Patents

Literature

38results about How to "Guaranteed Chemical Composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

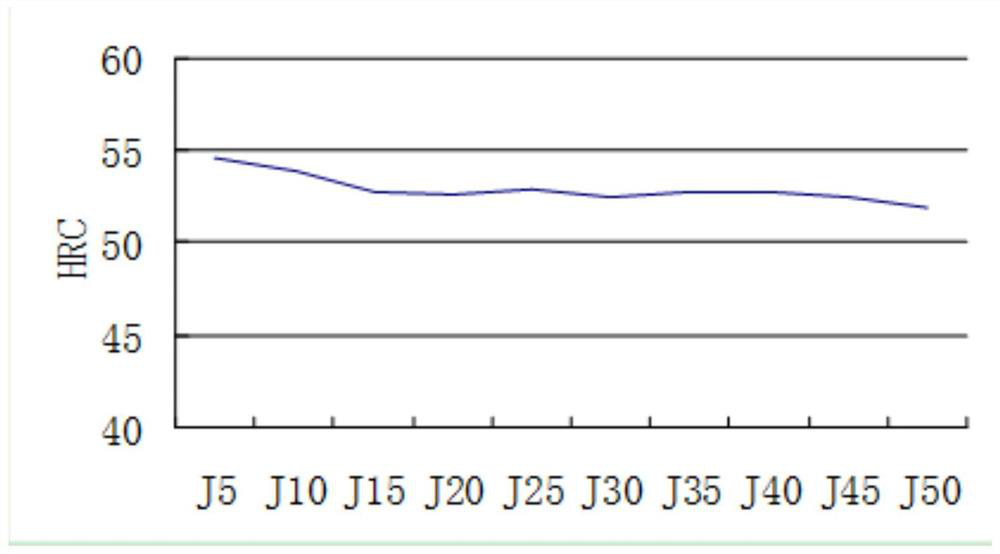

Smelting and updraft continuous casting process of Cu-Cr-Zr alloy

The invention discloses an updraft continuous casting process of Cu-Cr-Zr alloy bar materials with high strength, high conductivity and high softening temperature, mainly adopting a smelting furnace with non-vacuum and low-furnace pressure tightness, a casting furnace and an updraft device. The invention adopts an updraft continuous casting device and technique under the condition of non-vacuum, realizes continuous production of Cu-Cr-Zr alloy bars, is not affected by the capacity of a furnace body, and can produce Cu-Cr-Zr alloy bar materials with any lengths. Obtained products are important raw materials for producing copper alloy products with high strength and high conductivity, such as contact lines of high-speed trains, spot-welding electrodes, current contact nozzles, lead frames, motor conducting bars, and the like.

Owner:苏州中色华人铜业有限公司

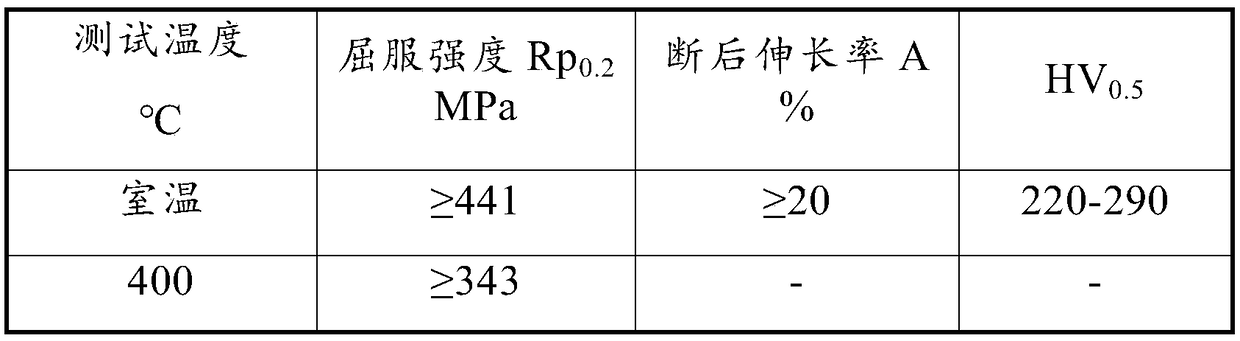

Austenitic stainless steel jacketing pipe for lead-bismuth fast reactor and preparation method of austenitic stainless steel jacketing pipe

ActiveCN105112811APrecise controlLow content of impurity elements and inclusionsQuenchingAustenitic stainless steel

