Cutting section structure of deep hole boring mechanical arm

A technology of mechanical arm and segment structure, which is applied to metal processing mechanical parts, boring heads, turning equipment, etc., can solve the problems of limited boring processing performance, difficulty in ensuring accuracy and processing efficiency, and difficulty in independent processing of complex profiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with an optimal implementation mode of a boring machining three-axis linkage mechanical arm of the present invention and the accompanying drawings.

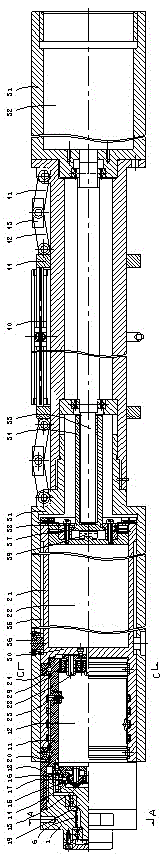

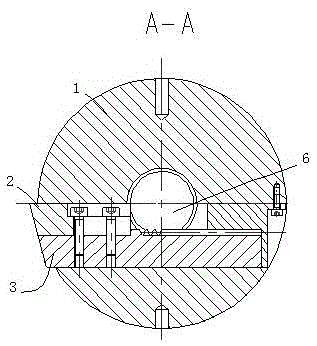

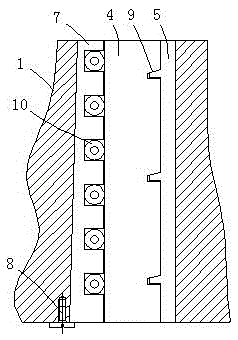

[0029] Such as Figure 1-7 As shown in , an optimal implementation of a three-axis linkage mechanical arm for boring processing includes a cylindrical handle and a tool as a whole. The tool is installed in the cutting section at the front end of the tool handle, wherein the cutting section on the handle The rear end is sequentially formed with a radial feed control section for controlling the radial feed of the tool, a circumferential rotation control section for controlling the circumferential rotation of the cutting section of the tool, and an axial section for controlling the axial expansion and contraction of the cutting section of the tool. The telescopic control section is also provided with a stabilizing support device for the tool to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com