Automatic core assembling machine for core body of warm wind radiator and working method thereof

A radiator and core technology, applied in the field of automobile manufacturing, can solve problems such as high labor intensity, increase product cost, and reduce yield, and achieve the effects of avoiding workpiece damage and bumping, scientific and reasonable design, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, the present invention will be further described with reference to the accompanying drawings and examples. The following examples are illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following examples.

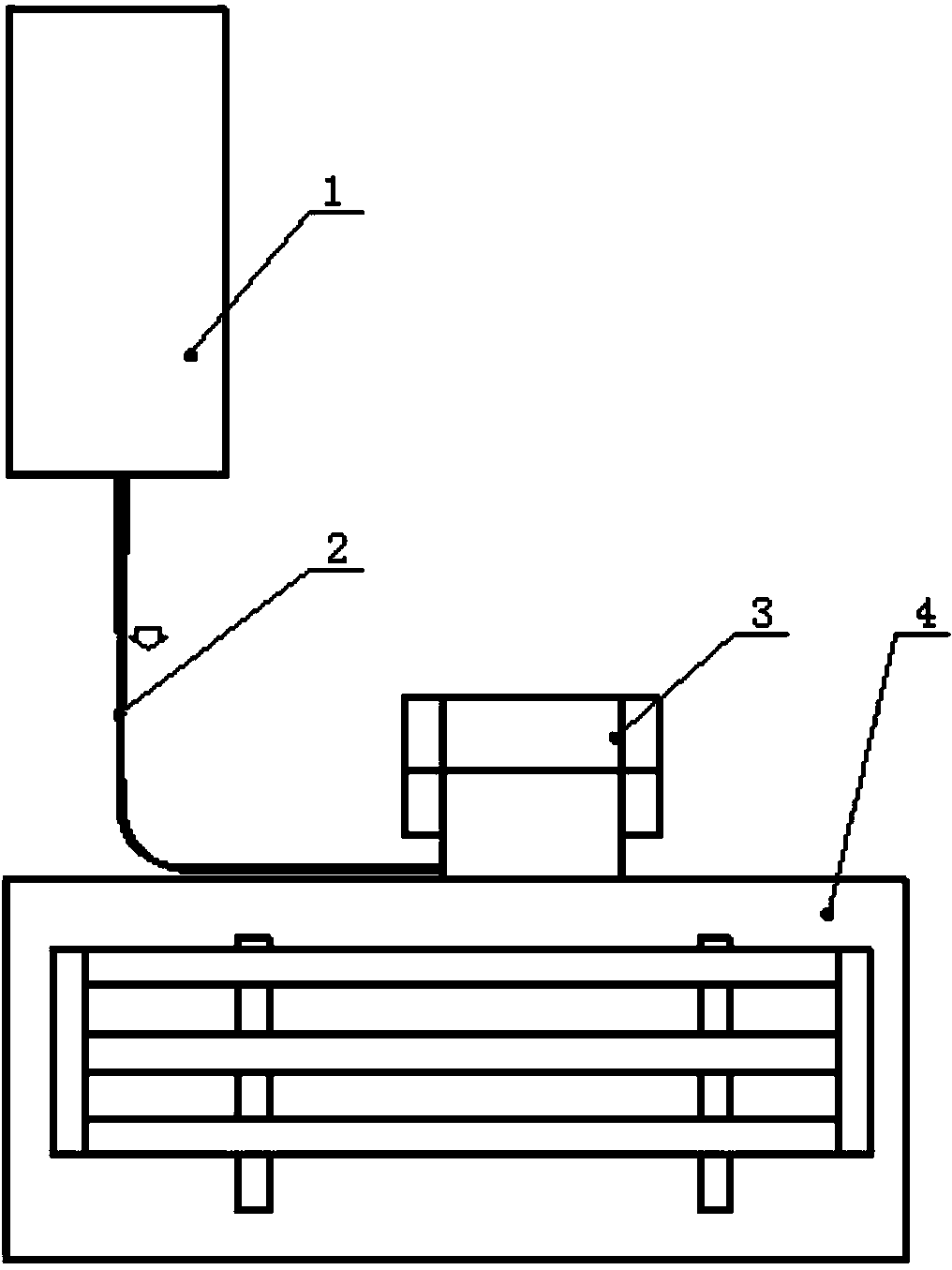

