Patents

Literature

80 results about "Gas tungsten arc welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

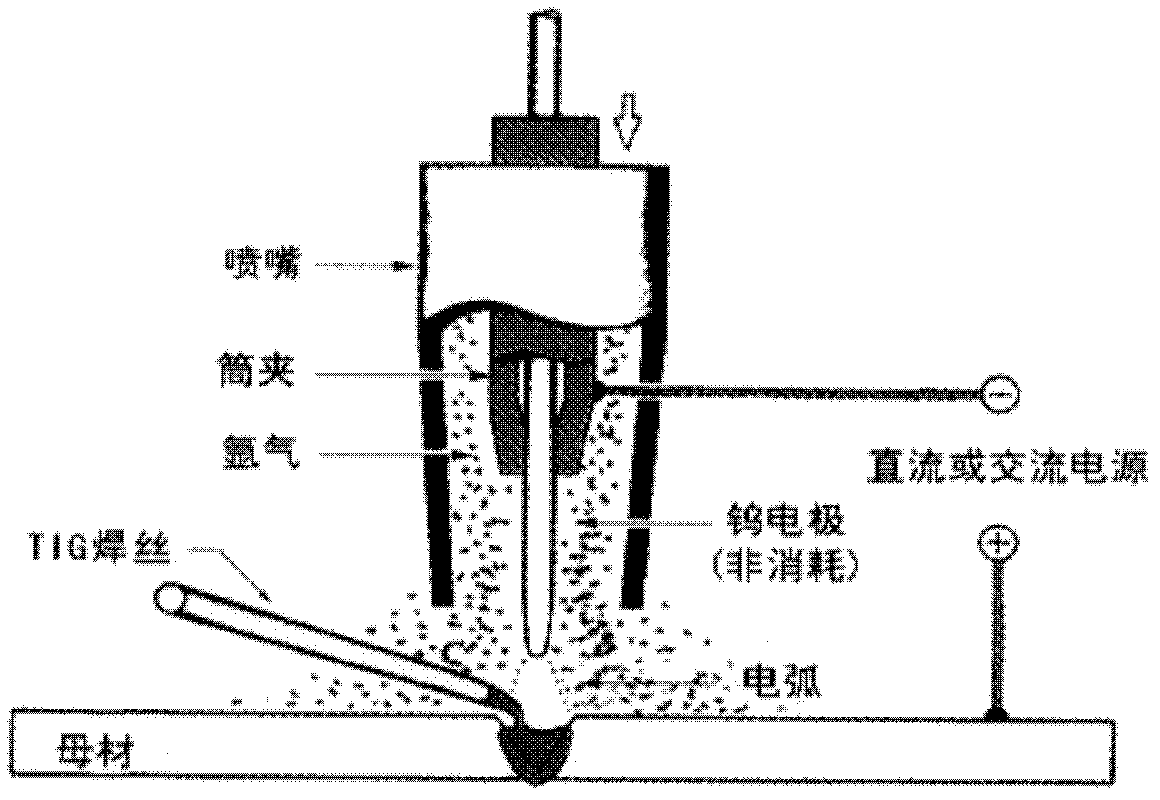

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode is protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium), and a filler metal is normally used, though some welds, known as autogenous welds, do not require it. When helium is used, this is known as heliarc welding. A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma.