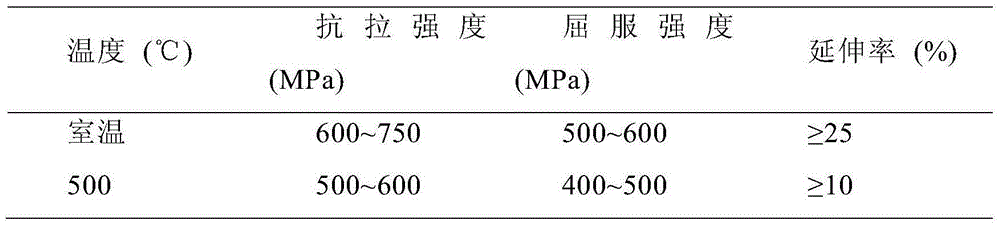

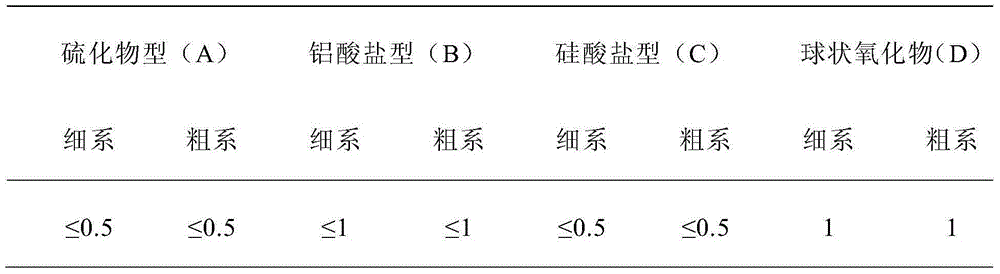

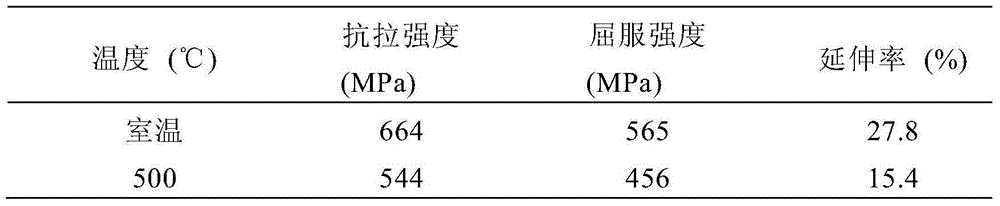

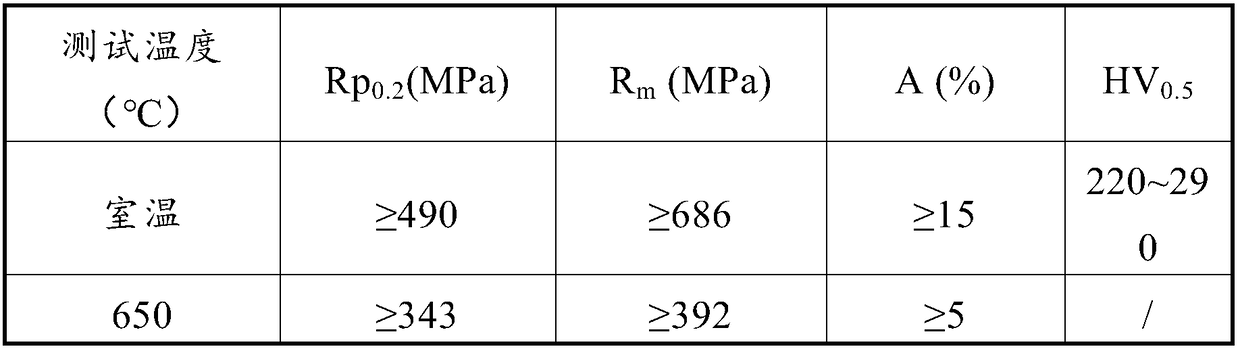

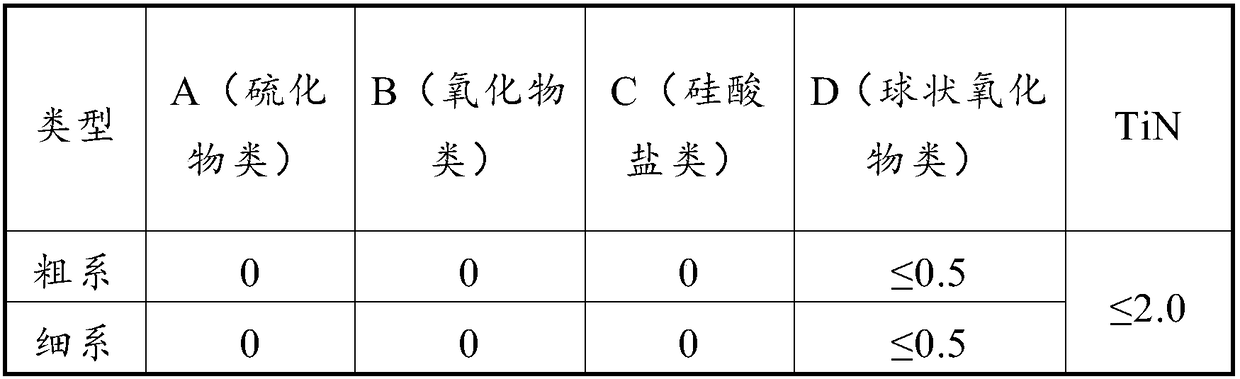

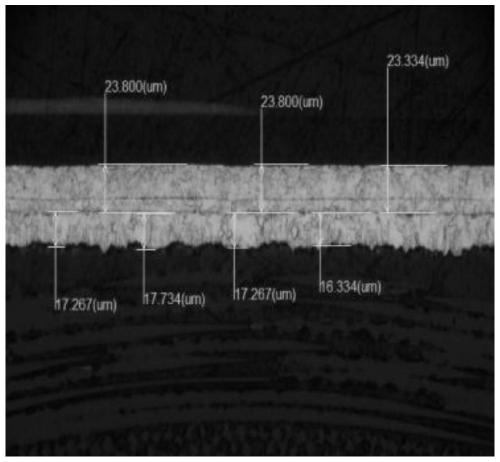

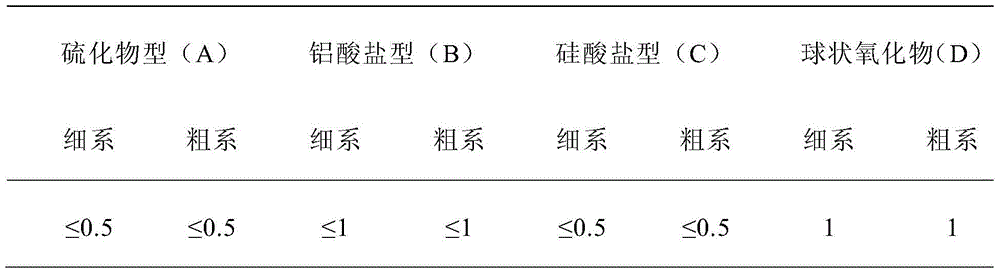

The invention discloses an austenitic stainless steel jacketing pipe for a lead-bismuth fast reactor and a preparation method of the austenitic stainless steel jacketing pipe. The austenitic stainless steel jacketing pipe comprises, by weight, 0.06%-0.1% of C, 0.5%-1.0% of Si, 14%-16% of Ni, 14%-16% of Cr, 0.3%-0.6% of Ti, 1.5%-2.0% of Mn, 1.2%-1.8% of Mo, smaller than or equal to 0.03% of P, smaller than or equal to 0.05% of Co, smaller than or equal to 0.05% of Al, smaller than or equal to 0.01% of B, smaller than or equal to 0.02% of N, and the balance Fe. The method for preparing the jacketing pipe through the materials includes the steps of smelting, forging, hot working, solution treatment, cold rolling and intermediate annealing, final heat treatment, final cold working, straightening, cleaning, finished product inspection, identification, packaging and the like. In the final heat treatment step, quenching is conducted in a high-pressure nitrogen cooling mode, and in the cleaning process, an acidic degreasing agent is prohibited.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

