Portable modular self-correcting rail three-dimensional detection system

A three-dimensional detection and modular technology, applied in the direction of railway vehicle shape measuring instrument, railway car body parts, railway auxiliary equipment, etc., can solve the problems of assembly error, influence measurement results, easy to leave fit gap, etc., to eliminate installation errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

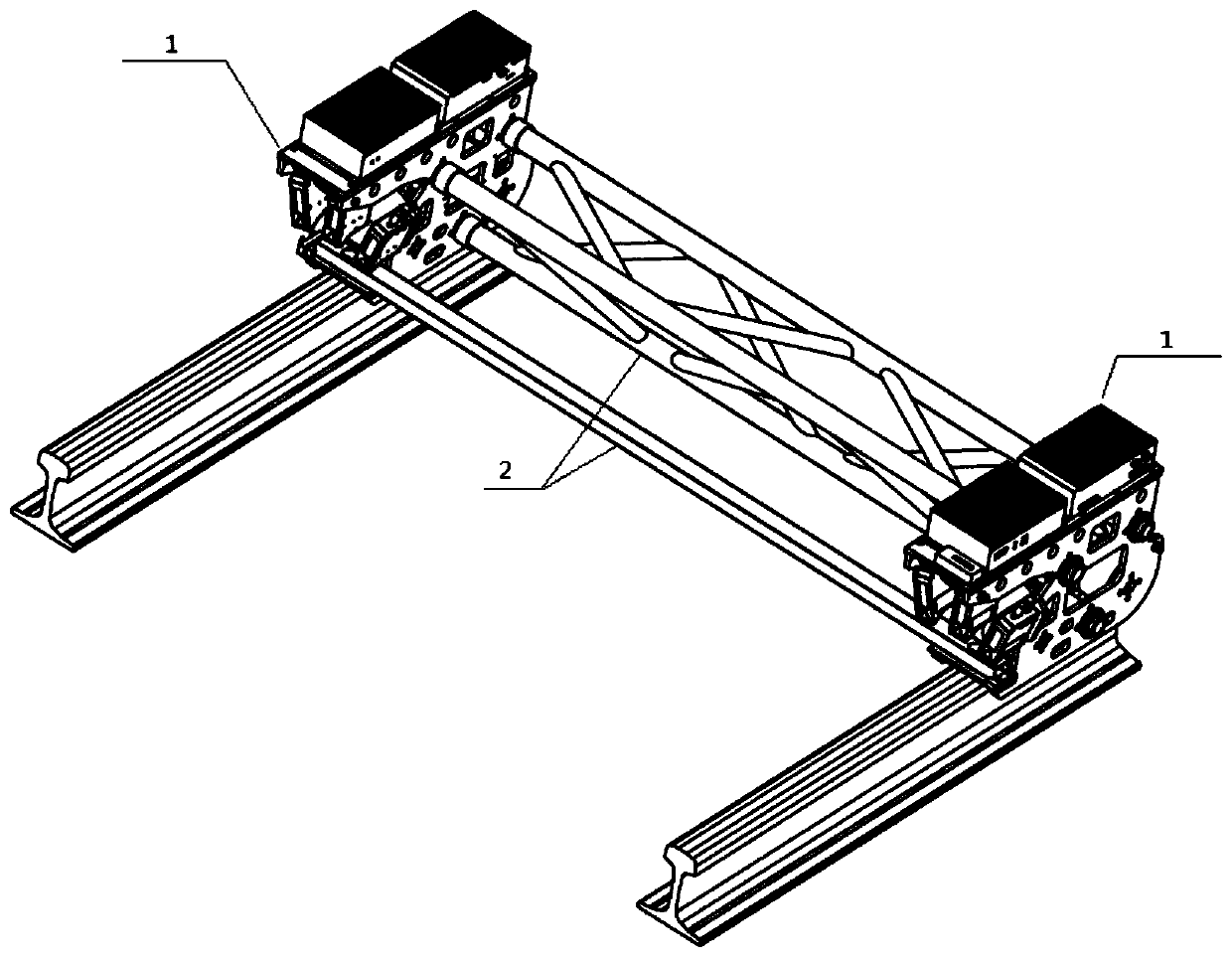

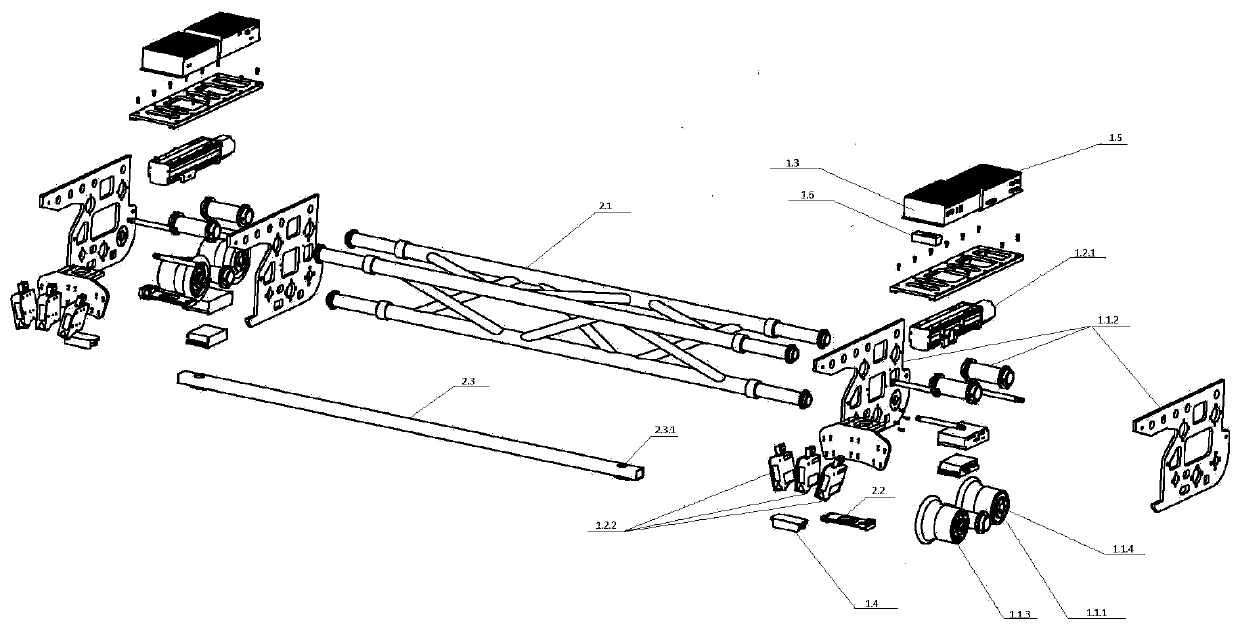