Welding process

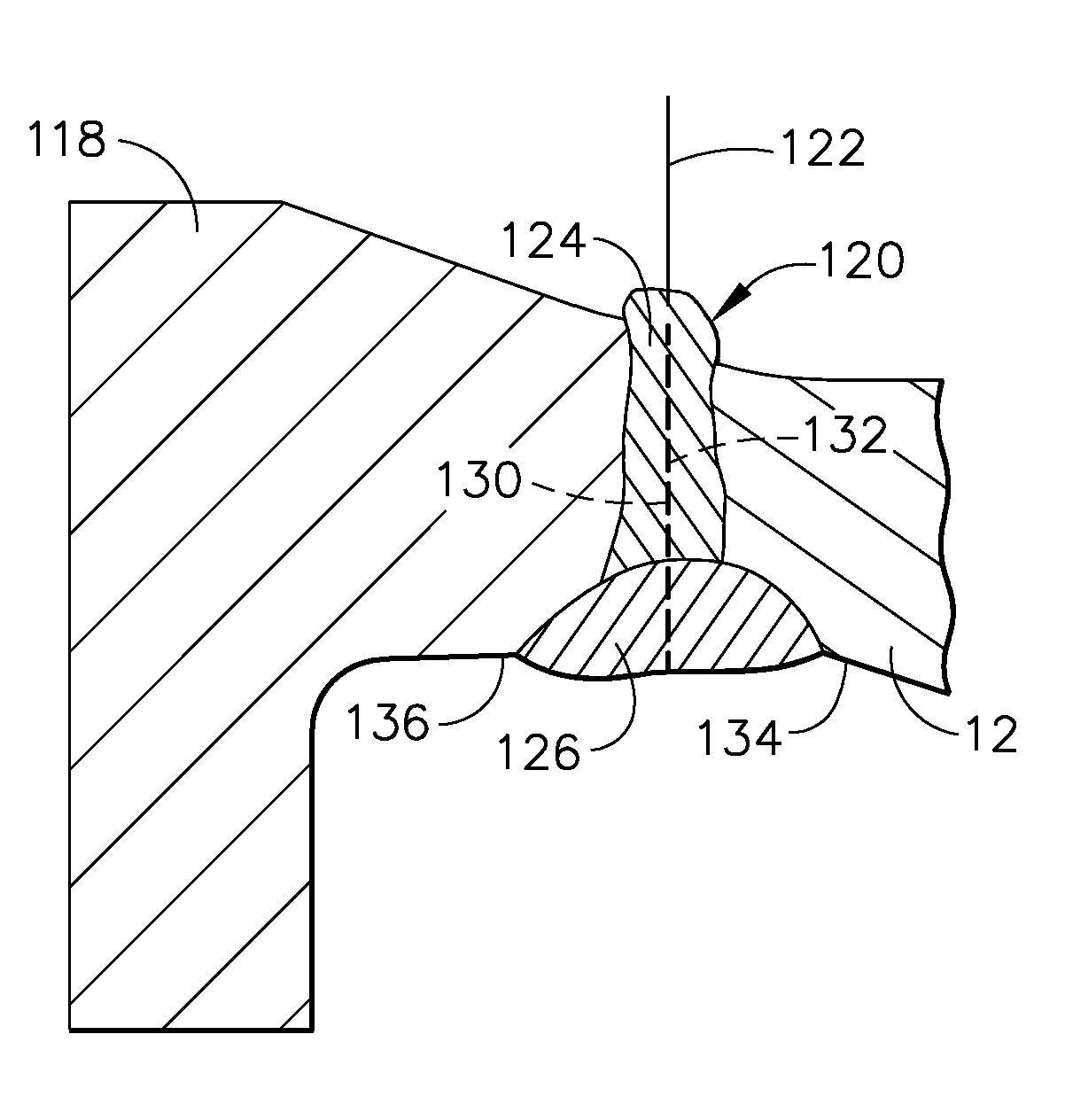

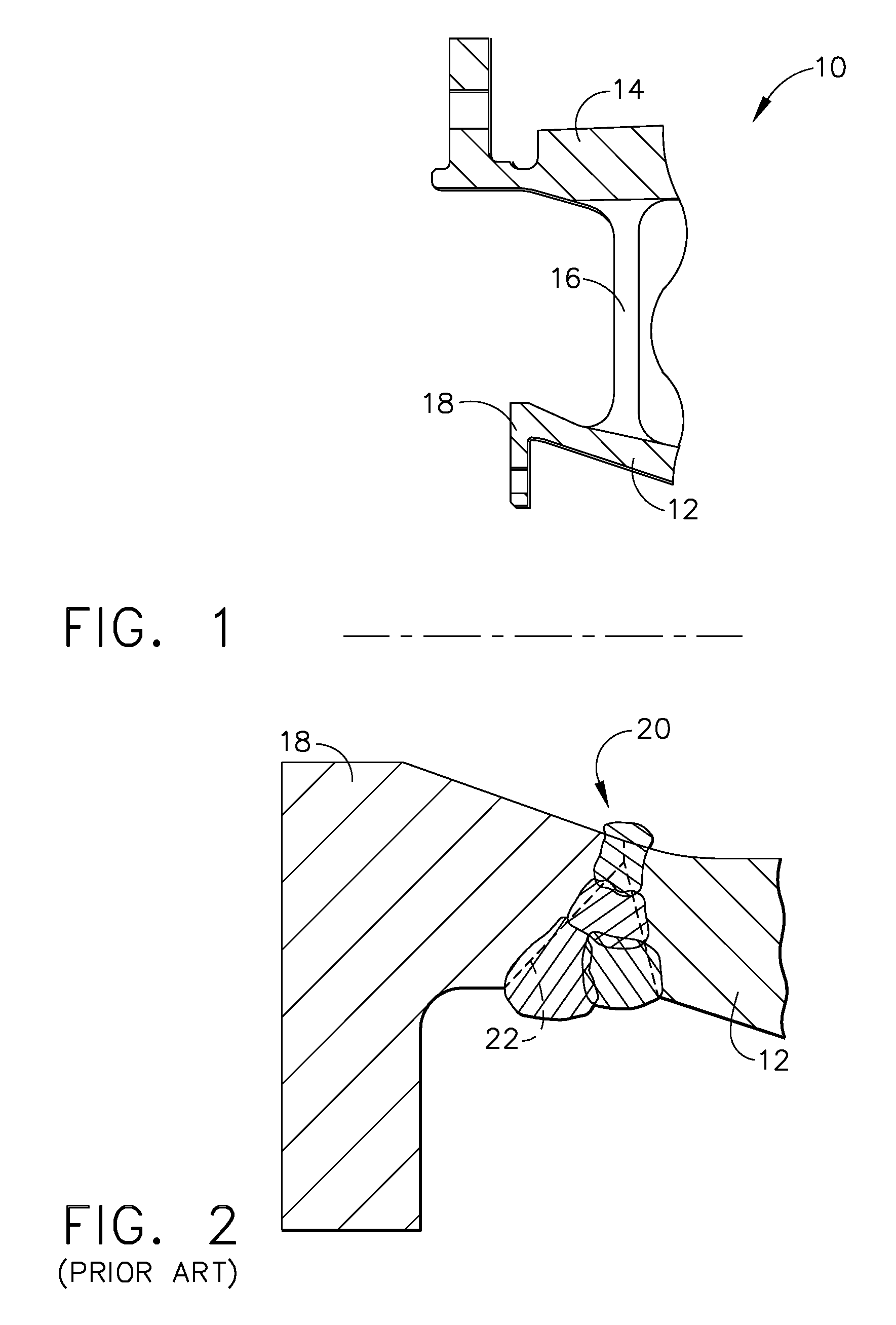

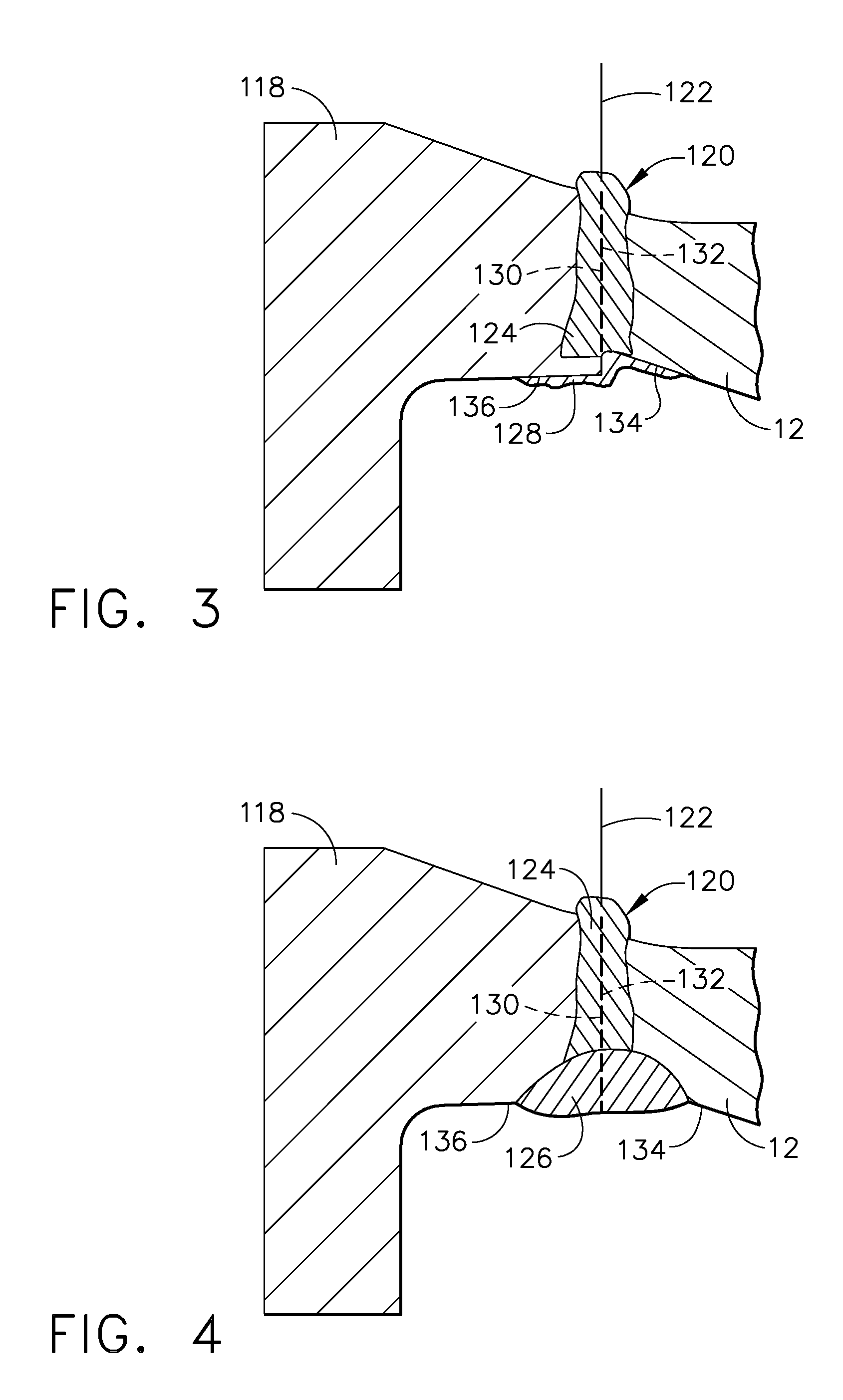

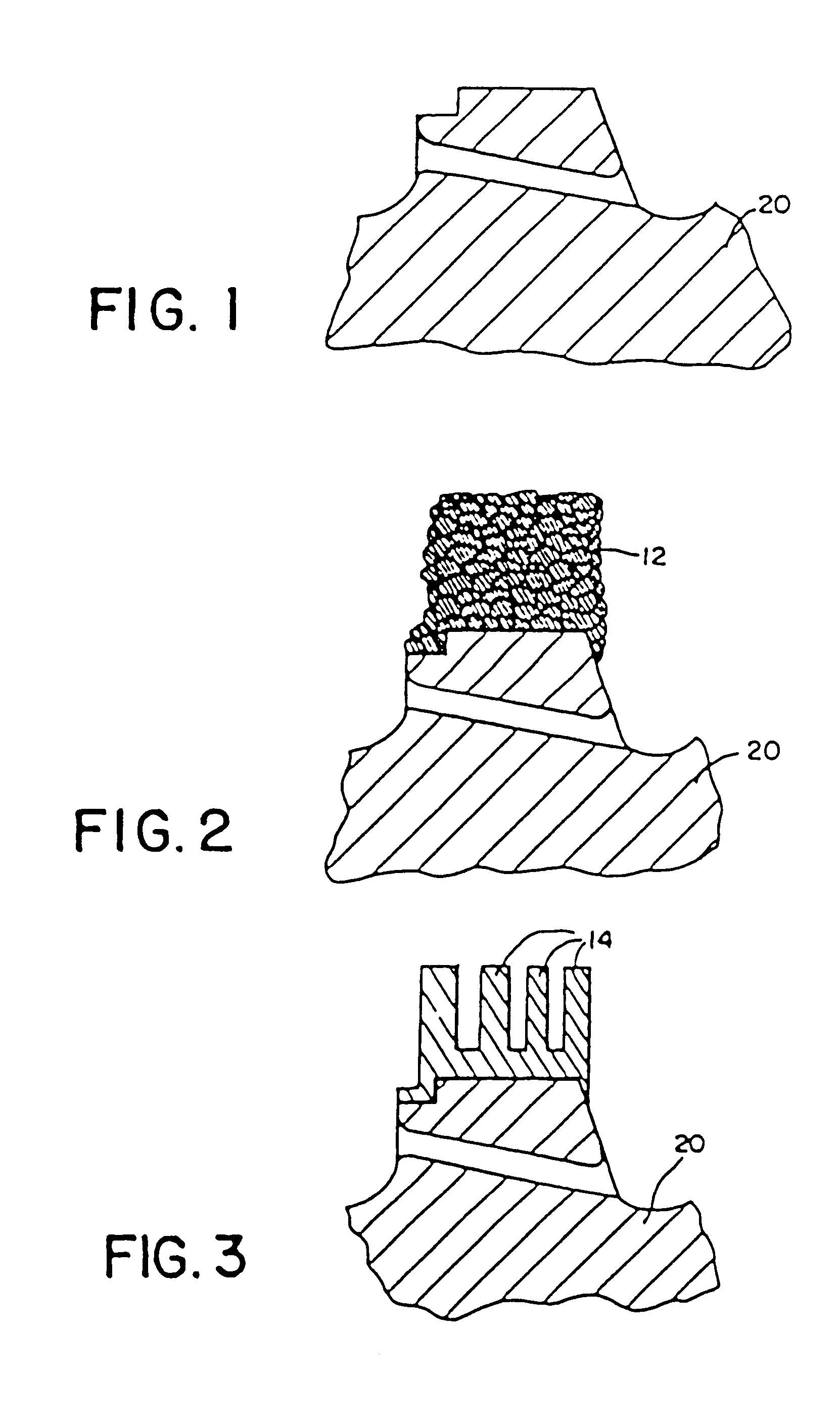

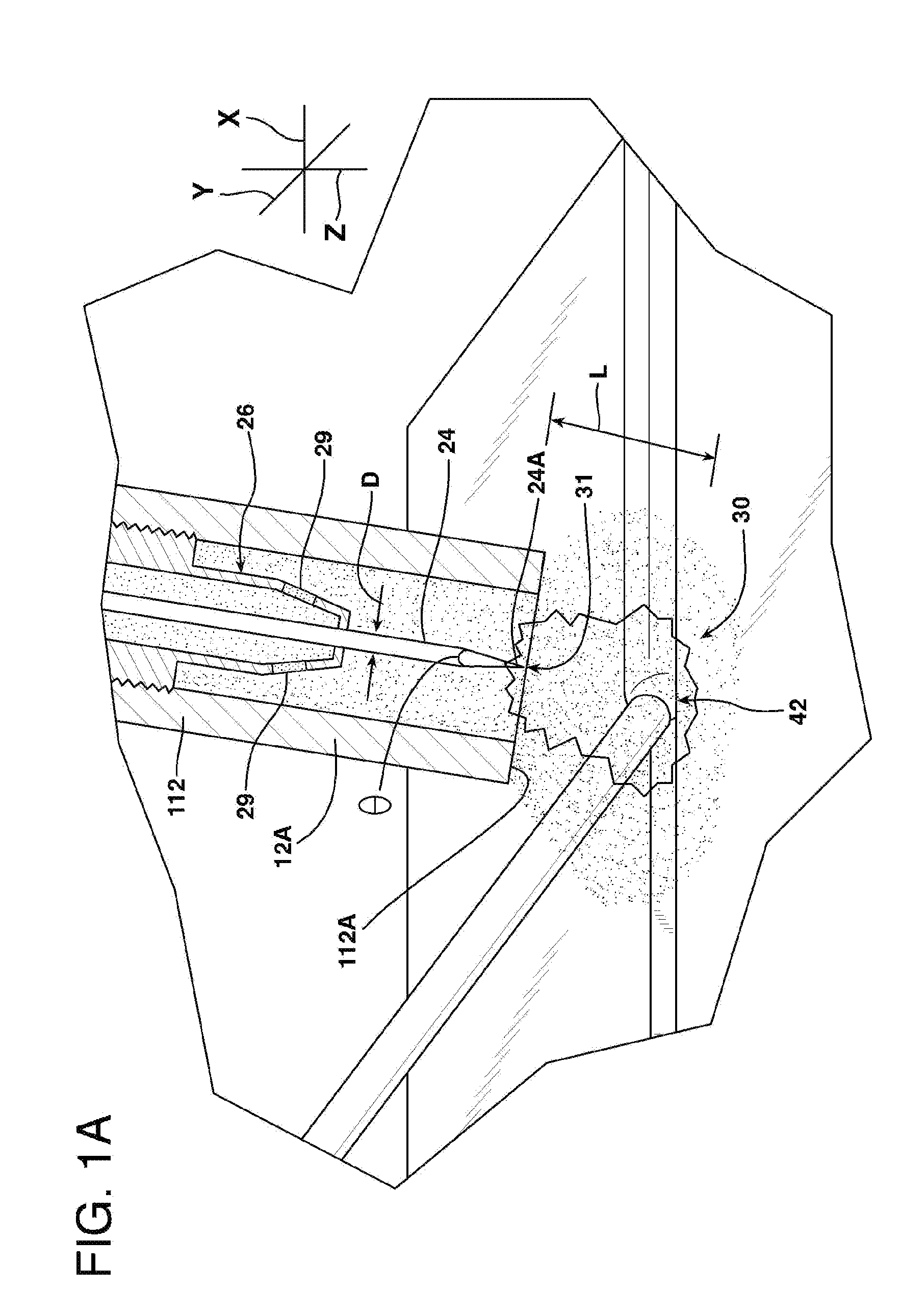

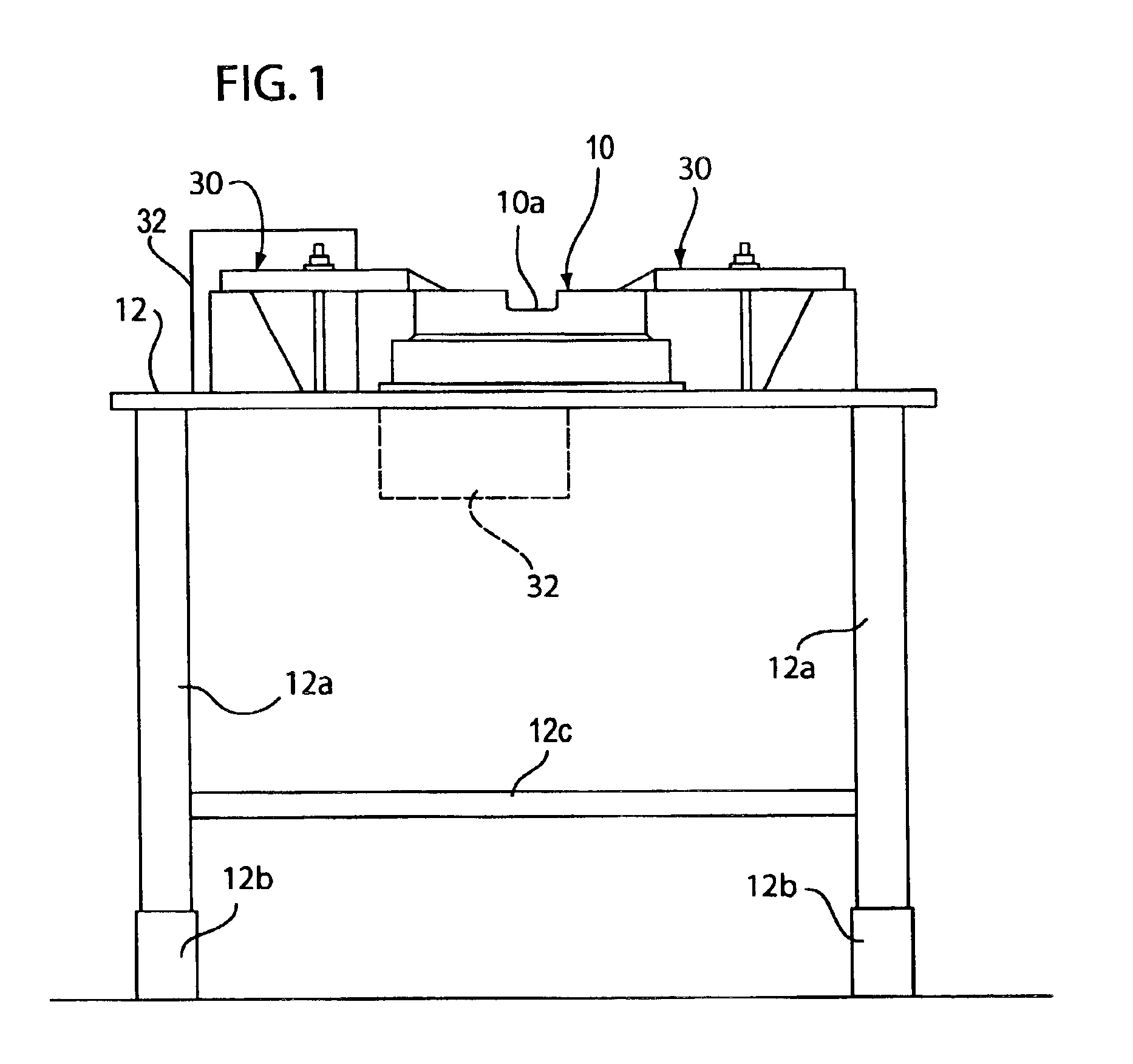

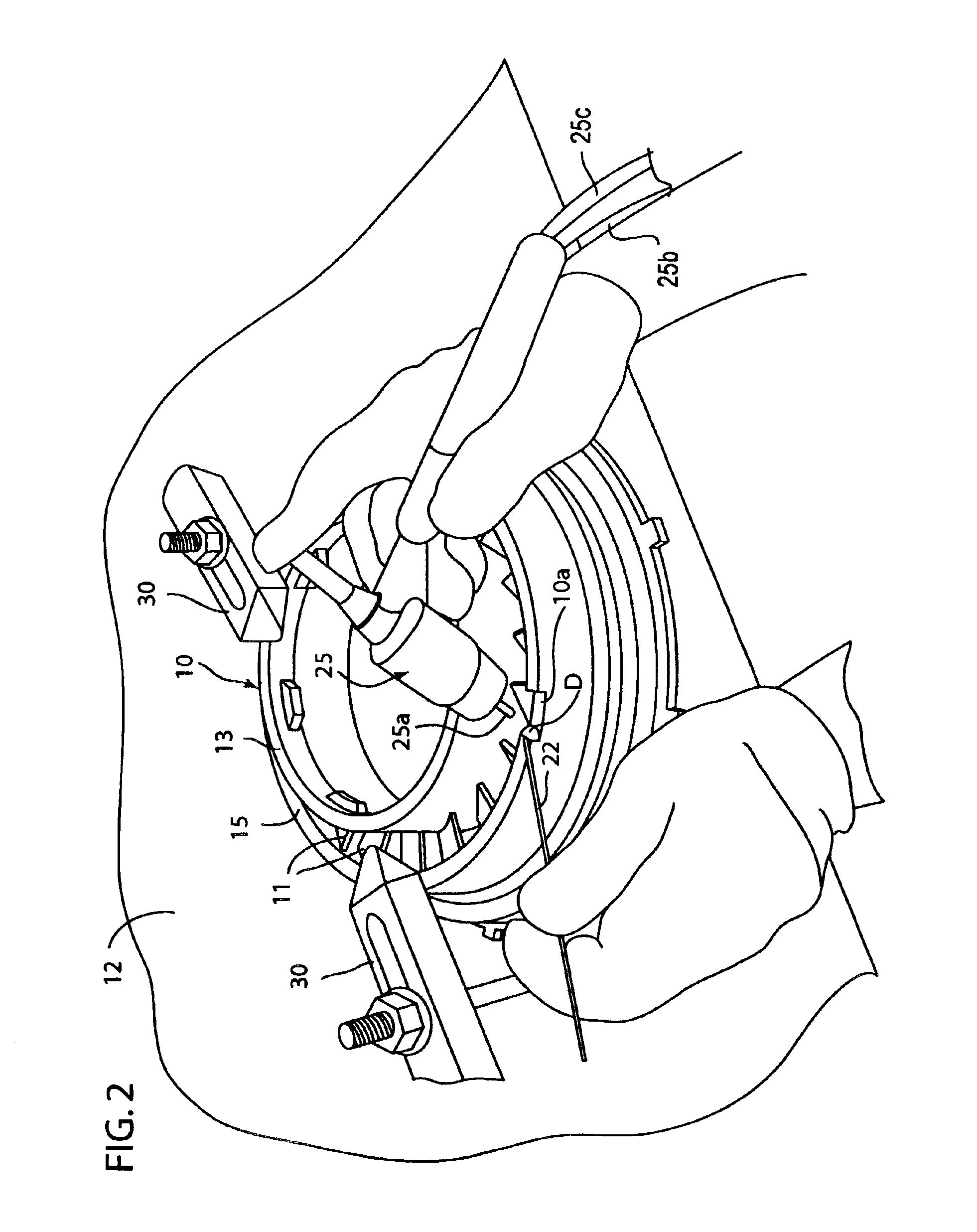

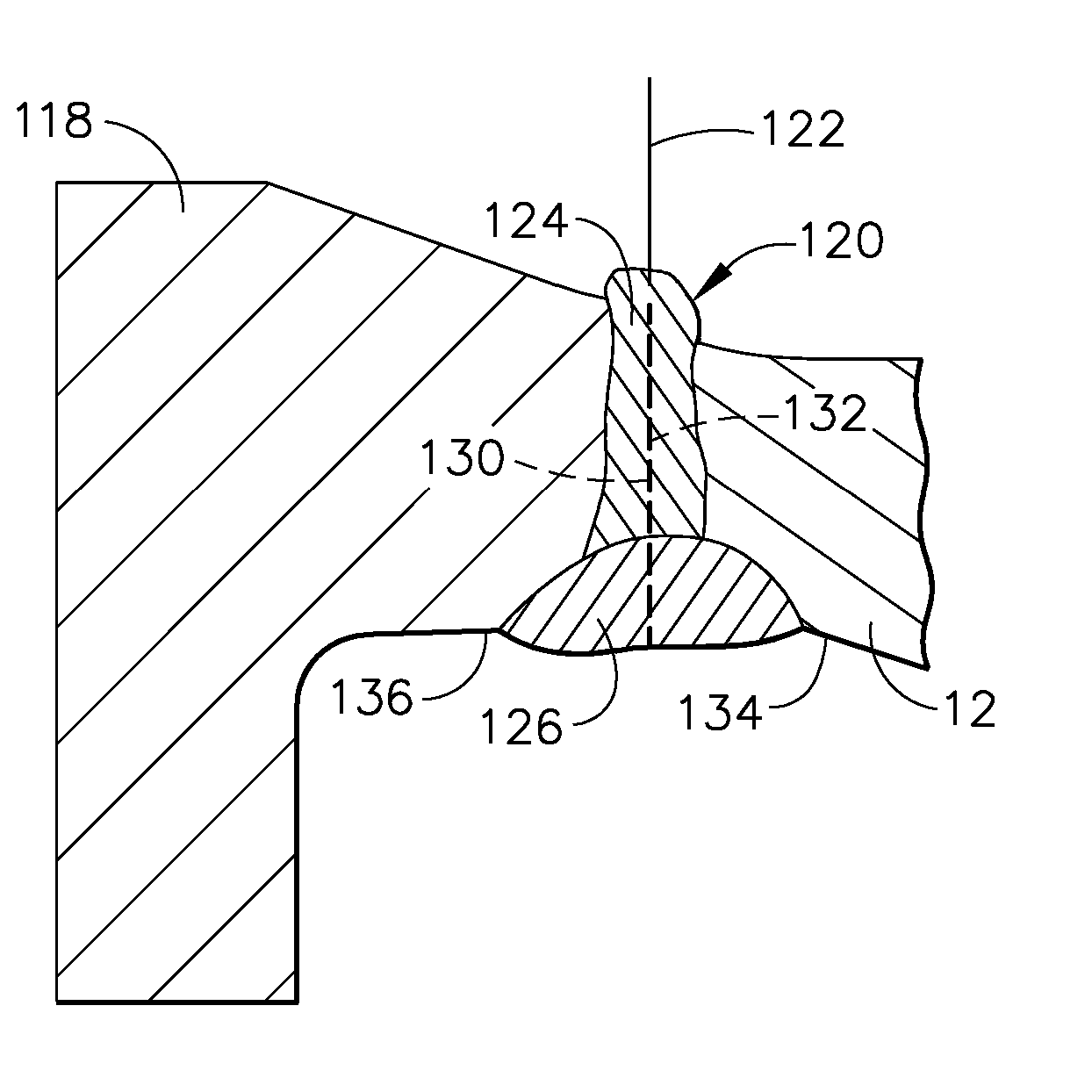

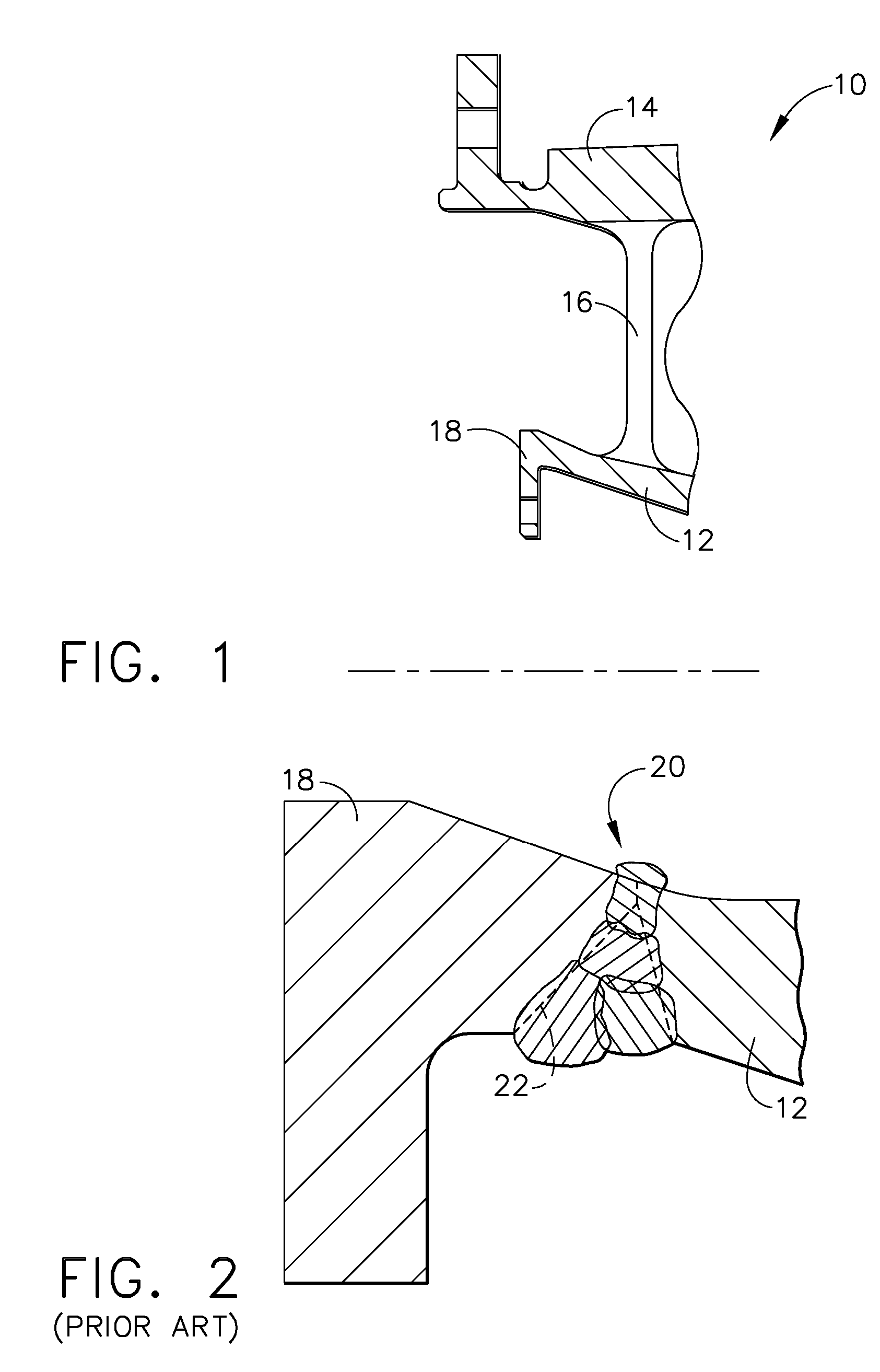

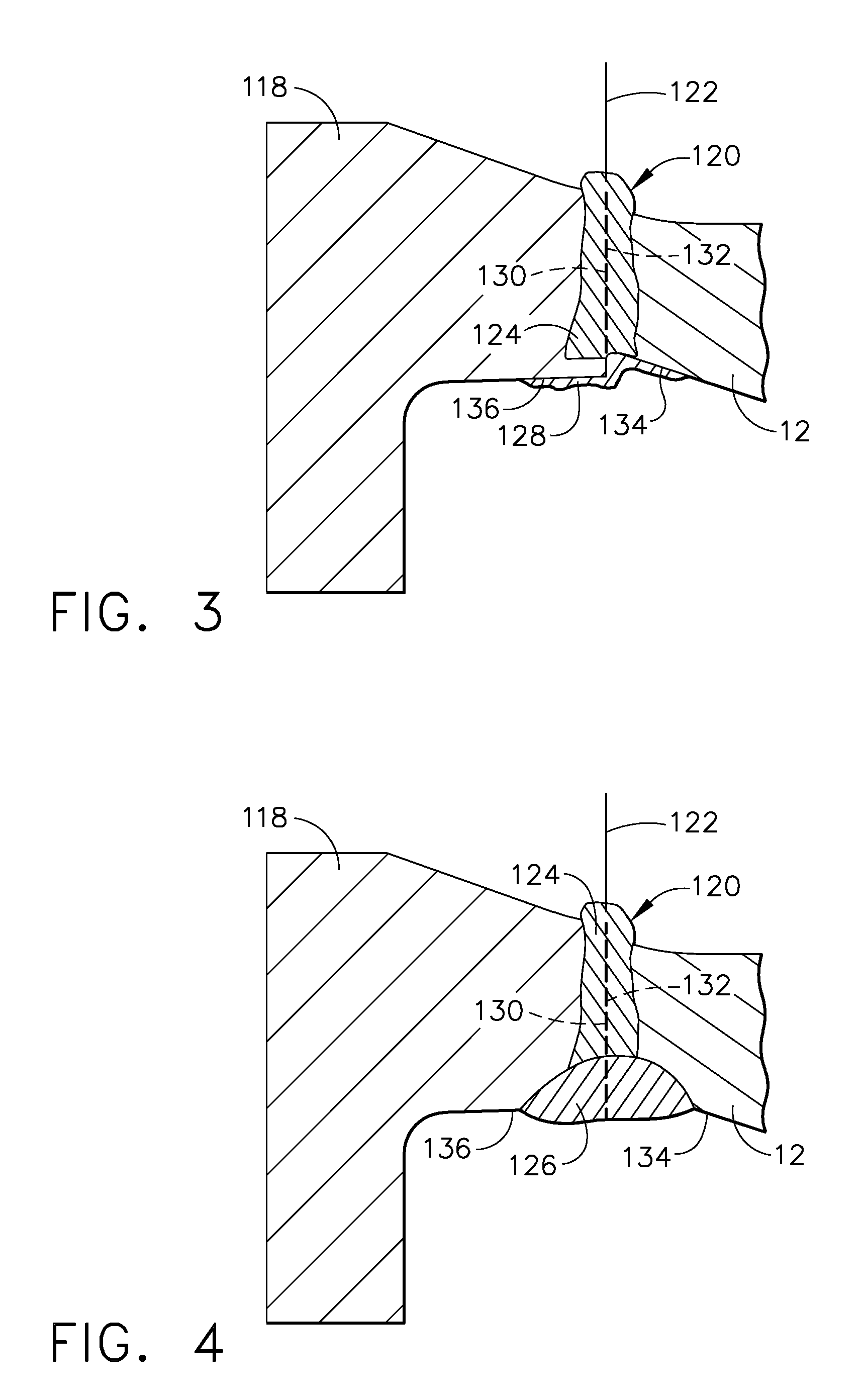

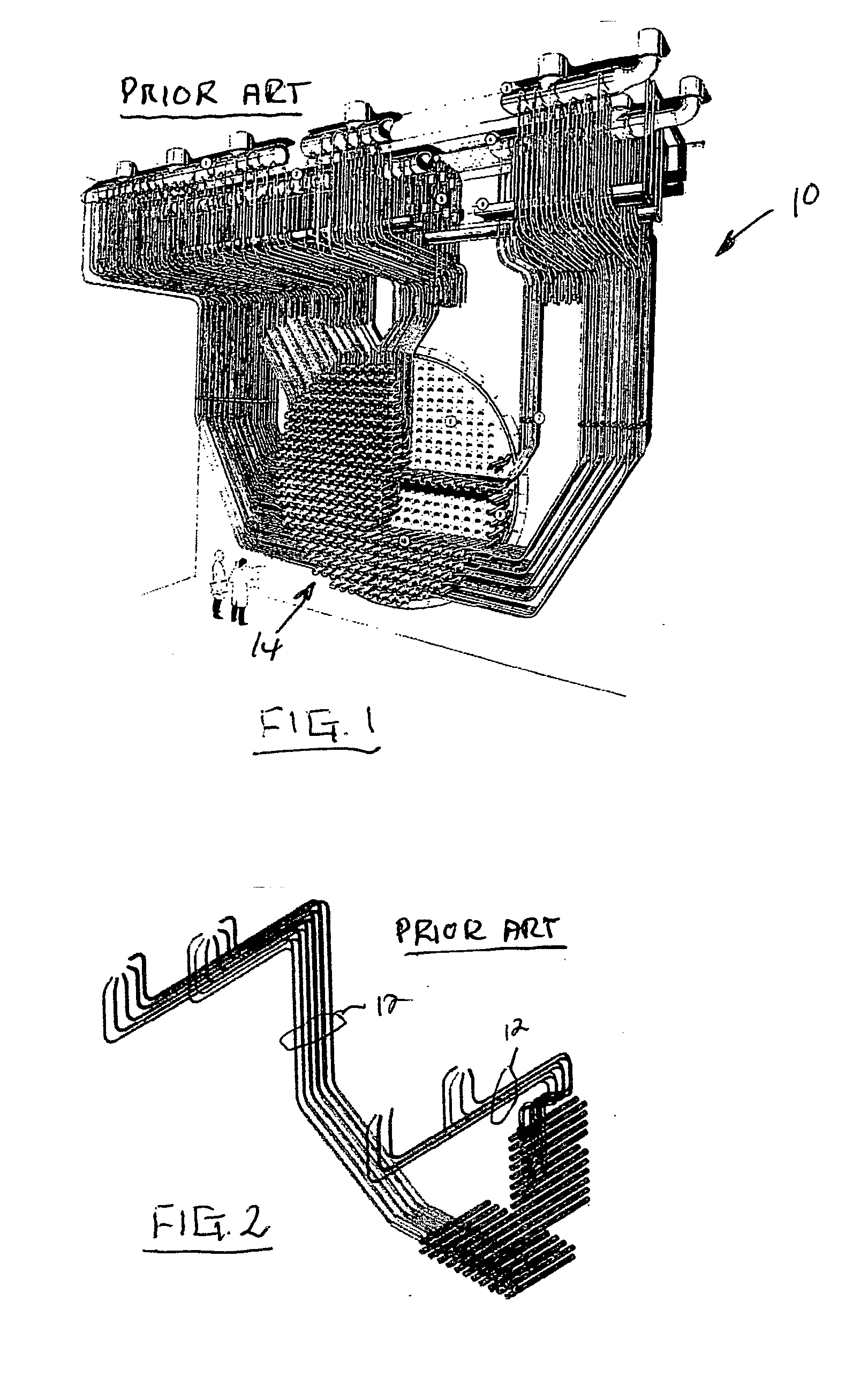

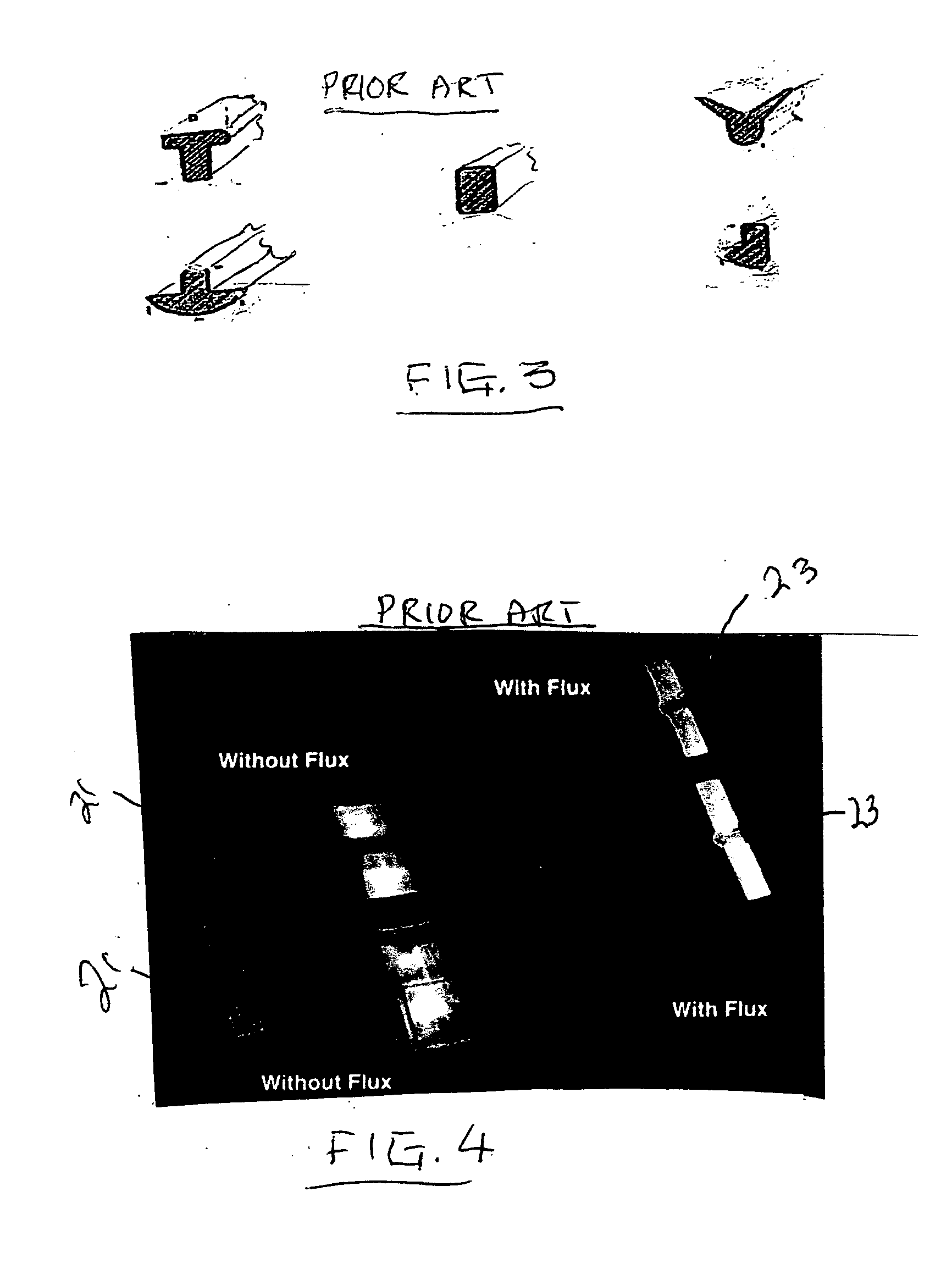

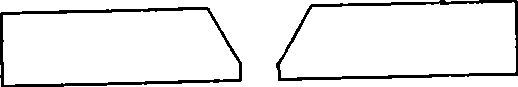

A process for repairing a compressor rear frame of a gas turbine engine. The process entails removing a seal flange from the inner casing wall of the frame to define an annular face on the casing wall, and fabricating a replacement flange to have an annular face with a radial width greater than the radial width of the annular face of the casing wall. The faces of the flange and wall are mated to form a joint, a penetration-enhancing flux is deposited adjacent the joint, and a single-pass gas tungsten arc welding operation is performed to form a root weldment that extends completely through the joint. The flux is then removed and a gas tungsten arc welding operation is performed to deposit a filler on the root weldment and form a second weldment that completely overlays but does not penetrate through the root weldment.

Owner:GENERAL ELECTRIC CO

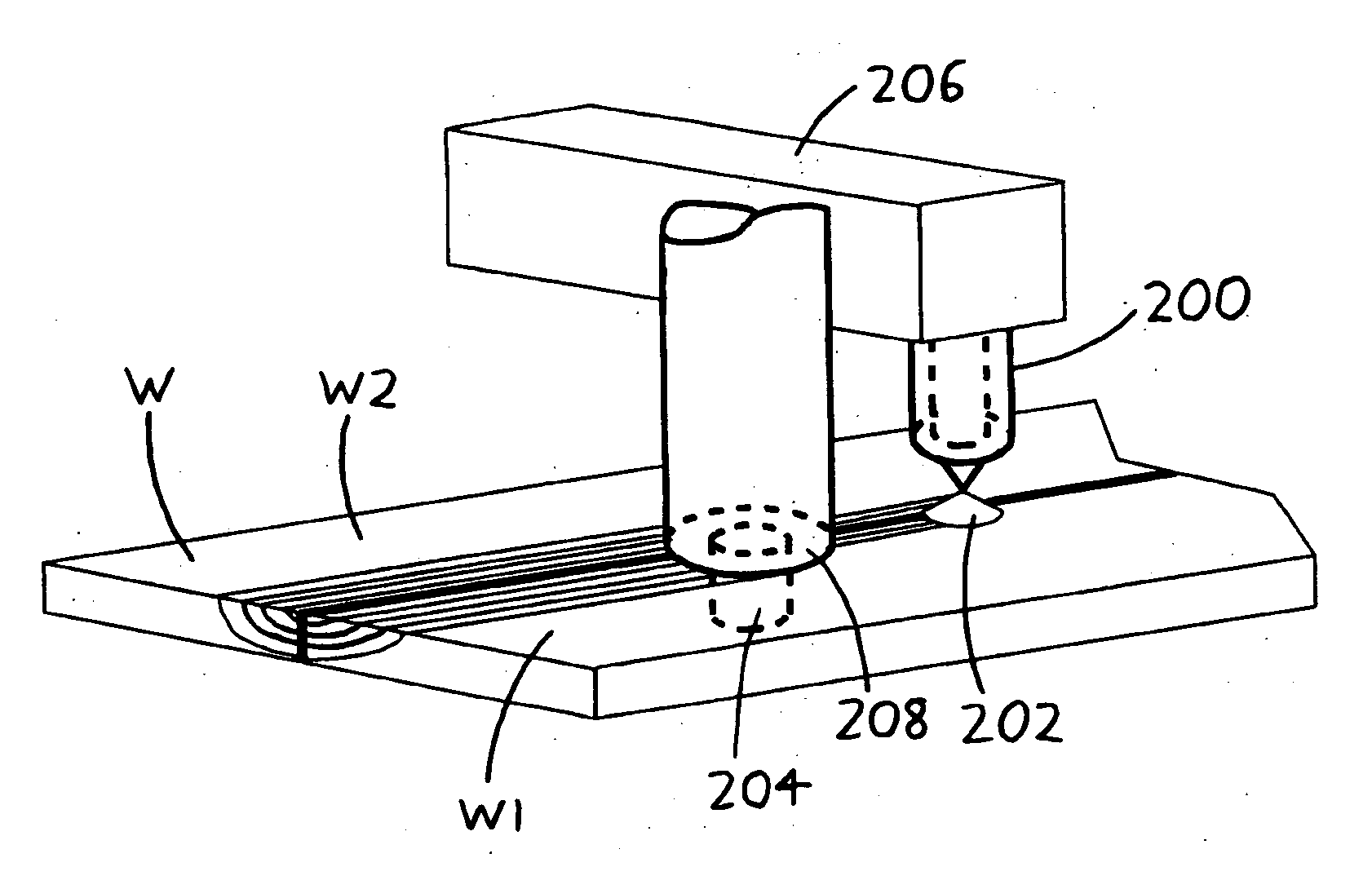

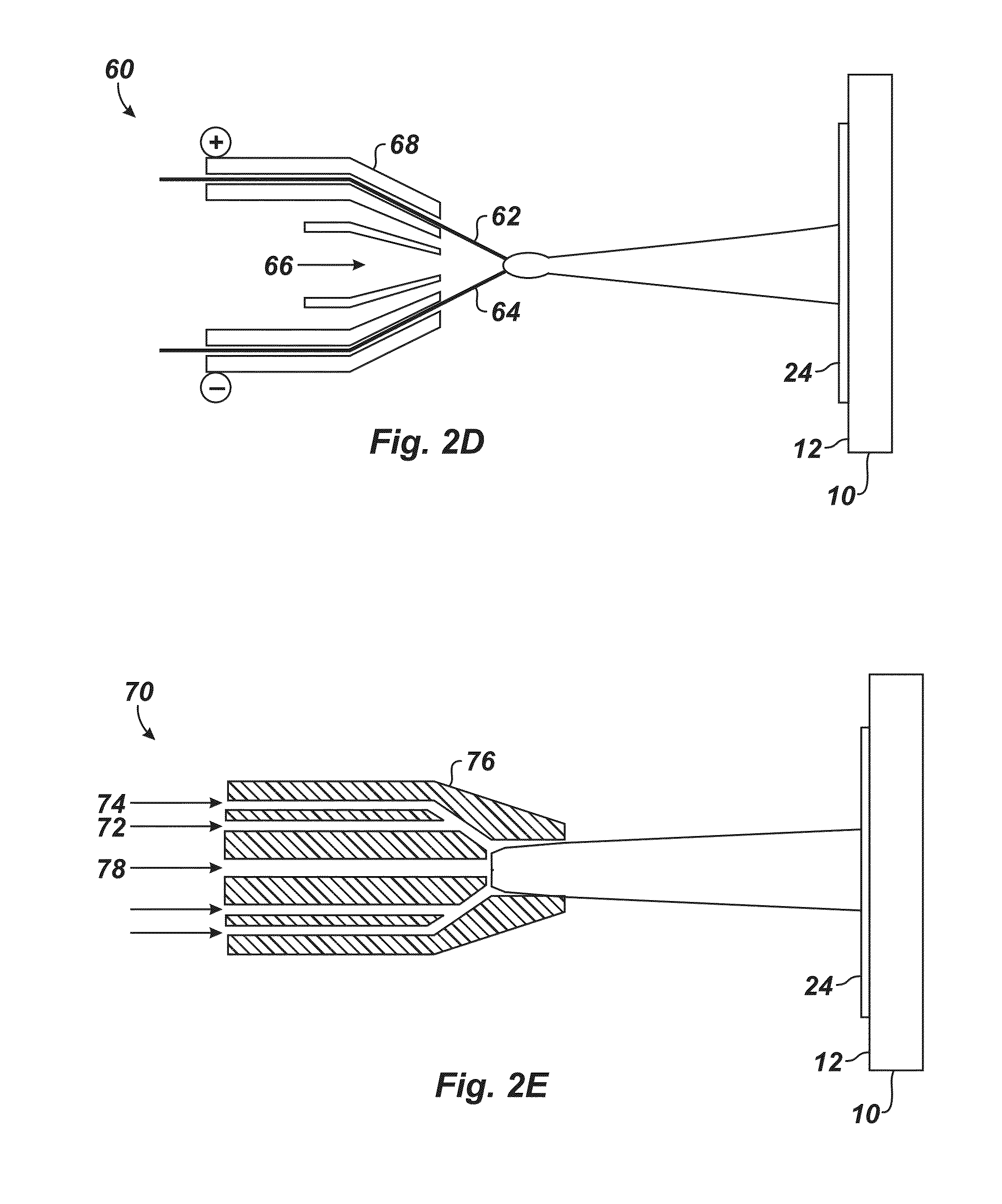

Arc-enhanced friction stir welding

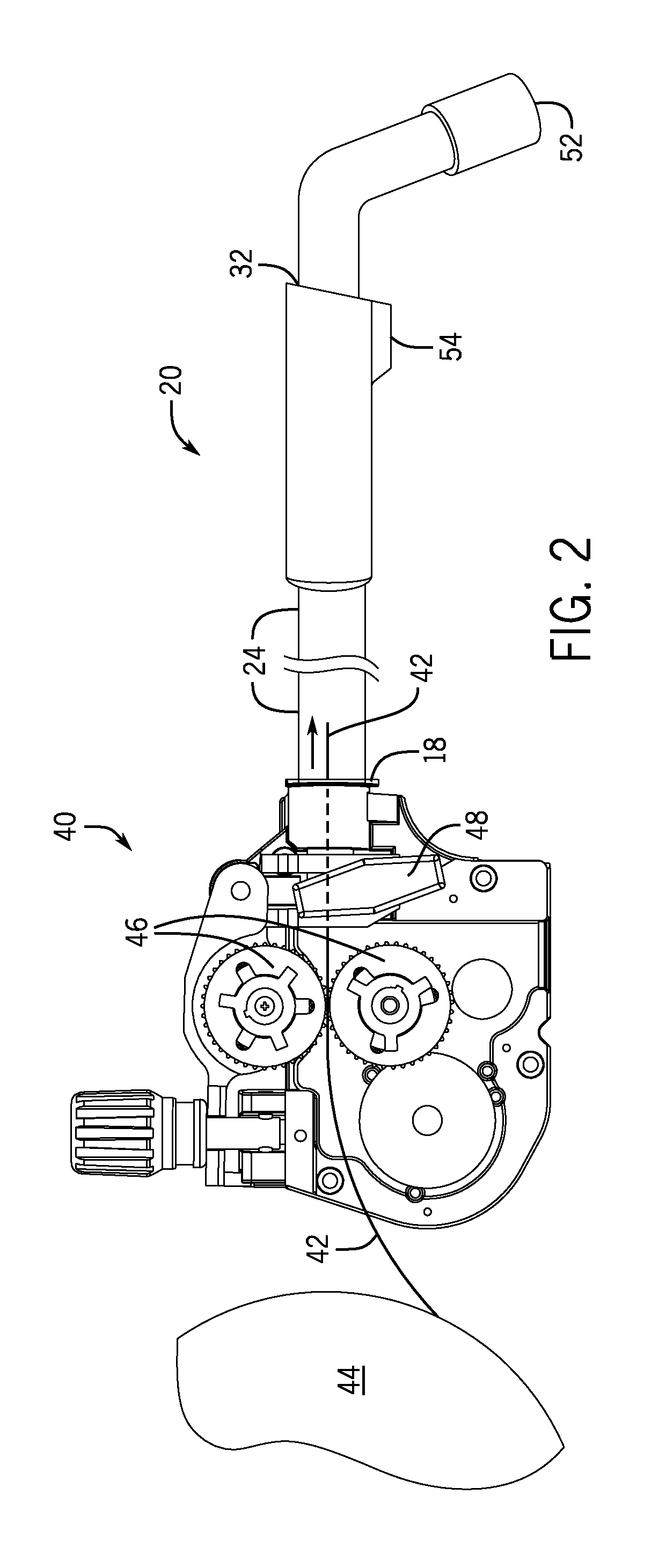

ActiveUS20060086707A1Less energy inputWelding/cutting media/materialsWelding electrode featuresEngineeringTorch