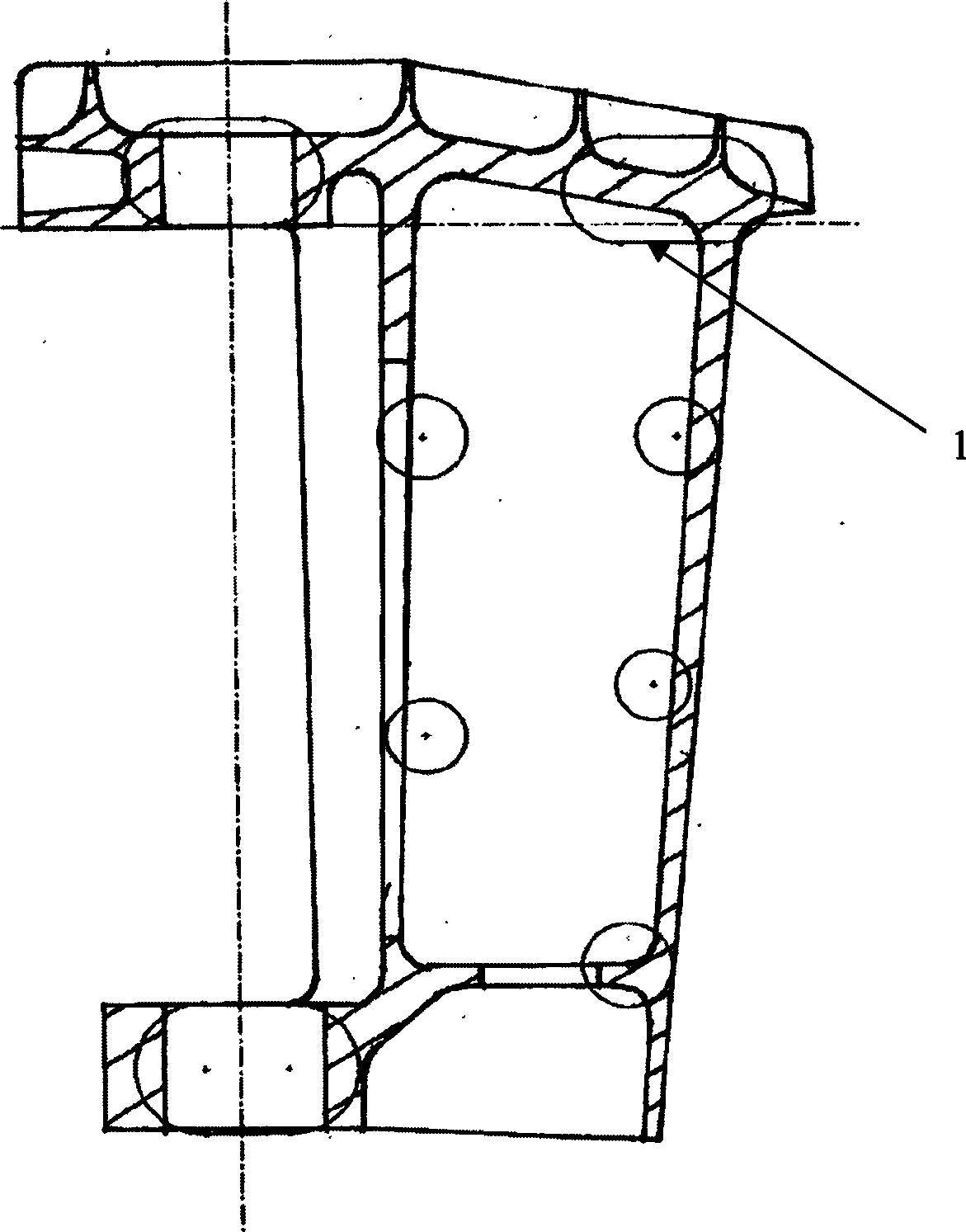

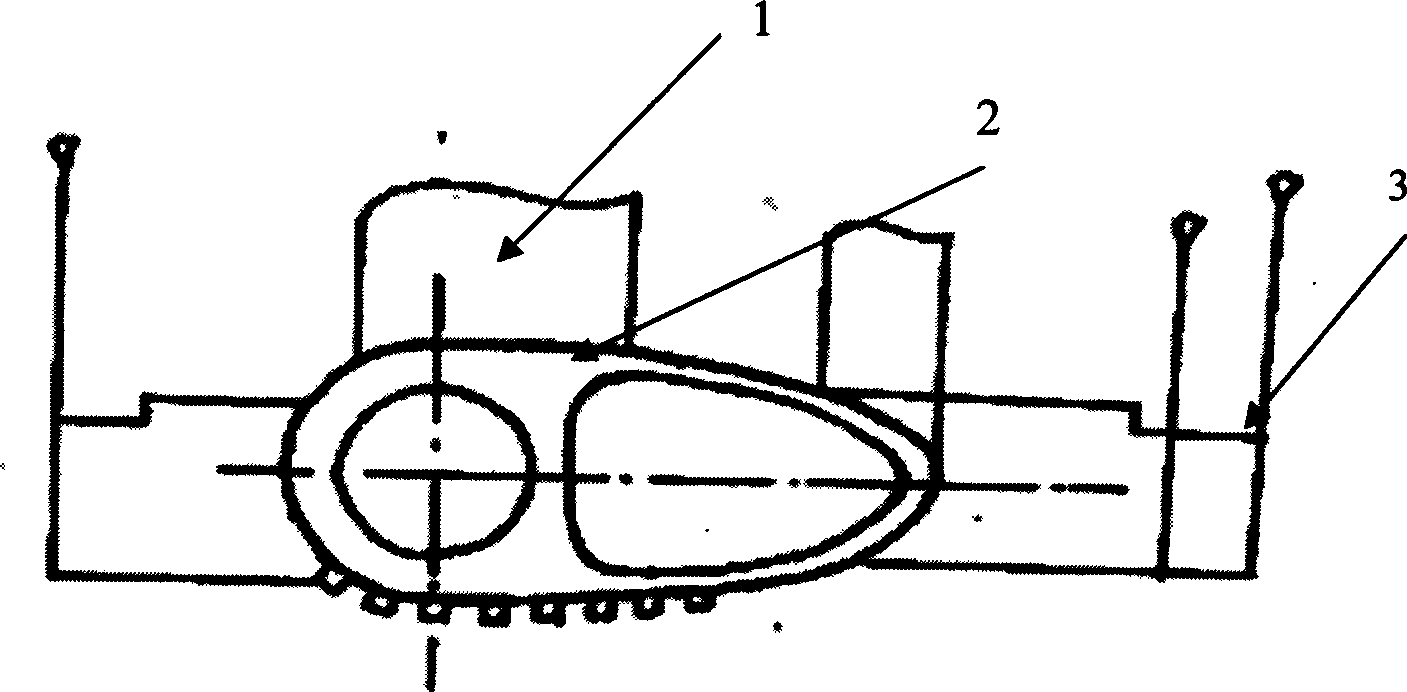

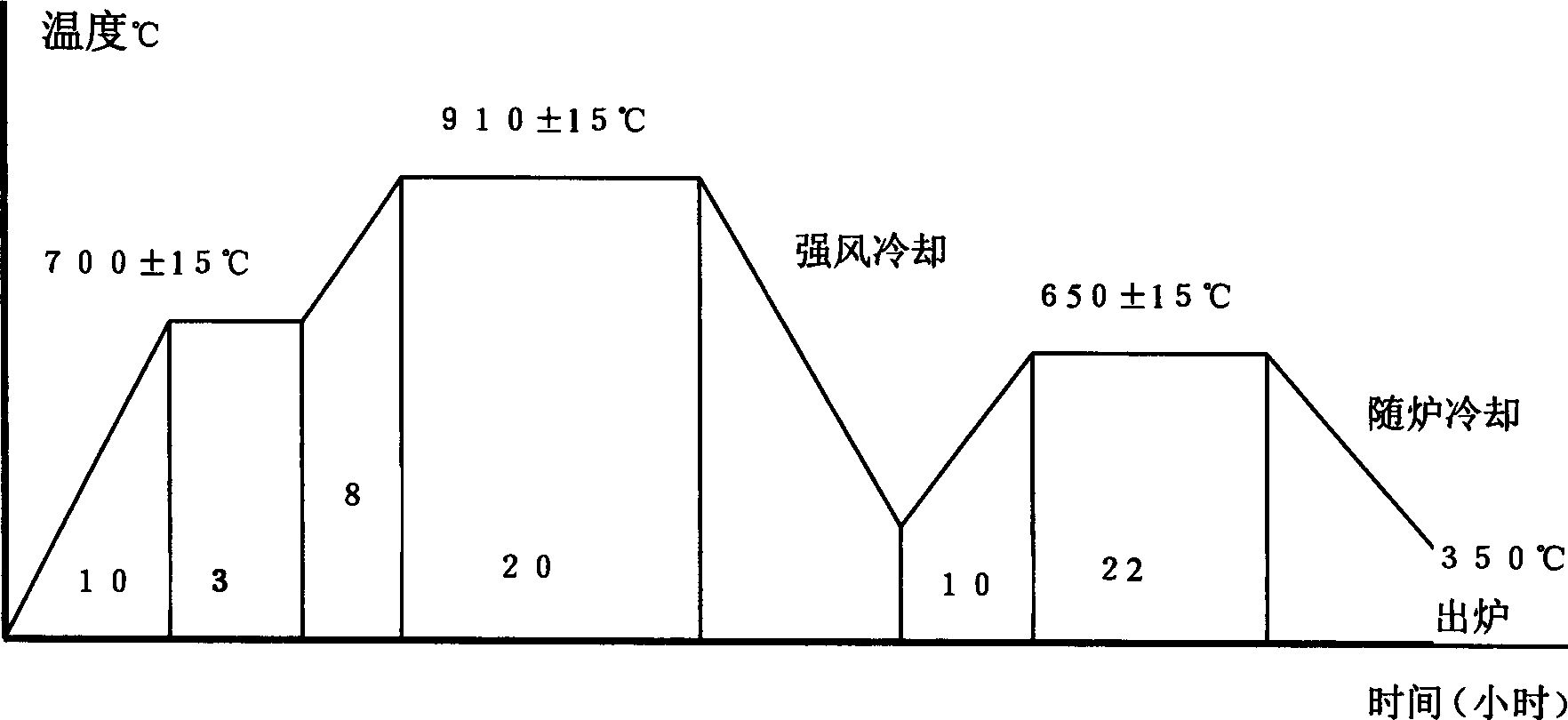

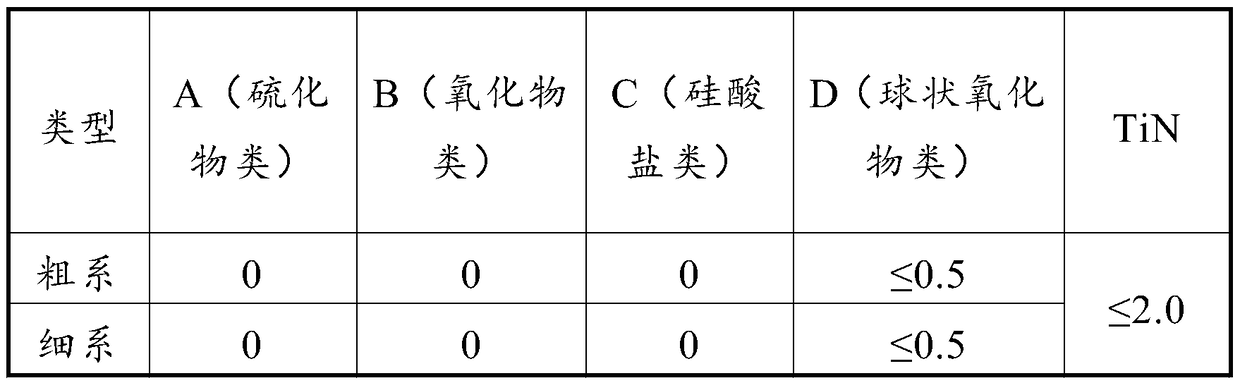

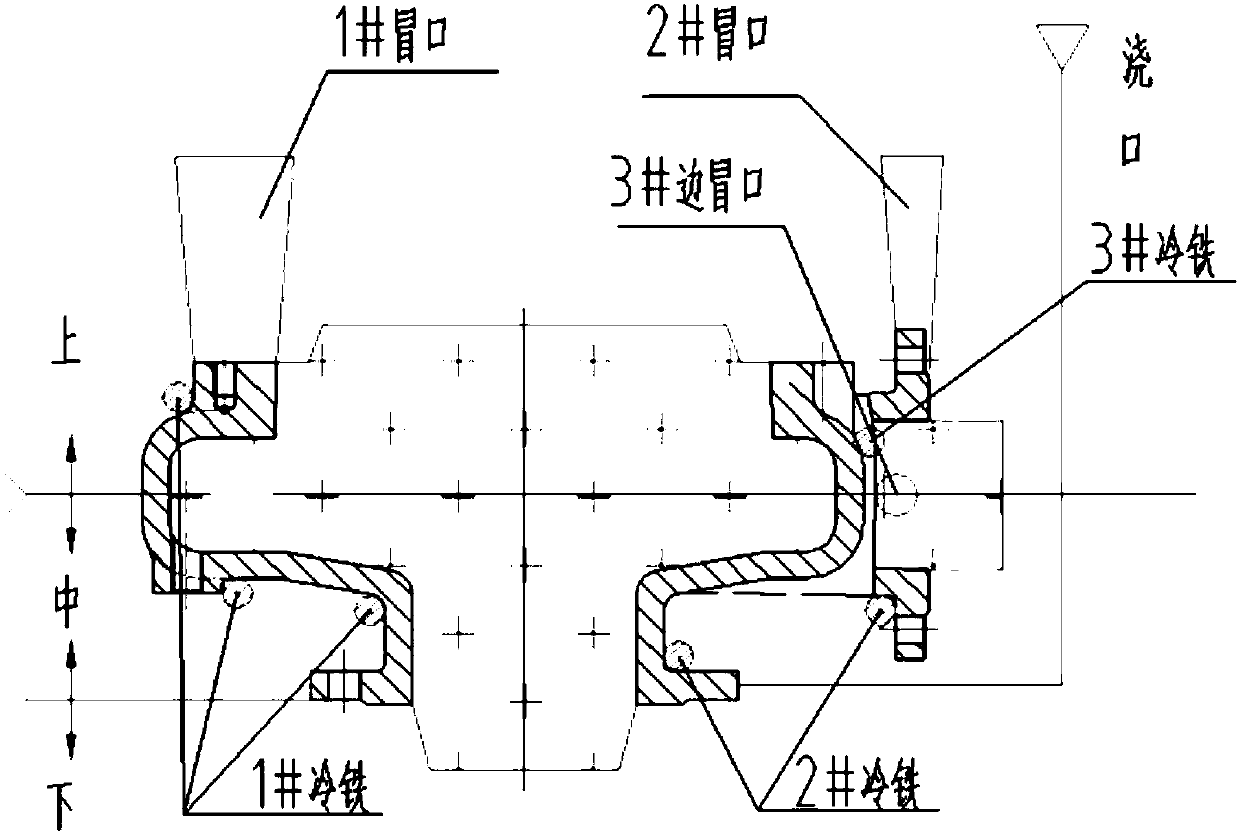

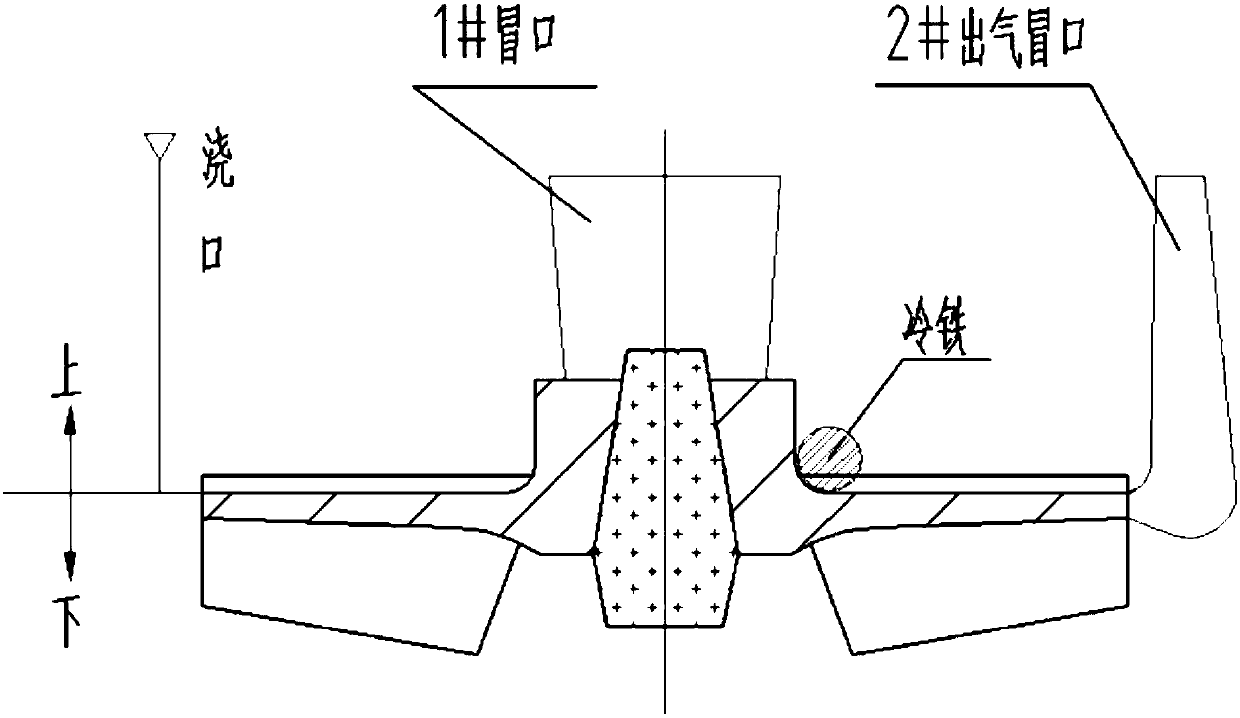

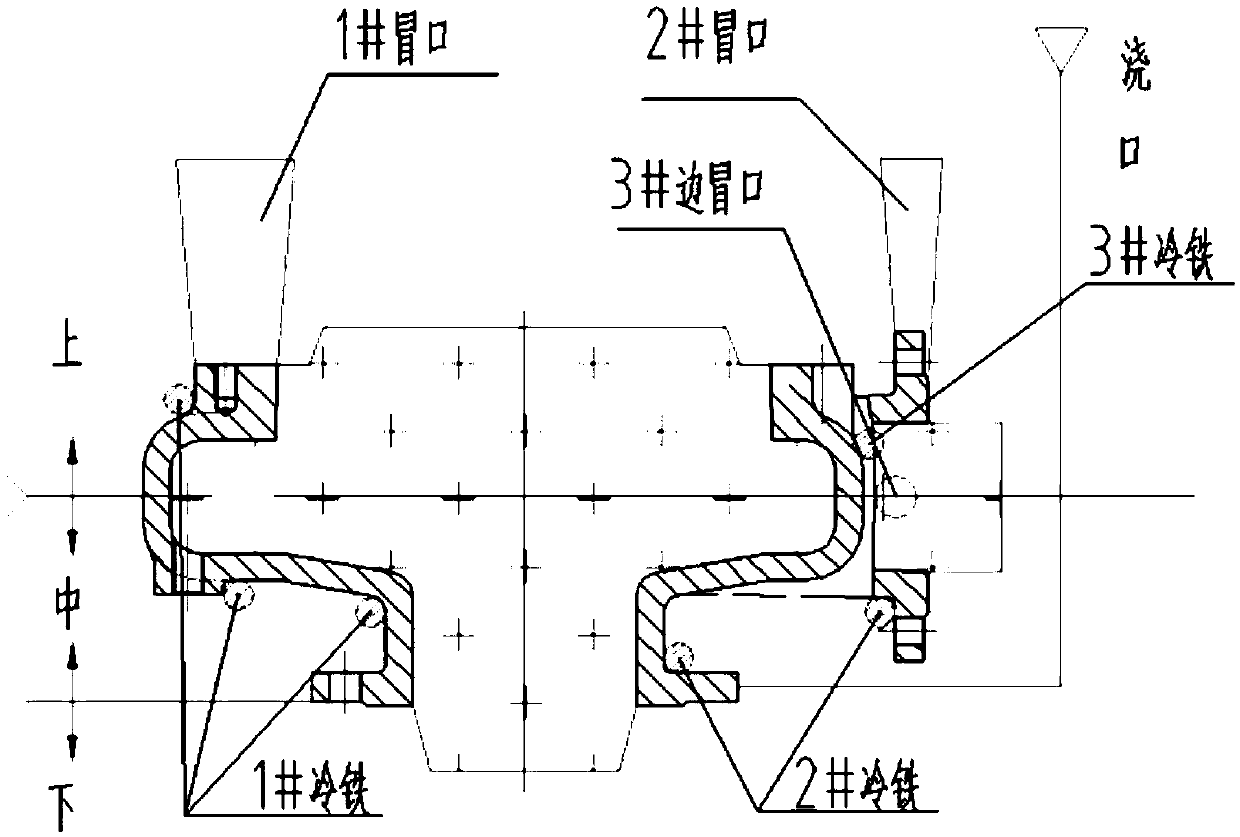

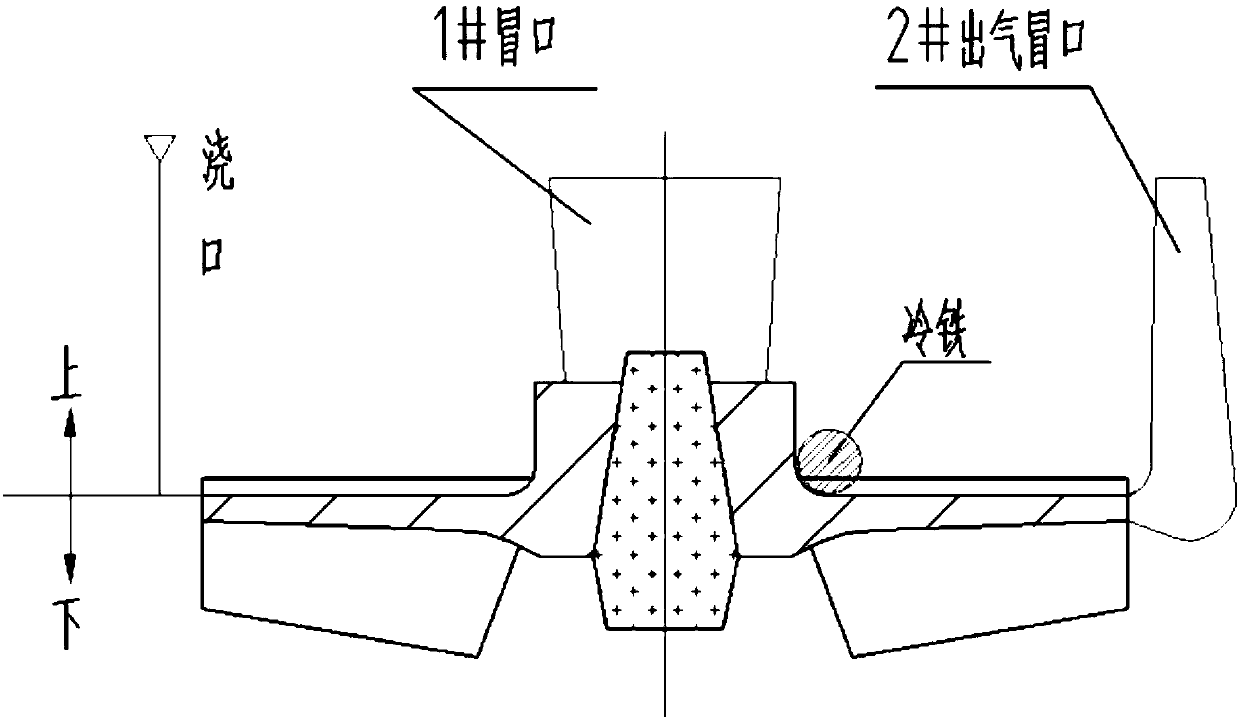

Manufacture method of ship rudder horn

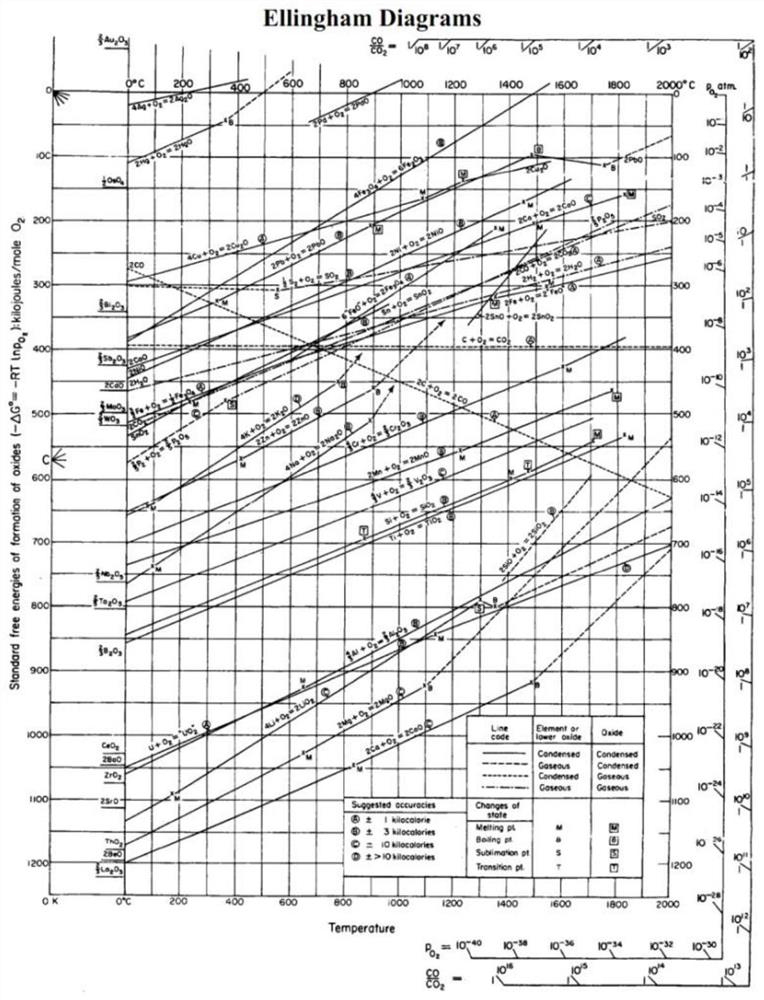

InactiveCN101362283AAchieving successful mass productionGuaranteed Chemical CompositionMolten metal pouring equipmentsFoundry mouldsAdditive ingredientOxygen

The invention discloses a method for producing a rudder horn of a ship, which can ensure that the technical and quality parameters of the rudder horn can achieve or override the material codes and requirements of foreign classification societies. The invention adopts the technical proposal so that a set of smelting technique is developed: ingredient selection, the control of smelting temperature, oxygen blast, and the control of argon blowing parameter, etc., are carried out so as to solve the problem of the control of the content of chemical elements, especially, ensure the content of aluminum and nitrogen to meet the requirement; the optimum casting technique is prepared: the design of the casting head and the pouring head and the selection of modeling material are carried out so as to avoid crack and shrinkage porosity, and meet the requirements on nondestructive examination of the cast and the size precision; a specific heat treatment technique is prepared: the selection of temperature and time for temperature rise, heat preservation and temperature decrease, especially the application of a temperature decrease method, so as to solve the problem of insufficient mechanical property of the cast, especially the low temperature impact property.

