Cutting equipment for cloth bag production

A cutting and equipment technology, applied in the cutting of textile materials, bag making operations, paper/cardboard containers, etc., can solve problems such as inappropriate setting of cutting mechanism, uneven incision, and cloth jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

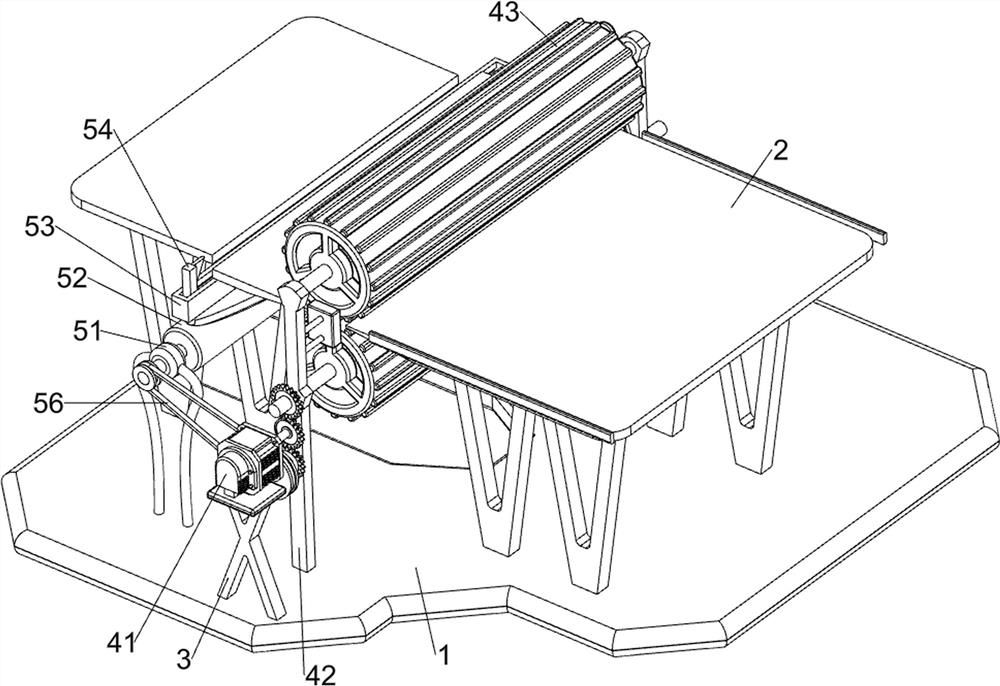

[0079] A cutting device for cloth bag production, such as figure 1 As shown, it includes a base 1, a workbench 2, a support 3, a transmission mechanism 4 and a cutting mechanism 5. Two workbenches 2 are connected to the upper side of the base 1, a support 3 is connected to the upper side of the base 1, and a support 3 is connected to the upper side of the support 3. The transmission mechanism 4 is connected with a cutting mechanism 5 on the upper side of the base 1 .

[0080] When the device needs to be used, the user can place the cloth on the upper side of the workbench 2, so that the cloth passes through the transmission mechanism 4, and starts the transmission mechanism 4 to rotate forward. The cloth moves to the left. When the transmission mechanism 4 rotates to the inside without contact, the cloth stops moving, so as to achieve the purpose of automatic transmission of the cloth and automatic feeding. When the transmission mechanism 4 rotates forward to contact with the ...