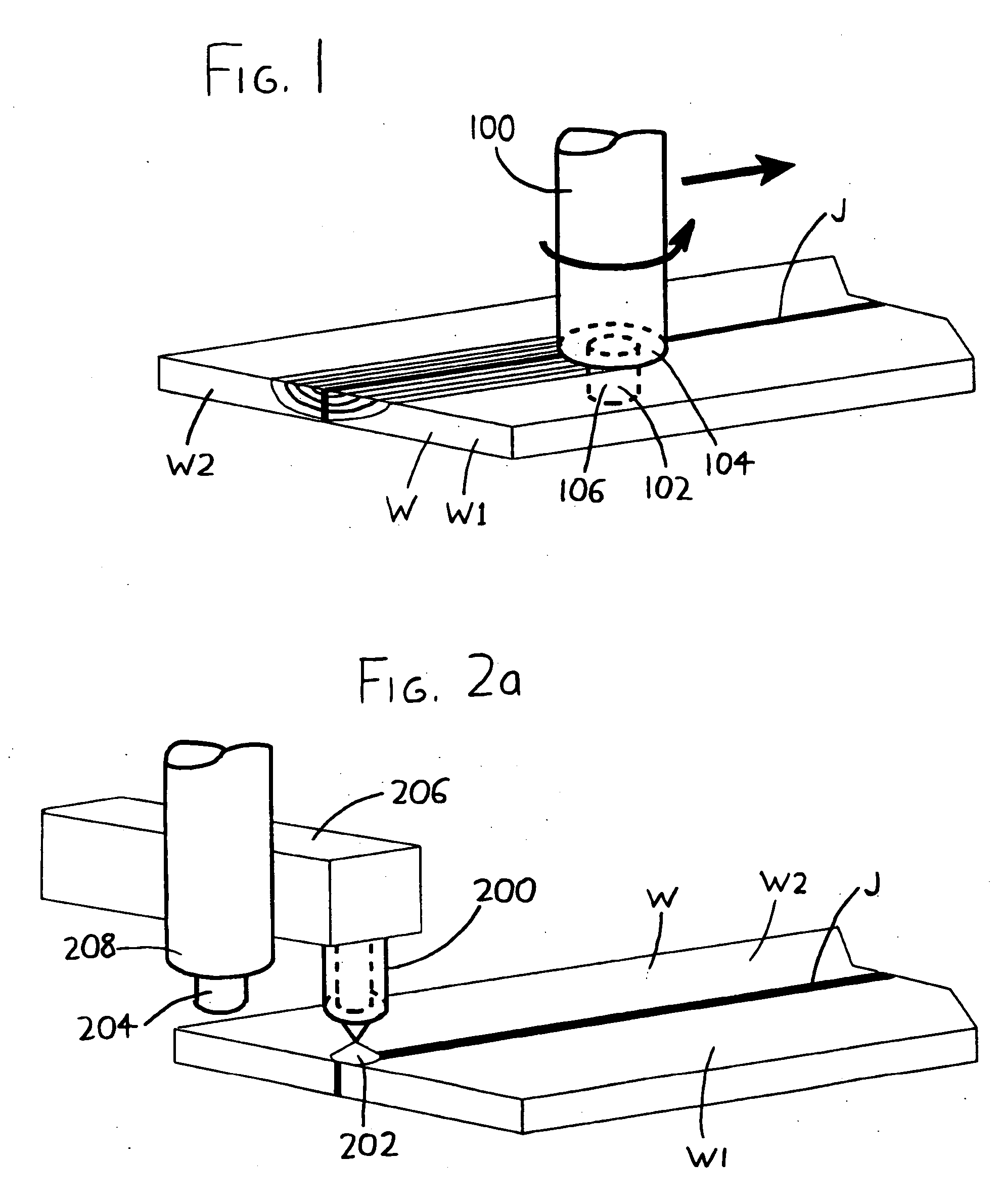

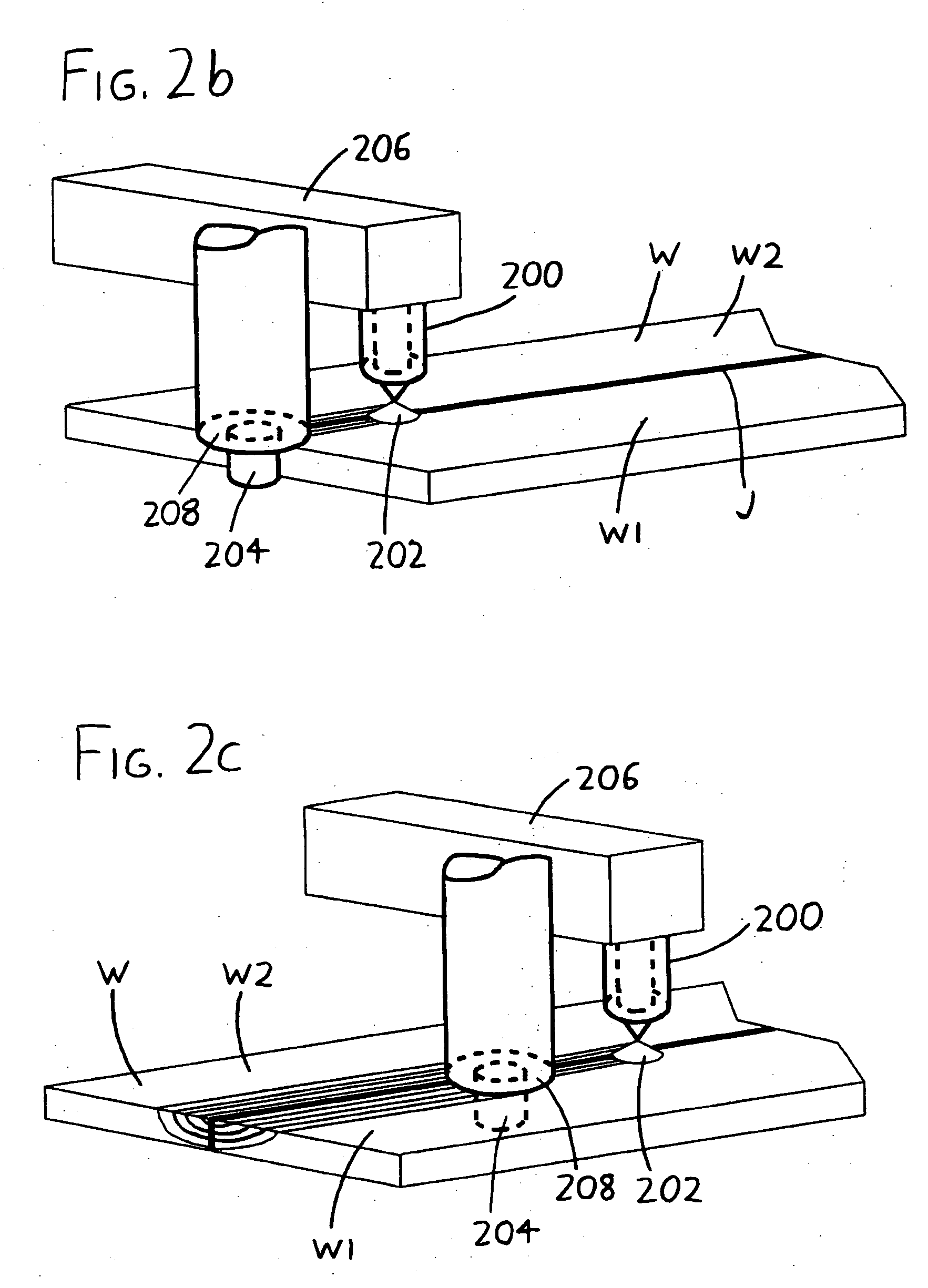

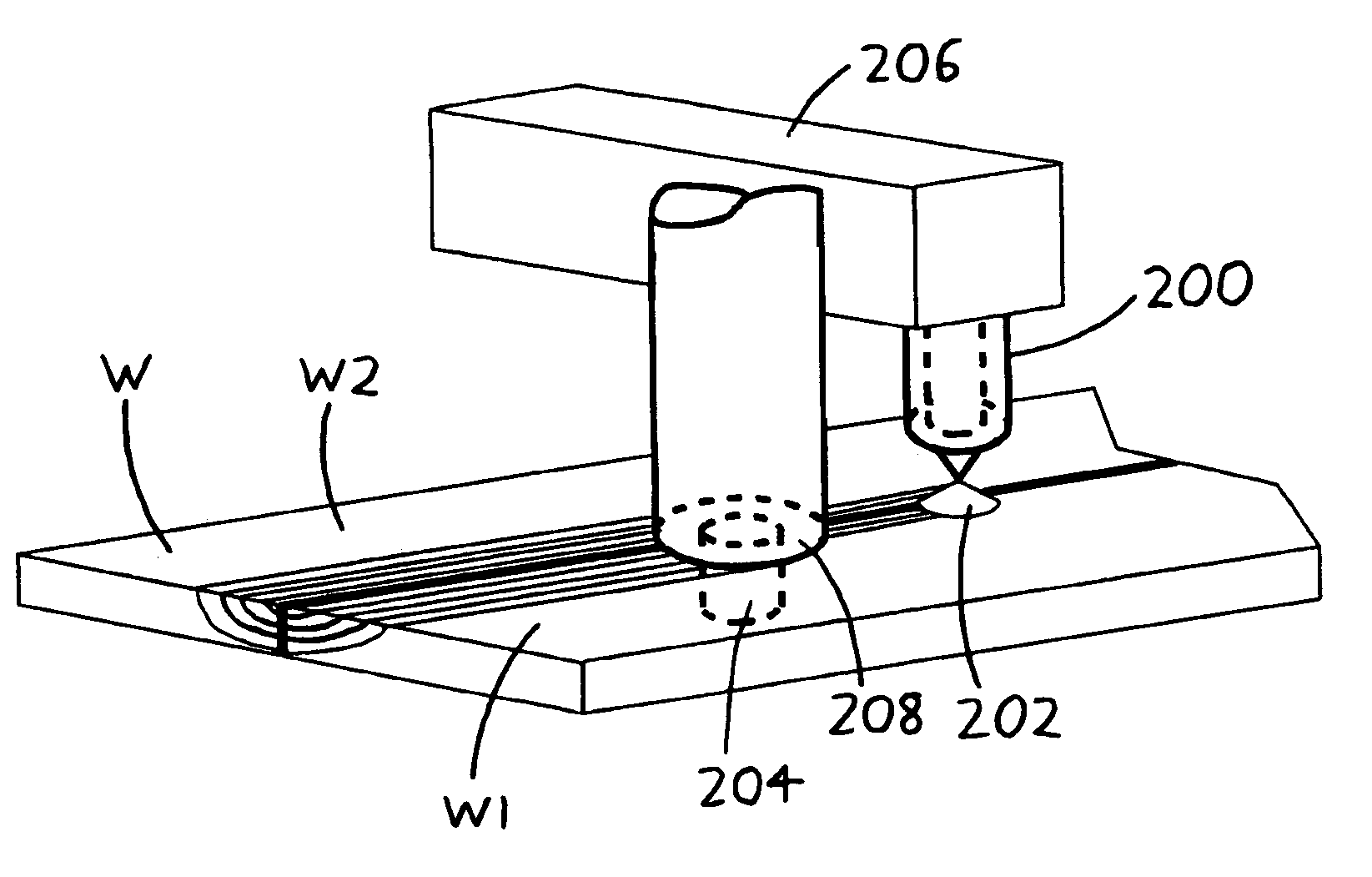

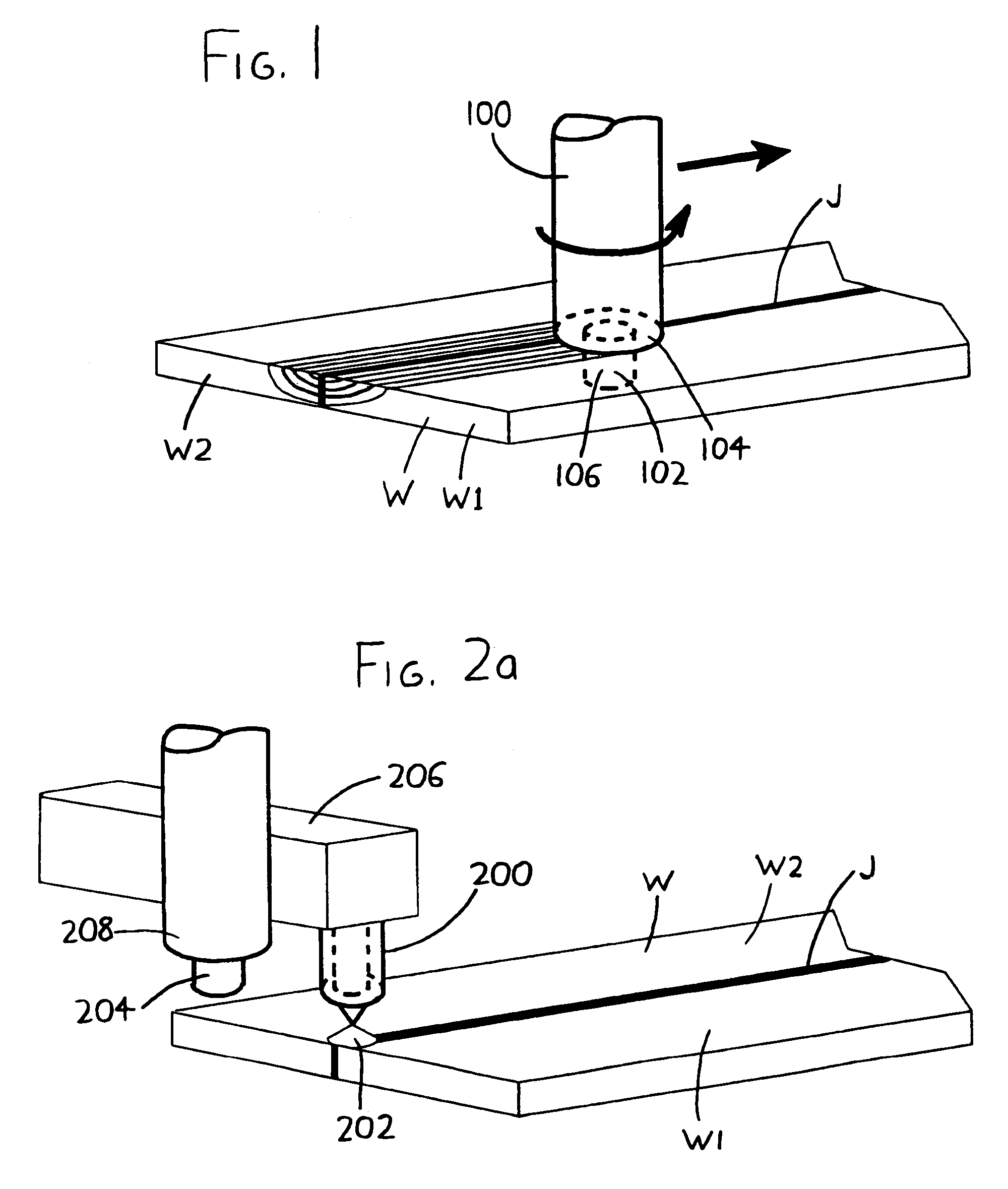

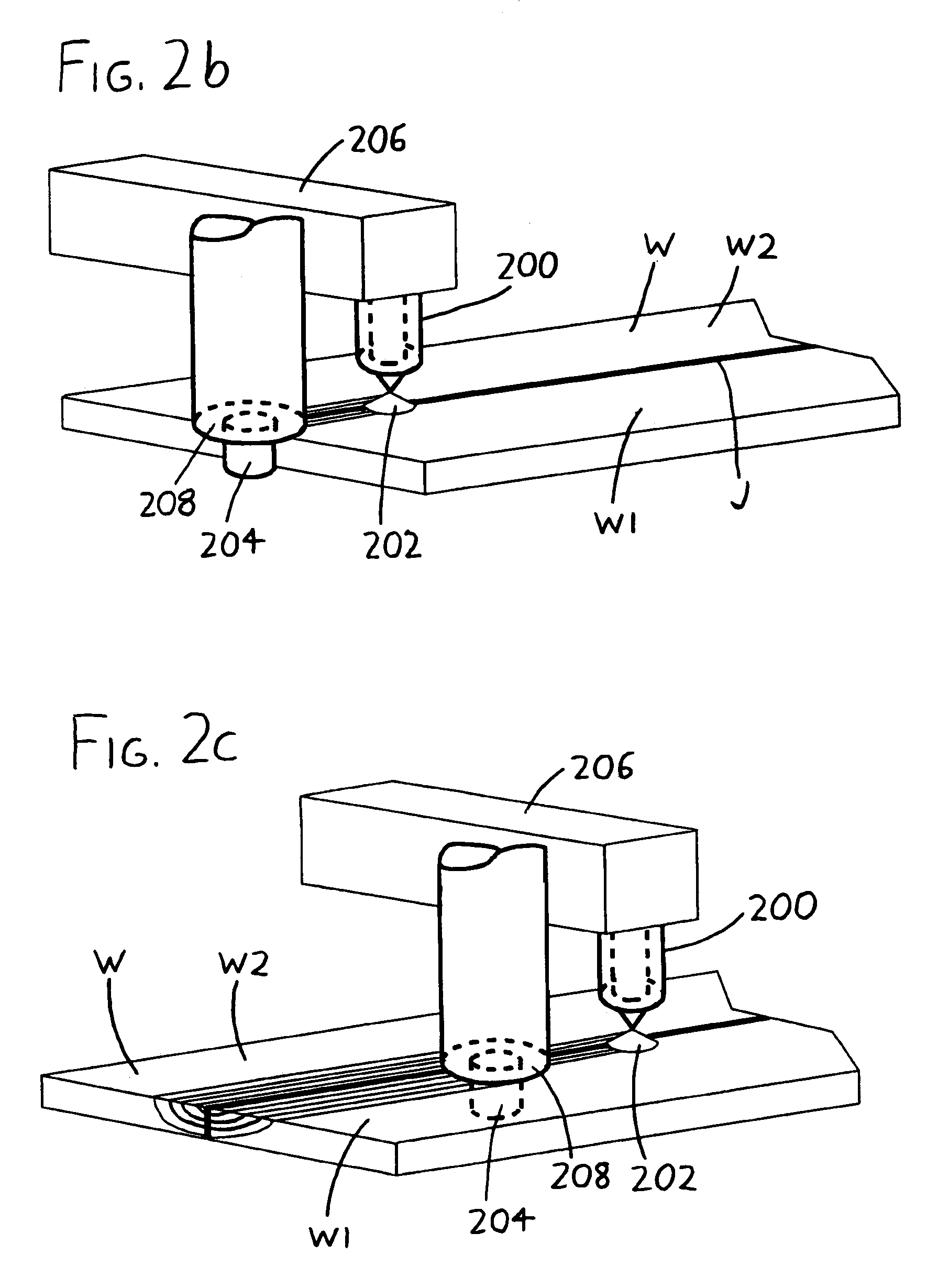

Friction stir welding is enhanced by preheating of the workpiece with an electrical arc, such as an arc applied by a common gas-tungsten arc welding (GTAW) torch. As the arc is moved about a path on the workpiece, it preheats or partially welds the path, with the friction stir welding head following along the path to complete the weld.

Owner:WISCONSIN ALUMNI RES FOUND

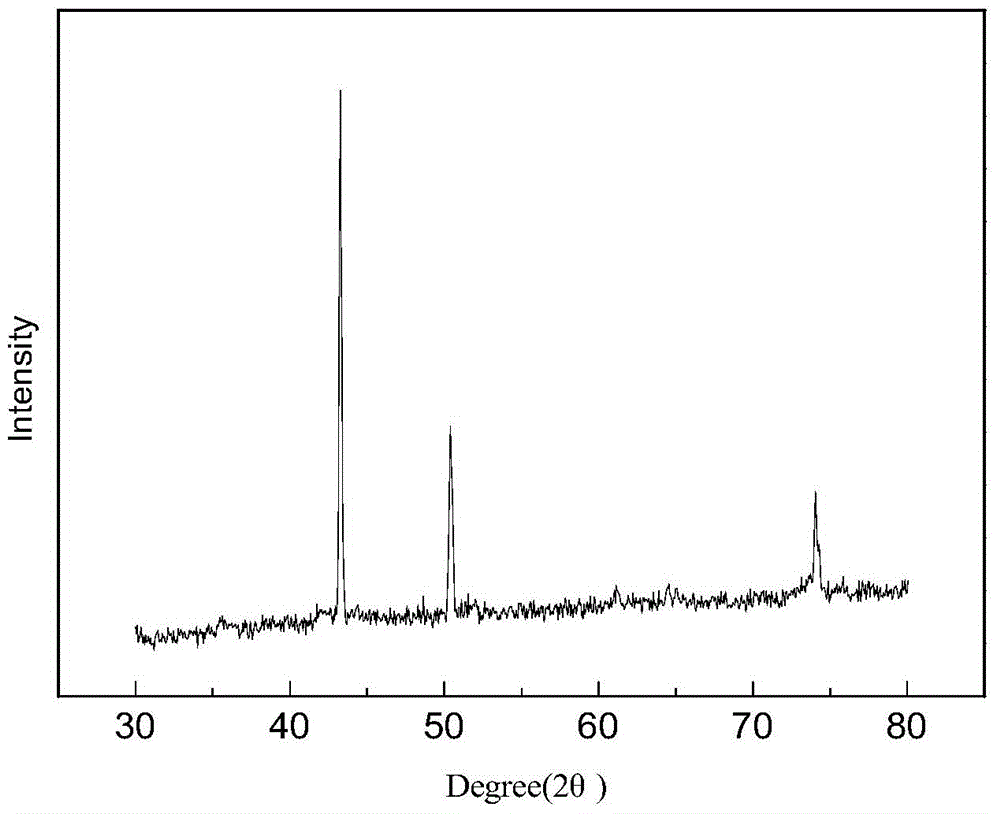

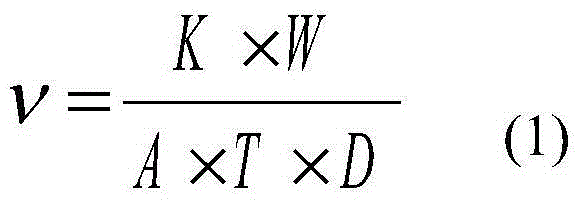

Method for detecting stability of gas tungsten arc welding (GTAW) additive manufacturing process based on arc voltage feedback

InactiveCN106363275AImprove stabilityLess susceptible to interferenceArc welding apparatusData acquisitionEngineering

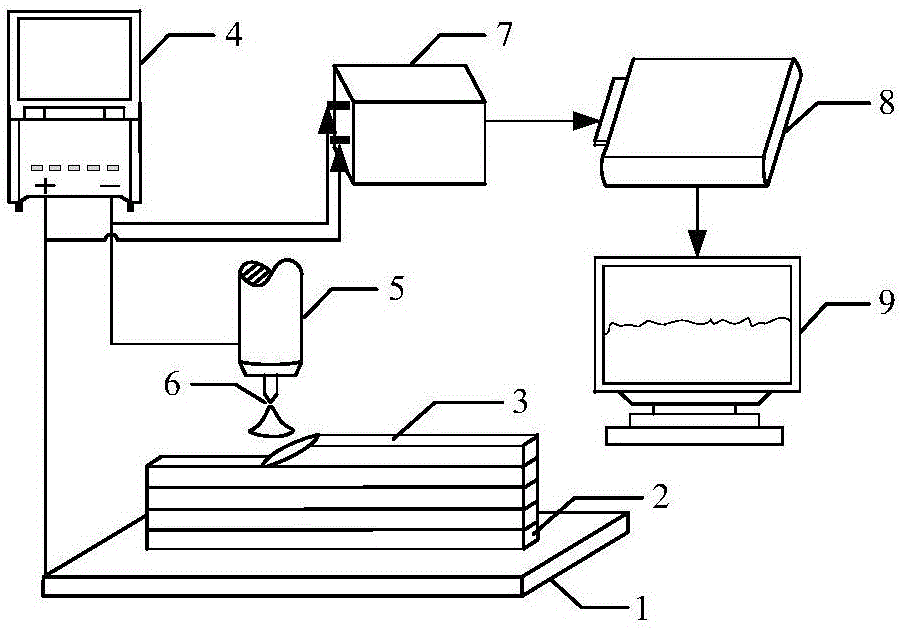

The invention provides a method for detecting the stability of the gas tungsten arc welding (GTAW) additive manufacturing process based on arc voltage feedback. The method comprises the steps that the stability of the process is reflected through the arc length, the arc length is indirectly fed back though arc voltage, and the initial position of a GTAW gun on a substrate is adjusted; in the forming process of a first layer, a voltage sensor is matched with a data acquisition card to obtain a variation signal of the arc voltage along a forming path; the arc voltage is converted into the arc length according to a calibration relationship, a variation signal of the arc length along a forming path is obtained, and a second layer, a third layer until the n layer are formed, so that a variation signal of the n layer arc length along a forming path is obtained; and if the arc length is within a certain range, it is judged that the forming process is stable. According to the method for detecting the stability of the GTAW additive manufacturing process based on arc voltage feedback, the purpose of real-time detection of the stability of the GTAW additive manufacturing process is effectively achieved, and the detection process is easy to operate, high in stability, not prone to being interfered by intense arc light, high in calculation speed, capable of achieving automation easily and suitable for engineering application of real-time site detection.

Owner:SOUTHWEST JIAOTONG UNIV

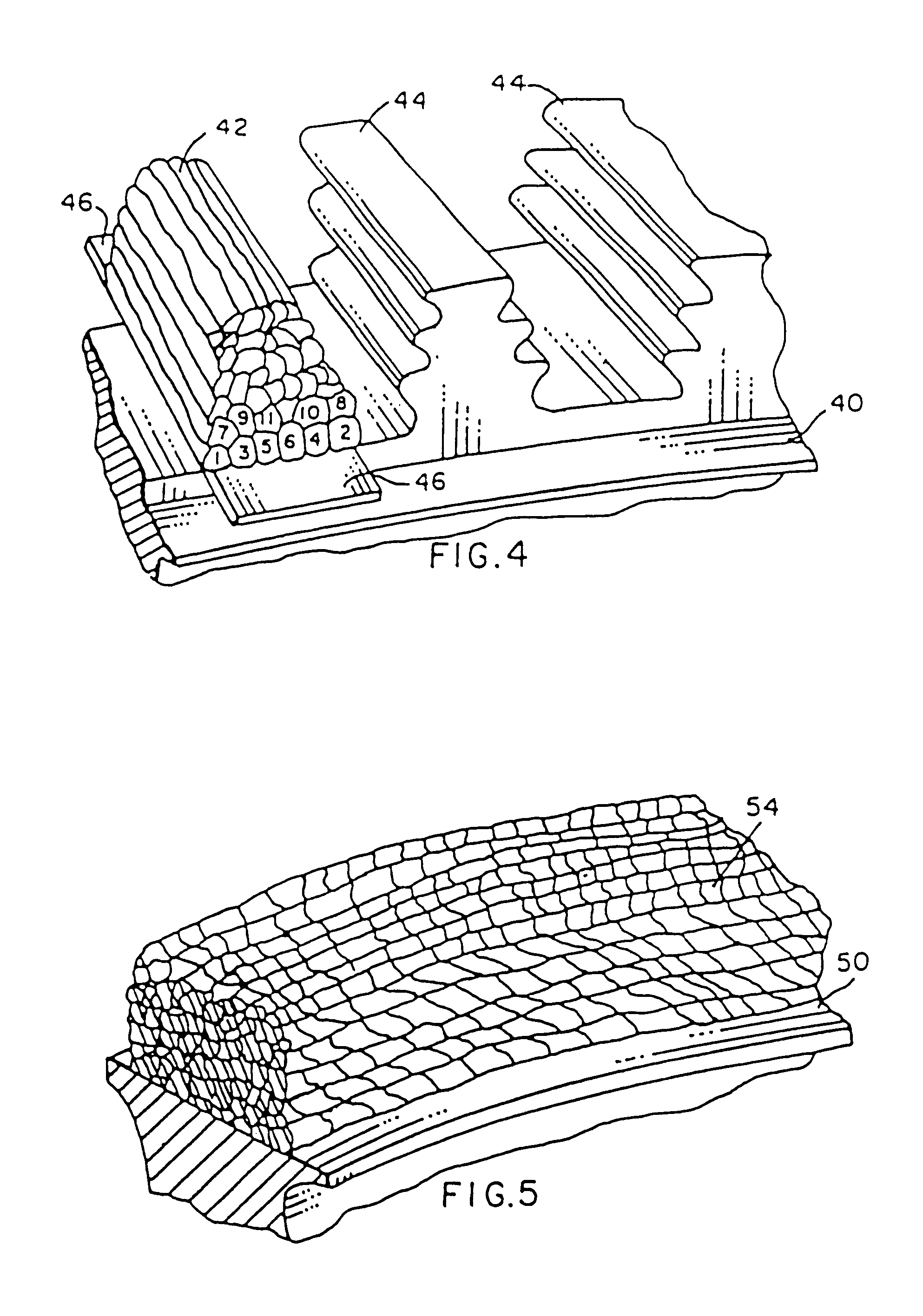

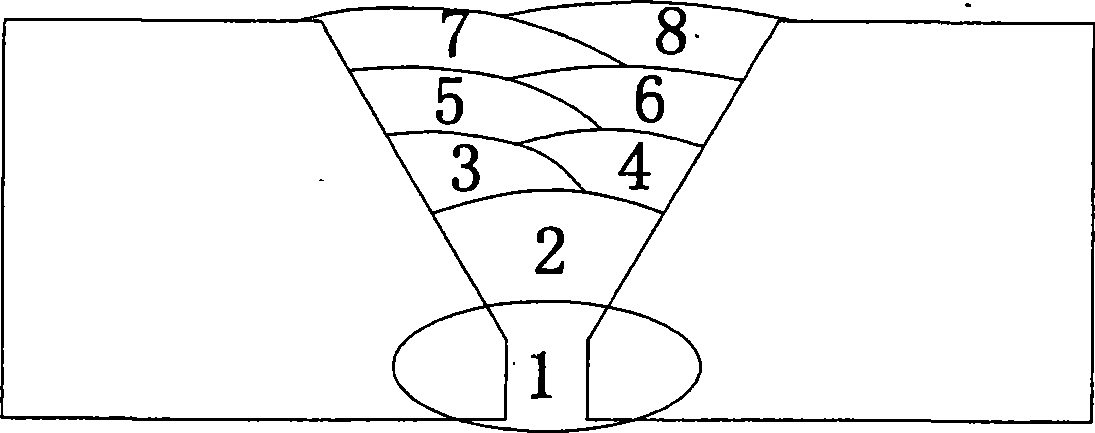

Turbine system having more failure resistant rotors and repair welding of low alloy ferrous turbine components by controlled weld build-up

InactiveUSRE37562E1Minimize weld stressMinimize cracksPropellersArc welding apparatusHeat-affected zoneAlloy

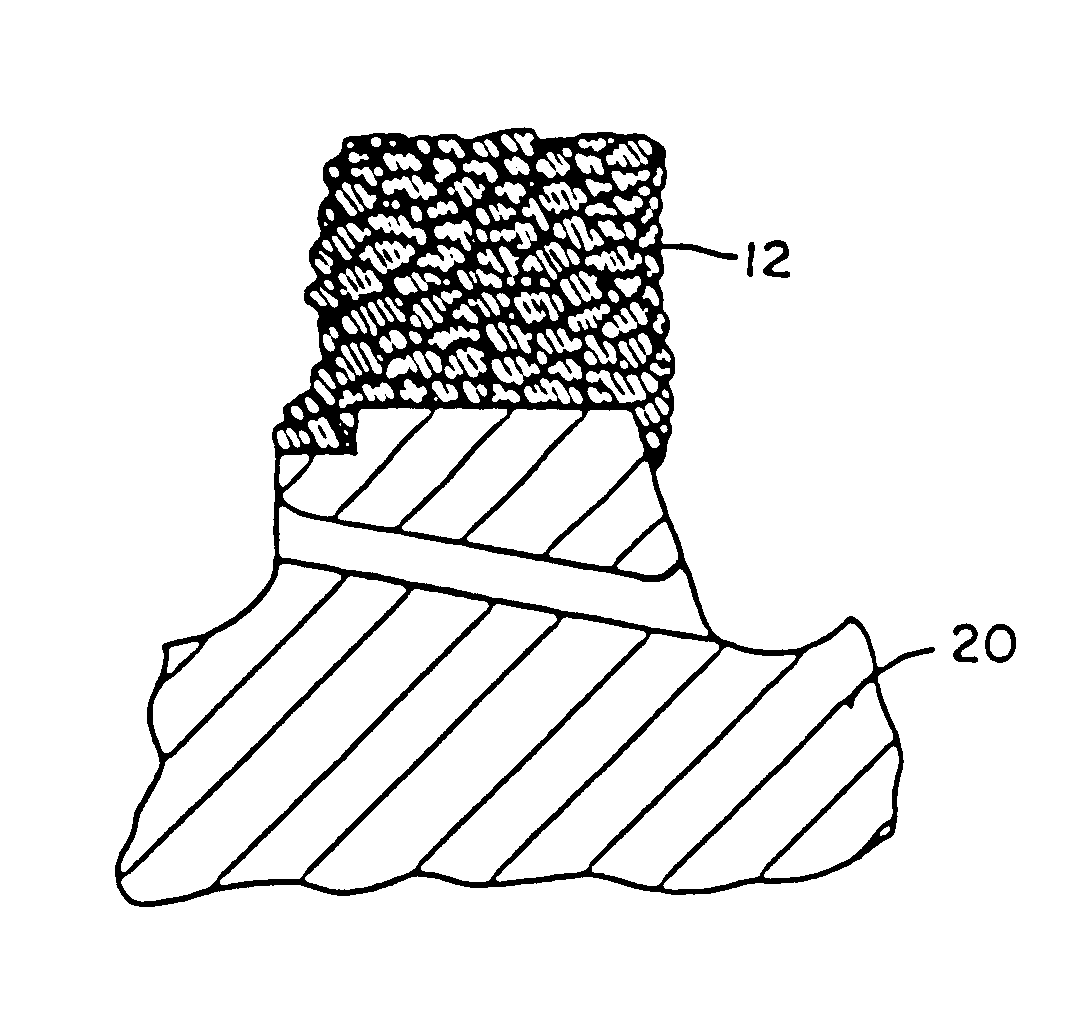

System for repairing worn surfaces of steam turbine components and especially high pressure turbine rotors, are disclosed. These systems include depositing a first layer of weld metal on a worn surface of the component, whereby a heat-affected zone is created. A second layer of weld metal is then deposited over the first layer using a greater amount of heat to temper at least a portion of the heat-affected zone produced by the first layer. The preferred embodiments include the use of gas tungsten arc welding for providing fine-grain size and more creep resistance, especially in the weld and heat-affected zone. The resulting build-up can be machined, for example into a blade fastening to produce a component having properties equal to or better than the base-metal alloy. The invention also provides a longer lasting turbine system, including rotors which have serrated steeples that are more resistant to failure.

Owner:SIEMENS POWER GENERATION

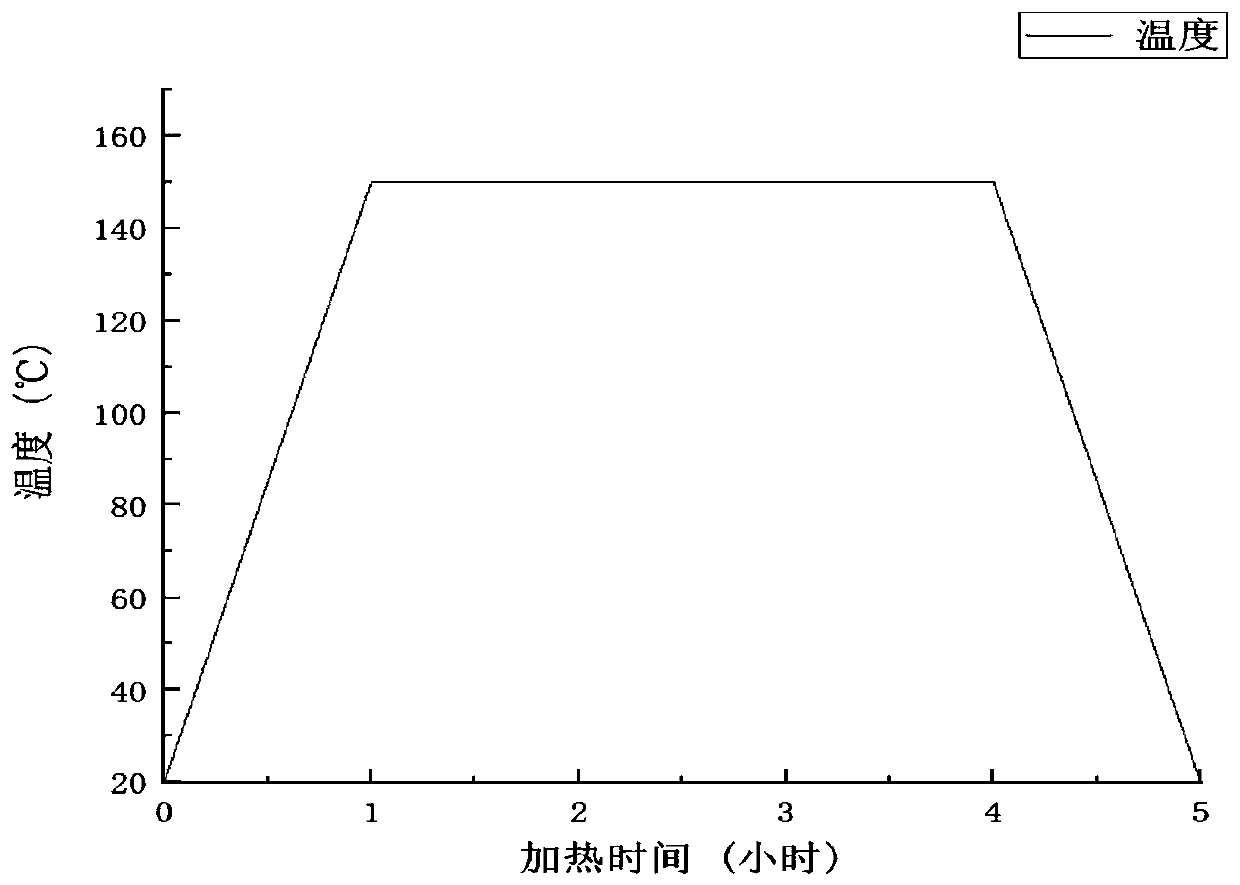

Method for preparing high-entropy alloy coating

InactiveCN103556146AHigh hardnessImprove wear resistanceArc welding apparatusMetallic material coating processesHigh entropy alloysGas tungsten arc welding

The invention relates to the field of multi-principal element high-entropy alloy materials and in particular relates to a method for preparing a high-entropy alloy coating, belonging to the field of coating preparation. The method for preparing the high-entropy alloy coating comprises the following steps: pretreating a substrate, so that the surface of the substrate is clean and flat; preparing high-entropy alloy powder, uniformly mixing, and adding 3-6wt% of organic solution in the alloy powder; uniformly mixing the organic solution and the high-entropy alloy powder, and preparing into paste; uniformly coating the pasty alloy powder on the treated substrate, wherein the thickness of the coating layer is 0.3-6mm; baking the treated coating layer and substrate in an oven at the temperature of 55-80 DEG C for 20-30 hours; cladding the coating layer on the surface of the substrate through gas tungsten arc welding. According to the method for preparing the high-entropy alloy coating, the high-entropy alloy coating with the thickness of 0.3-6mm can be prepared, a heat affected zone to the substrate in the preparation process is small, and the coating is uniform in distribution and firmly bound to the base material.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Method for welding circumferential weld between metal thin-wall clad layer and base layer of clad pipe

InactiveCN101927390AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsStainless steel electrodeUltimate tensile strength

The invention provides a method for welding circumferential weld between a metal thin-wall clad layer and a base layer of a clad pipe, which is used for welding circumferential weld of dual-metal clad steel pipes. The method is characterized by (A) groove processing: cleaning oil stains on the groove; (B) carrying out surfacing on the truncated edge, close to the clad layer, of the groove and coping the groove; (C) fitting up the groove of the dual-metal clad pipe; (D) root backing weld: adopting the gas tungsten arc welding method and carrying out welding along the groove of the dual-metal clad pipe under the state of argon-filled protection inside the pipe; (E) carrying out second layer welding on the root backing weld and welding the welding base layer of the dual-metal clad pipe; and (F) filled welding and cosmetic welding: wherein the welding materials are stainless steel electrodes. The method has the following effects: adopting 309 or 309Mo welding materials, thus ensuring the strength and good toughness of the weld; eliminating the gaps which probably exist between the clad layer and the base layer at the end of the groove; and increasing the effective thickness of the stainless steel layer at the groove root so that the quality of the welding joints are insensitive to misalignment, thus ensuring the corrosion resistance.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

