Macro-micro integrated motion high-precision parallel mechanism device and control method

A technology that integrates motion and mechanism devices. It is used in program-controlled manipulators, manipulators, and manufacturing tools. It can solve problems such as difficult to achieve sub-micron positioning accuracy, eliminate rotary joint clearance, eliminate assembly errors and dimensional errors, and has a compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

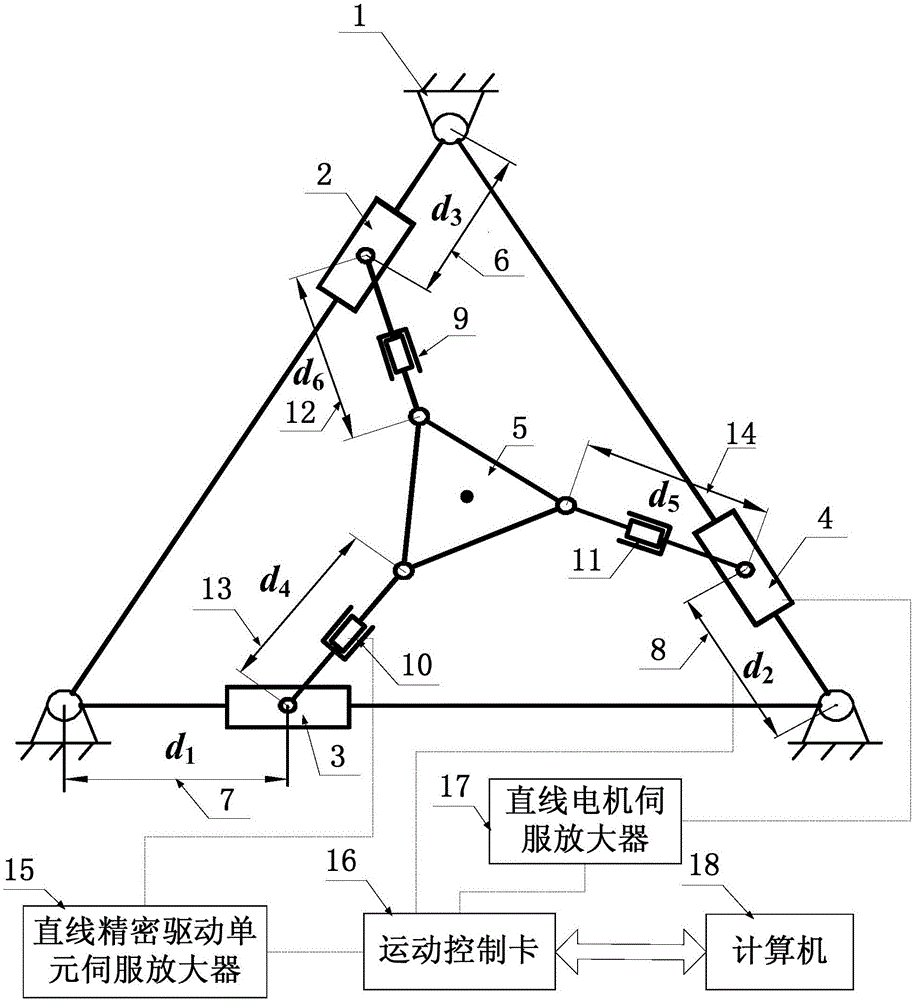

[0036] Such as figure 1 As shown, a macro-micro integrated motion high-precision parallel mechanism device includes a mechanical body part and a control part;

[0037] The mechanical body part includes a moving platform 5 and a static platform 1, and the shape of the static platform 1 is a triangle, and the three sides of the triangle are respectively equipped with linear motor-driven branch chains 2, 3, 4 with the same structure, symmetrically distributed, as figure 1 There are three linear motor-driven branch chains in total. The linear motor-driven branch chains are composed of guide rails, sliders and moving pairs formed by linear motors. The guide rails are fixed on the sides of the triangle and are used to adjust the macro motion of the moving platform. motion, the three sides of the static platform are respectively installed with linear grating displacement sensors 6, 7, and 8 for detecting the linear displacement of the slider movement, the measuring head of the linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com