Owner:江苏皓一机械制造有限公司

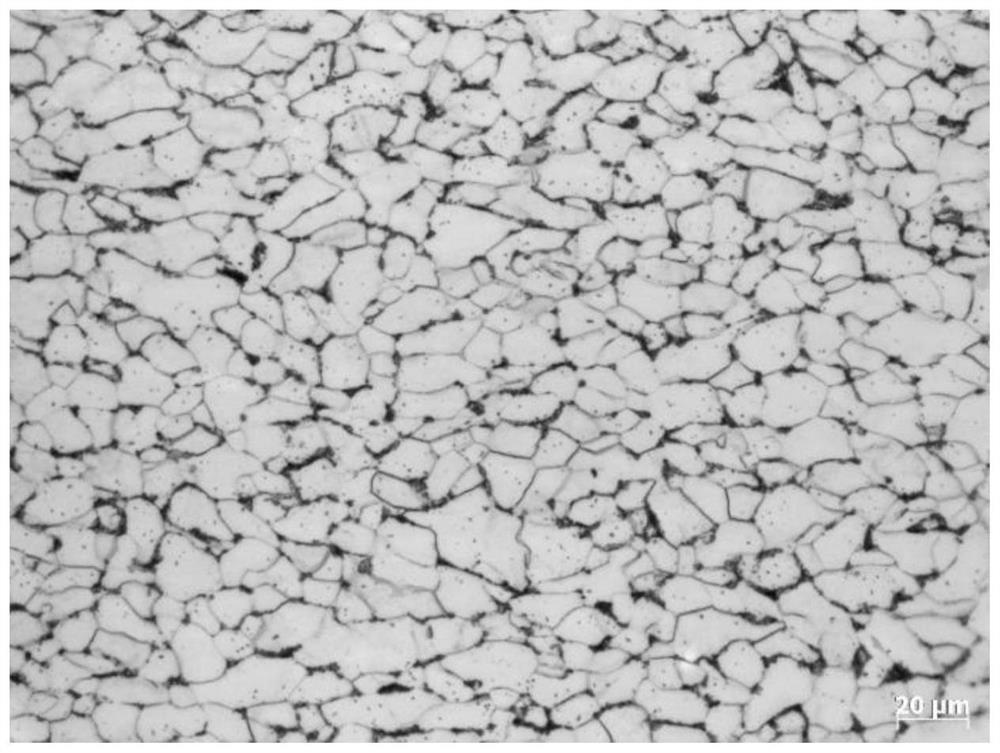

Manufacturing method for tube blank made of high-silicon titanium-contained austenitic stainless steel

ActiveCN108866271AGuaranteed Chemical CompositionAssurance Control RequirementsIncreasing energy efficiencyFurnace typesVacuum arc remeltingAustenite

The invention belongs to the technical field of metallurgical materials, and relates to a manufacturing method for a tube blank made of high-silicon titanium-contained austenitic stainless steel. Themanufacturing method sequentially comprises the following steps that (1) ingredients of the high-silicon titanium-contained austenitic stainless steel are smelted in a vacuum induction furnace; (2) vacuum arc remelting is carried out; and (3) homogenization and forging are carried out, specifically, forging in a rapid forging machine and forging in a precision forging machine are carried out in sequence, wherein in the forging process of the rapid forging machine, the tong handle forging process, the pre-deformation process, the homogenization heat treatment process, the rapid forging processand the cutting process are carried out in sequence, and in the forging sequence of the precision forging machine, the heat preservation process and the precision forging process are carried out in sequence. The manufacturing method for the tube blank made of the high-silicon titanium-contained austenitic stainless steel has the advantage that the produced tube blank can meet the uniformity control requirements of a fast reactor core cladding material on the content of harmful elements O and S, the inclusion level and the tissues in the tube blank.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