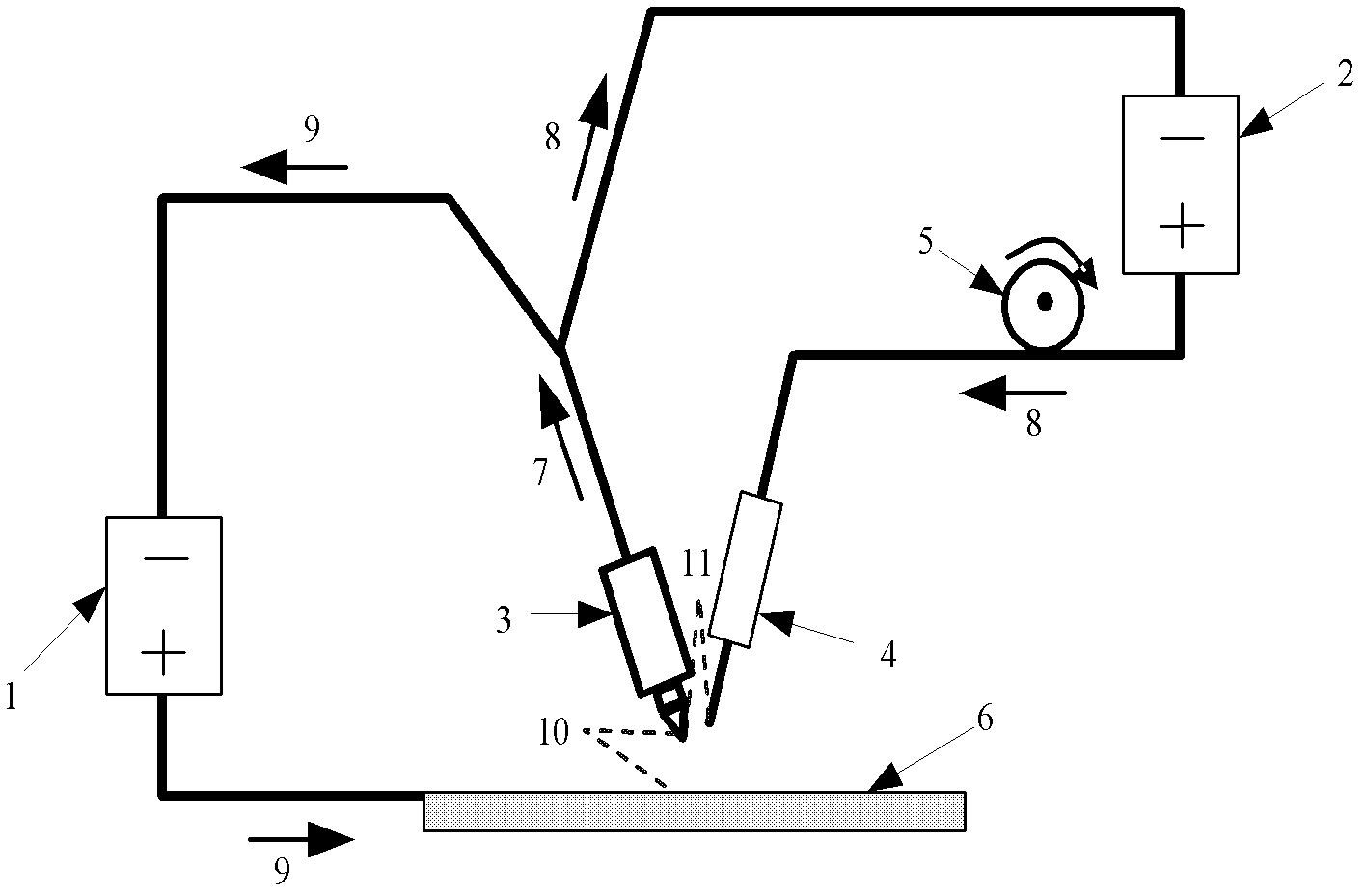

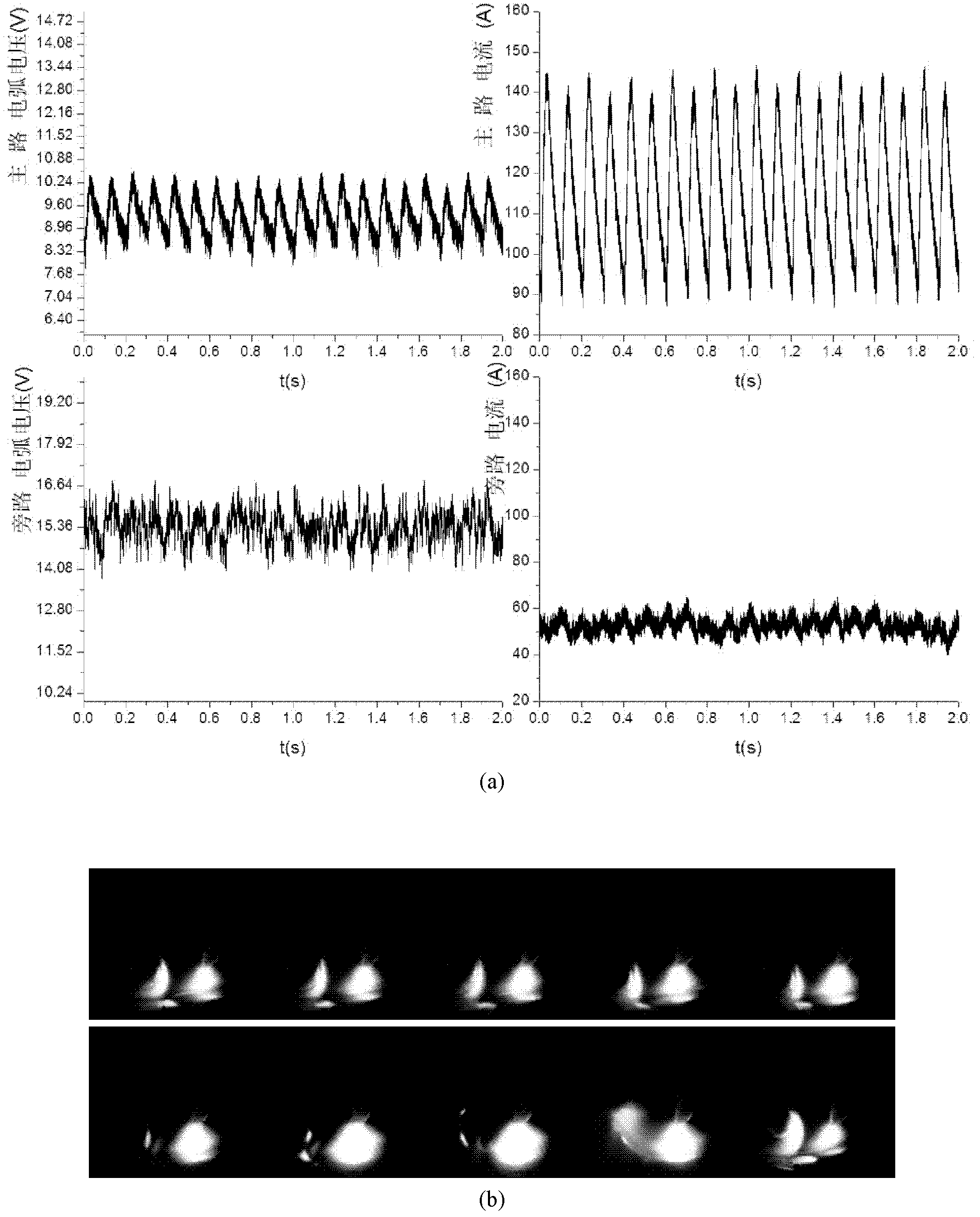

Gas tungsten arc welding (GTAW) system and welding method thereof

InactiveCN102500885AImprove heating efficiencyReduce the chance of failureArc welding apparatusHot meltEngineering

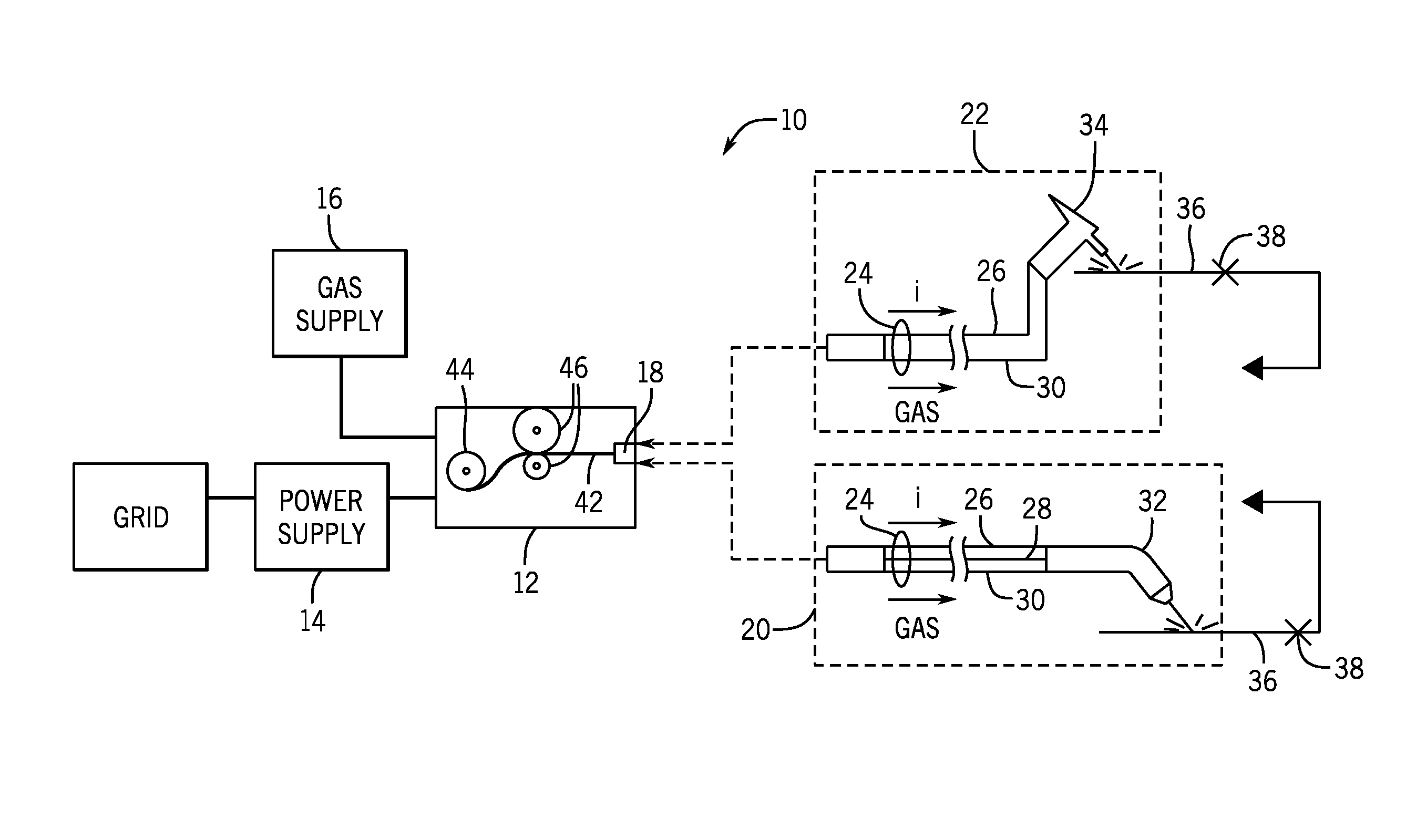

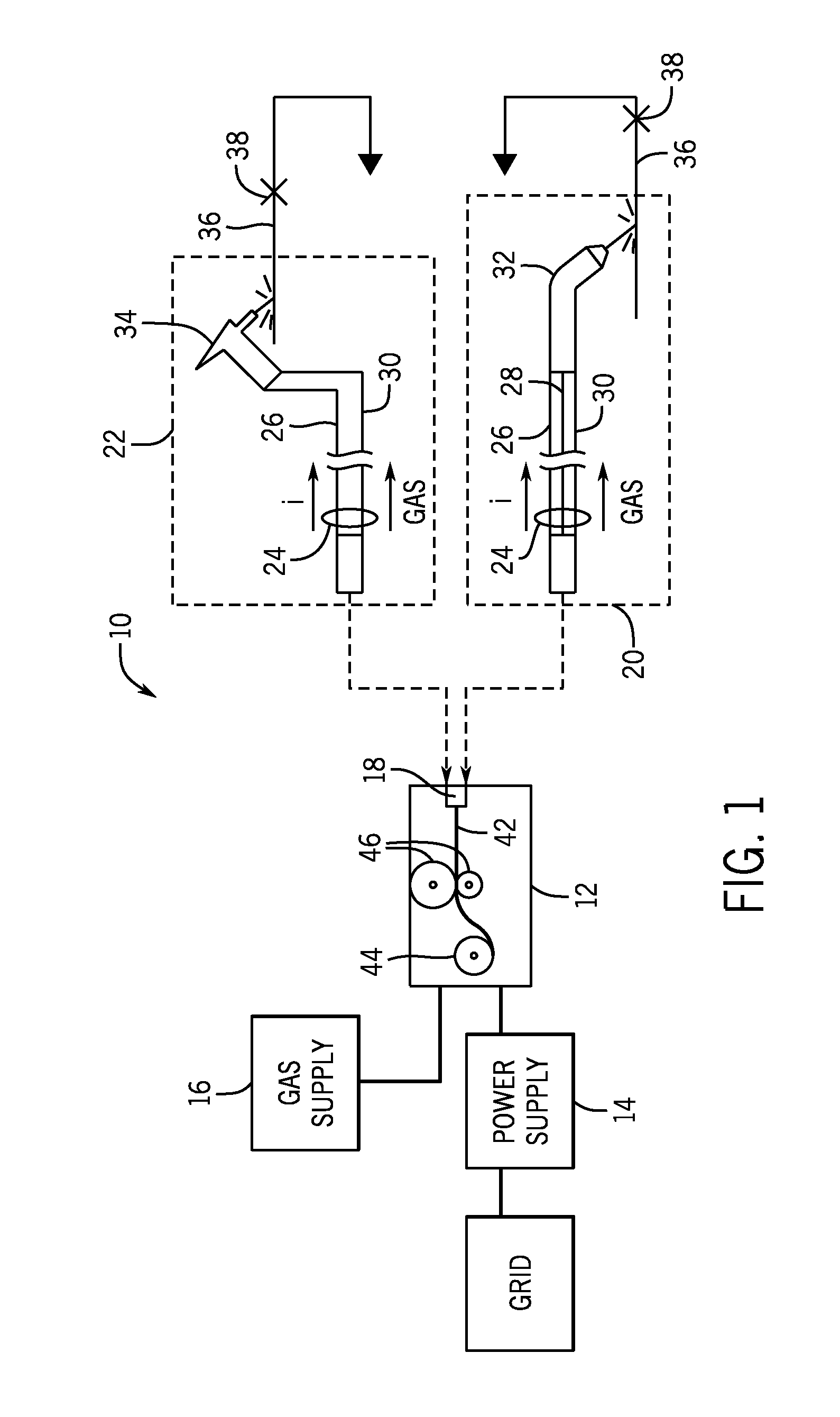

The invention discloses a gas tungsten arc welding (GTAW) system and a welding method thereof. The GTAW system comprises a first welding machine, a second welding machine, a wire conveying device, a first welding torch and a second welding torch, wherein the negative electrode of the first welding machine and the negative electrode of the second welding machine are connected with the first welding torch; the positive electrode of the first welding machine is connected with a workpiece; the positive electrode of the second welding machine is connected with the second welding torch; the first welding machine and the first welding torch form a main loop, so that a main loop arc is formed between the first welding torch and the workpiece; and the second welding machine, the wire conveying device and the second welding torch form a bypass loop, so that a bypass arc is formed between the second welding torch and the first welding torch. According to the method, the resistance heat of a welding wire is fully used for preheating the welding wire, and an arc heating fuse is used, so that the melting efficiency of the welding wire is improved further; due to the arc between a filling wire and a tungsten electrode and a self-adjusting function of the arc, the feeding speed of the welding wire is flexible, so that a wire clamping phenomenon is avoided, and the welding process is relatively stable; and the system and the method are suitable for various metal filling wires.

Owner:TIANJIN UNIV

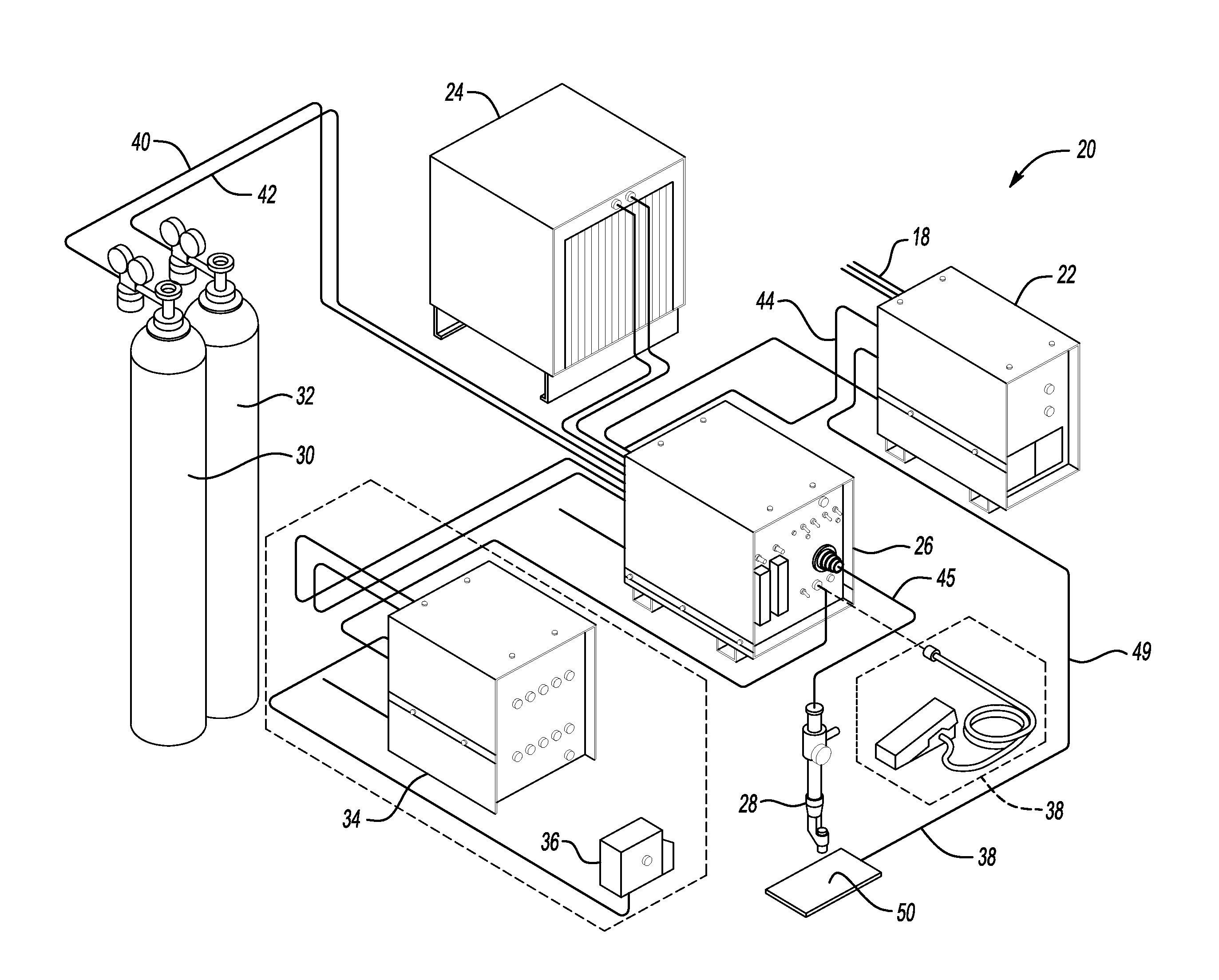

Method of converting a gas tungsten arc welding system to a plasma welding system

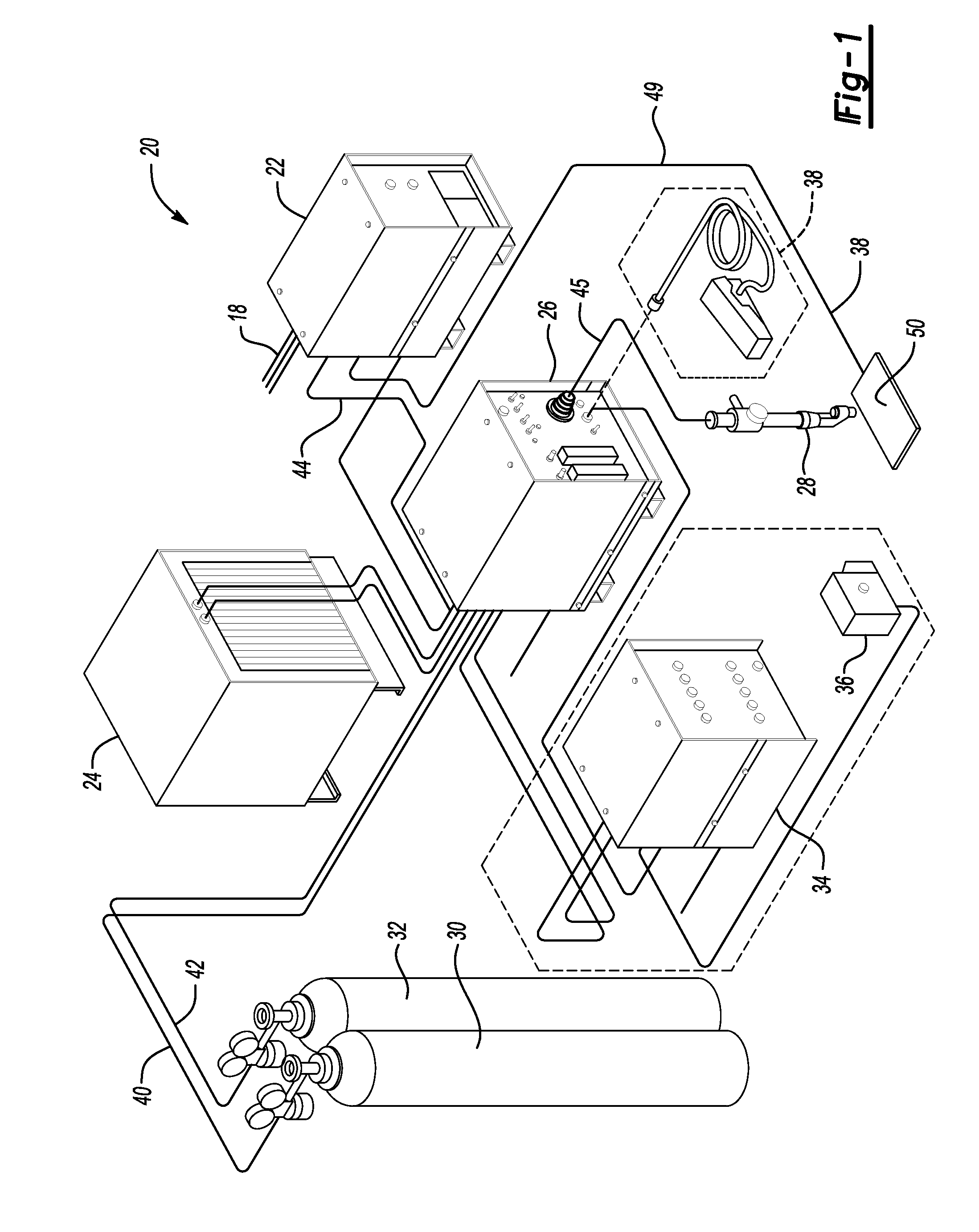

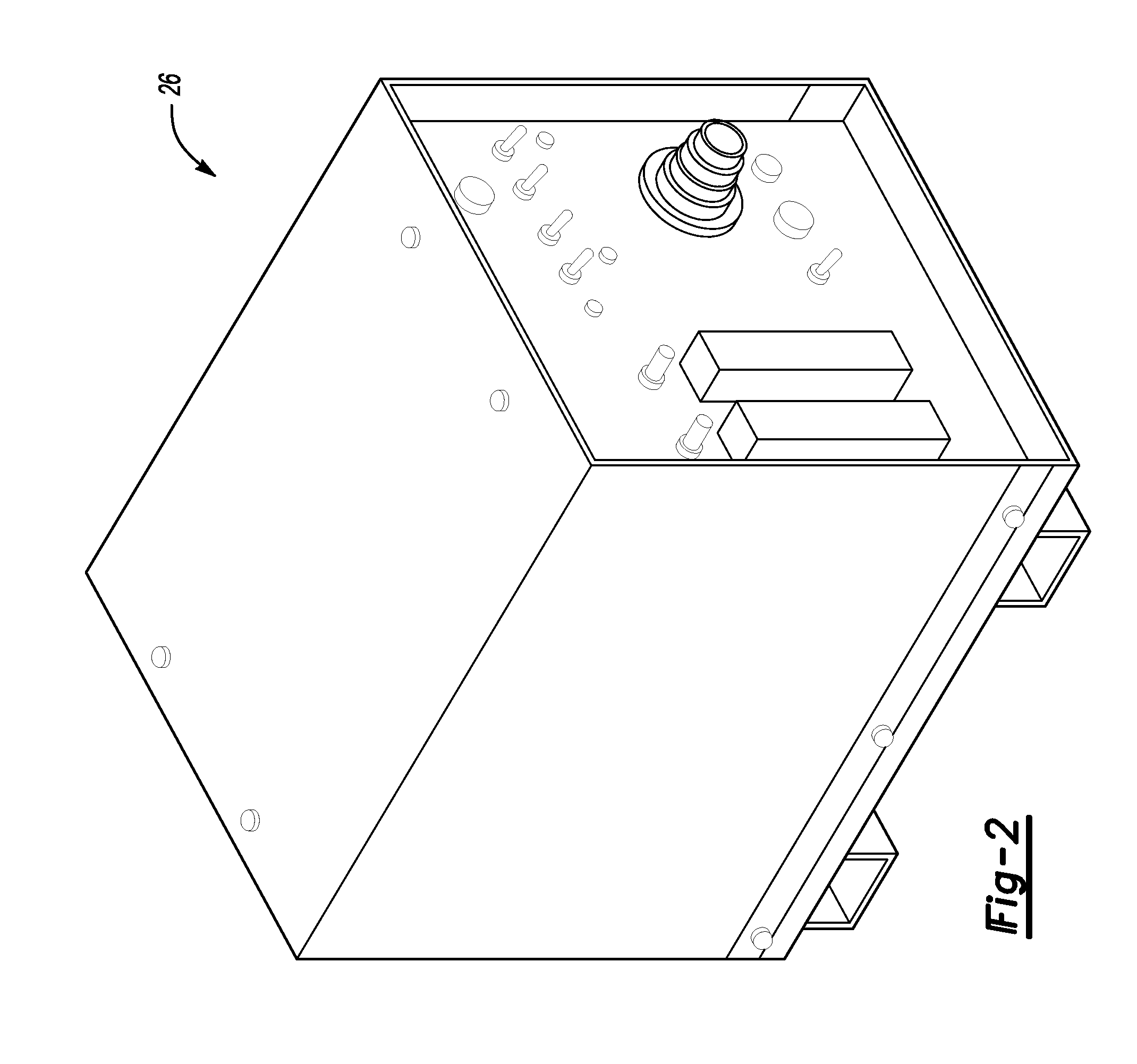

InactiveUS20100258534A1Prevent leakagePlasma welding apparatusWelding/cutting media/materialsCoolant flowWelding power supply

A welding system includes a gas tungsten arc welding power source having a welding arc contactor, a plasma welding torch, and a gas console that supplies gases to the plasma welding torch. The welding system also includes a coolant flow switch connected in series with the welding arc contactor. Power is not provided from the gas tungsten arc welding power source to the plasma welding torch when the coolant flow switch is not actuated.

Owner:CAMARC

Gas tungsten arc welding using flux coated electrodes

A method of applying a weld using a gas tungsten arc welding procedure. A filler element is provided to a welding location. The filler element includes a first material used during formation of a weld, and a second material that is capable of producing a slag upon melting thereof. A welding arc provides heat that melts portions of first and second components and the filler element proximate to the welding location to form a weld pool. The second material melts and forms a slag, which flows to an outer surface of the weld pool and shields the weld pool from exposure to reactive elements in the atmosphere. Upon cooling of the weld pool, the weld pool solidifies to form a weld between the first component and the second component.

Owner:SIEMENS ENERGY INC

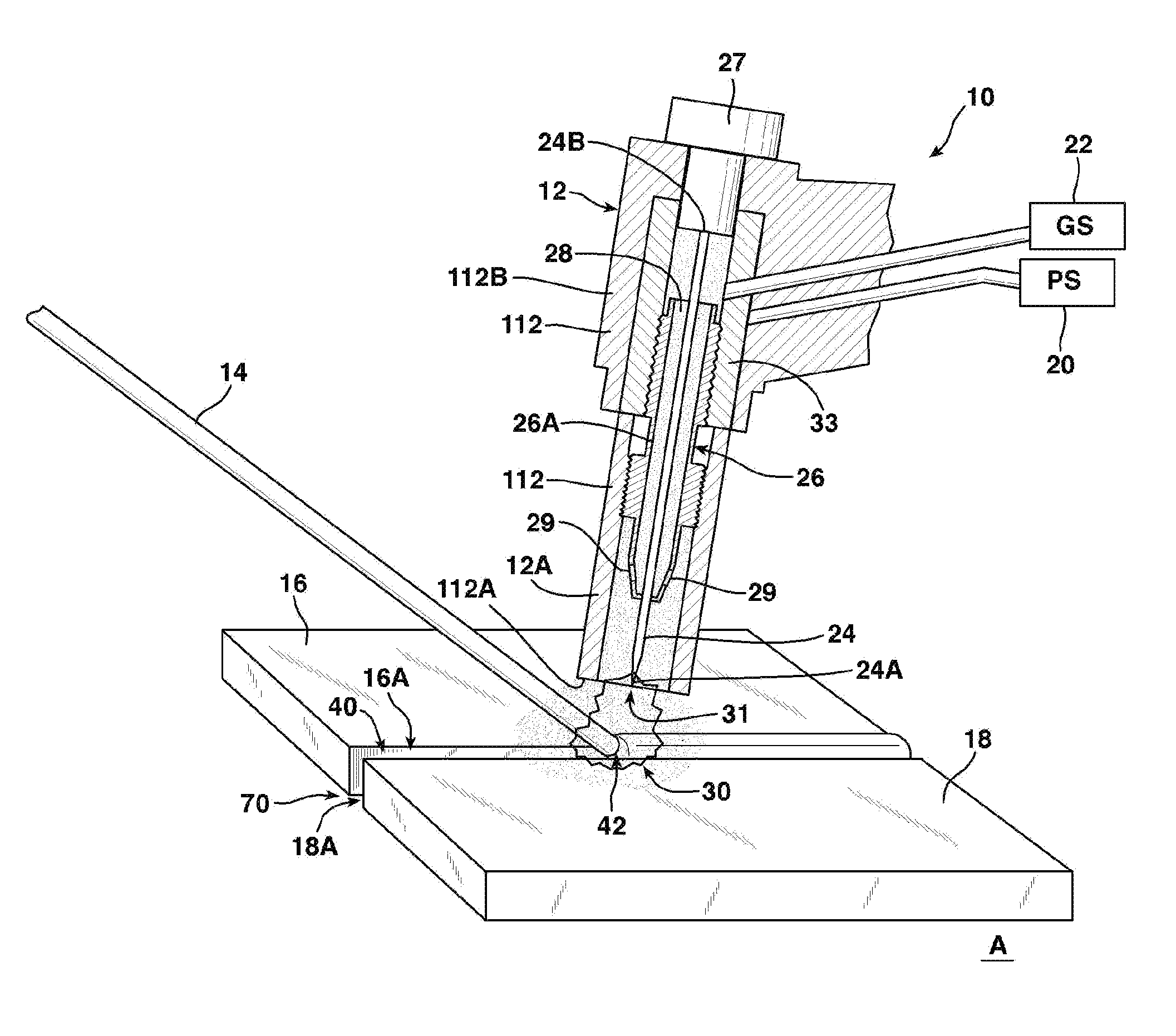

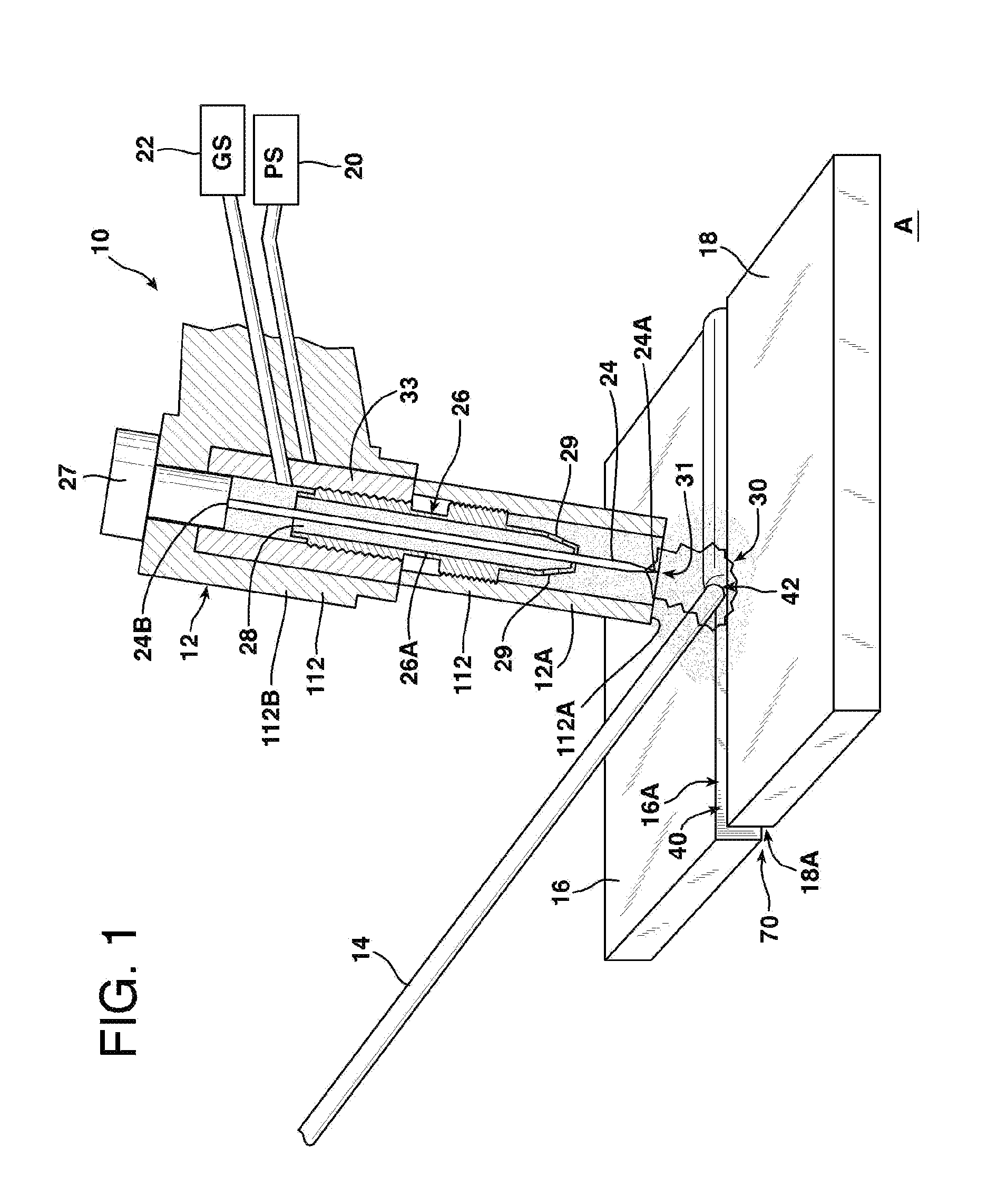

Arc-enhanced friction stir welding

ActiveUS7078647B2Welding/cutting media/materialsWelding electrode featuresFriction weldingEngineering

Friction stir welding is enhanced by preheating of the workpiece with an electrical arc, such as an arc applied by a common gas-tungsten arc welding (GTAW) torch. As the arc is moved about a path on the workpiece, it preheats or partially welds the path, with the friction stir welding head following along the path to complete the weld.

