Non-contact type angular sensor for automobile electronic accelerator

An angle sensor and automotive electronics technology, applied in the field of sensors, can solve problems affecting the promotion of electronic accelerator pedals, and achieve the effect of accurate angle detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

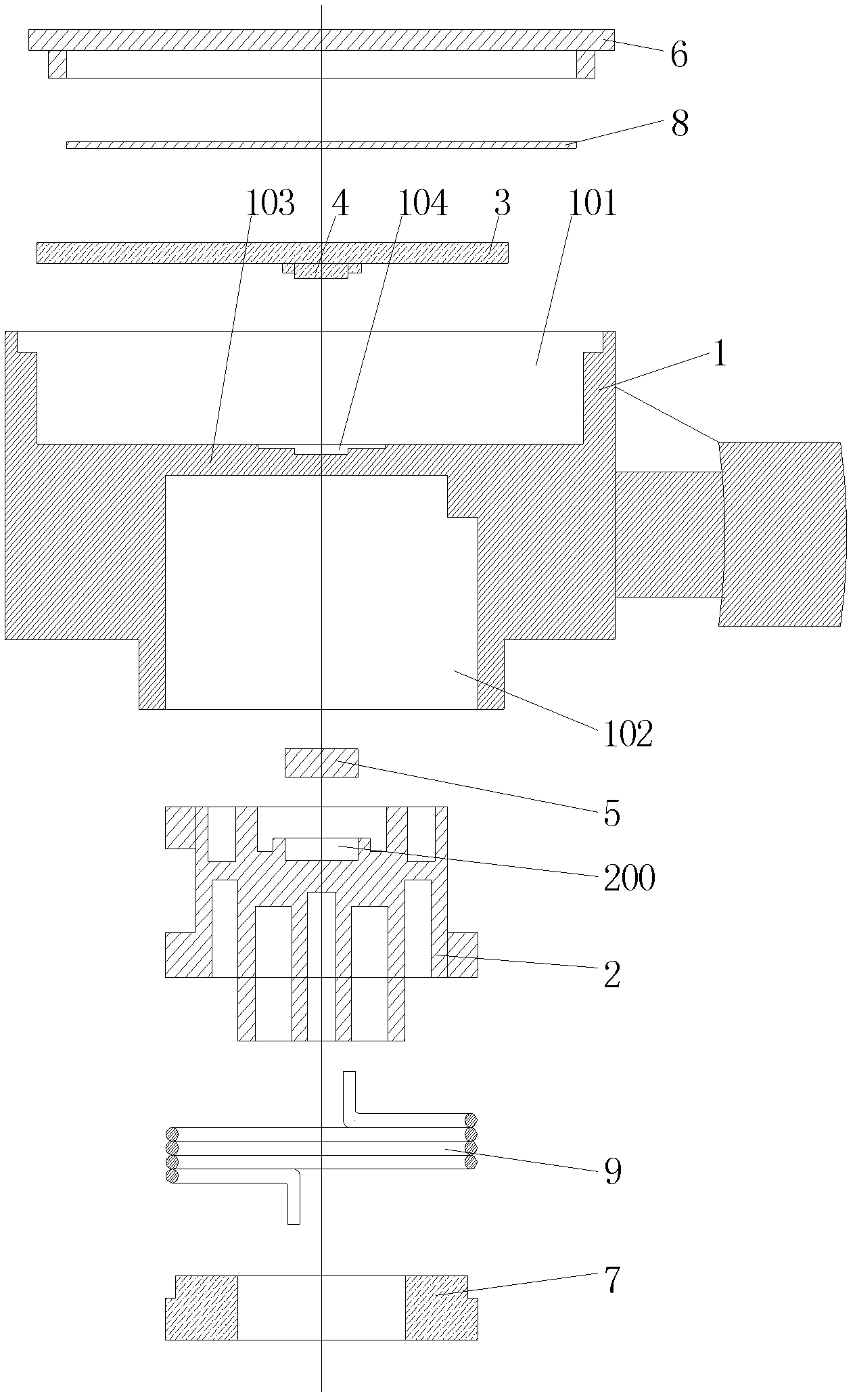

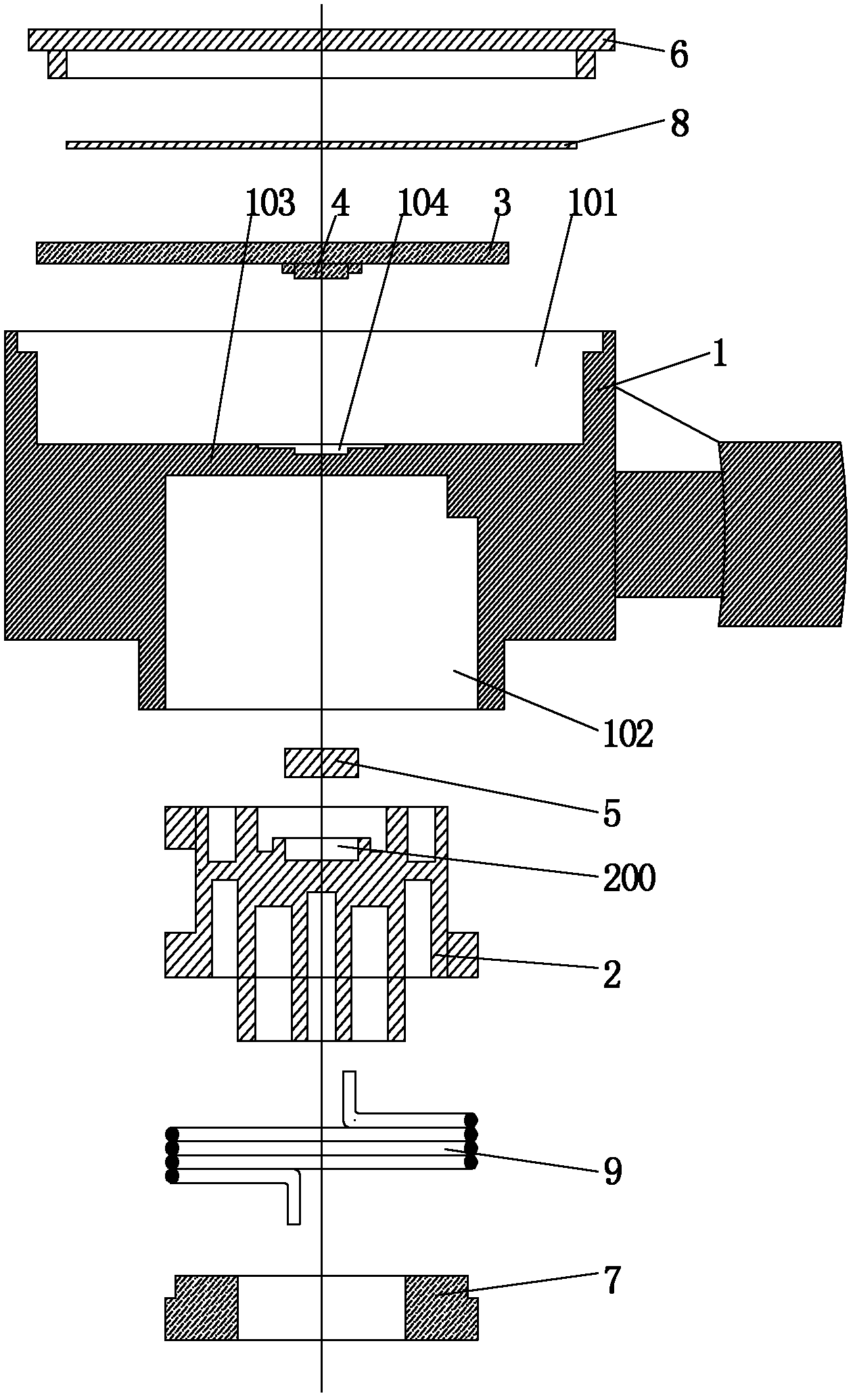

[0015] refer to figure 1 , the non-contact automotive electronic throttle angle sensor of the present invention includes a housing 1, a rotor 2, a circuit board 3, a chip 4, a magnet 5, a cover plate 6 and a rotor cover 7, and the housing 1 is provided with a circuit board assembly cavity 101 and the rotor accommodating chamber 102 , the chip 4 is welded on the circuit board 3 . An isolation plate 103 is provided between the circuit board assembly cavity 101 of the housing 1 and the rotor accommodation cavity 102. The isolation plate 103 and the housing 1 are integrally formed by injection molding. Since the isolation plate 103 is made of plastic, the isolation plate 103 is only The circuit board assembly cavity 101 is isolated from the rotor accommodating cavity 102 , and the magnetic field generated by the magnet 5 is not isolated, so the magnetic field induction of the chip 4 to the magnet 5 will not be affected. A chip positioning frame 104 is arranged on the isolation pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com