Linear adjustment device for aligning transverse ribs of high-torque screw-thread steel

An adjustment device and a technology for rebar, applied in the field of steel rolling machinery, can solve the problems of high production cost, transmission failure, and easily damaged pin threads, etc., and achieve the effects of improving mechanical stability, shortening adjustment time, and enhancing connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present invention is selected to be installed on the left universal joint shaft.

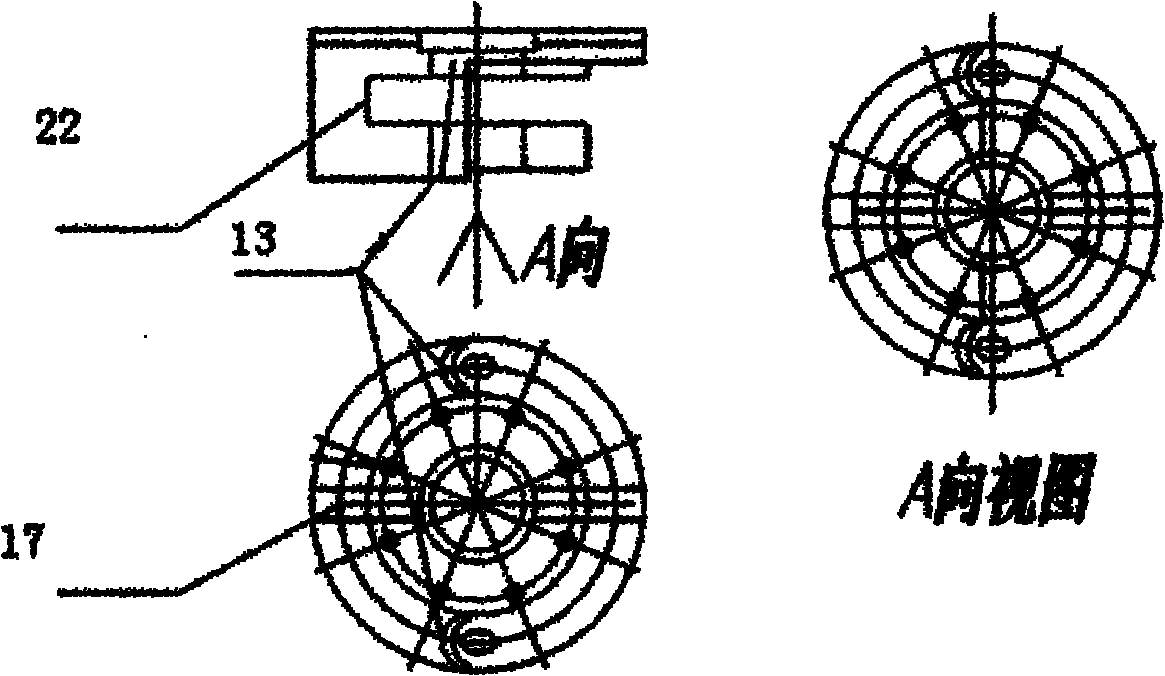

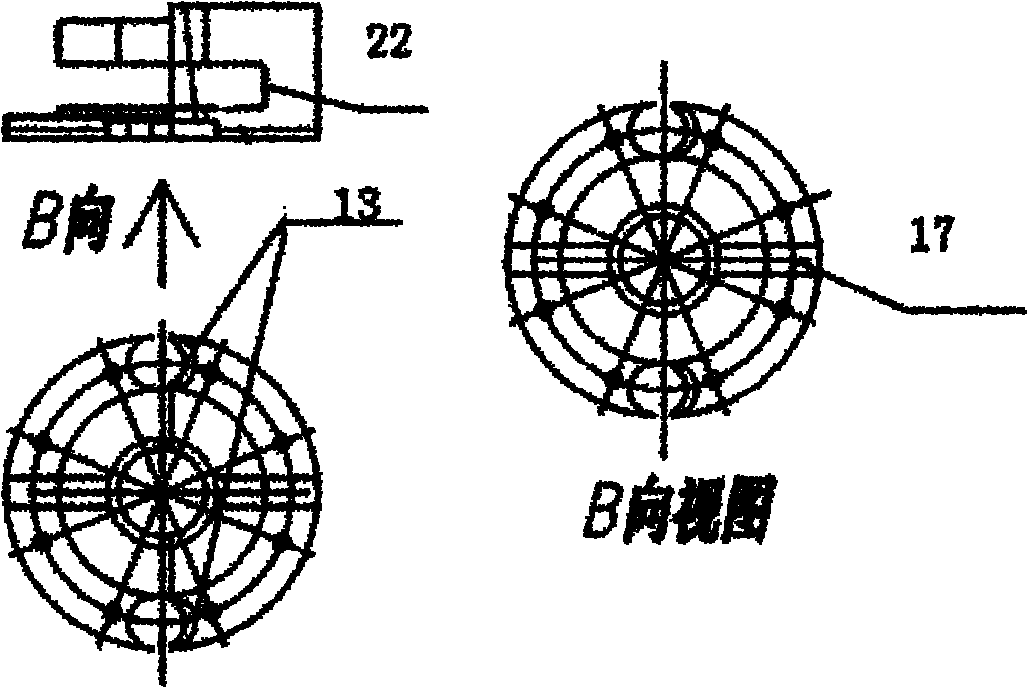

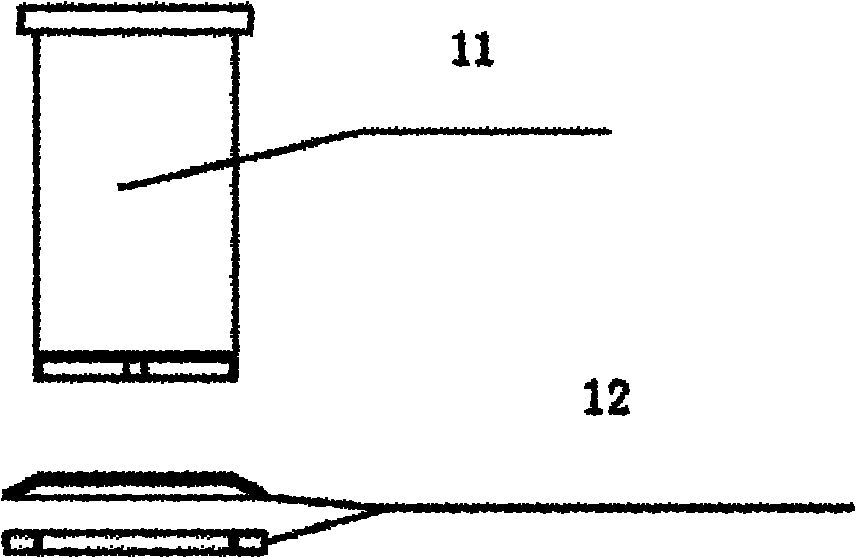

[0041] A high-torque threaded steel transverse rib alignment linear adjustment device 5, including a left adjustment disc 9, a right adjustment disc 10, an intermediate mandrel 11 and a lock nut 12, and the left adjustment disc 9 and the right adjustment disc 10 pass through the middle The mandrels 11 are intersected and connected together, and the middle mandrel 11 is axially fixed between the left adjustment disc 9 and the right adjustment disc 10 through the lock nut 12 along the middle mandrel 11; There are two wedge holes 13 symmetrically arranged on the edge of the right adjustment plate 10, and two wedge holes 13 are symmetrically arranged on the edge of the right adjustment plate 10; a wedge 14 runs through the wedge hole 13 provided on the left adjustment plate 9 and the wedge hole 13 of the right adjustment plate 10 Among them, another wedge 14 is set through another wedge h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com