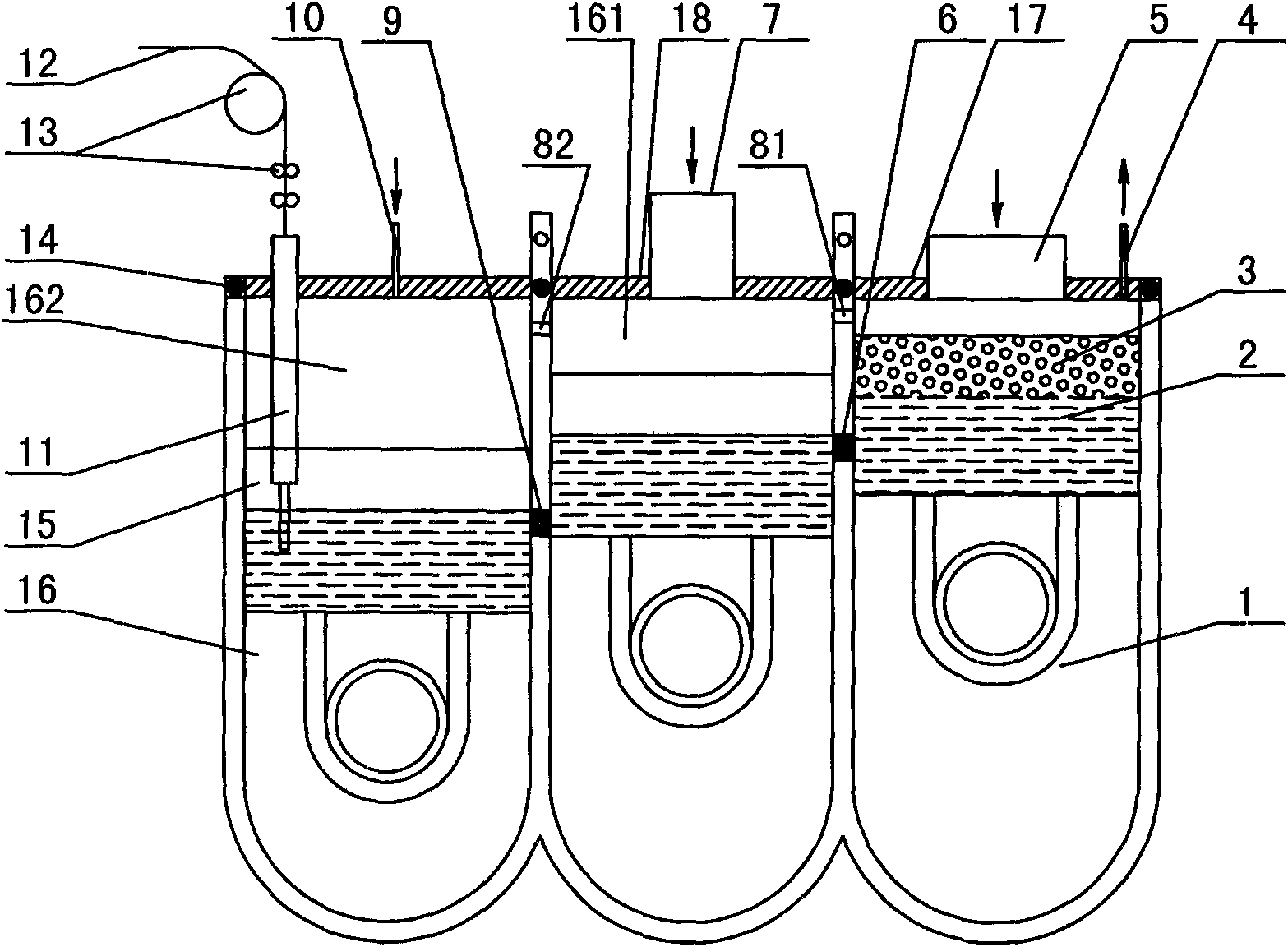

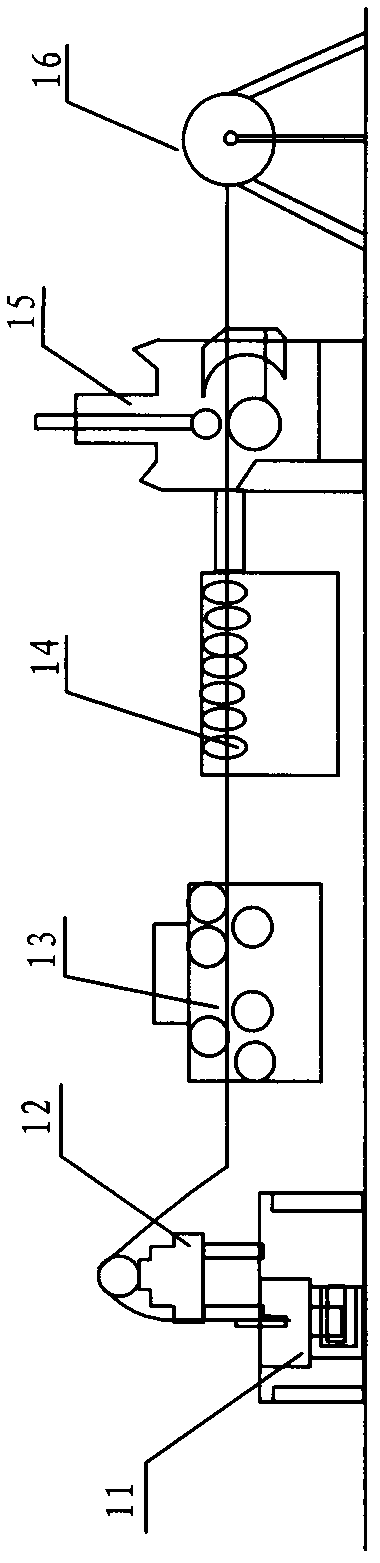

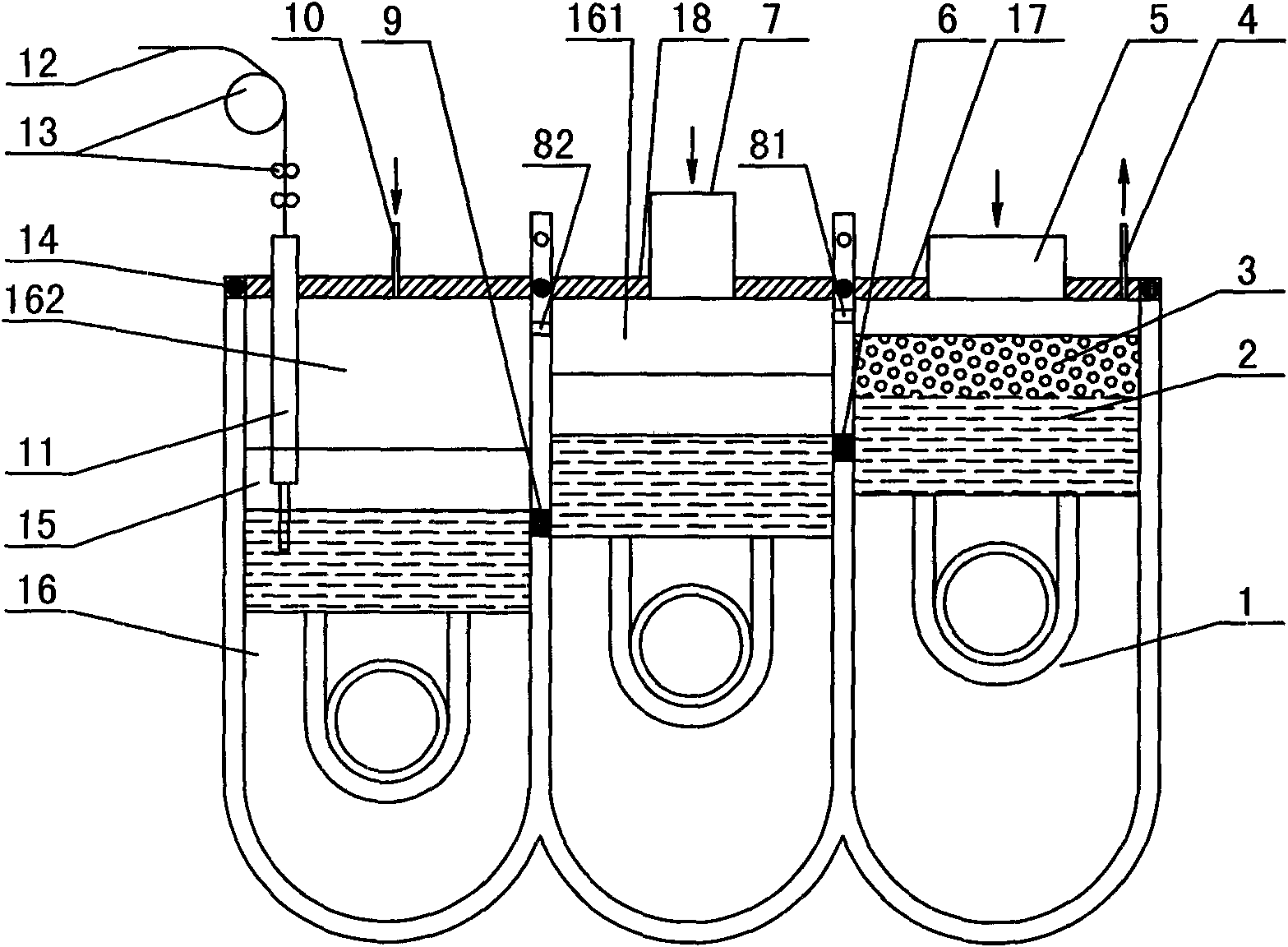

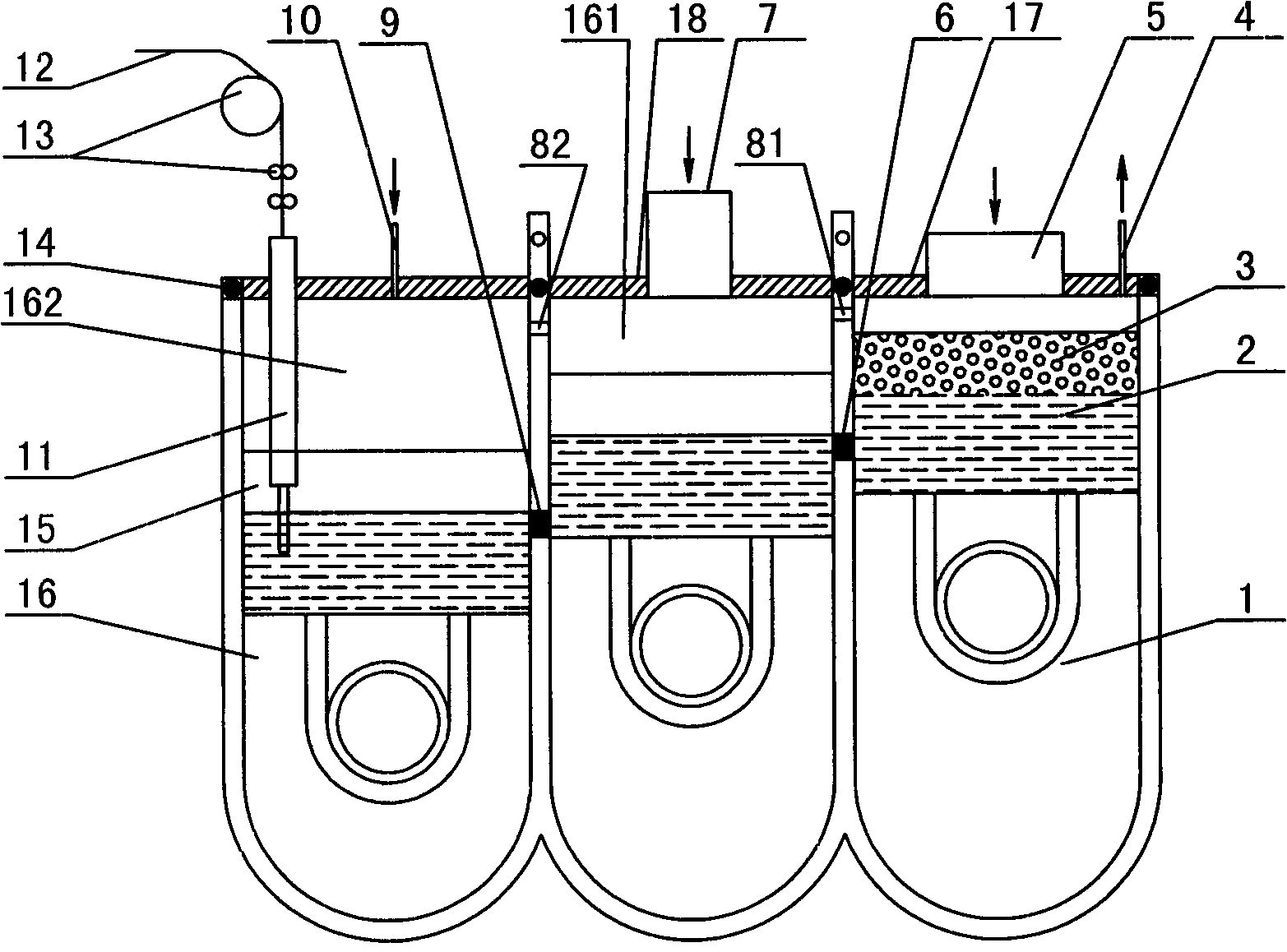

Non-vacuum continuous production equipment and process of copper chromium zirconium alloy

InactiveCN103302263AReduce production difficultyRealize continuous productionZirconium alloyChromium

The invention discloses a non-vacuum continuous production process and production equipment of copper chromium zirconium alloy. The production process comprises the following steps: adding standard cathode copper and copper chromium intermediate alloy into a smelting furnace, closing the smelting furnace and filling the smelting furnace with protective gas for smelting; after the smelting is finished, opening an undercurrent passage valve and injecting molten-state alloy liquid into a heat preserving furnace through a standing cavity; when the temperature of the heat preserving furnace reaches 1,180-1,200 DEG C, starting upward continuous casting equipment to perform casting; feeding a cast copper chromium zirconium alloy rod into a straightener to straighten and then performing extrusion molding through a continuous extruder. According to the non-vacuum continuous production process of the copper chromium zirconium alloy, the production difficulty can be reduced and the aim of continuous production is achieved.