Owner:WISCONSIN ALUMNI RES FOUND

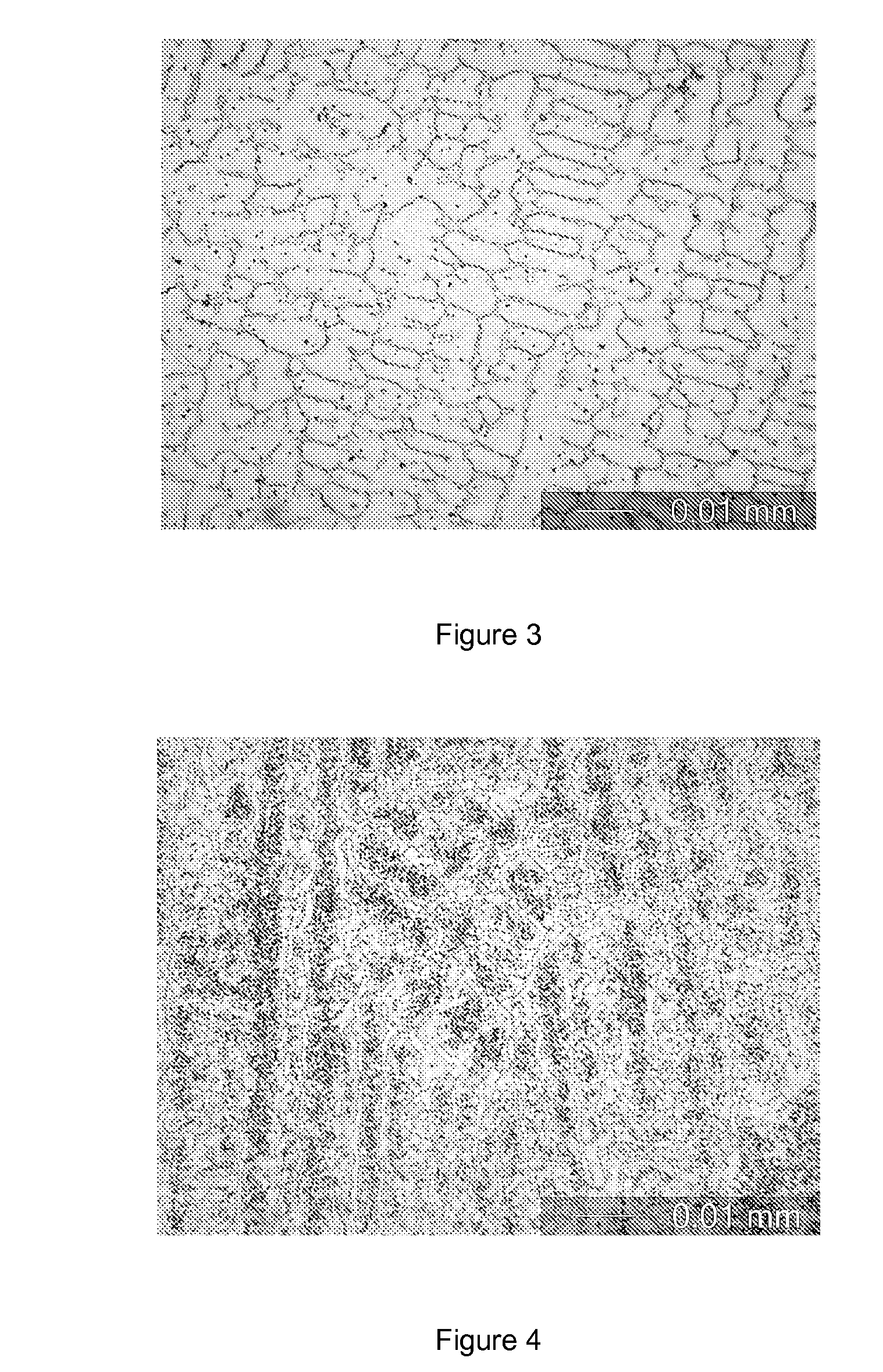

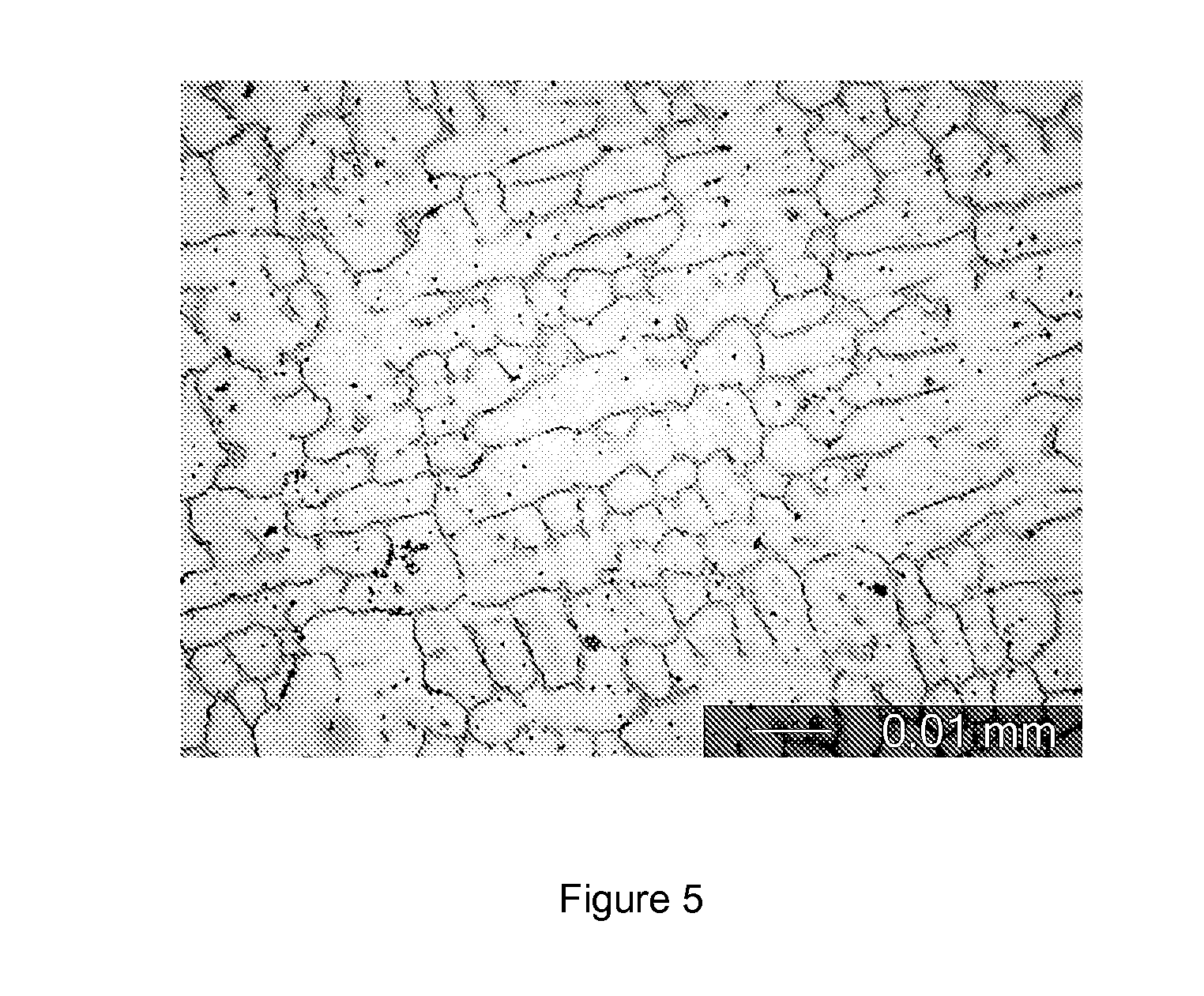

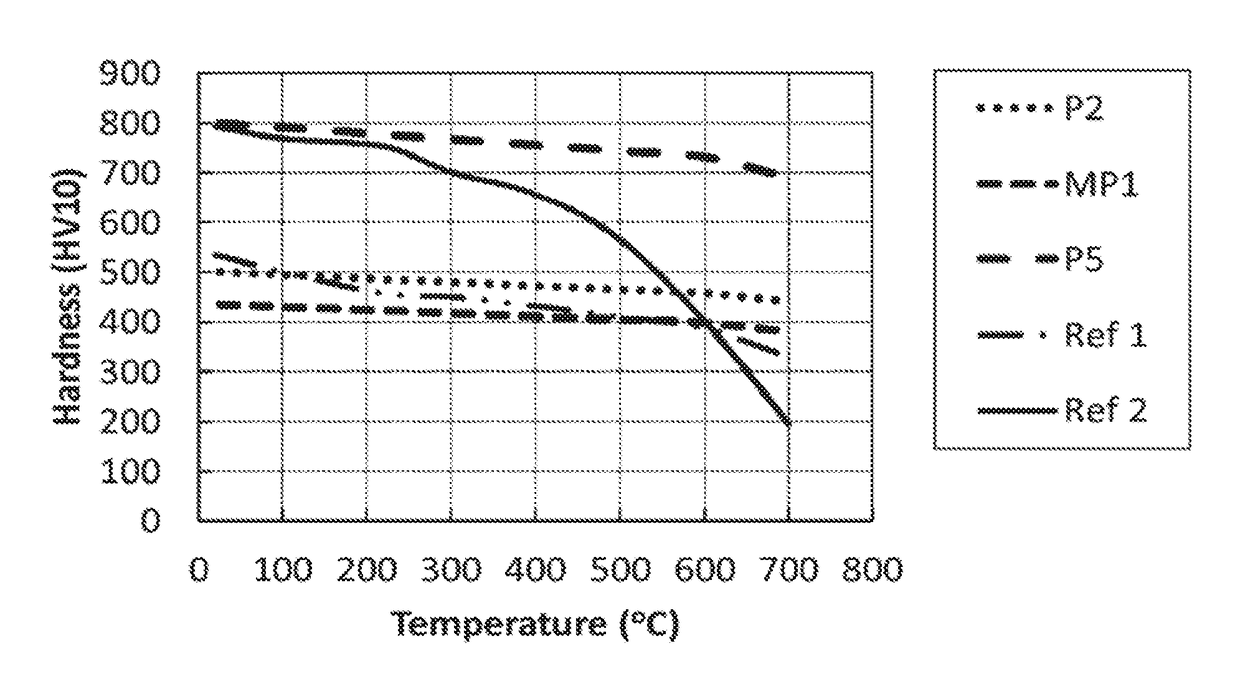

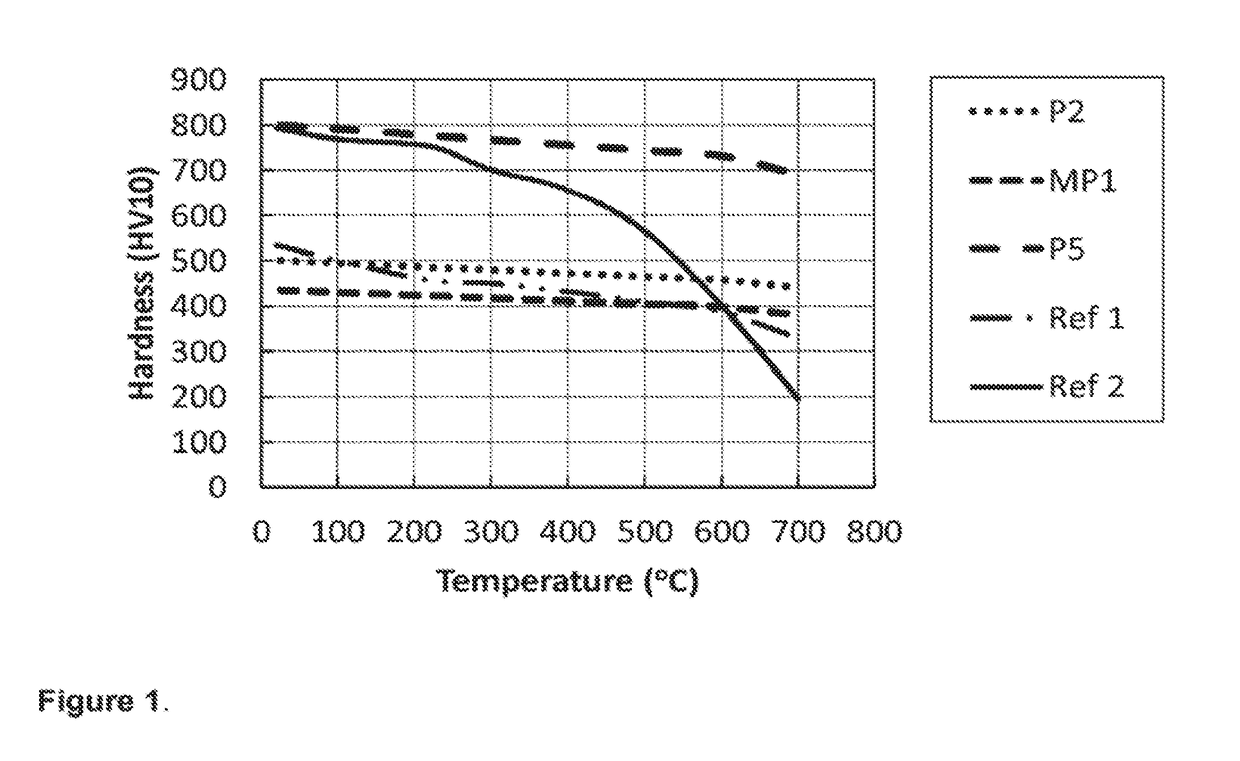

PROCESS AND METHOD TO INCREASE THE HARDNESS OF Fe-Cr-C WELD OVERLAY ALLOY

ActiveUS20080230155A1High hardnessResistance to abrasive wearFurnace typesHeat treatment furnacesSufficient timeMechanical components

A method of preparing a mechanical component with an Fe—Cr—C hardfacing weld overlay alloy for improving the resistance of the mechanical component to abrasion, erosion or erosion / corrosion for use in very abrasive, erosion or erosive / corrosive environments by significantly increasing the hardness of the weld overlay is disclosed. To improve the resistance to abrasion, erosion or corrosion, a weld overlay of a Fe—Cr—C hardfacing alloy is applied onto the surface of a metallic component, such as tubes, pipes, or vessels. Welding and cladding methods including gas-metal-arc welding (GMAW), gas-tungsten-arc welding (GTAW), and laser cladding may be utilized. Then, the component is heat-treated at elevated temperatures for a sufficient time, resulting in additional hardening and thus further increasing the weld overlay's resistance to abrasion, erosion, or erosion / corrosion.

Owner:AZZ WSI

Weld repair of superalloy castings

A method of repairing a void on a nickel or cobalt base superalloy investment casting by vibrating the casting for a time before repairing the void, vibrating the casting while filling the void wherein the void is filled by repeatedly making incremental weld deposits of a superalloy filler material in the void using pulsed gas tungsten arc welding, and impinging each incremental deposit with a cooling gas after each incremental weld deposit is made and before the next incremental weld deposit is made, and vibrating the casting for a time after the void is filled.

Owner:HOWMET CORPORATION

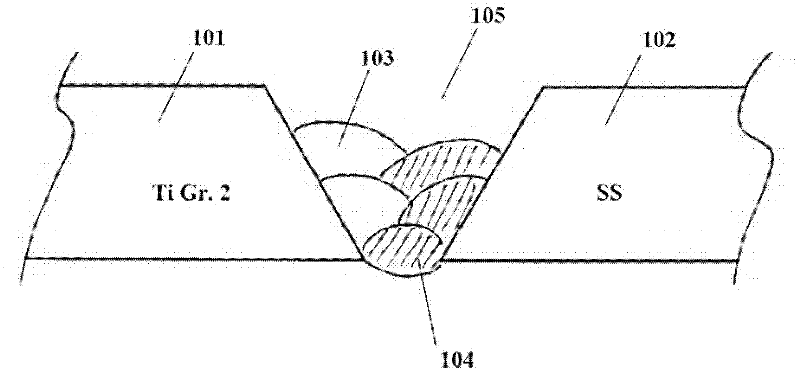

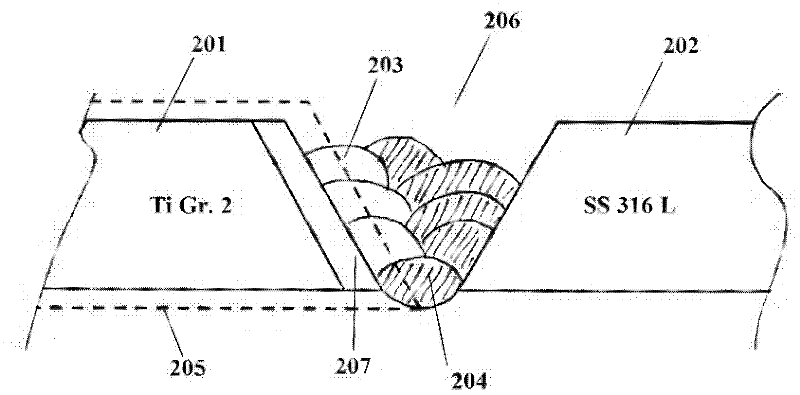

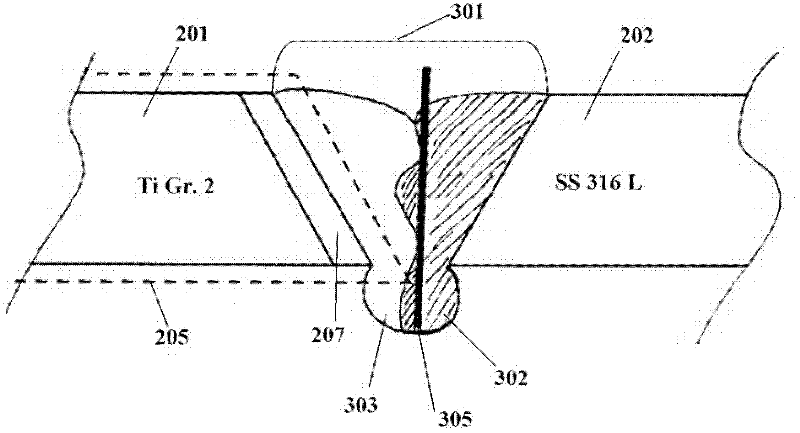

Method for welding dissimilar metals

The present invention discloses method for joining titanium and stainless steel using Gas Tungsten Arc welding with V butt joint welding type. Intermediate bi-filler rods of vanadium and aluminum bronze are introduced to the weld pool between the titanium and the stainless steel, as the arc welding current is applied thereof The vanadium filler rod is placed adjacent to the titanium and the aluminum bronze filler rod is placed adjacent to the stainless steel, and the two intermediates filler rods are placed adjacent to each other. The present invention also discloses method for joining titanium and carbon steel by means of Gas Tungsten Arc welding with V butt joint welding type.

Owner:SHELL CHEM SERAYA PTE

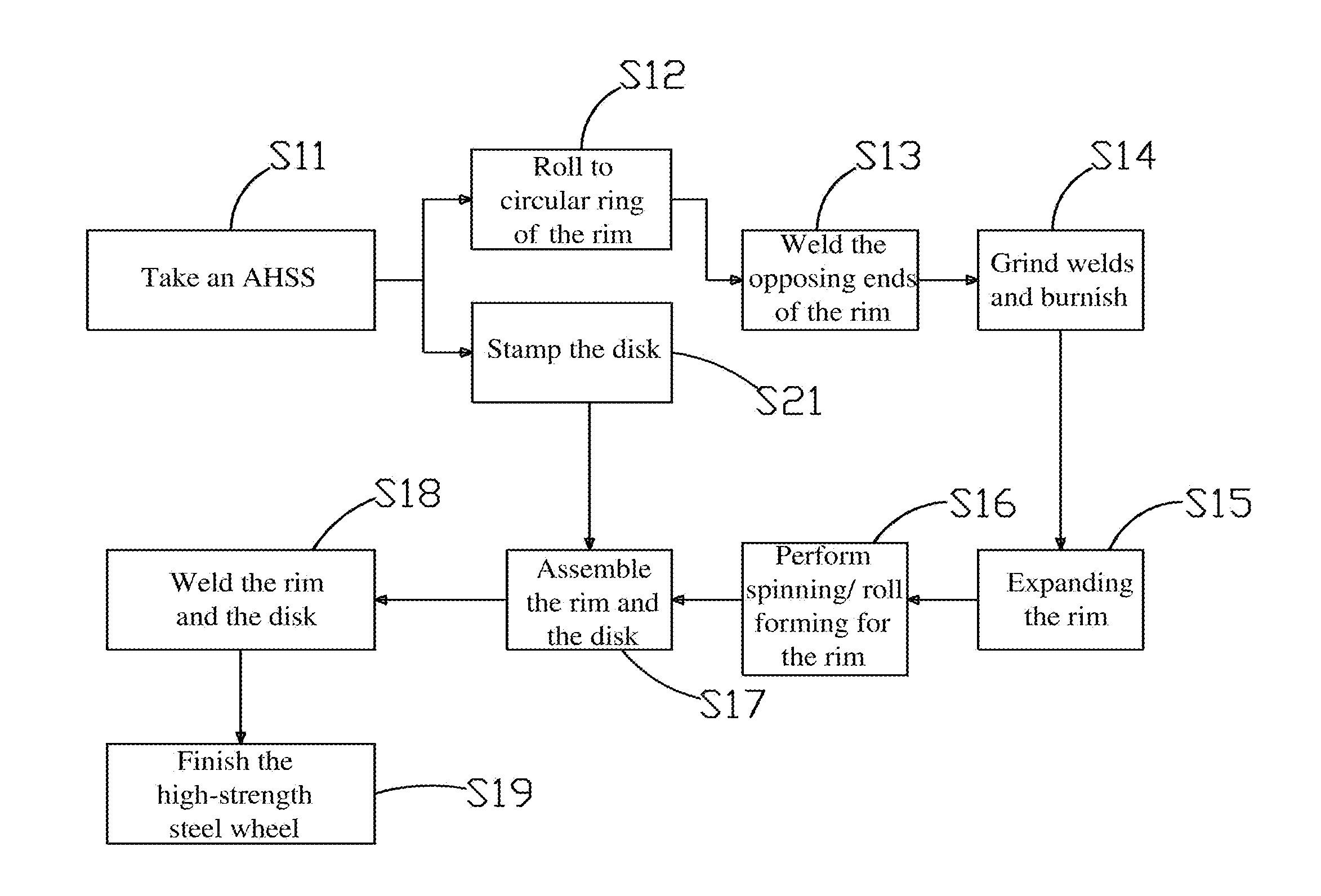

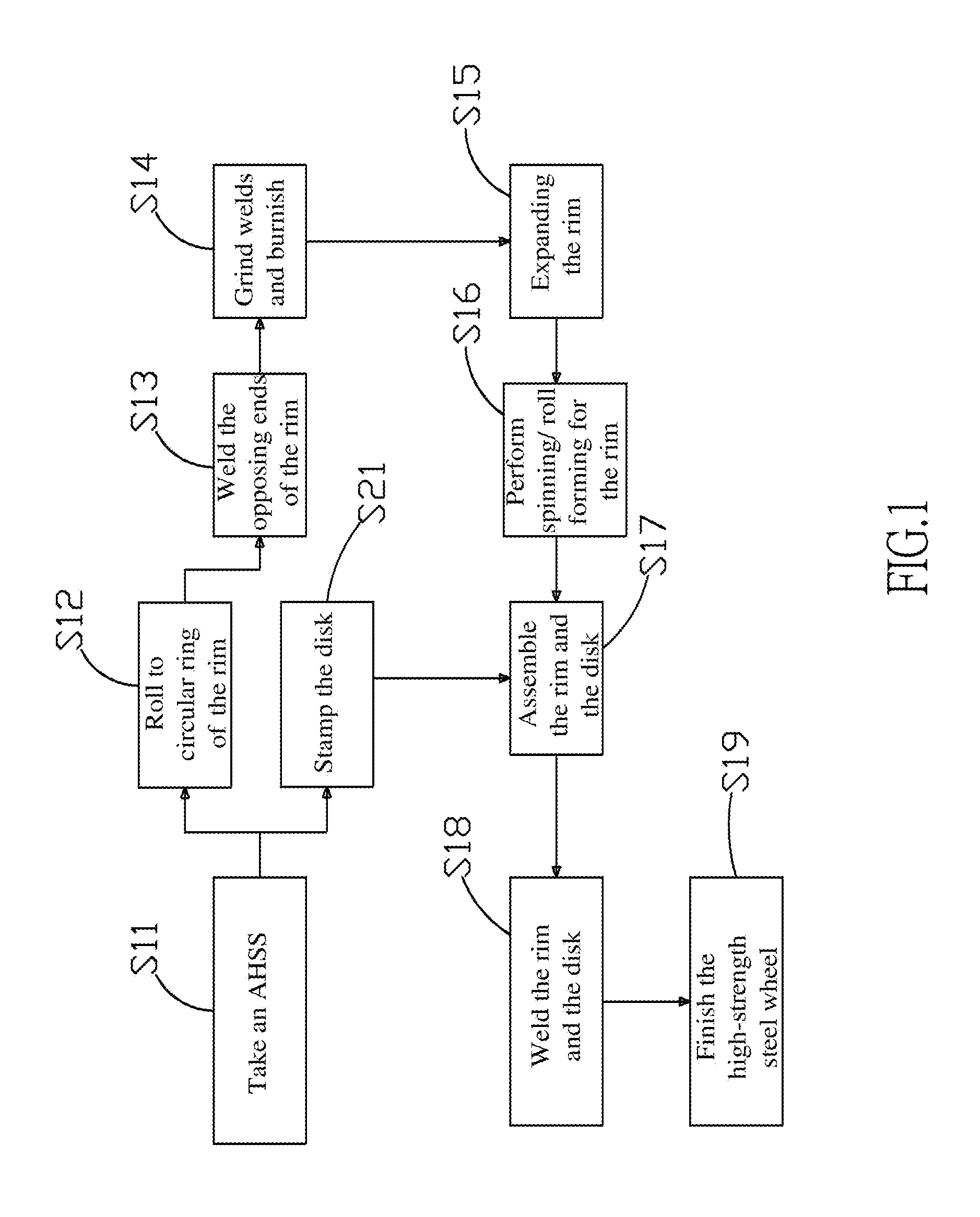

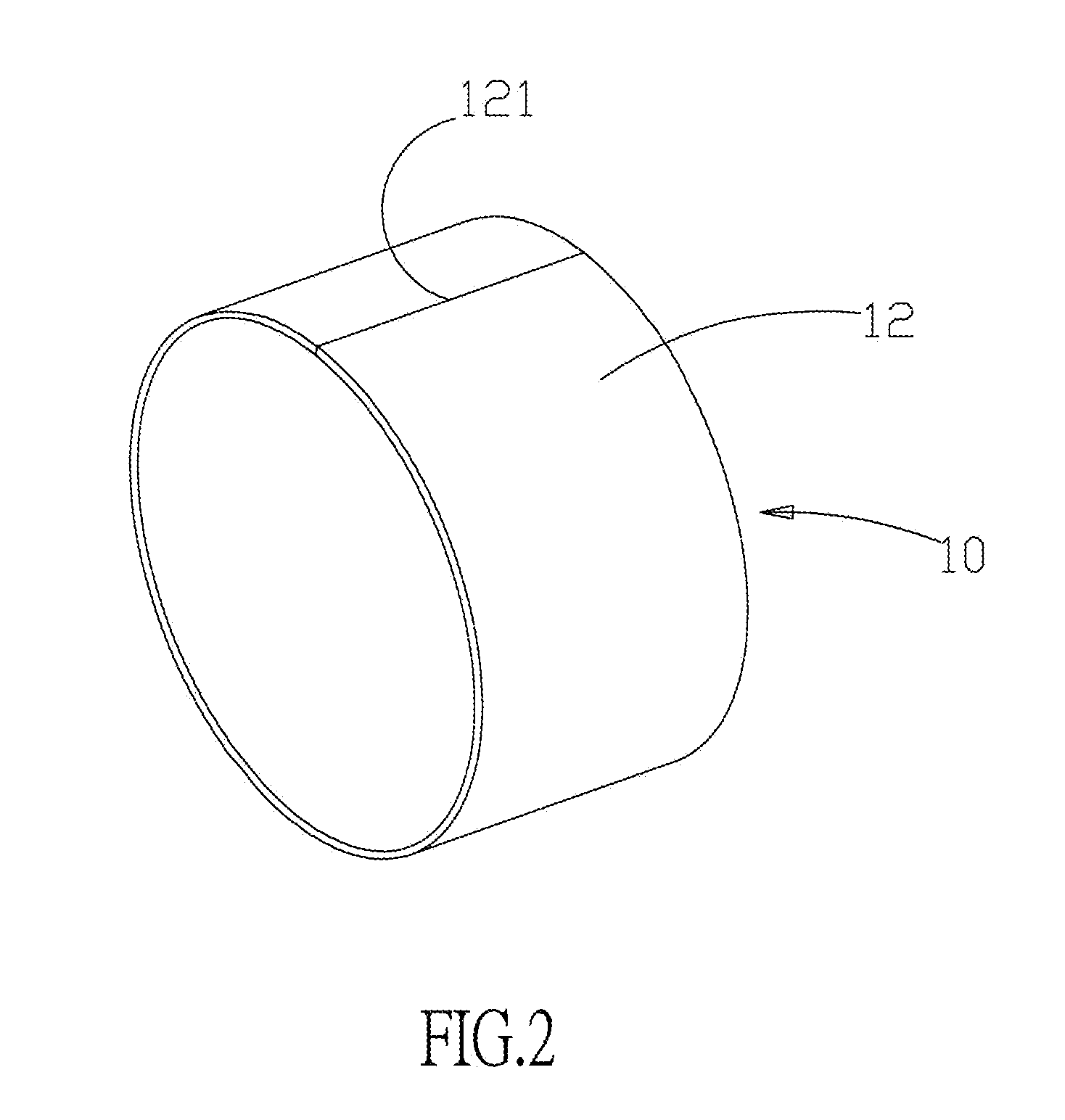

Manufacturing method for advanced high-strength steel wheel and jig device thereof

ActiveUS20140183166A1Improve product qualityFatigue can be enhancedWelding/cutting auxillary devicesArc welding apparatusHigh intensityRoll forming

The present invention relates to a manufacturing method for advanced high-strength steel (AHSS) wheel, comprising the following steps. Take an AHSS with at least 590 MPa of tensile strength for rolling to circular ring of a rim. Apply low heat input welding, such as the cold metal transfer (CMT) welding or the gas tungsten arc welding / tungsten inert gas arc welding (GTAW / TIG), at the junction of the rim to form a hollow cylindrical rim. Then perform hole expanding and spinning / roll forming operations to the rim. Take another AHSS with at least 980 MPa of tensile strength for pressing and forming a disk. Apply low heat input welding, such as cold metal transfer (CMT) welding, to the rim and the disk to produce a wheel. According to the present invention, the welding quality of products can be improved significantly; the fatigue lifetime of wheels can be enhanced; and wheels are lightweight.

