Flux-cored wire for welding of 2Al2 high-strength aluminum alloy gas tungsten arc welding

A technology of flux-cored welding wire and aluminum alloy, applied in the field of aluminum alloy welding, can solve the problems of low joint strength, hot crack, coarse structure, etc., and achieve the effects of low cost, simple operation process, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

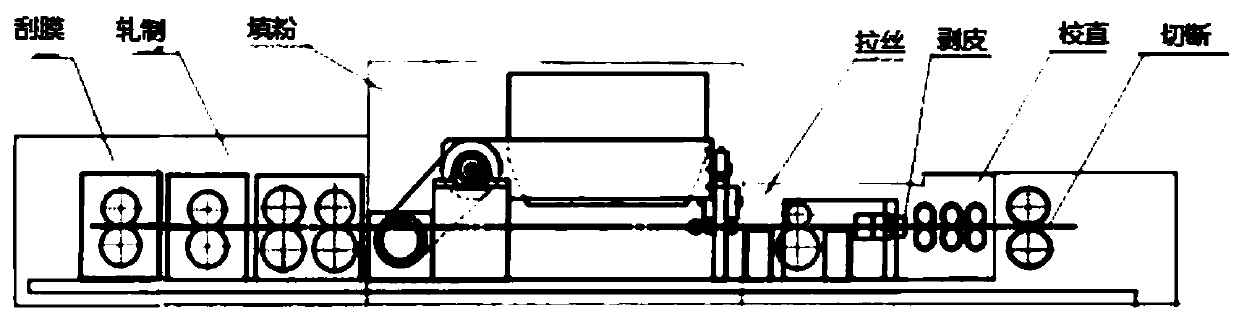

Method used

Image

Examples

Embodiment 1

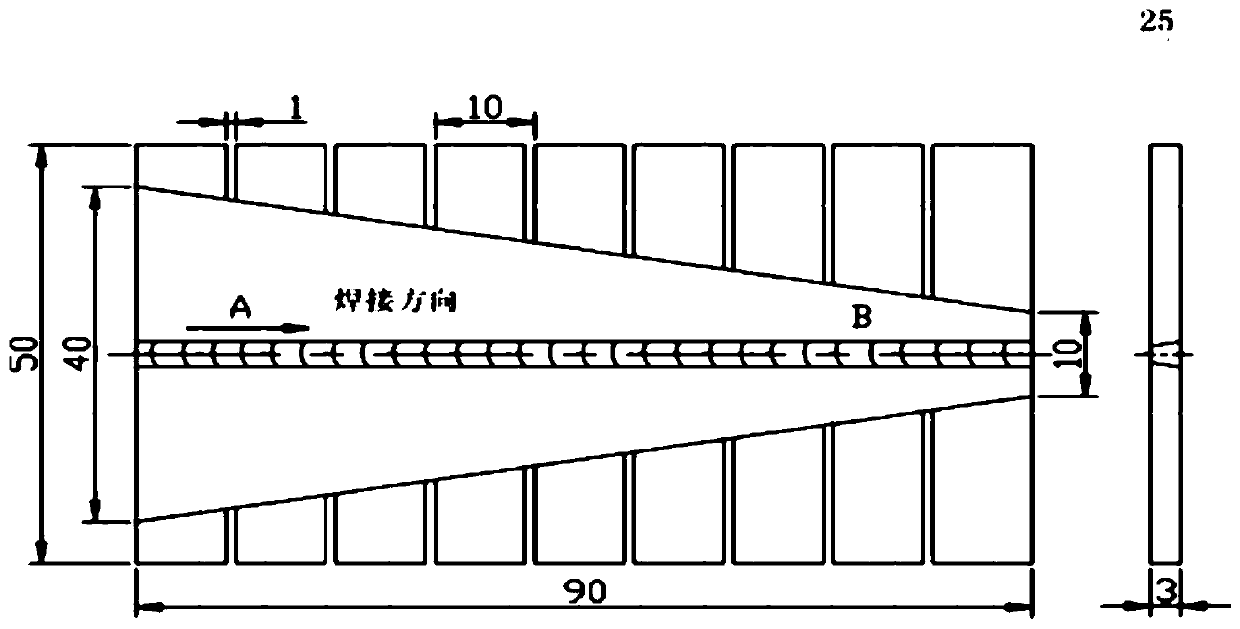

[0045] The aluminum alloy flux-cored wire used for 2A12 high-strength aluminum alloy TIG welding adopts 1070 semi-hard pure aluminum strip sheath 10×1.0mm, the filling rate is 20%, and the diameter of the wire after drawing, reducing, peeling, straightening, and cutting The chemical composition (% by weight) of the drug core is as follows: wherein the metal Cu powder is 23%, the content of the metal Mn powder is 3%, the content of the metal V powder is 2%, and the content of the titanium-aluminum alloy powder is 1.5%. The content of metal Zr powder is 2%; the composite micro-nano ceramic particles are TiC: 8%; the rare metal powder is Sc powder with a content of 1.5%, and the balance is pure aluminum powder. 99.99% pure argon is used as the shielding gas, the gas flow is 17L / min, the welding current is 80A, and the voltage is 18V.

Embodiment 2

[0047] The flux-cored welding wire used for TIG welding of 2A12 high-strength aluminum alloy is made of 1070 pure aluminum strip sheath 10×1.0mm, the filling rate is 22%, and the diameter of the filler wire after drawing, reducing, peeling, straightening and cutting is 1.2mm; The chemical composition (% by weight) of the drug core is metal Cu powder: 24%, metal Mn powder: 3.5%, metal V powder: 1.5%, titanium aluminum alloy powder: 1.5%, metal Zr powder: 2.5%; composite micro-nano ceramics Particles are TiC: 10%, ZrC: 10%; rare metals are Er: 2%; the balance is pure aluminum powder. 99.99% pure argon is used as the shielding gas, the gas flow rate is 18L / min, the welding current is 100A, and the voltage is 20V.

Embodiment 3

[0049] The flux-cored welding wire used for TIG welding of 2A12 high-strength aluminum alloy adopts 1070 pure aluminum strip sheath 12×0.8mm, the filling rate is 24%, and the diameter of the filling wire is 1.4mm after drawing, reducing, peeling, straightening and cutting; The chemical composition (% by weight) of the drug core is metal Cu powder: 25%, metal Mn powder: 2.5%, metal V powder: 2%, titanium aluminum alloy powder: 1.5%, metal Zr powder: 3%; micronano ceramic particles It is TiN: 18%; the rare metal powder is Sc+Zr, among which Sc: 2%, Zr: 4%, and the balance is pure aluminum powder. 99.99% pure argon is used as the shielding gas, the gas flow rate is 15L / min, the welding current is 120A, and the voltage is 21V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com