Embodiment 2

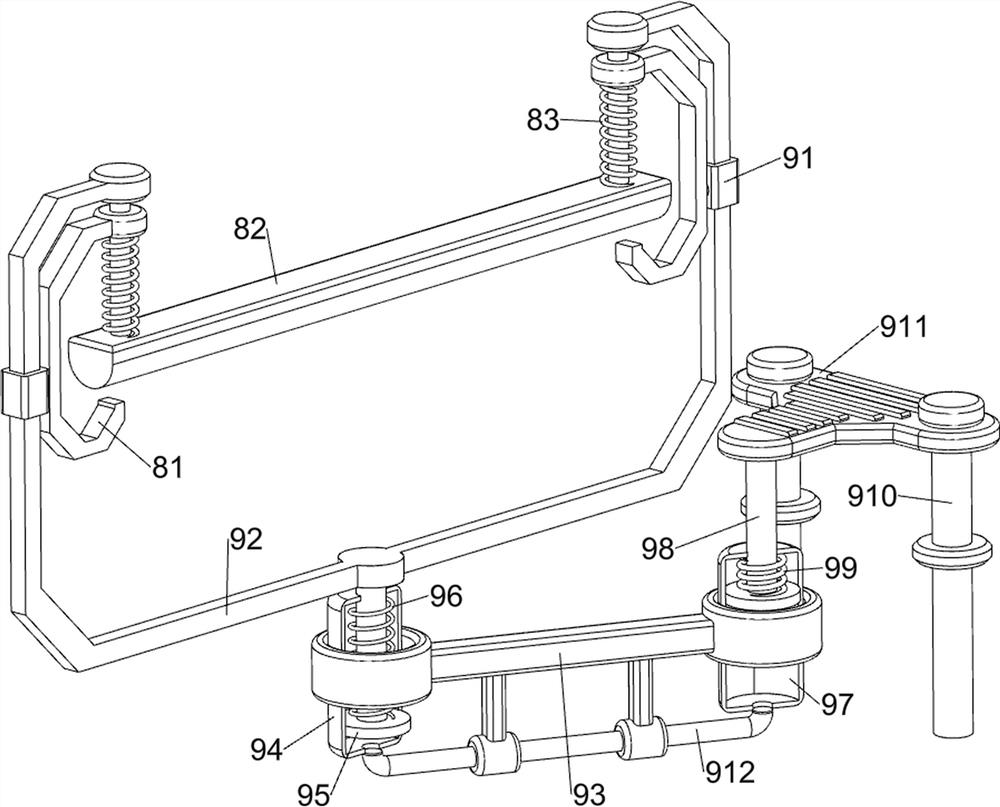

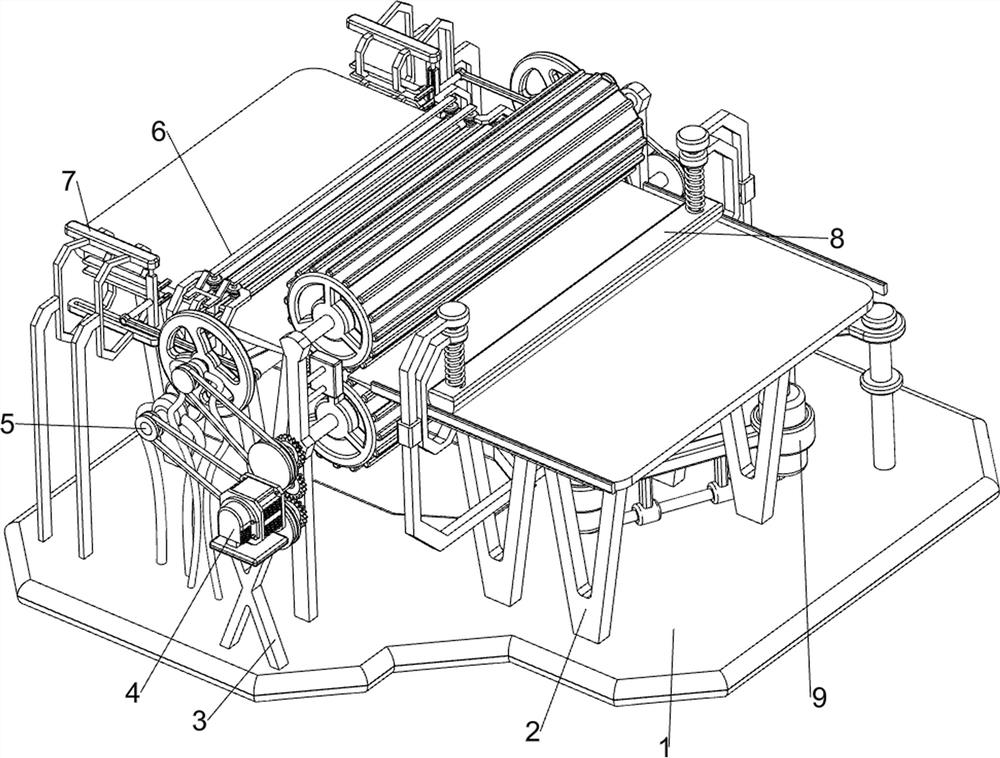

[0082] On the basis of Example 1, such as figure 2 and image 3 As shown, the transmission mechanism 4 includes a servo motor 41, a mounting plate 42, a transmission cylinder 43, a first full gear 44, a missing gear 45, a rotating shaft 46, a gear set 47, a first belt transmission assembly 48 and a block 49, and the bracket 3 The upper side is connected with a servo motor 41, the front and rear sides of the upper part of the base 1 are connected with a mounting plate 42, two transmission cylinders 43 are connected in rotation between the mounting plates 42, and the first full gear 44 is connected to the transmission cylinder 43 below, the servo A missing gear 45 is connected to the output shaft of the motor 41, and the missing gear 45 is meshed with the first full gear 44. A rotating shaft 46 is connected to the rear mounting plate 42 in a rotational manner, and a gear set 47 is connected between the upper transmission cylinder 43 and the rotating shaft 46. A first belt tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com