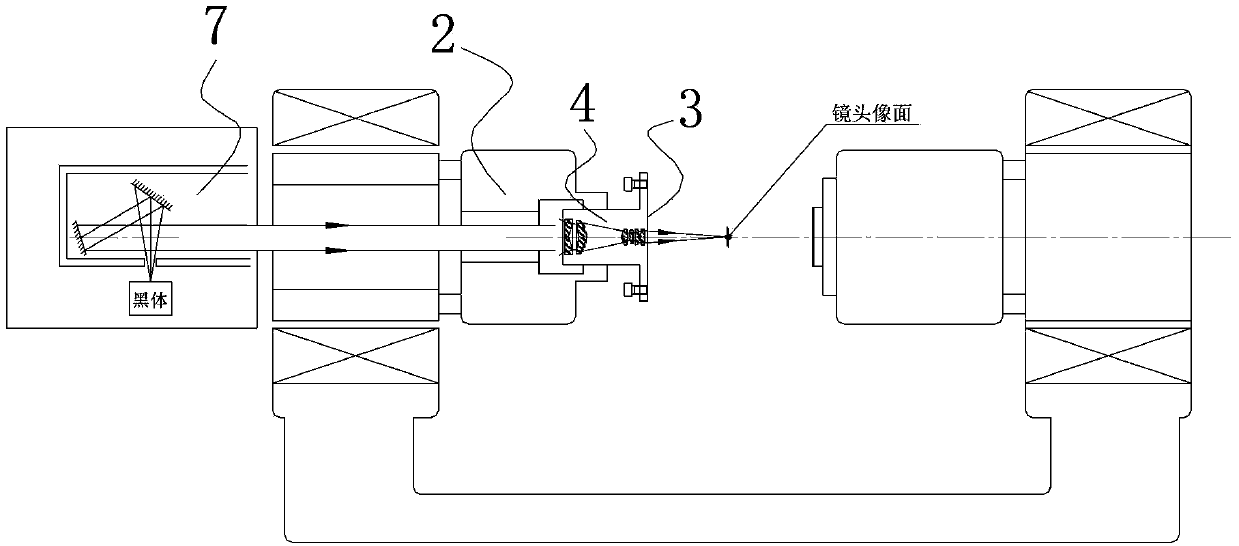

[0028] The invention system consists of borrowing a high-precision two-axis horizontal or two-axis vertical lathe as a platform, such as figure 1 As shown, each of its two rotation axes is fixed with an optical centering adjustment device that can realize four-degree-of-freedom adjustment, and the optical lens is fixed on the optical centering adjustment device close to the surface source black body, infrared collimator and internal focusing centering device , the object plane of the optical lens faces the collimator and the inner focusing and centering instrument; the focal plane component is fixed on another optical centering adjustment device, and its focal plane faces the direction of the collimator and the inner focusing and centering instrument.

[0029] The method of the invention specifically comprises the following steps:

[0030] 1. Adjust the parallelism between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com