Combination type hollow bearing roller

A hollow bearing and combined technology, applied in the field of bearing components, can solve the problems of low bearing precision, increased manufacturing cost, and high consumption of bearing steel materials, and achieve the effects of reducing centrifugal inertial force, eliminating assembly gaps, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

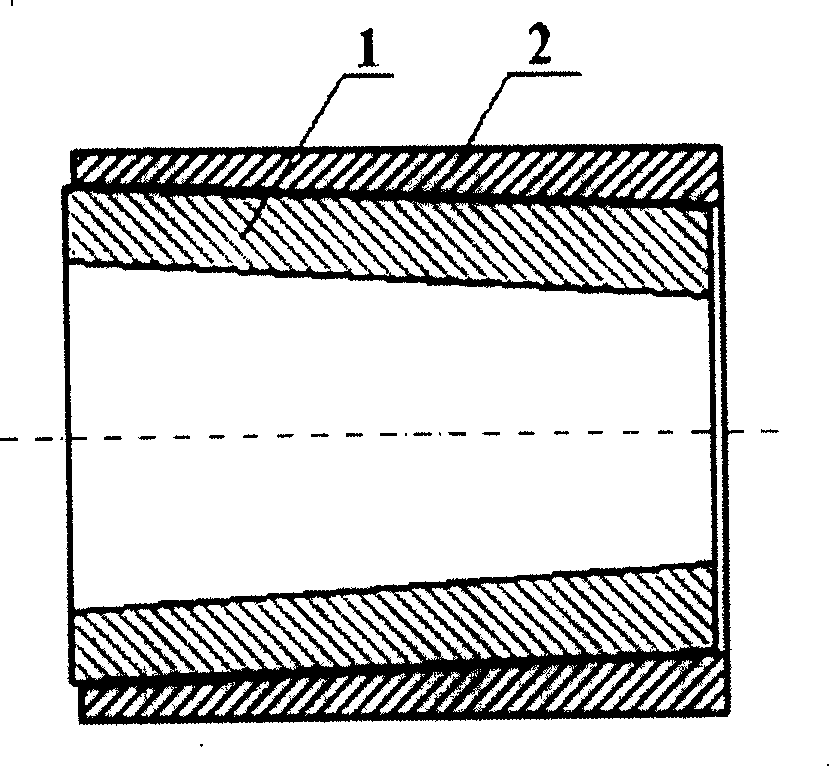

[0022] Embodiment 1, see attached figure 1 , This embodiment of the combined hollow bearing roller of the present invention is made of bearing steel to make the sleeve 2, which is cylindrical and has an inner frustum-shaped cavity. The expansion sleeve 1 is made of cast iron and is in the shape of a truncated cone, which matches the size of the inner cavity of the sleeve 2 and also has an inner truncated cone cavity. The expansion sleeve 1 is coaxially inserted into the sleeve 2, and the expansion sleeve 1 and the outer sleeve 2 are tightly fitted together. If the gap between the roller and the inner and outer rings of the bearing is found to be too large during the assembly process of the rolling bearing, special pressure equipment can be used to apply pressure to the expansion sleeve in the axial direction to force the gap between the expansion sleeve 1 and the outer sleeve 2. Axial movement occurs between them. Due to the pushing effect of the tapered surface of the inne...

Embodiment 2

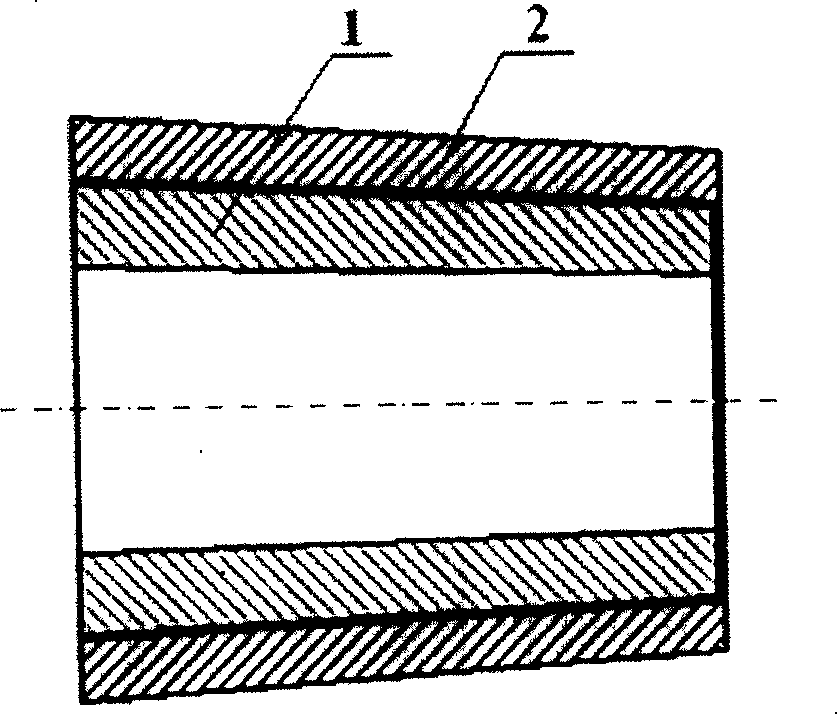

[0023] Embodiment 2, see attached figure 2 , The sleeve 2 is made of bearing steel, which is in the shape of a truncated cone and has an inner truncated cone cavity. The expansion sleeve 1 is made of cast iron, and is also in the shape of a truncated cone, matching the size of the inner cavity of the sleeve 2, and also has an inner truncated cone cavity. The coaxial expansion sleeve 1 is inserted into the sleeve 2, and is tightly fitted with the outer sleeve 2. Others are with embodiment 1.

[0024] The combined hollow bearing roller of the present invention thus constituted has a remarkable effect through trial production and clinical trials, and fully meets the design requirements. Due to the different materials for making the expansion sleeve 1 and the sleeve 2, their respective mechanical properties are also different. The mechanical properties of the combined bearing rollers are also different, so the effect of vibration and noise reduction is better, and it is quite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com