Owner:METAL INDS RES & DEV CENT

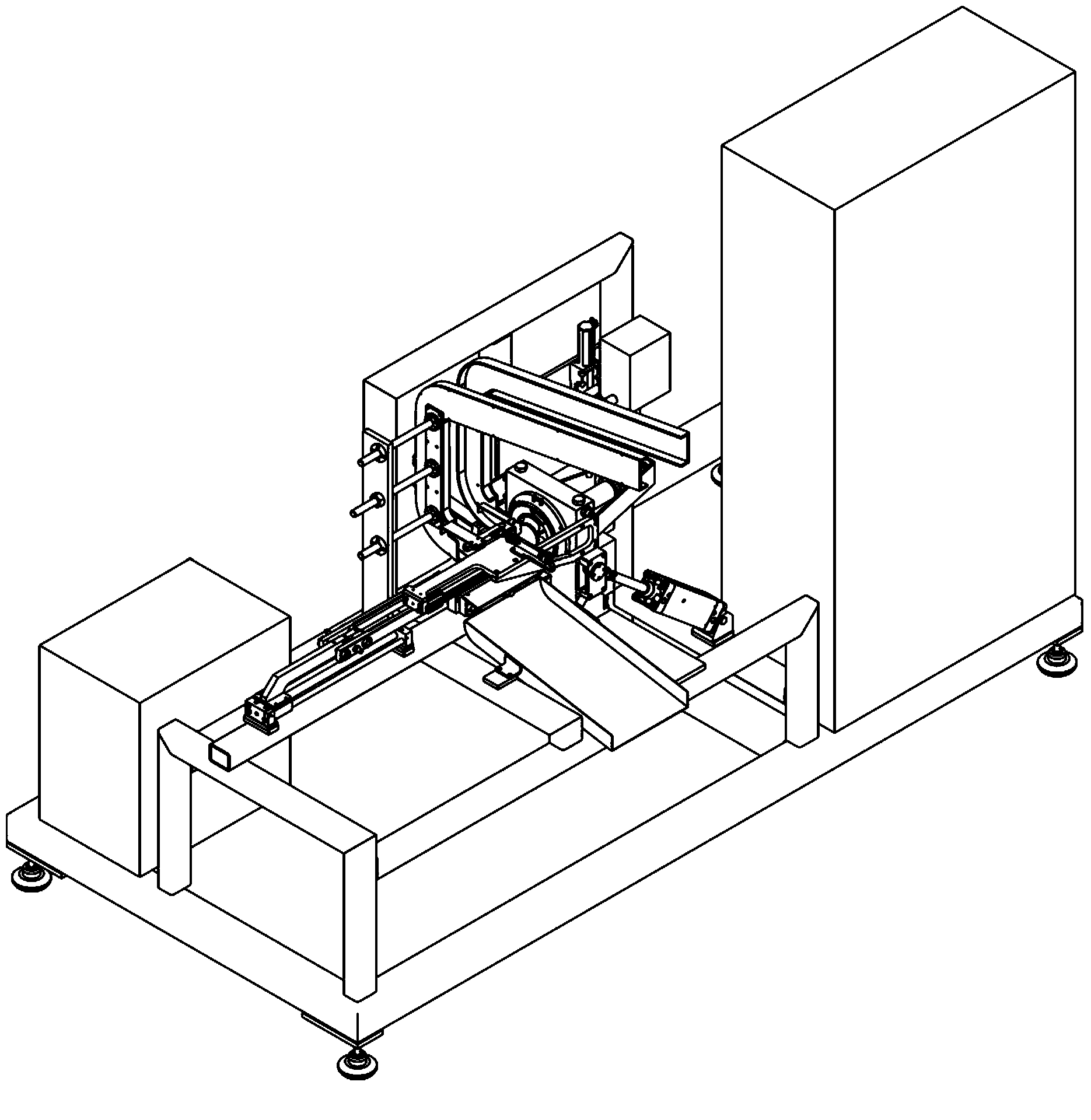

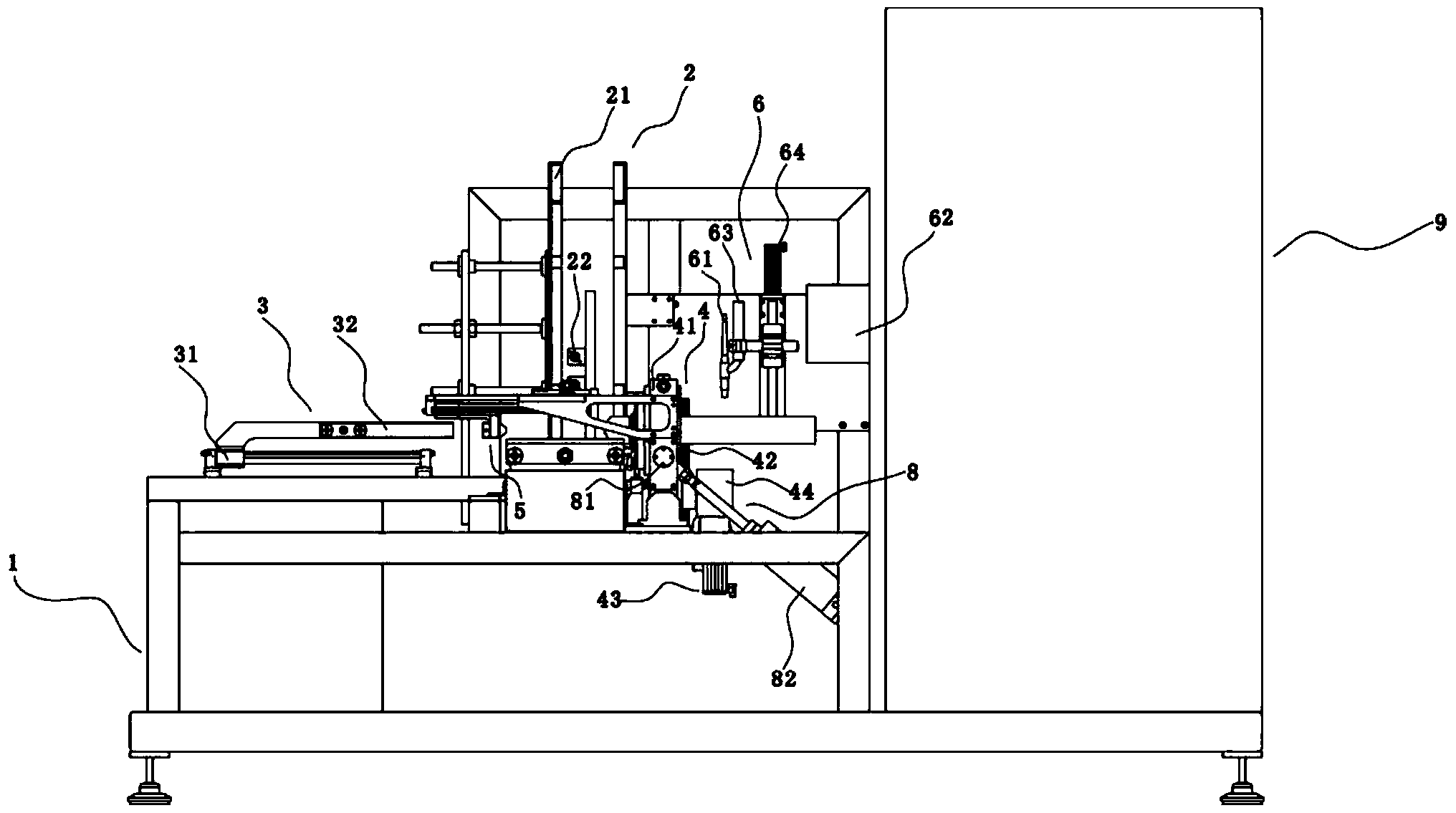

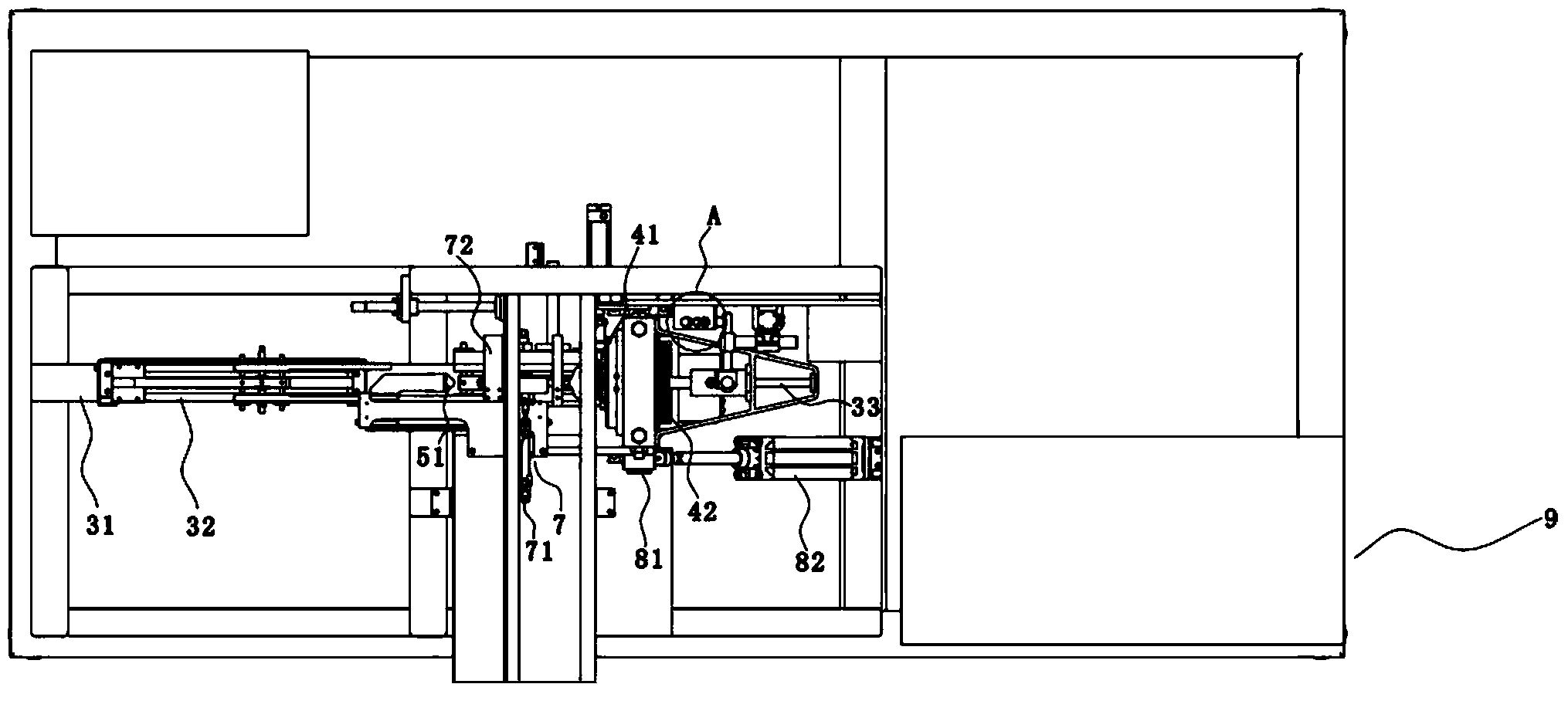

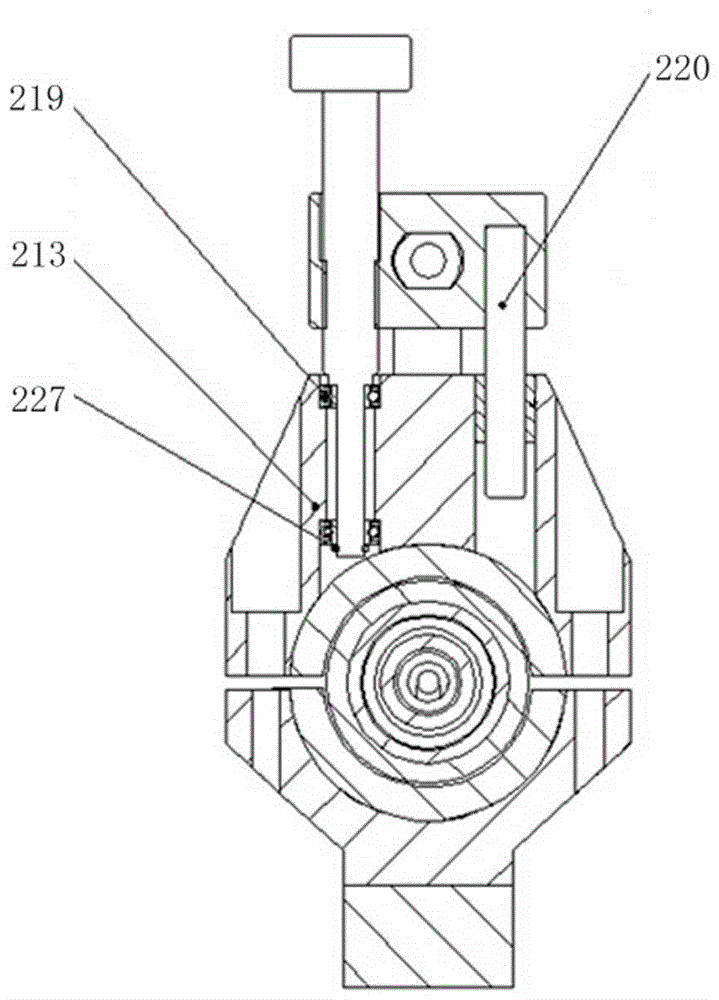

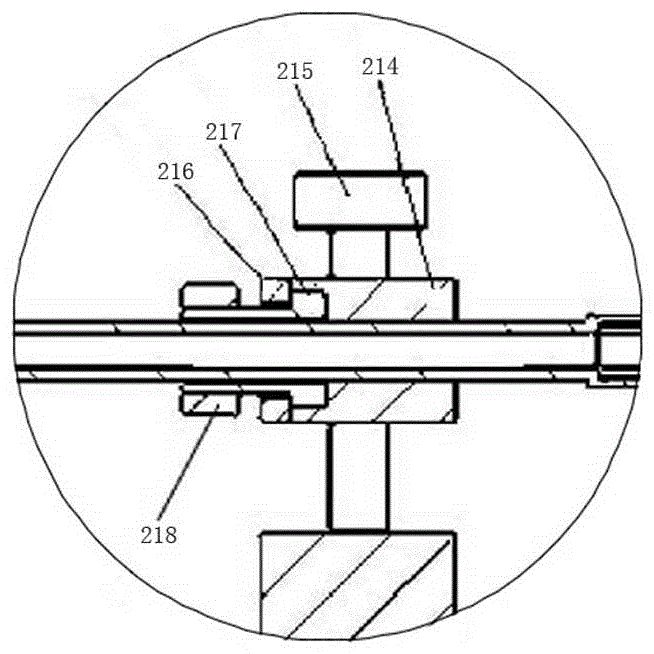

Special device for circular seam welding and application

ActiveCN104368901AAchieve perfect weldingImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

The invention provides a special device for circular seam welding and application which are used for welding in a gas tungsten arc welding and wire feeding mode. The device comprises a rack, a feeding mechanism, a positioning pushing mechanism, a mechanical power mechanism, a blocking inflation mechanism, a welding mechanism and a discharging mechanism. The feeding mechanism comprises a material duct and a capture and release assembly. The positioning pushing mechanism pushes an overlap welding workpiece in the length direction of the overlap welding workpiece, and a positioning pushing head positions the position to be welded of the overlap welding workpiece. The mechanical power mechanism is located between the positioning pushing head and a rear positioning device and comprises a chuck, a transmission gear and a servo motor. In the welding process, the included angle between the axial line of the chuck and the horizontal plane ranges from 2 degrees to 178 degrees. The blocking inflation mechanism is connected with the mechanical power mechanism and comprises a rotary connector and an air inlet formed in the rotary connector. The welding mechanism is movably arranged on the rack and located above the mechanical power mechanism.

Owner:HANSHAN RUIKE METAL CO LTD

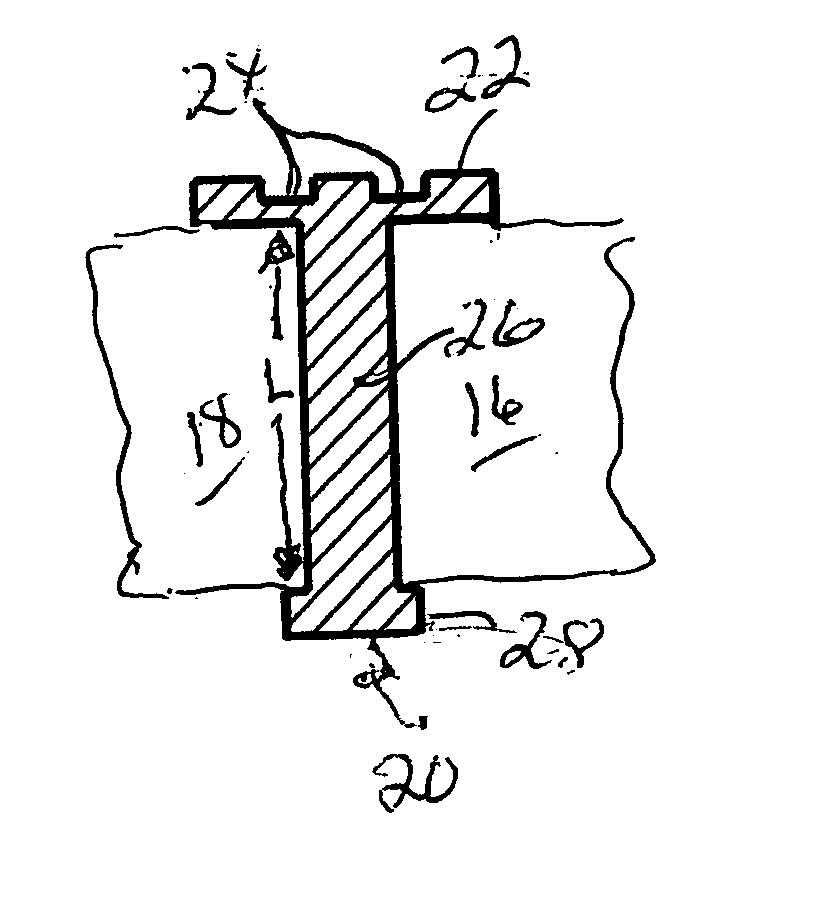

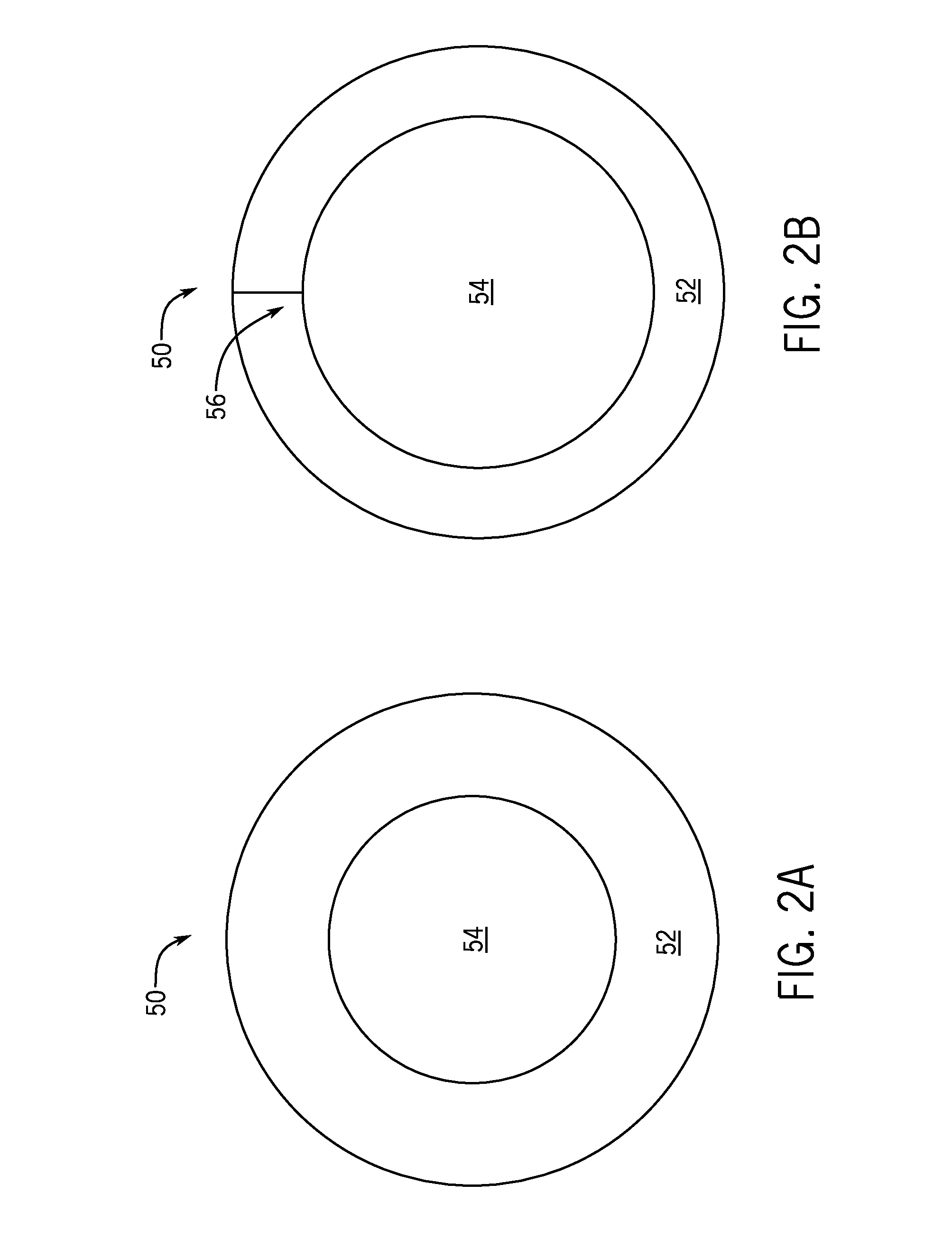

Welding process

InactiveUS20050224487A1Suitable for repairAvoid machiningTurbinesPump componentsGas tungsten arc weldingGas turbines

A process for repairing a compressor rear frame of a gas turbine engine. The process entails removing a seal flange from the inner casing wall of the frame to define an annular face on the casing wall, and fabricating a replacement flange to have an annular face with a radial width greater than the radial width of the annular face of the casing wall. The faces of the flange and wall are mated to form a joint, a penetration-enhancing flux is deposited adjacent the joint, and a single-pass gas tungsten arc welding operation is performed to form a root weldment that extends completely through the joint. The flux is then removed and a gas tungsten arc welding operation is performed to deposit a filler on the root weldment and form a second weldment that completely overlays but does not penetrate through the root weldment.

Owner:GENERAL ELECTRIC CO

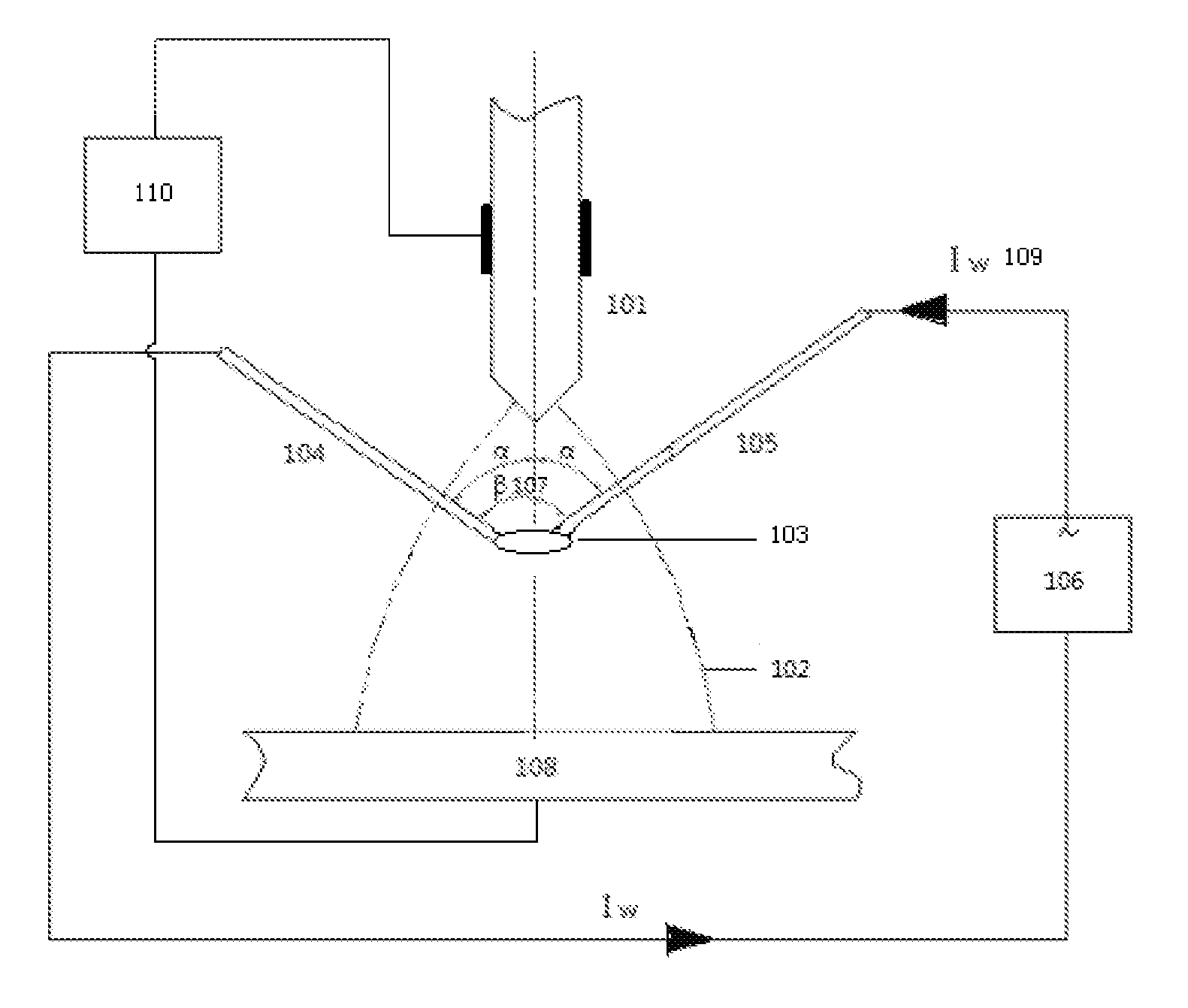

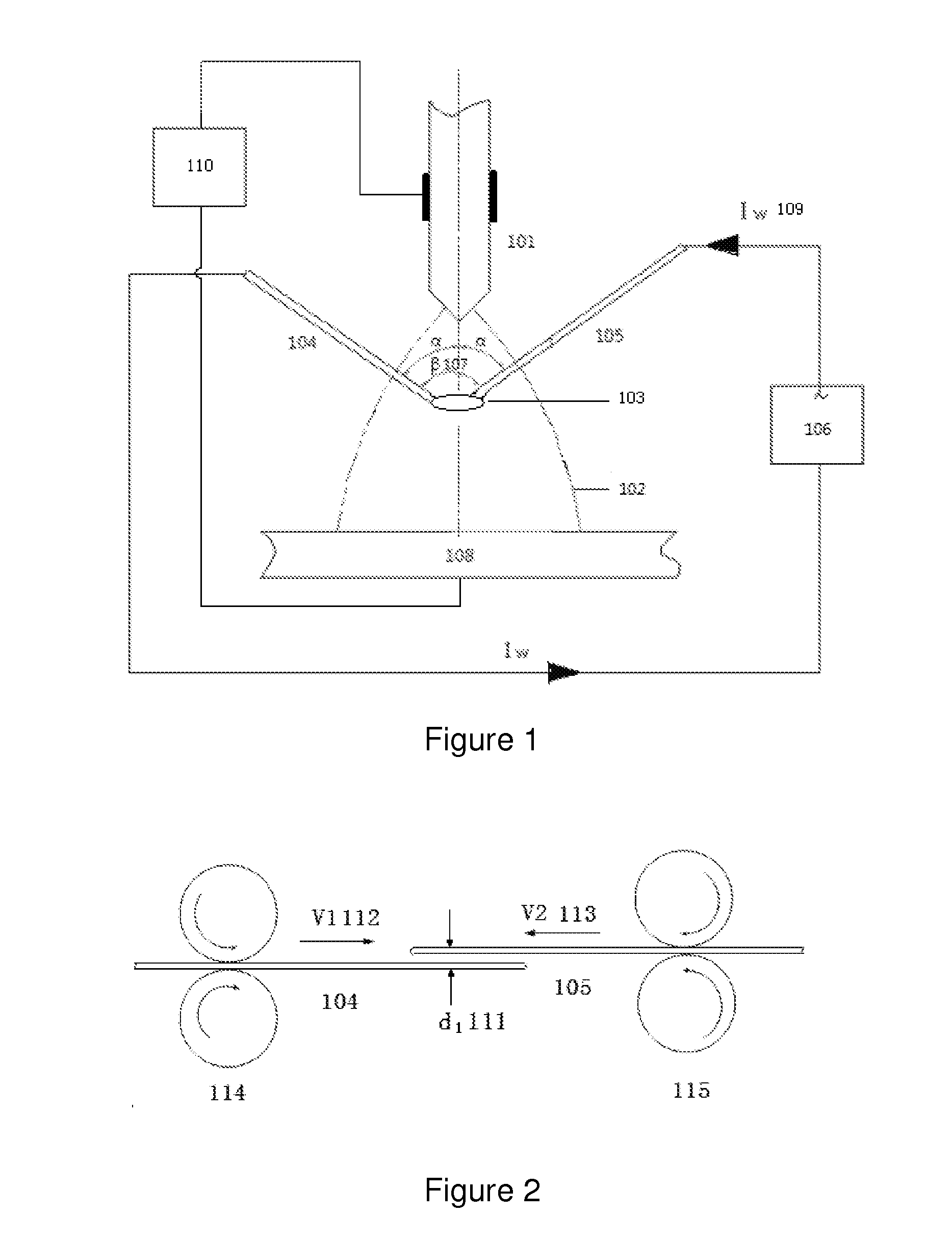

Gas tungsten arc welding with cross ac arcing twin wires

ActiveUS20140291297A1High depositionLow heat inputArc welding apparatusPlasma welding apparatusSide effectGas tungsten arc welding

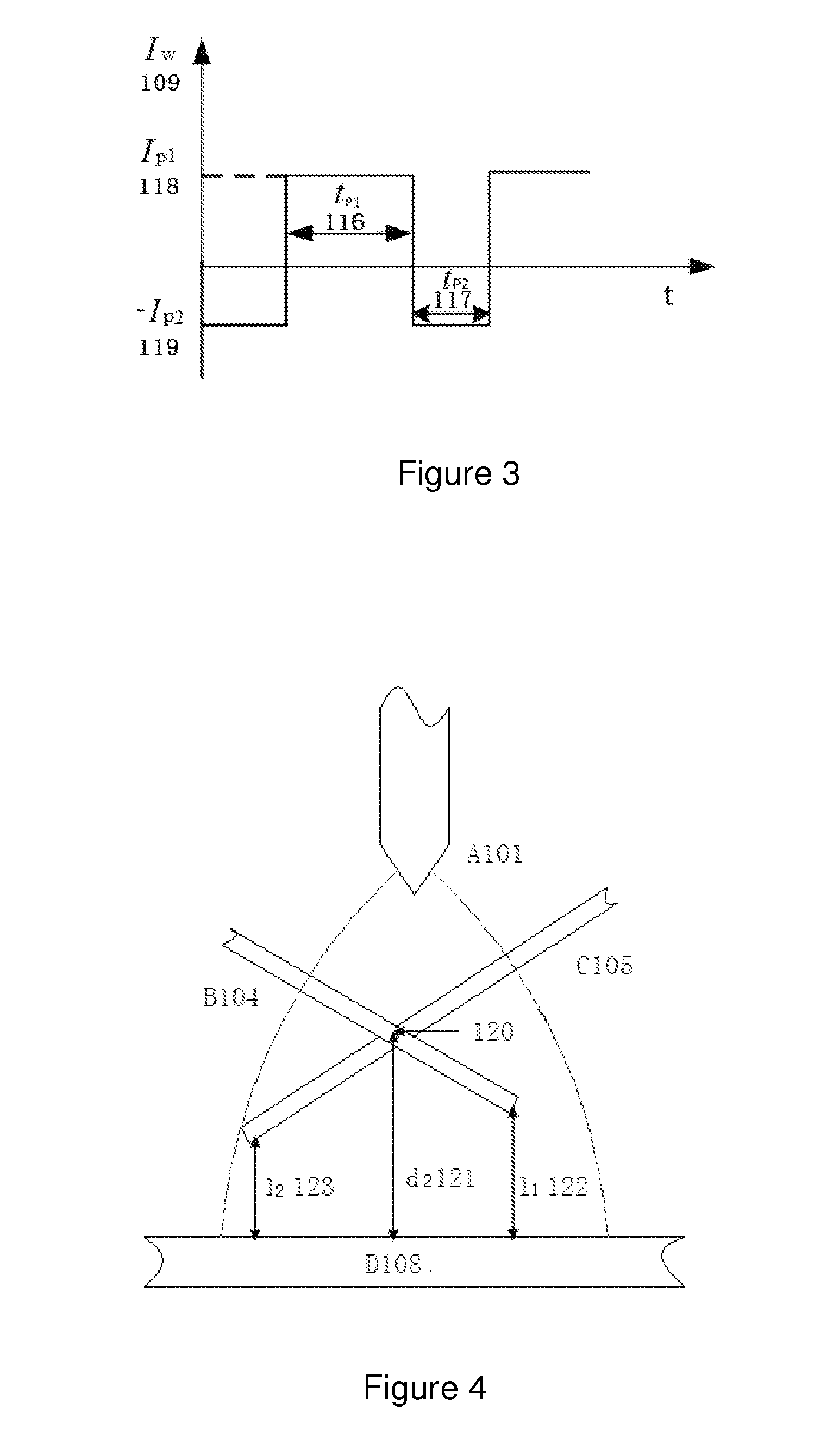

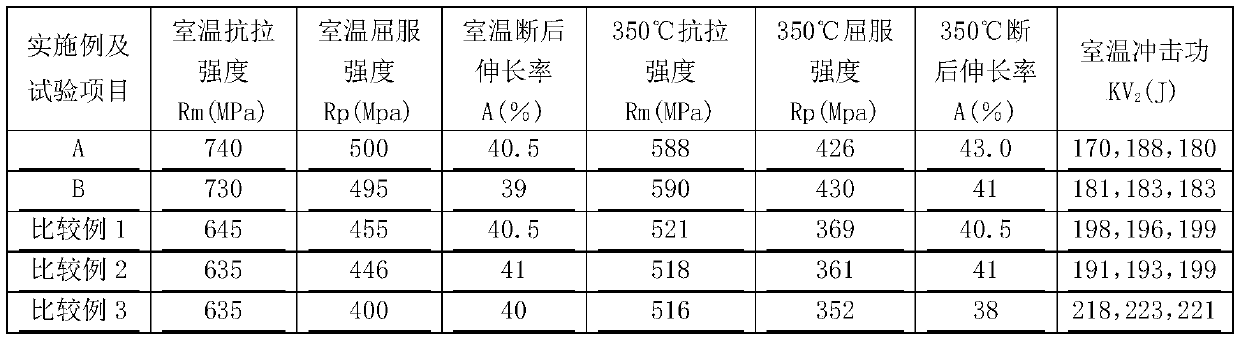

Gas metal arc welding (GMAW) is a widely used process for joining metals. Its main advantage over its competition gas tungsten arc welding (GTAW) is its high productivity in depositing metals. However, to melt metal from the wire to deposit into the work-piece, additional heat is consumed and applied to the work-piece with an uncontrolled fixed proportion to the effective heat that melts the wire. Such additional heat is often in excess of the needed heat input for the work-piece. The side-effects include a waste of the energy, an increased distortion, and possible materials property degradation. This invention is to device a method to transfer this part of heat to melt the wire by adding two wires, which form a pair of arc spots, under a tungsten arc. It also devices a method to assure the arc between the two wires be maintained stable such that the transfer be successfully continuous. The successful continuous transfer improves the energy efficiency, eliminates the adverse effects on the distortion and materials property, and decouples the controls on mass input and heat input on the work-piece.

