Welding process of ultra-supercritical fossil power unit for welding SA335-P91/P92 steel

A technology of SA335-P91, thermal power unit, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effect of improving first-time welding pass rate, improving input technology, and solving welding quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

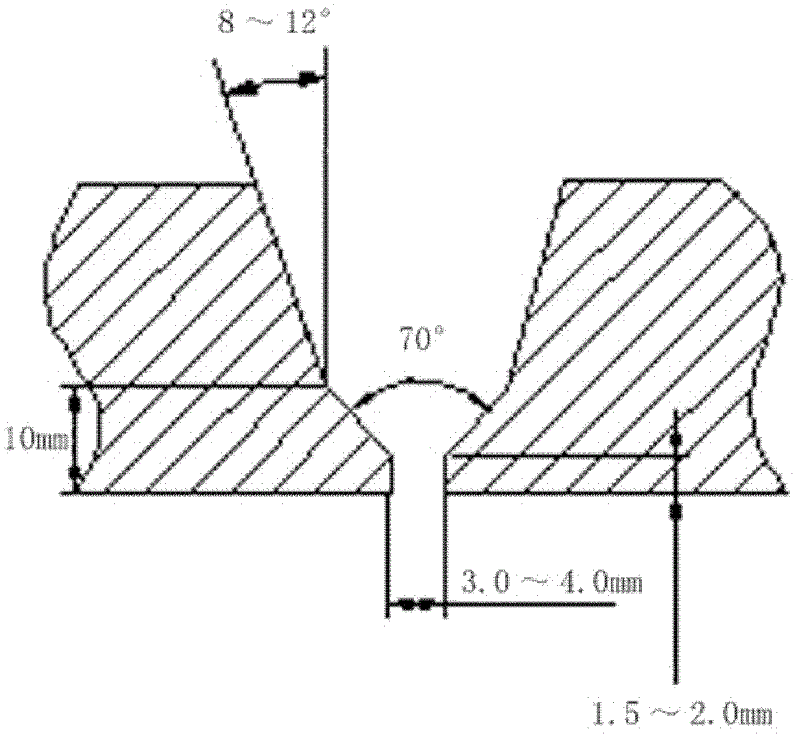

[0038] Figure 1-Figure 4 Constitute the specific embodiment 1 of the present invention.

[0039] refer to figure 1 , this embodiment includes three aspects of preparation before welding, optimization of welding parameters and optimization of welding process,

[0040] 1) Preparation before welding

[0041] Select the workpiece and use manual arc welding rod as the welding workpiece;

[0042] Set up the weld bead, set the weld bead into a double V-shaped groove shape, and clean the surface of the groove;

[0043] Carry out counterpart assembly, place the pipeline to be welded in the aforementioned weld bead, and place the pipeline firmly after the counterpart connection of each section. The requirements for the counterpart of each pipeline are: misalignment 0.1-1.0mm, gap 3.0-4.0mm, blunt edge 1.5- 2.0mm;

[0044] For large-diameter thick-walled pipes, use positioning blocks to fix them in the groove;

[0045] 2) Optimization of welding parameters

[0046] Select the wel...

specific Embodiment 2

[0076] refer to Figure 5 with Image 6 , The main features of the specific embodiment 2 of the present invention are: the welding bead is set to a double V-shaped groove shape, and the surface of the groove is cleaned, and the electrode material is CHROMET92. All the other are with specific embodiment 1.

[0077] P91 steel is equivalent to the national standard 10Cr9Mo1VNb. This steel not only has high oxidation resistance and high temperature steam corrosion resistance, but also has good impact toughness, high and stable durable plasticity and thermal strength. When the service temperature is lower than 620°C, its allowable stress is higher than that of austenitic stainless steel. Above 550°C, the recommended design allowable stress is about twice that of T9 and 2.25Cr-1Mo steel. It can be used as high-temperature superheater and reheater steel pipes for subcritical and supercritical boilers with a wall temperature of ≤625°C, as well as high-temperature headers and steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com