Ta-Nb composite nickel-based welding wire for nuclear power equipment and welding method thereof

A welding method and composite technology, applied in the direction of arc welding equipment, welding equipment, welding medium, etc., can solve problems such as cracks easily, and achieve the effect of good forming performance, good forming, and no scum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

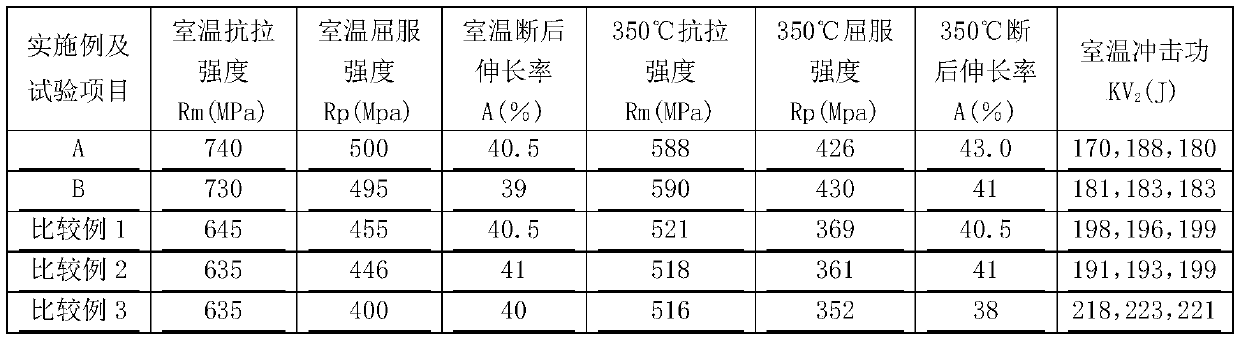

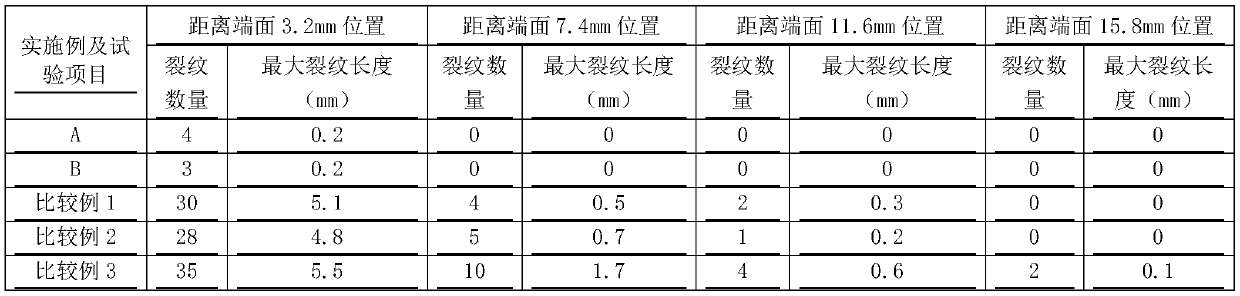

Examples

specific Embodiment approach 1

[0015] Specific Embodiment 1: In this embodiment, a Ta&Nb composite nickel-based welding wire for nuclear power equipment is composed of C: <0.04%, Si: 0.10-0.20%, Mn: 0.5%-1.0%, S: < 0.003%, P: <0.003%, Cr: 28.0%-31.5%, Mo: 3.0%-4.0%, Cu: <0.05%, Nb: 0.5%-1.5%, Ta: 1.0%-4.0%, Ti: 0.4 %~0.9%, Al: <0.50%, Fe: 3%~10%, Ca: <0.005%, Mg: <0.005%, O: <0.005%, N: 0.20%~0.40%, B: <0.001% , Zr: <0.005%, impurity elements: <0.10%, Ni is the balance.

[0016] In this embodiment, the content of Nb is 0.5% to 1.5%, and the content of Ta is 1.0% to 4.0%.

[0017] In this embodiment, the preparation of Ta&Nb composite nickel-based welding wire for nuclear power equipment: use vacuum melting and casting furnace smelting or electric furnace plus refining outside the furnace method to smelt the master alloy billets that meet the above composition according to the weight percentage; the master alloy steel ingots are subjected to conventional forging, Rolling, and then after multi-pass cold dra...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the weight percent composition is C: <0.04%, Si: 0.15%, Mn: 0.8%, S: <0.003%, P: <0.003%, Cr : 30%, Mo: 3.5%, Cu: <0.05%, Nb: 1.0%, Ta: 2.5%, Ti: 0.6%, Al: <0.50%, Fe: 5%, Ca: <0.005%, Mg: < 0.005%, O: <0.005%, N: 0.3%, B: <0.001%, Zr: <0.005%, impurity elements: <0.10%, Ni is the balance. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that the weight percent composition is C: <0.04%, Si: 0.12%, Mn: 0.6%, S: <0.003%, P: <0.003%, Cr : 29.5%, Mo: 3.3%, Cu: <0.05%, Nb: 1.2%, Ta: 2.8%, Ti: 0.5%, Al: <0.50%, Fe: 6%, Ca: <0.005%, Mg: < 0.005%, O: <0.005%, N: 0.29%, B: <0.001%, Zr: <0.005%, impurity elements: <0.10%, Ni is the balance. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com