Owner:BEIJING UNIV OF TECH

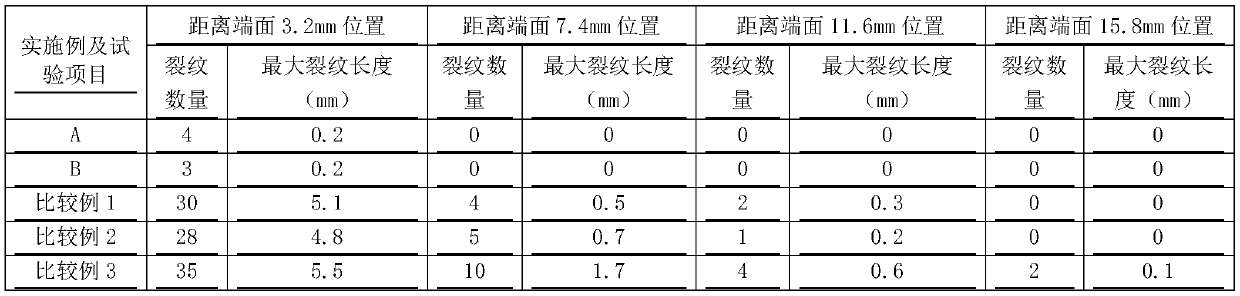

Ta-Nb composite nickel-based welding wire for nuclear power equipment and welding method thereof

PendingCN110560961ASolve problems prone to crack defectsAvoid crack defectsArc welding apparatusWelding/cutting media/materialsNuclear powerWeld seam

The invention discloses a Ta-Nb composite nickel-based welding wire for nuclear power equipment and a welding method thereof, relates to the technical field of welding materials, and solves the problem that existing welding wires are prone to crack defects under the severe condition of high restraint degree welding. The components of the welding wire consist of C, Si, Mn, S, P, Cr, Mo, Cu, Nb, Ta,Ti, Al, Fe, Ca, Mg, O, N, B, Zr, impurity elements and Ni. The welding method adopts automatic wire filling GTAW (Gas Tungsten Arc Welding). According to the Ta-Nb composite nickel-based welding wirefor the nuclear power equipment and the welding method thereof, when the surfacing thickness of the nickel-based welding wire reaches 30 millimeters, deposited metal still has no crack defect; when the nickel-based welding wire is used for welding, the process parameter adaptability is strong, an arc in a welding process is stable, the wire feeding performance of the welding wire is good, no dross exists, the forming performance is good, and the process performance is good; and micro-alloying of a welding seam is realized, and the welding seam meeting standard requirements is obtained. The Ta-Nb composite nickel-based welding wire for the nuclear power equipment and the welding method thereof are suitable for welding nuclear island main equipment.

Owner:HARBIN WELL WELDING CO LTD +1

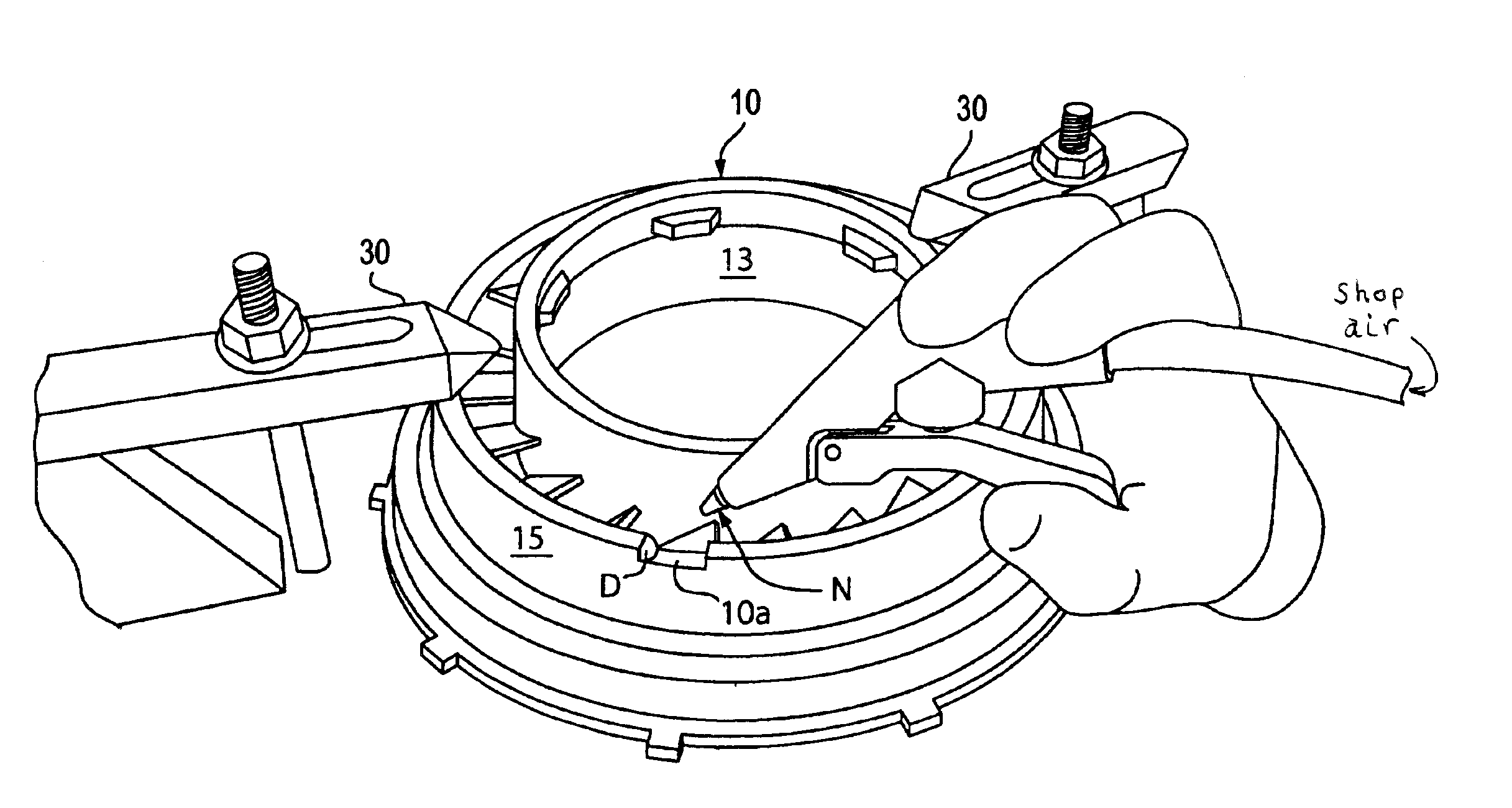

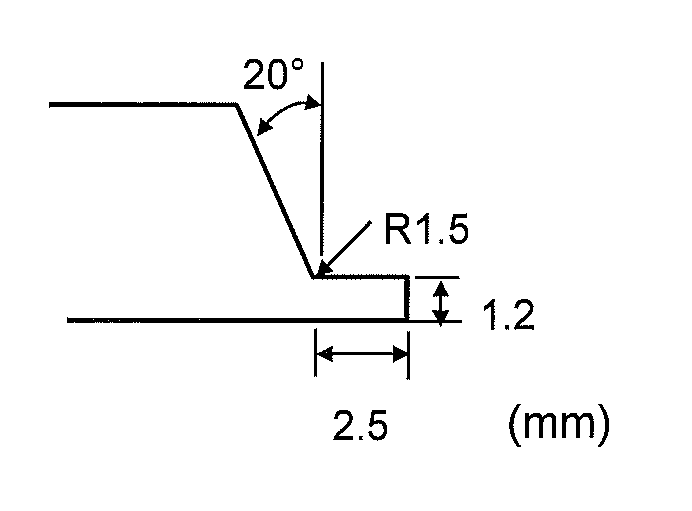

Flux assisted gas tungsten arc welding utilizing consumable inserts for ultra low profile welding applications

InactiveUS20050092813A1Technique is very compactArc welding apparatusWelding/cutting media/materialsEngineeringWeld penetration

A speedy method of welding in a tight space using a single pass is provided using a technique which involves the use of a particularly shaped, flux treated consumable insert to provide deep weld penetration by a GTAW machine which is compact and fits the narrow spaces found in applications such as feeder tube repair since it does not require an insert wire flux feed system and is thus capable of negotiating narrow spaces found in feeder tubes.

Owner:ATREVA NP

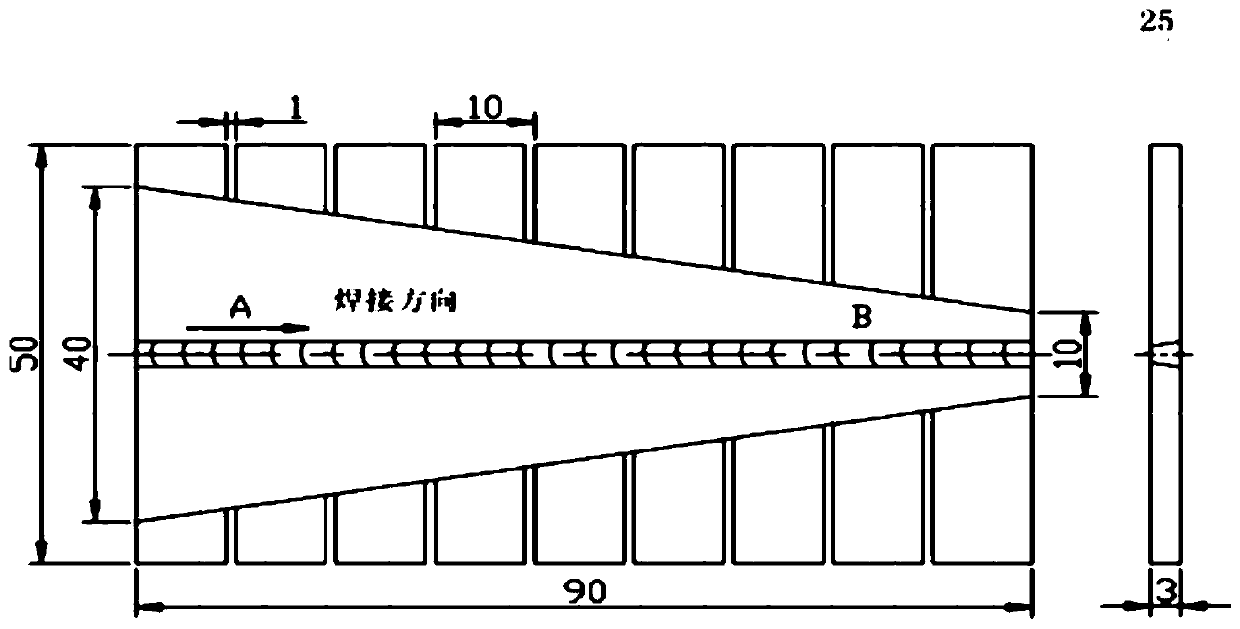

Biphase steel SA-240 S31803 handwork tungsten electrode argon arc GTAW welding process

The invention relates to a manual dual phase steel SA-240 S31803 gas tungsten arc welding (GTAW) technology which is characterized by comprising the following steps: a 30 degree plus 5 degree divided edge is formed on a welding surface by a mechanical method, water, oil stain, iron rust and welding wires on the surface and both sides of the divided edge are gotten rid of, a contravariant AC tungsten electrode argon arc welding machine is used as a welder, (Ar plus (1 to 2 percent) N 2) mixed gas is the protective gas in a welding torch, pure argon is used as back protective gas, the diameter of the selected solid ER2209 welding wire is 2.4mm, the diameter of the welding nozzle of the contravariant AC tungsten electrode argon arc welding machine is 12 mm, the diameter of a tungsten bar is 2.4mm, and the purity quotient of argon is 99.995 percent. The welding technology includes the bottoming of the bottom of the divided edge and the welding of the surface of an upper filling cover, the welding operation is the straight channel welding, and the welding of the surface of the upper filling cover comprises the welding of left and right crossed straight channels. The heat input ranges from 0.5 to 2.5 KJ / mm during welding, the interlayer-temperature does not exceed 150 DEG C, and the thickness of each layer welding seam does not exceed 2.5mm. The welding technology has the advantages that the content of ferrolites in each welding seam can be guaranteed to range from 35 to 60 percent, and the resistance to corrosion and chemical components of the dual phase steel can not be destroyed.

Owner:上海贤达美尔森过程设备有限公司

Aluminum metal-cored welding wire

ActiveUS20160243656A1Additive manufacturing apparatusArc welding apparatusGas metal arc weldingAlloy

The present disclosure relates to a metal-cored welding wire, and, more specifically, to a metal-cored aluminum welding wire for arc welding, such as Gas Metal Arc Welding (GMAW) and Gas Tungsten Arc Welding (GTAW). A disclosed metal-cored aluminum welding wire includes a metallic sheath and a granular core disposed within the metallic sheath. The granular core includes a first alloy having a plurality of elements, wherein the first alloy has a solidus that is lower than each of the respective melting points of the plurality of elements of the first alloy.

Owner:HOBART BROS LLC

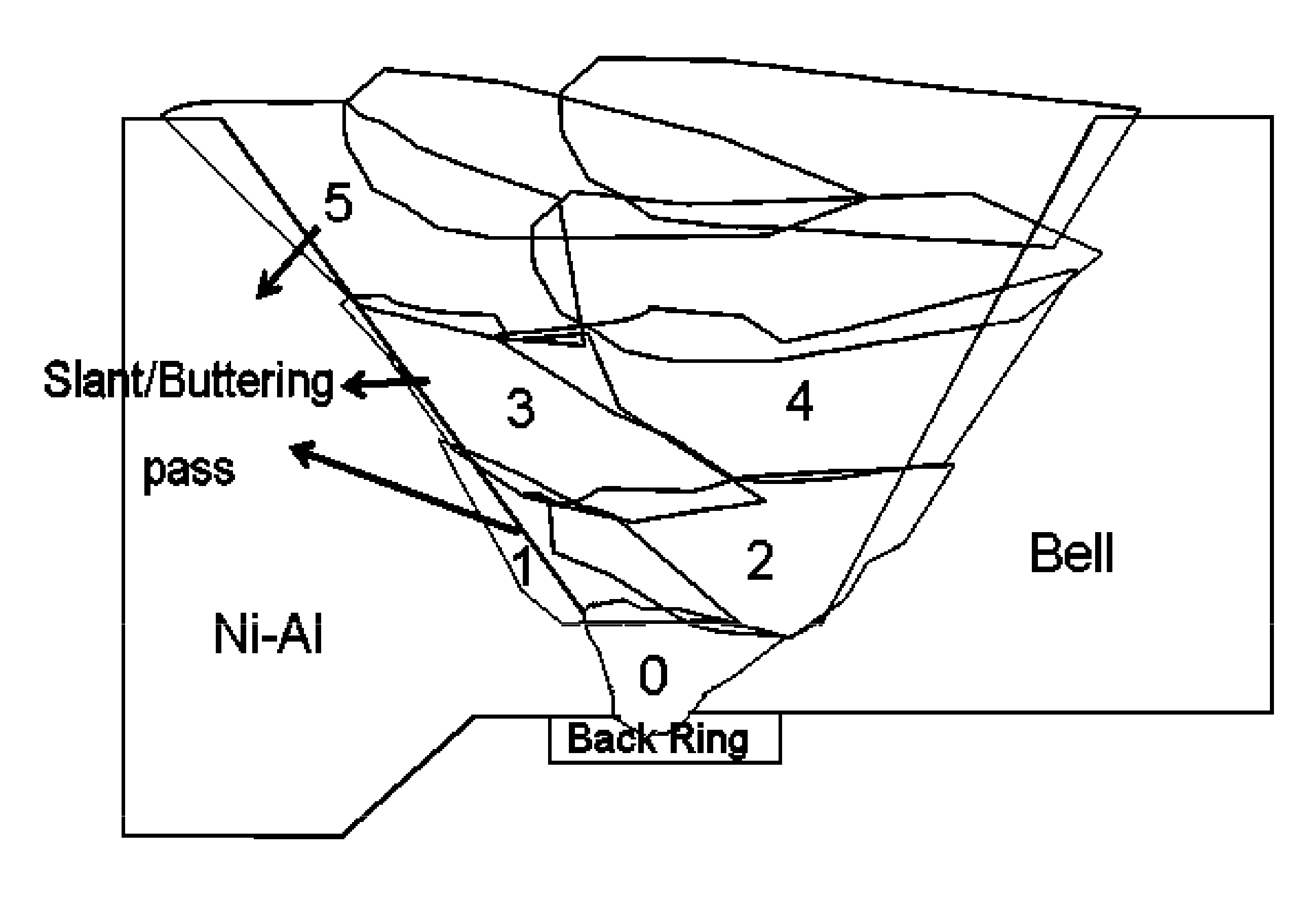

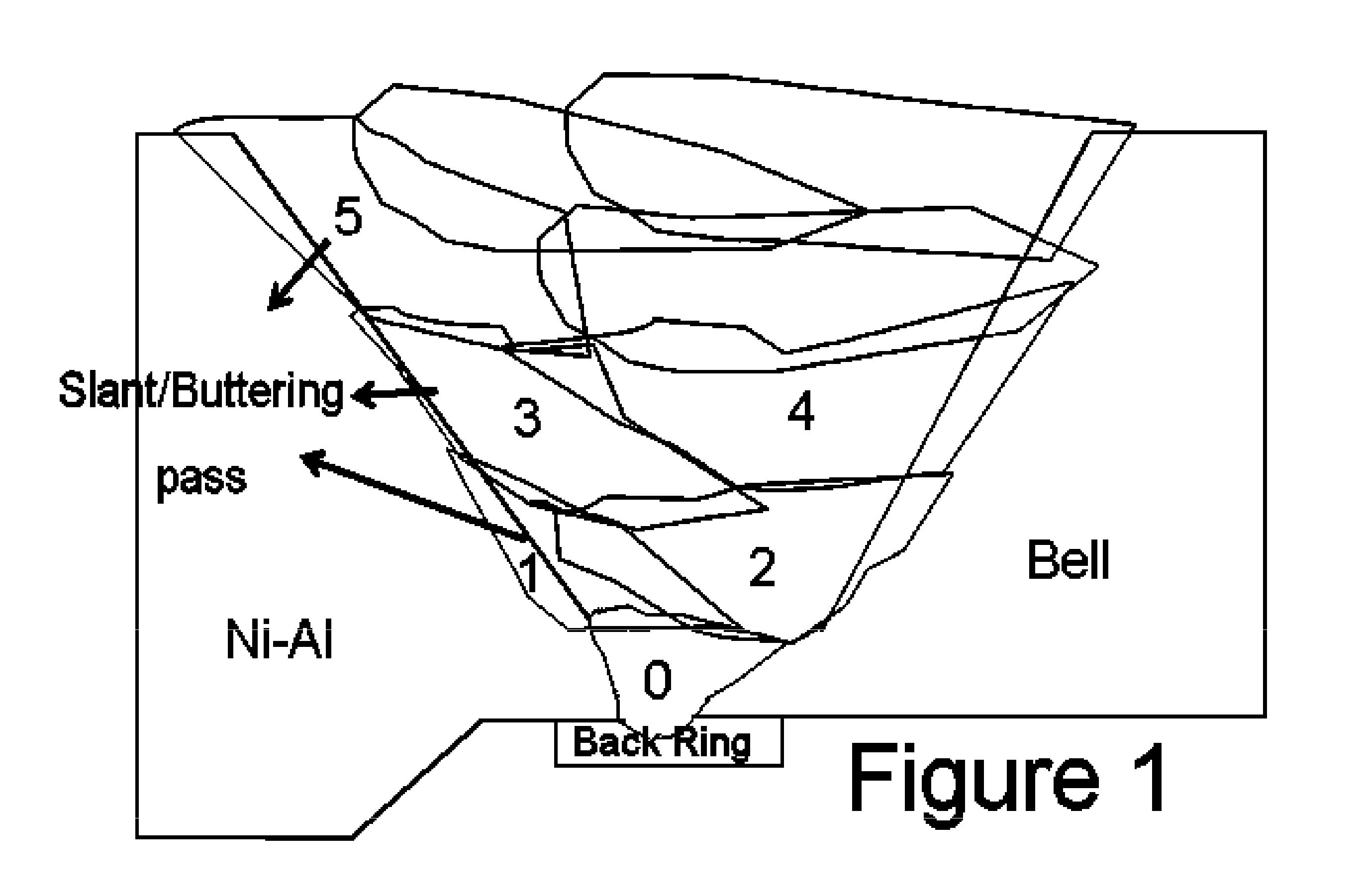

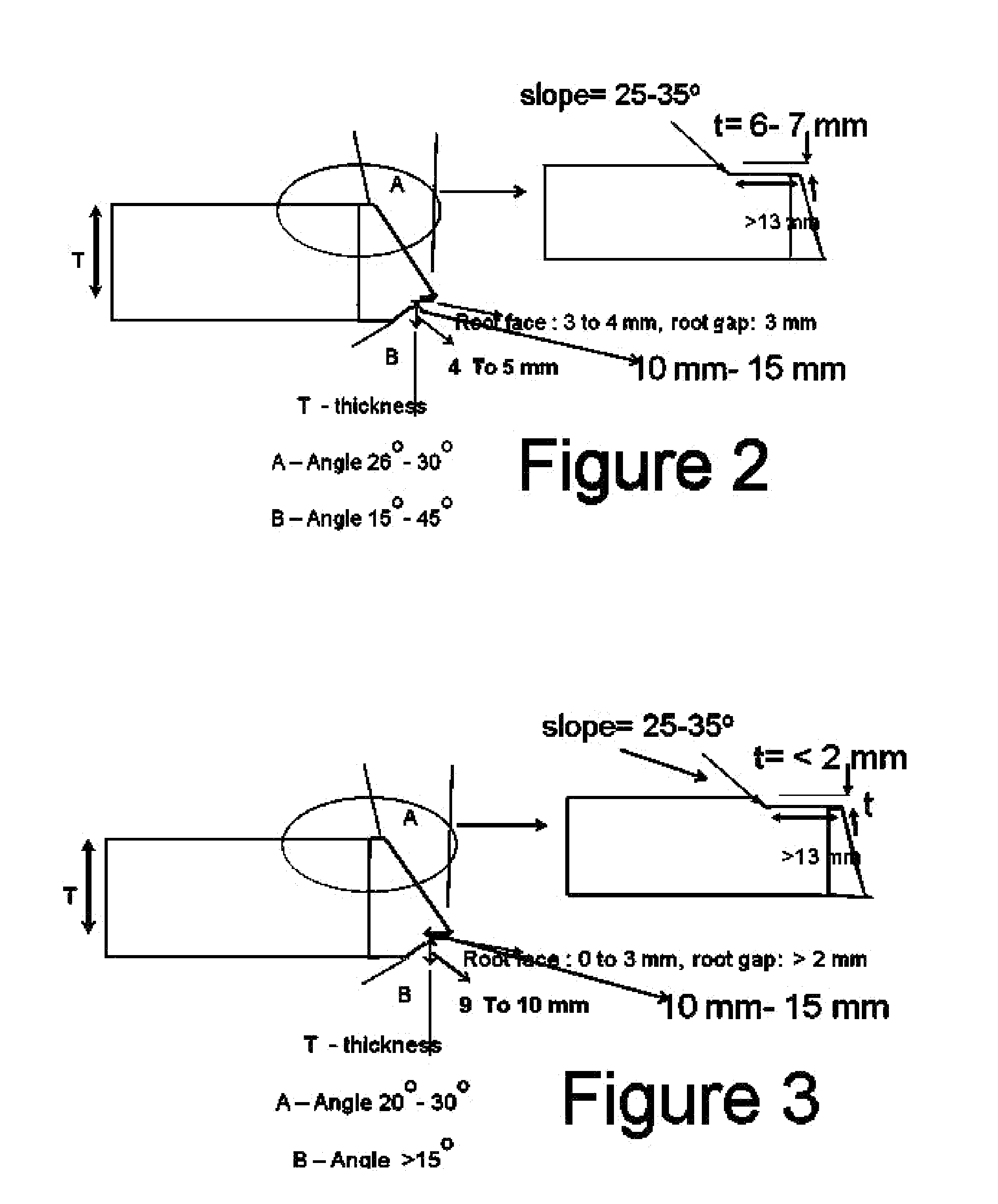

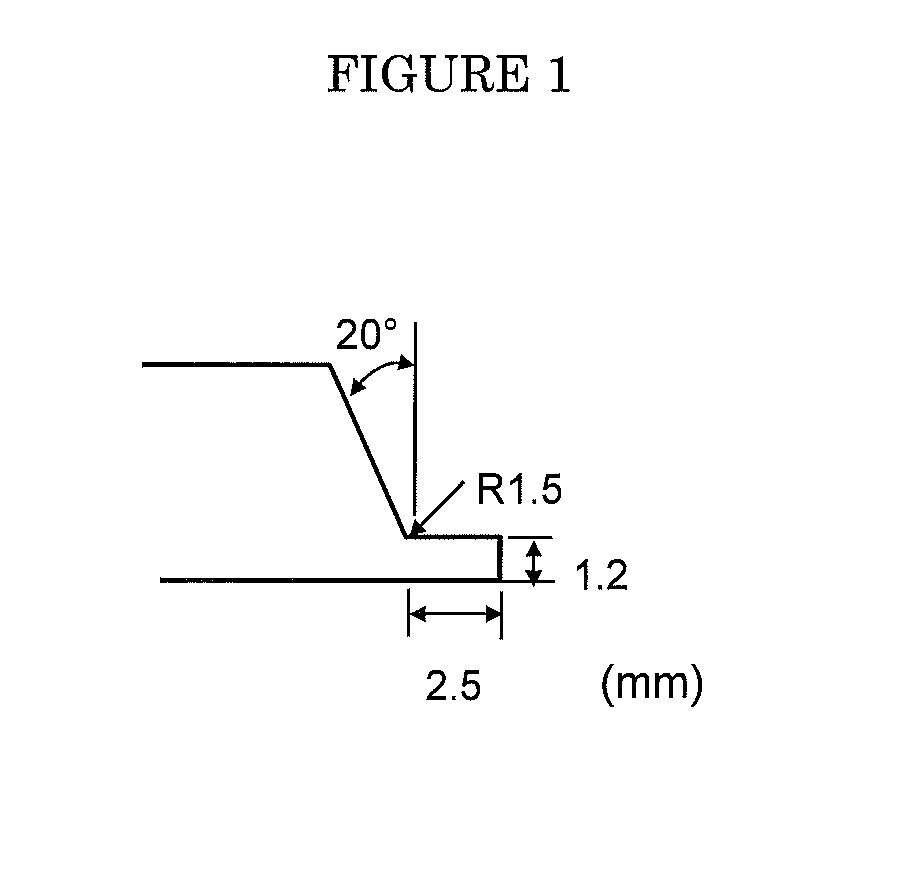

Method of welding nickel-aluminide

ActiveUS20120175355A1Increase deposition rateArc welding apparatusWelding/soldering/cutting articlesGas tungsten arc weldingNickel aluminide

A method for gas tungsten arc welding (GTAW) of nickel-aluminide to itself or other nickel-based alloys using a filler wire. Method limitations: I) outer surface of weld groove has 1-2 mm machining, weld groove angle <30°; and root face <3 mm; II) measured temperature 30 cm (12″) from weld torch and 3 mm from groove edge <200° C.; and interpass temperature <85° C. at 3 mm from weld groove edge; III) except for root pass, all filler and cap pass layering should start from nickel-aluminide edge; each bead should be peened; and weld cap pass should overlap nickel-aluminide edge by 3 mm; IV) weld bead layout at the nickel-aluminide edge should be laid at torch angle <30°; V) weld heat input should be 17-23 kJ / in; and VI) linear welding speed is >8.6 cm / min; and deposition rate should be >3.0 cm3 / min.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

