Material transfer mechanical hand and plate stamping production line

A technology of manipulators and production lines, applied in metal processing equipment, feeding devices, stripping devices, etc., can solve the problems of inability to guarantee the straight-through rate of noodles, high safety hazards, and many people in demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0039] The present invention will be described in detail below with reference to the accompanying drawings and examples.

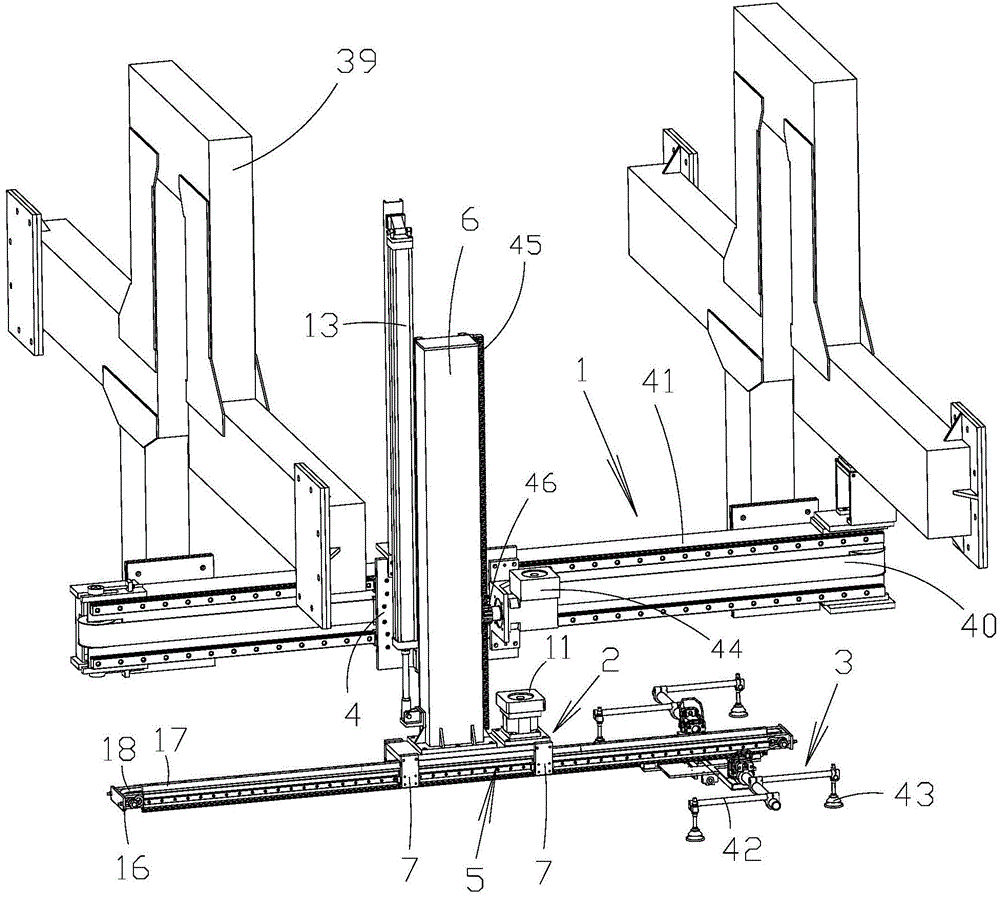

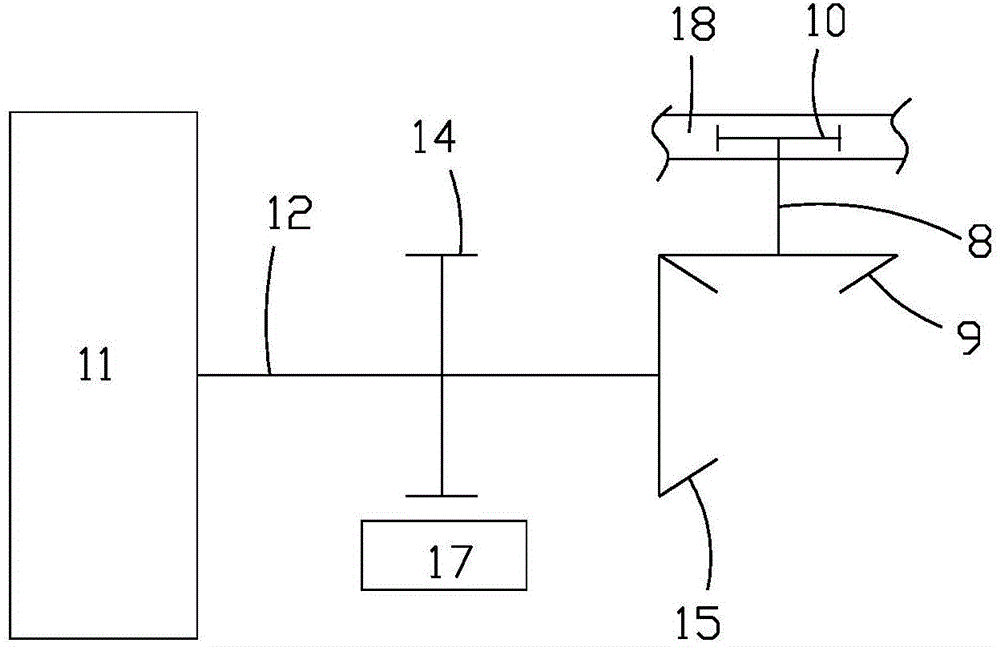

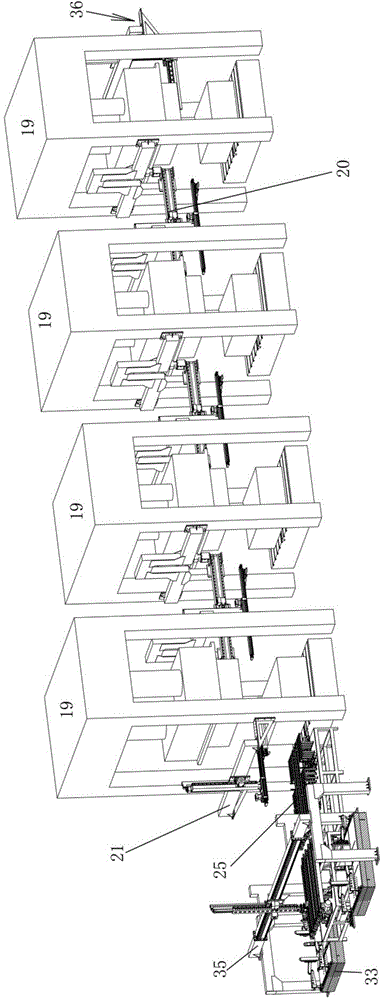

[0040] Such as figure 1 As shown, the material transfer manipulator of the present invention includes a first X-direction track device 1, a second X-direction track device 2 and a material grabbing device 3, wherein the second X-direction track device 2 is slidably arranged in the X direction on the second On one X-direction track device 1 , the material grabbing device 3 is slidably arranged on the second X-direction track device 2 in the X direction.

[0041] Since the second X-direction track device 2 can slide upwards in X, and at the same time, the material grasping device 3 can also slide in the same direction as the second X-direction track device 2 in the X direction, in this wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com