Robot-type gas tungsten arc welding system

A technology of gas shielded welding and robot body, which is applied to the characteristics of welding electrodes, welding equipment, welding accessories, etc., can solve the problems of no uniform standard for tungsten electrodes, restrict welding efficiency, and affect the staff, so as to improve welding quality and shorten wire feeding. The effect of positioning time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following is only exemplary and does not limit the protection scope of the present invention.

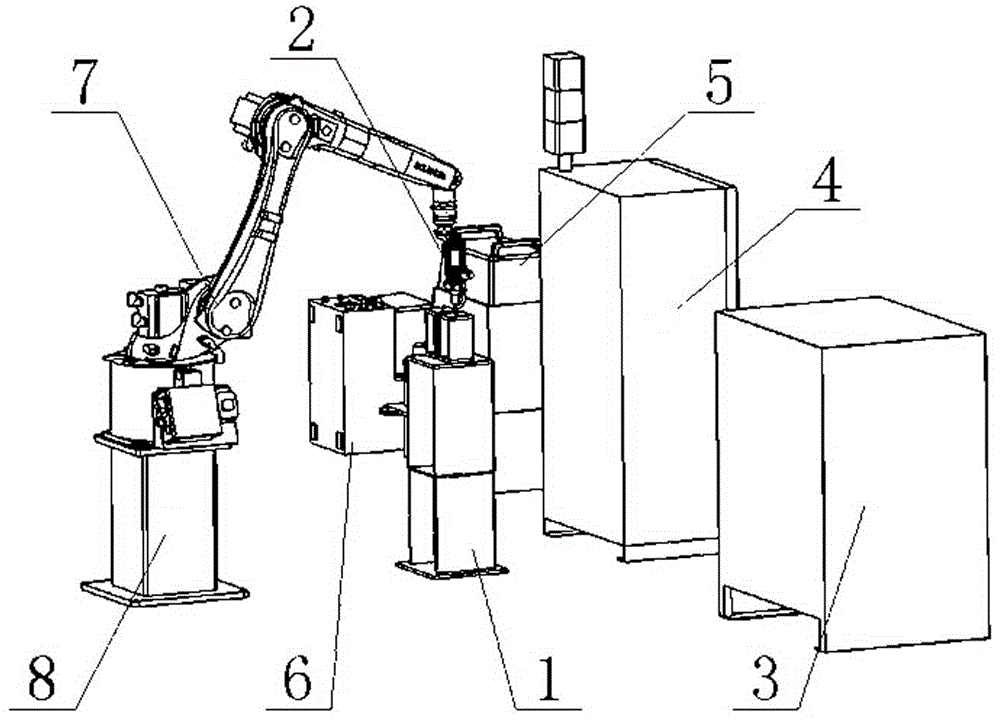

[0028] Such as figure 1 As shown, the robot gas tungsten shielded welding system of the present invention includes a robot body 7, a TIG welding torch 2 connected to the robot body, a tungsten electrode automatic replacement and grinding device 1, a robot control cabinet 3 connected to the robot body, Welding power supply 5, electrical control cabinet 4 and cold water tank 6 for controlling the whole system, robot body 7 is arranged on the robot base 8, welding power supply 5 is connected with TIG welding torch and workpiece to provide suitable current and voltage for TIG welding torch and workpiece, cold water The box 6 is used to cool the high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com