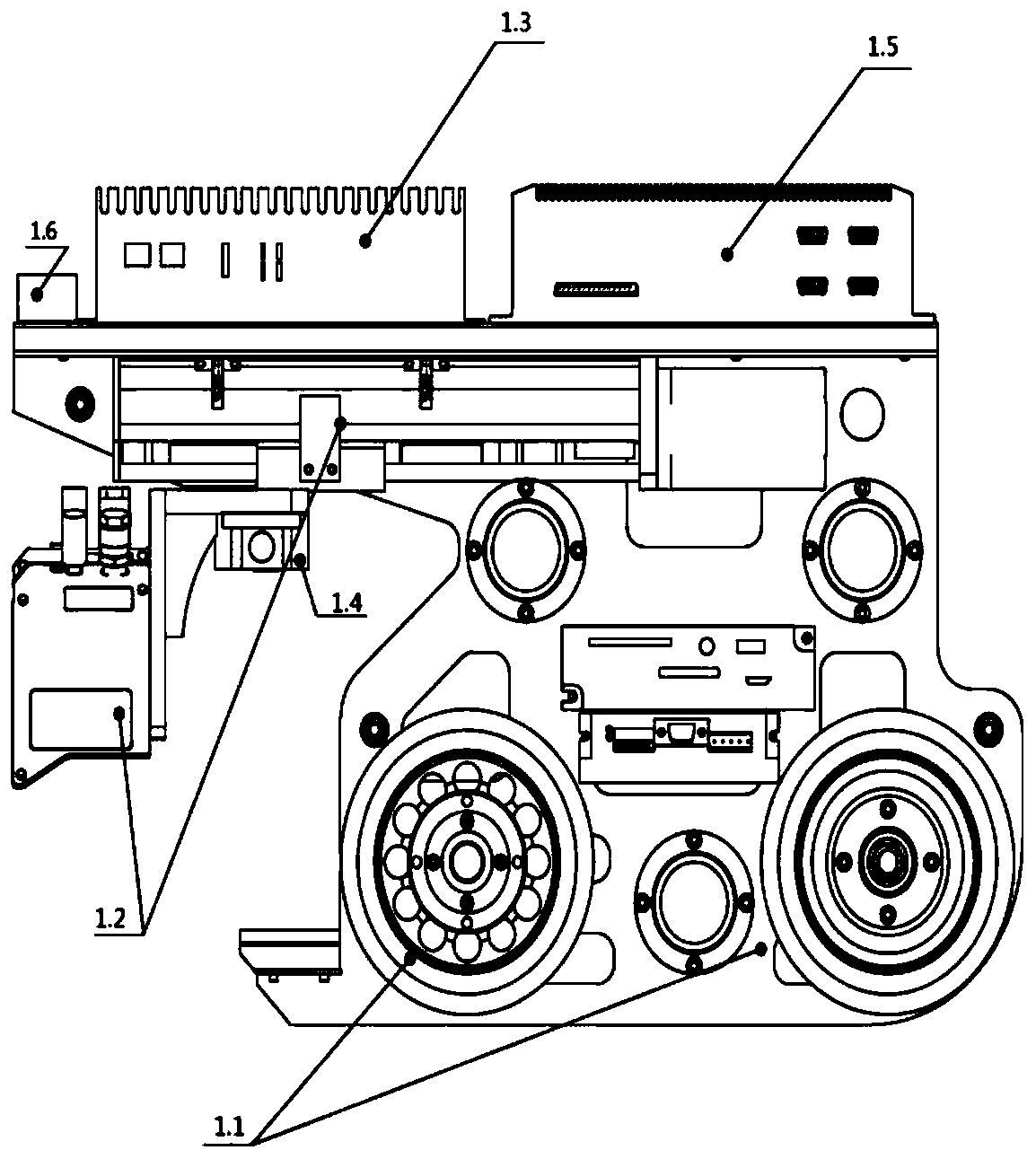

[0097] The main structure of the portable modularized self-correcting railroad track three-dimensional detection system involved in this embodiment includes two detection units 1 for detection, a mounting bracket 2 for support and connection, and a hand operator 3, wherein the detection unit 1 The main structure includes a running mechanism 1.1, a scanning mechanism 1.2, a control unit 1.3, a level detection sensor 1.4, a power supply unit 1.5, and a temperature and humidity sensor 1.6. The running mechanism 1.1 is connected with the scanning mechanism 1.2 to realize scanning while moving; level detection The sensor 1.4 is installed on the rear side of the scanning mechanism 1.2; the control unit 1.3 communicates with the running mechanism 1.1, the scanning mechanism 1.2, and the level detection sensor 1.4 to collect and process information of the above components; the power supply unit 1.5 supplies the running mechanism 1.1 and the scanning mechanism 1.2, control unit 1.3, lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com