Self-centering target ball mounting stand for small bore diameter

A self-centering, small-aperture technology, applied in the direction of using optical devices, measuring devices, using re-radiation, etc., can solve problems such as the inability to achieve gapless fit, and achieve the effect of eliminating assembly gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

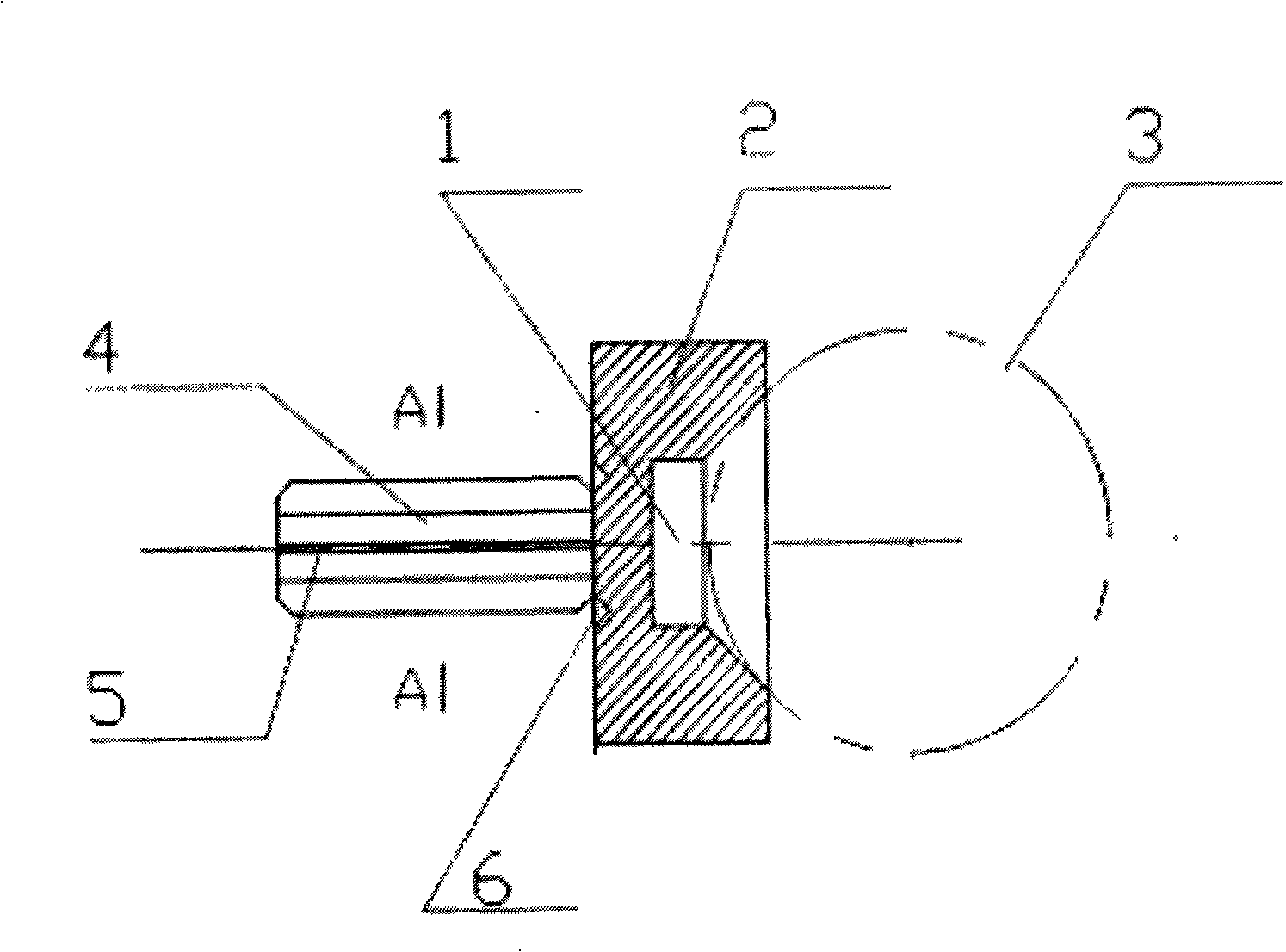

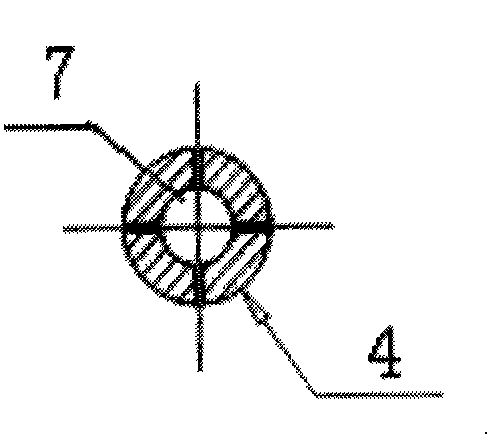

[0013] in figure 1 in. The mounting seat is composed of a target ball mounting head 2 and a positioning column 4 two parts. It is suitable for installing 1.5 inch or 0.5 inch target ball. The target ball 3 can be a corner cube mirror or a TBR mirror. The target ball mounting head 2 with the positioning column 4 has a cylindrical center hole for placing the cylindrical magnet 1 in the center of the axially outer spherical groove of the large end step, and the cylindrical magnet 1 is coaxially assembled in the cylindrical center hole , The target ball 3 is attracted to the cylindrical magnet 1. The target ball mounting head 2 with a spherical groove in the center is coaxially connected to the positioning column 4. A fractal groove 6 is formed at the junction of the positioning column 4 and the large end step of the target ball mounting head 2. A hollow hole 7 is formed on the central axis of the positioning column 4. On the cylindrical surface of the positioning column 4 is made fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com