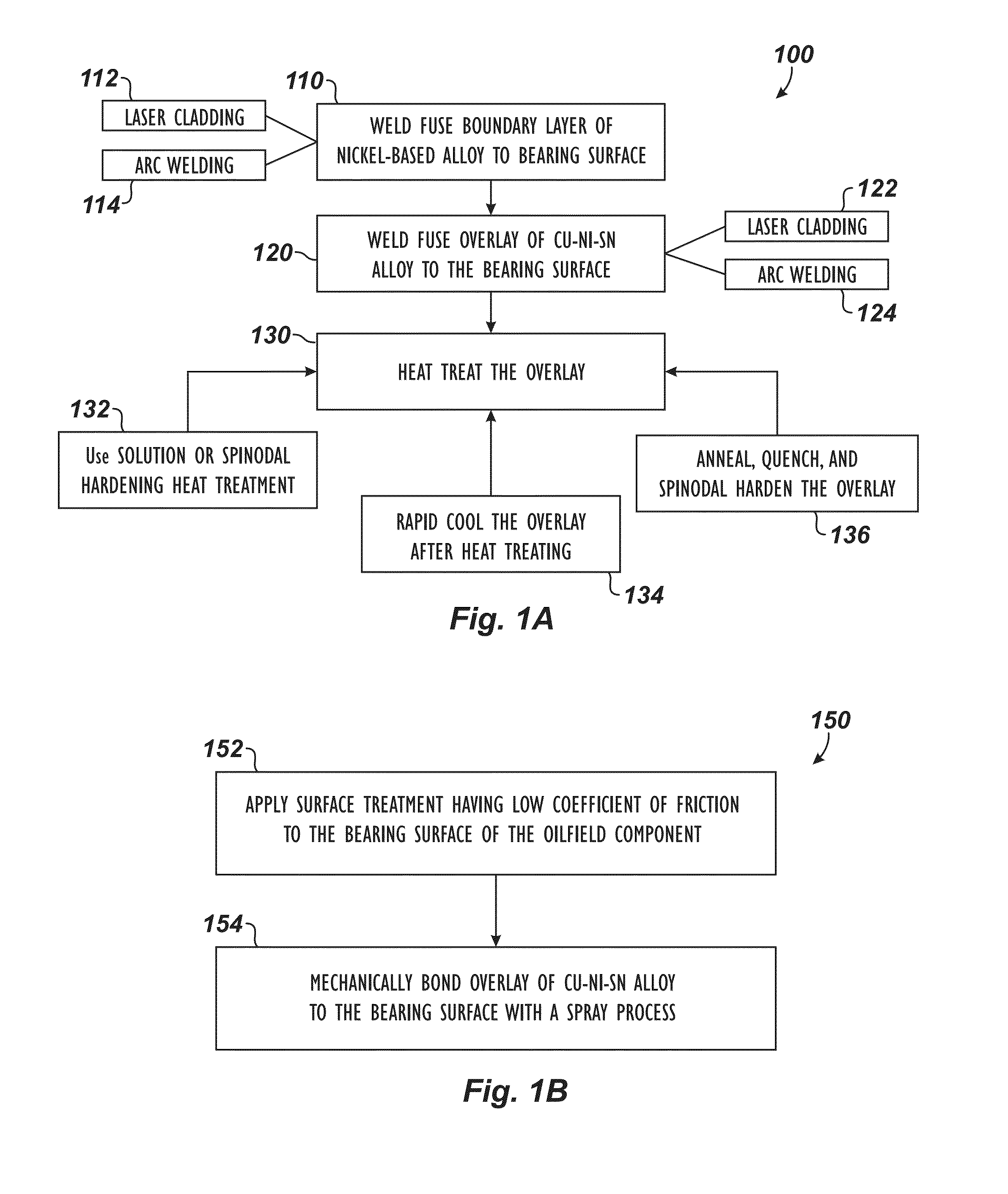

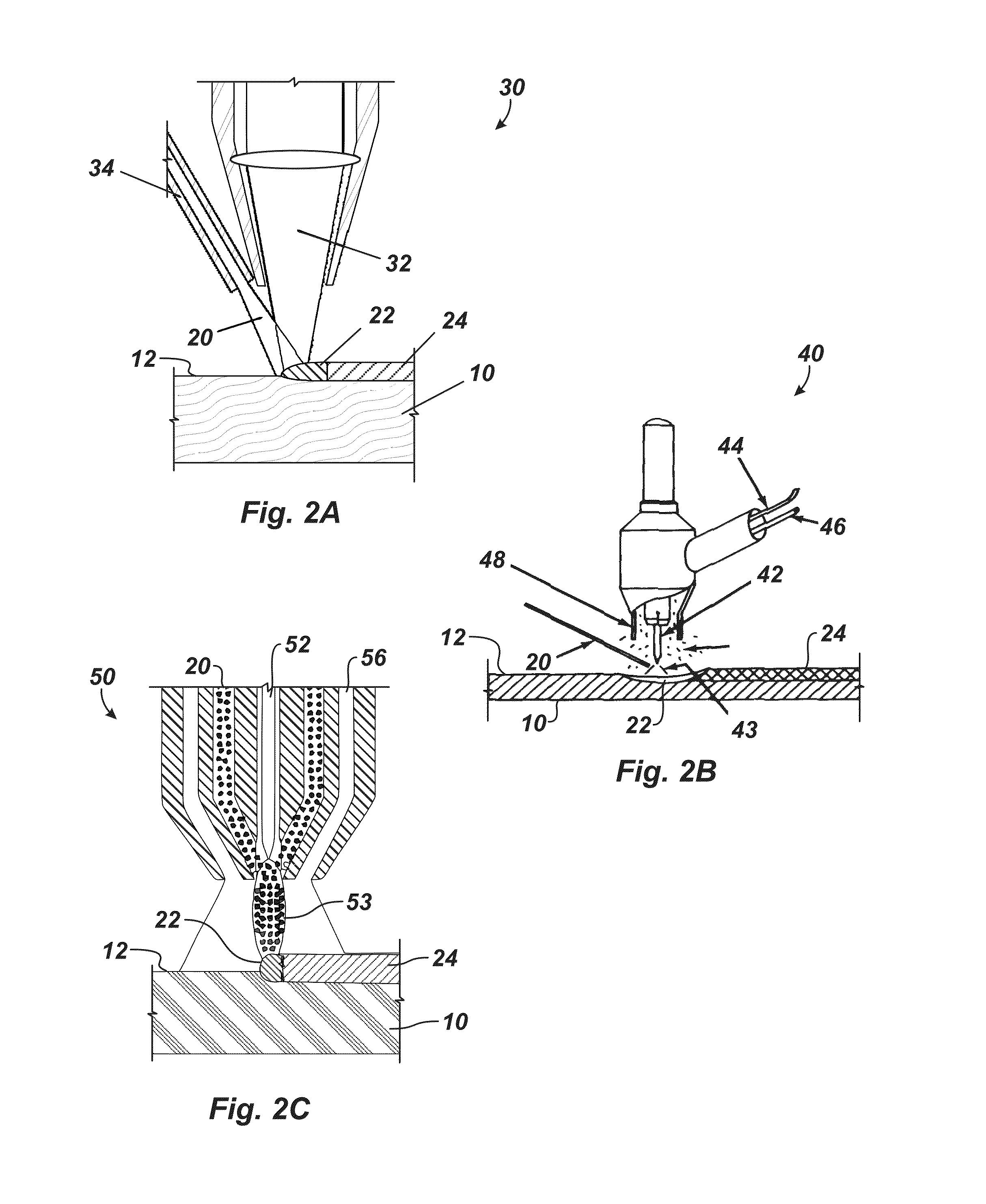

Cu-Ni-Sn Alloy Overlay for Bearing Surfaces on Oilfield Equipment

ActiveUS20150111793A1Reduce solid solubilityAvoid problemsDielectric heatingMolten spray coatingAlloyTungsten

A bearing surface of an oilfield component is treated by applying a surface treatment having a low coefficient of friction to the bearing surface of the oilfield component by weld fusing an overlay of a Cu—Ni—Sn alloy material to the bearing surface. Weld fusing the overlay of the Cu—Ni—Sn alloy material to the bearing surface can involve laser surface cladding the overlay of the Cu—Ni—Sn alloy material to the bearing surface, gas tungsten arc welding the overlay of the Cu—Ni—Sn alloy material to the bearing surface, or plasma tungsten arc welding the overlay of the Cu—Ni—Sn alloy material to the bearing surface.

Owner:WEATHERFORD TECH HLDG LLC

Austenitic steel welded joint

ActiveUS20140186101A1High strengthImprove hydrogen embrittlement resistanceFurnace typesPipeline systemsNichromeAustenite

An austenitic steel welded joint is produced by gas tungsten arc welding an austenitic steel base metal with a welding material of austenitic steel having a composition comprising: C≦0.1%; Si≦0.8%; Mn: 1.5 to 5.5%; Ni: 8 to 15%; Cr: 18 to 24%; Al<0.05%; N: 0.15 to 0.35%; and one or more of V≦0.5%, Nb≦0.5%, and Mo≦4.5% if necessary, the balance being Fe and impurities that contain O≦0.02%, P≦0.05%, and S≦0.03%. The chemical composition satisfies [413−462(C+N)−9.2Si−8.1 Mn−13.7Cr−9.5Ni−18.5Mo≦−70]. The amount of ferrite of the weld metal is 20% or less in area ratio. The welded joint has high strength and excellent hydrogen embrittlement resistance and is useful in high-pressure hydrogen gas piping where no postweld heat treatment is performed.

Owner:NIPPON STEEL CORP

Arc assisted activating gas tungsten arc welding method

InactiveCN101347858AStrong penetrating powerArc welding apparatusShielding gasCarbon Dioxide / Helium

The invention discloses an argon porous tungsten-arc welding method that is assisted by arc, which is characterized in that the surface of a welding bead to be welded is premelted by small current tungsten arc, and active gas oxygen or the mixed gas of carbon dioxide and argon is taken as shielding gas, and argon tungsten-arc welding is carried out according to normal welding instructions after the solidification of a molten pool. Compare with A-TIG welding, due to no use of a surfactant and no surfactant coating process, the welding method of the invention can realize full automatic production, and has the advantages of more environmental protection, more efficiency, good process stability, high welding quality, etc.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

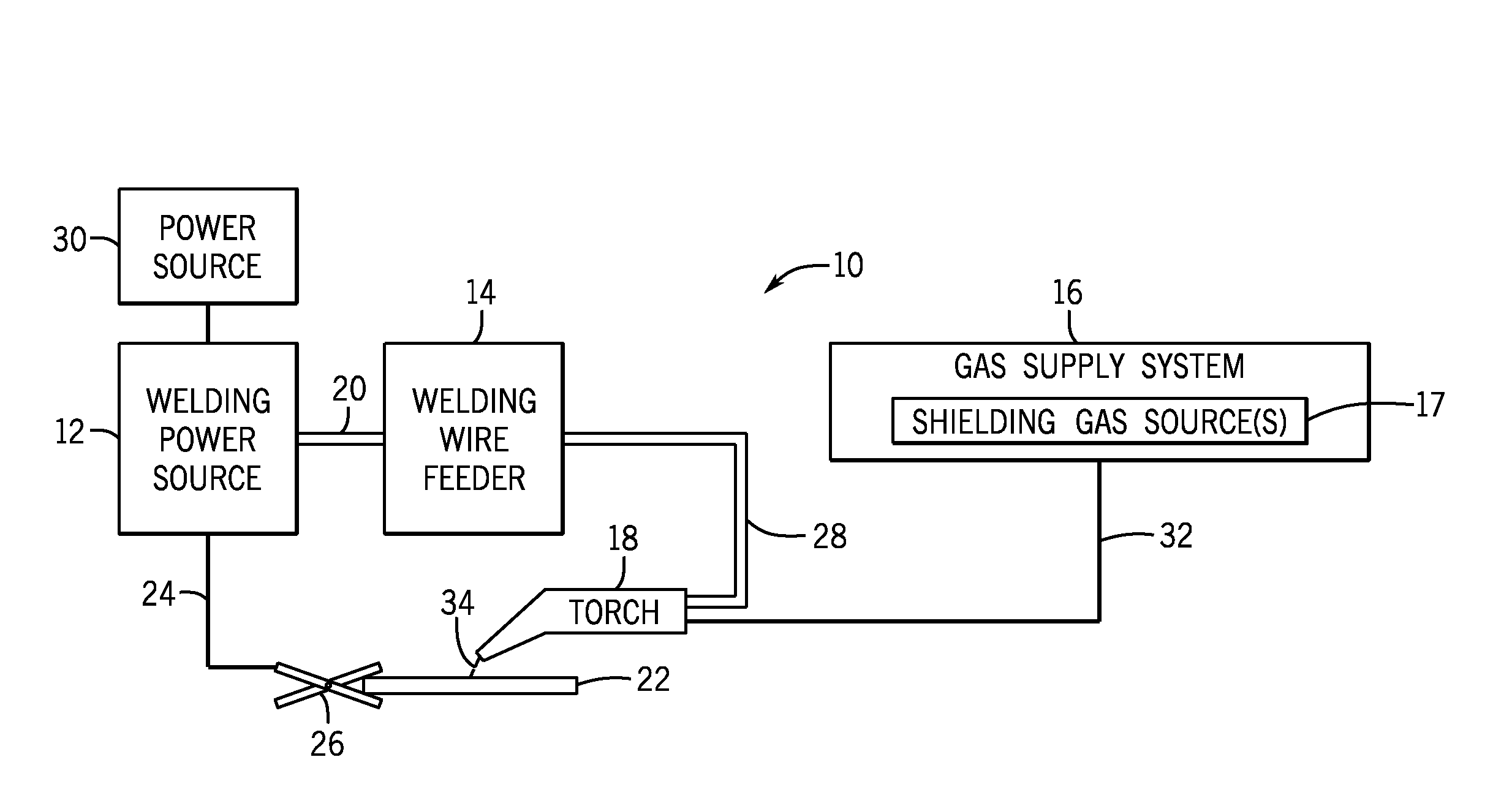

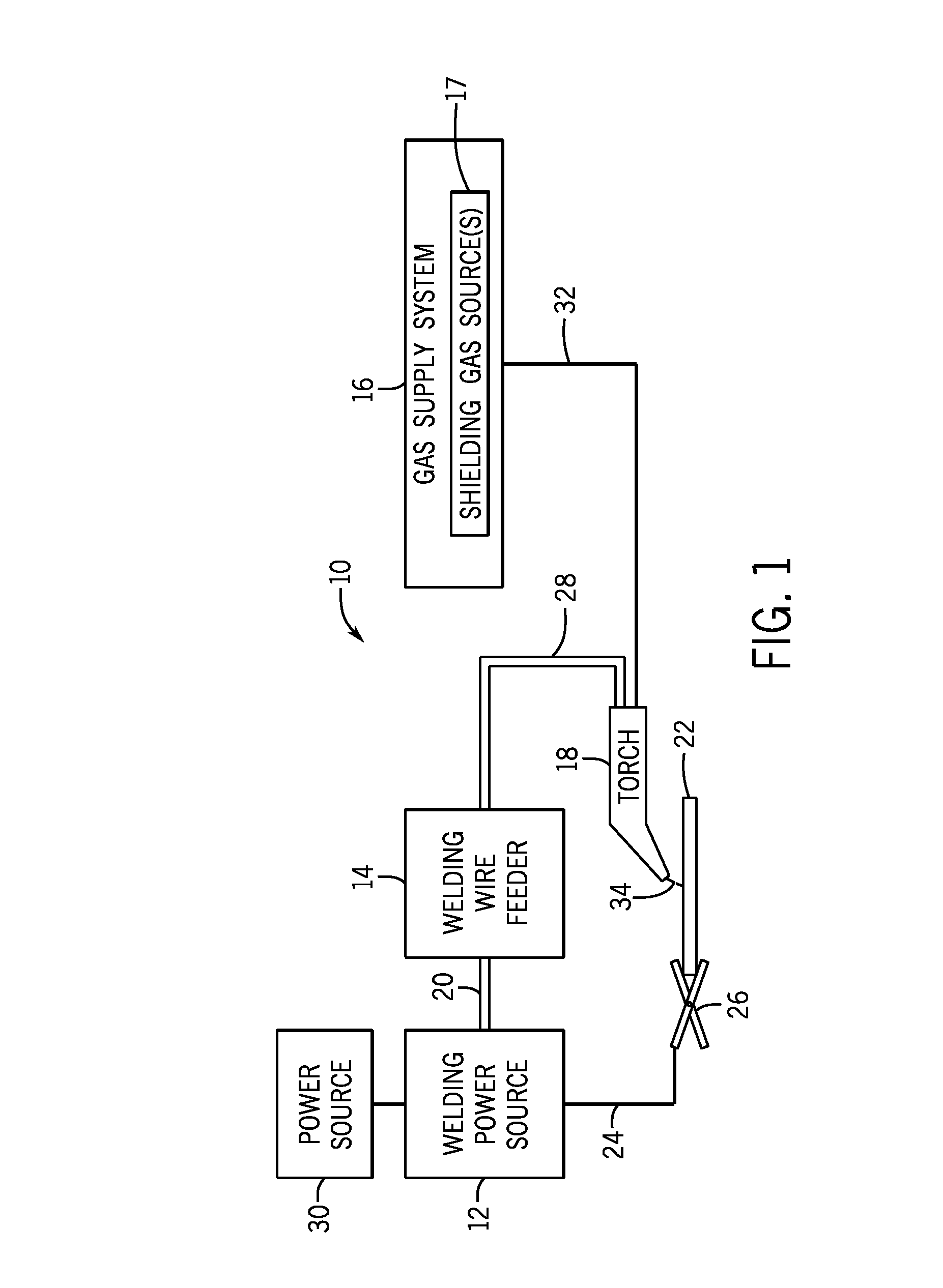

Welding process wire feeder adapter

A welding system may include a welding power source that provides power for both a gas metal arc welding (GMAW) process and a gas tungsten arc welding (GTAW) process. Further, the welding system may include a wire feeder coupled to the welding power source for providing wire, gas flow, and electrical current flow for the GMAW process. Additionally, the welding system may include an adapter that couples to the wire feeder to provide the electrical current flow and the gas flow for the GTAW process.

Owner:ILLINOIS TOOL WORKS INC

New powder composition and use thereof

ActiveUS20180066343A1Improve thermohardnessHigh heat intensityArc welding apparatusMetallic material coating processesThermal sprayingAlloy

A laser cladding or plasma transferred arc overlay welding process may be used advantageously to apply and to control the material properties of a coating designed for protecting the substrate against wear, corrosion and oxidation at elevated temperature. Furthermore, a laser cladding or plasma transferred arc overlay welding process may be used to apply the coating alloy materials in applications where traditional thermal spray or weld-applied coatings are not practical. By using these welding methods very good bonding is achieved by fusion during welding. At the same time the properties of the clad layer is preserved by the limited dilution typical of these two welding methods compared traditional overlay welding, by e.g. Gas Tungsten Arc Welding and the like.

Owner:HOGANAS AB

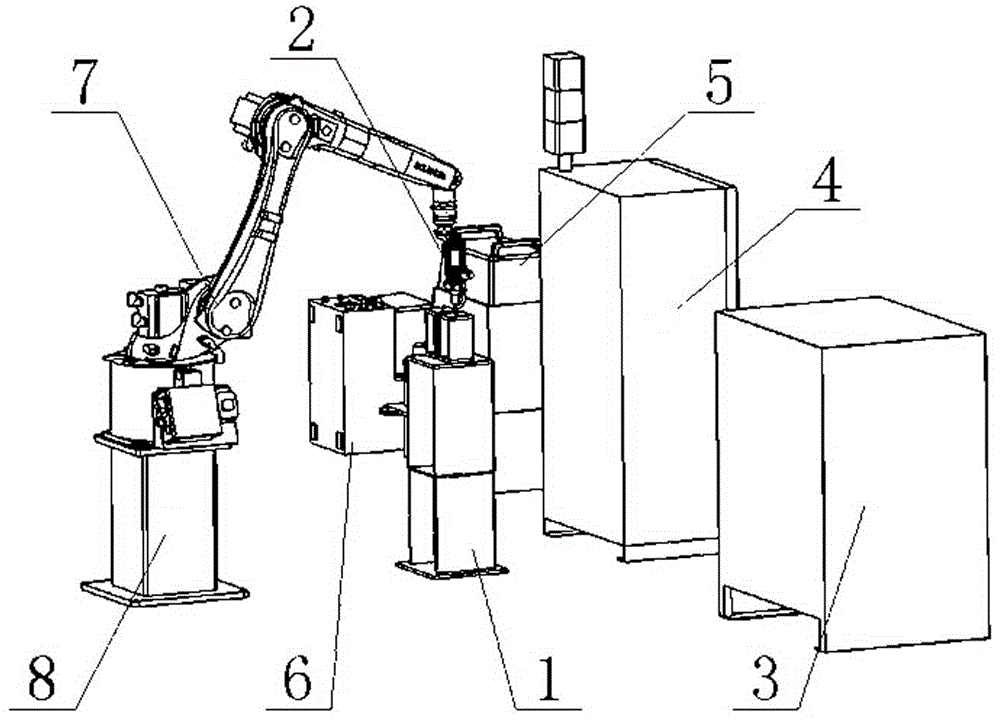

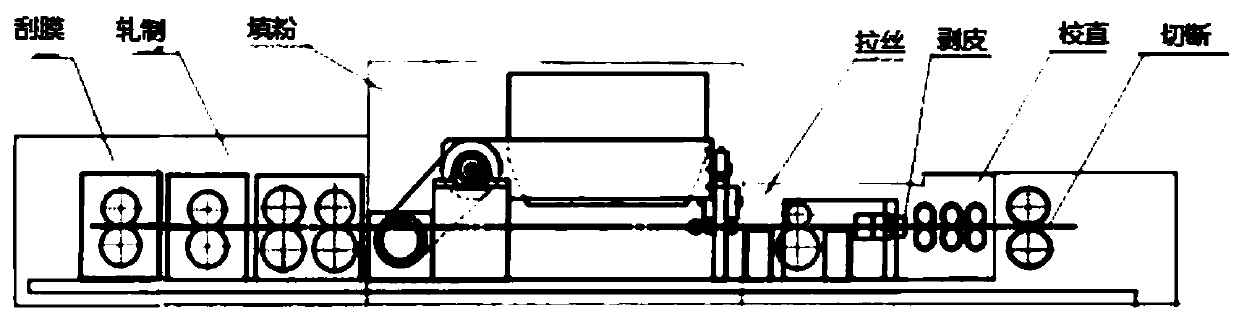

Robot-type gas tungsten arc welding system

ActiveCN105750707ALow technical requirementsHigh adjustment accuracyElectrode supporting devicesGrinding machinesWelding power supplyElectrical control

The invention discloses a robot-type gas tungsten arc welding system. The robot-type gas tungsten arc welding system comprises a robot body, a TIG (tungsten inert gas) welding gun, an automatic tungsten electrode replacing and grinding device, a robot control cabinet, a welding power source and an electrical control cabinet, wherein the TIG welding gun is connected to the robot body, the robot control cabinet is connected with the robot body, the electrical control cabinet is used for controlling the whole system, and the automatic tungsten electrode replacing and grinding device comprises a tungsten electrode replacing device and a tungsten electrode grinding device fixedly connected with the tungsten electrode replacing device. The robot-type gas tungsten arc welding system has the advantages that welding wires can be positioned precisely automatically, wire feeding and positioning time is shortened, automatic tungsten electrode replacement and automatic tungsten electrode grinding are integrated, working efficiency is improved, technical requirements on welding workers are lowered, and the welding workers can be protected from being harmed.

Owner:SHANDONG ROBOT INTELLIGENT TECH

Flux-cored wire for welding of 2Al2 high-strength aluminum alloy gas tungsten arc welding

ActiveCN111015013AImprove mechanical propertiesHigh strengthWelding/cutting media/materialsSoldering mediaAl powderMicro nano

The invention discloses a flux-cored wire for welding of 2Al2 high-strength aluminum alloy tungsten inert gas arc welding, and belongs to the technical field of aluminum alloy welding. The filling rate of the flux-cored wire is 20 % to 30 % with a 1070 semi-hard pure aluminum strip as the outer skin, wherein powder comprises the alloy components in percentage by mass: 22 % to 29 % of Cu powder, 0.5 % to 25 % of micro-nano ceramic powder, 2 % to 4.5 % of Mn powder, 1 % to 2.5 % of V powder, 1 % to 2 % of AlTi alloy powder, 1.5 % to 5 % of Zr powder, 1 % to 6 % of rare earth metal powder, and the balance of pure aluminum powder. The welding is well formed, defects such as bulge and undercut are avoided, and all properties of weld metal meet the engineering requirements.

Owner:BEIJING UNIV OF TECH

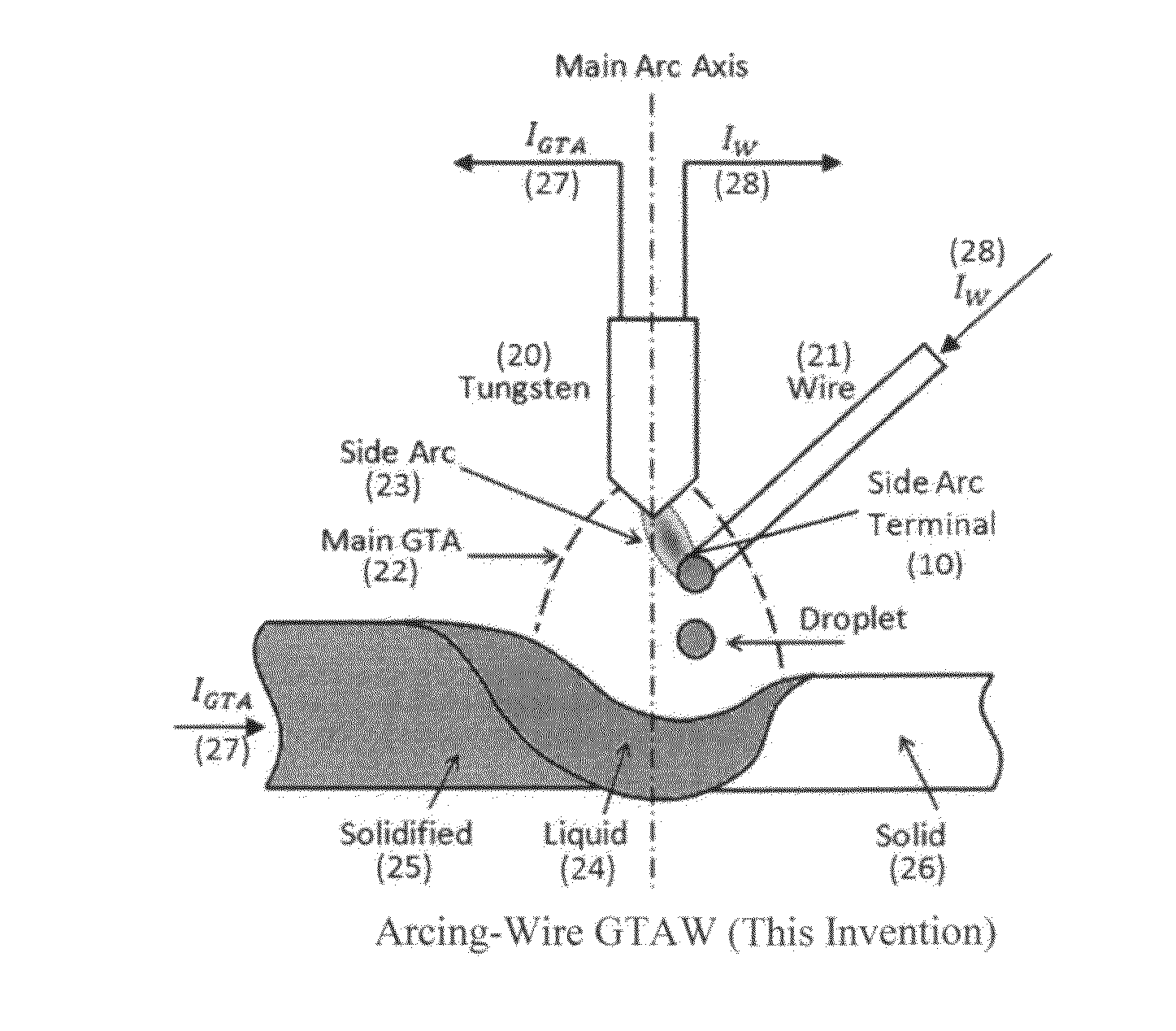

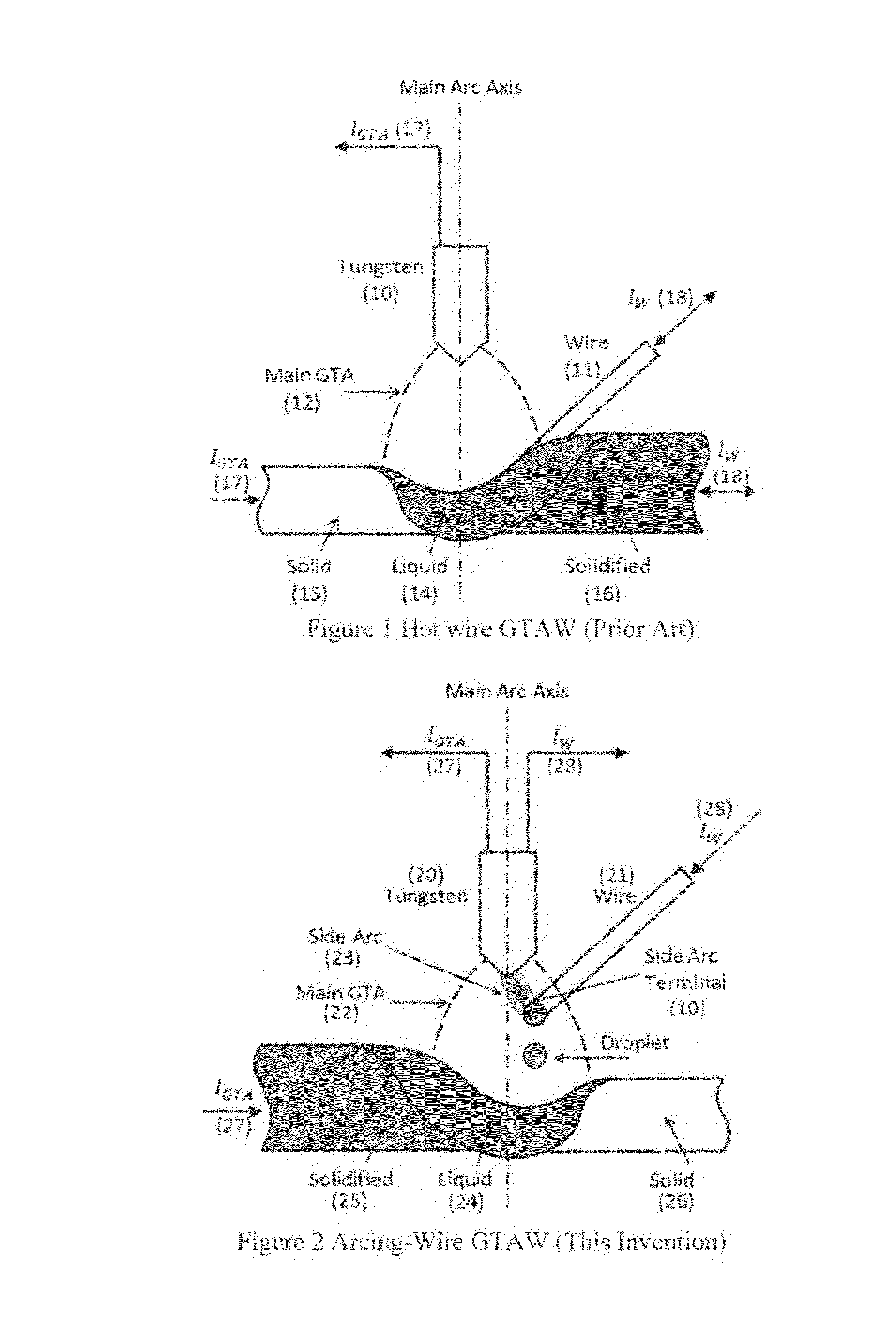

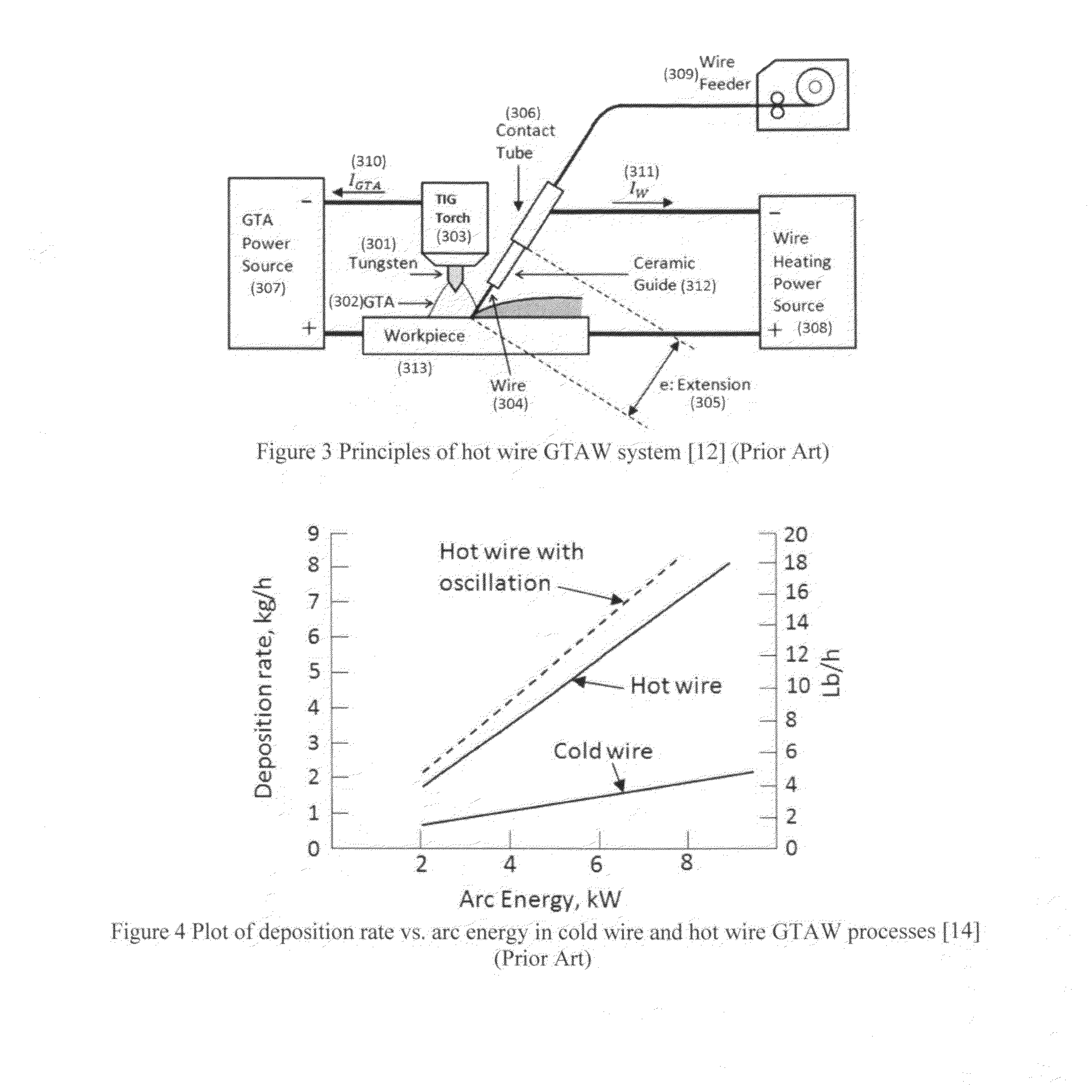

Gas tungsten arc welding using arcing-wire

InactiveUS20140131334A1Arc welding apparatusWelding/cutting media/materialsMelting tankGas tungsten arc welding

In gas tungsten arc welding (GTAW), the achievable deposition rate of the filler wire is coupled with the arc energy and the mass of the molten metal in the weld pool. In this invention, a side arc is added into the GTA (gas tungsten arc) between the wire and the same tungsten that establishes the GTA with the work-piece. While its anode provides a GMAW (gas metal arc welding) melting mechanism to completely melt the wire at high speeds, the undesirable dependence of deposition rate on the weld pool mass is also eliminated. As a result, the deposition rate is increased and the ability to provide desirable deposition rate and base metal melting / penetration freely without coupling is established for the GTAW.

Owner:ADAPTIVE INTELLIGENT SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com