[0033] A warm air radiator core automatic core loading machine, such as figure 1 As shown, it includes a fin machine 1, a flat tube feeding device 3 and an assembly machine 4. The fin machine is connected to the feed port of the assembly machine through a transmission track 2, and the discharge port of the flat tube feeding device is also connected to the assembly machine. feed port connection.

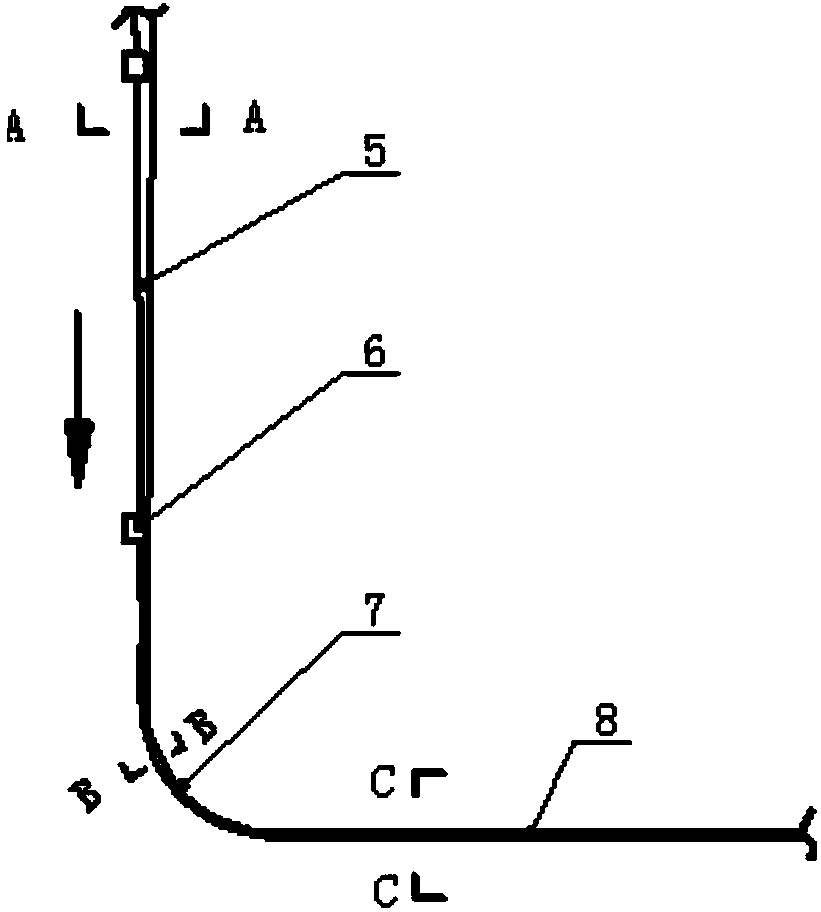

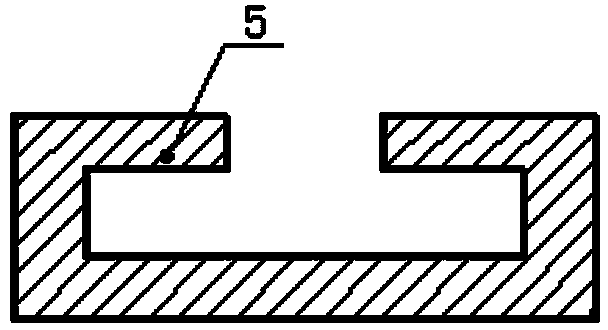

[0034] In this embodiment, the transmission track is as figure 2 As shown, it is composed of a guide rail section 5, an arc section 7 and a conveyor belt section 8. The guide rail section and the conveyor belt section are vertically arranged and connected together through the arc section transition. Nozzle 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com