Owner:JIANGSU KINDLE COPPER

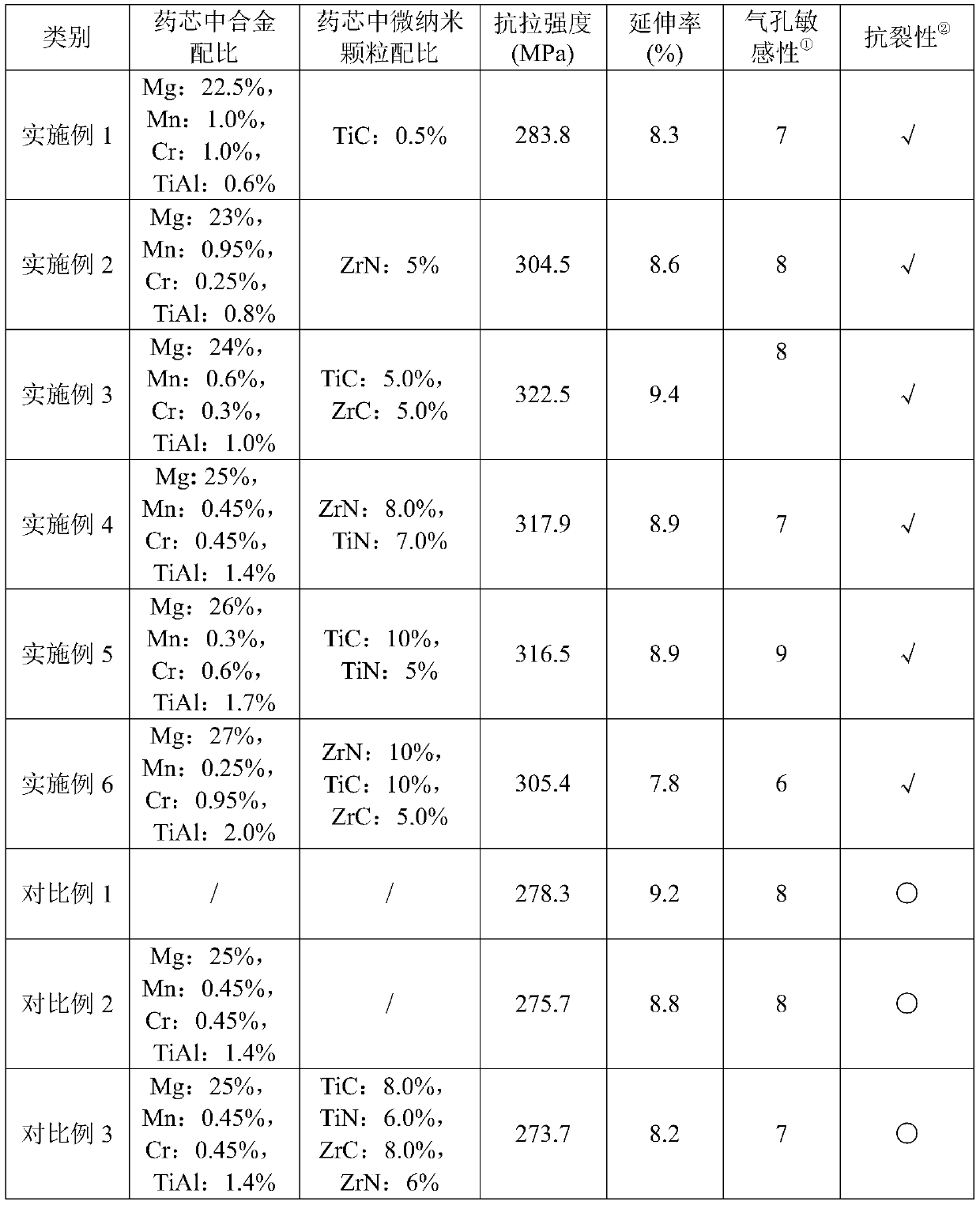

Micro-nano particle reinforced aluminum alloy flux-cored filler wire used for TIG welding of 7075 aluminum alloy

InactiveCN111015012AThe solution cannot change the alloy compositionSolve the problem of adding particle reinforcement phaseWelding/cutting media/materialsSoldering mediaMicro nanoAl powder

The invention discloses a micro-nano particle reinforced aluminum alloy flux-cored filler wire used for TIG welding of 7075 aluminum alloy, and belongs to the technical field of aluminum alloy flux-cored welding wire. Pure aluminum tape is used as an outer skin, powder is prepared from the following components in percentage by mass: 22.5-27.5% of metal magnesium powder, 0.25%-1% of metal manganesepowder, 0.25-1% of metal chrome powder, 0.6-2% of titanium aluminum alloy powder, 0.5-25% of composite micro-nano ceramic powder, and the balance of pure aluminum powder; the filling rate of a welding wire is 10% to 35 %; and the ratio of titanium to aluminum in titanium aluminum alloy is 1:1. According to the micro-nano particle reinforced aluminum alloy flux-cored filler wire, the tensile strength of a welded joint is improved, at the same time crack resistance is improved, and porosity sensitivity is reduced. The dosage of specific compositions of micro-nano ceramic particles has a certaineffect on welding performance, while the total dosage of the micro- nano ceramic particles has a greater impact on the performance of the welded joint.

Owner:BEIJING UNIV OF TECH

Manufacturing method of high-silicon titanium-containing outer sleeve made of austenitic stainless steel

The invention belongs to the technical field of metallurgical materials, and relates to a manufacturing method of a high-silicon titanium-containing outer sleeve made of austenitic stainless steel. The manufacturing methods sequentially comprises the following steps of (1) smelting, (2) forging, (3) hot extrusion, (4) intermediate cold rolling and intermediate heat treatment, (5) final heat treatment, and (6) final cold rolling. By utilizing the manufacturing method of the high-silicon titanium-containing outer sleeve made of the austenitic stainless steel, the manufactured outer sleeve can meet strict requirements of the aspects such as alloy component, structure uniformity, dimensional precision and surface quality.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

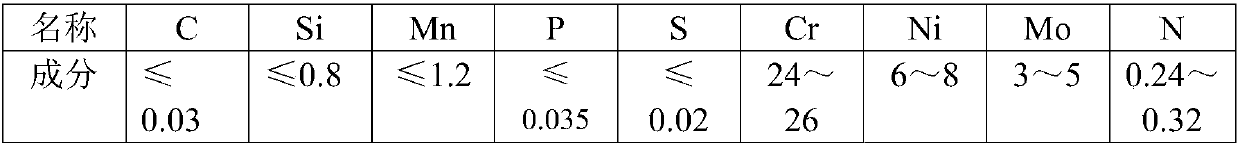

A production method of a 2507 stainless steel pump casting

ActiveCN107745092AAvoid Casting DefectsReduce repair rateFoundry mouldsFoundry coresSlagCasting defect

The invention relates to a production method of a 2507 stainless steel pump casting. The method includes (1) die designing and manufacturing, (2) moulding and core manufacturing, (3) paint brushing, (4) sand mould and sand core drying, (5) mould assembling, (6) smelting, (7) pouring, (8) mould disassembling and sand removing, (9) gate and riser removing, (10) repair welding, and (11) polishing andshot blasting. Through a reasonable casting process design, casting defects including air holes, oxide slag inclusion and cracks are prevented, the repair rate and the rejection rate of casting are reduced, product quality is ensured, subsequent repair welding is greatly reduced, and the production cost of the casting is reduced.

Owner:CHENGDU YONGYI PUMPS

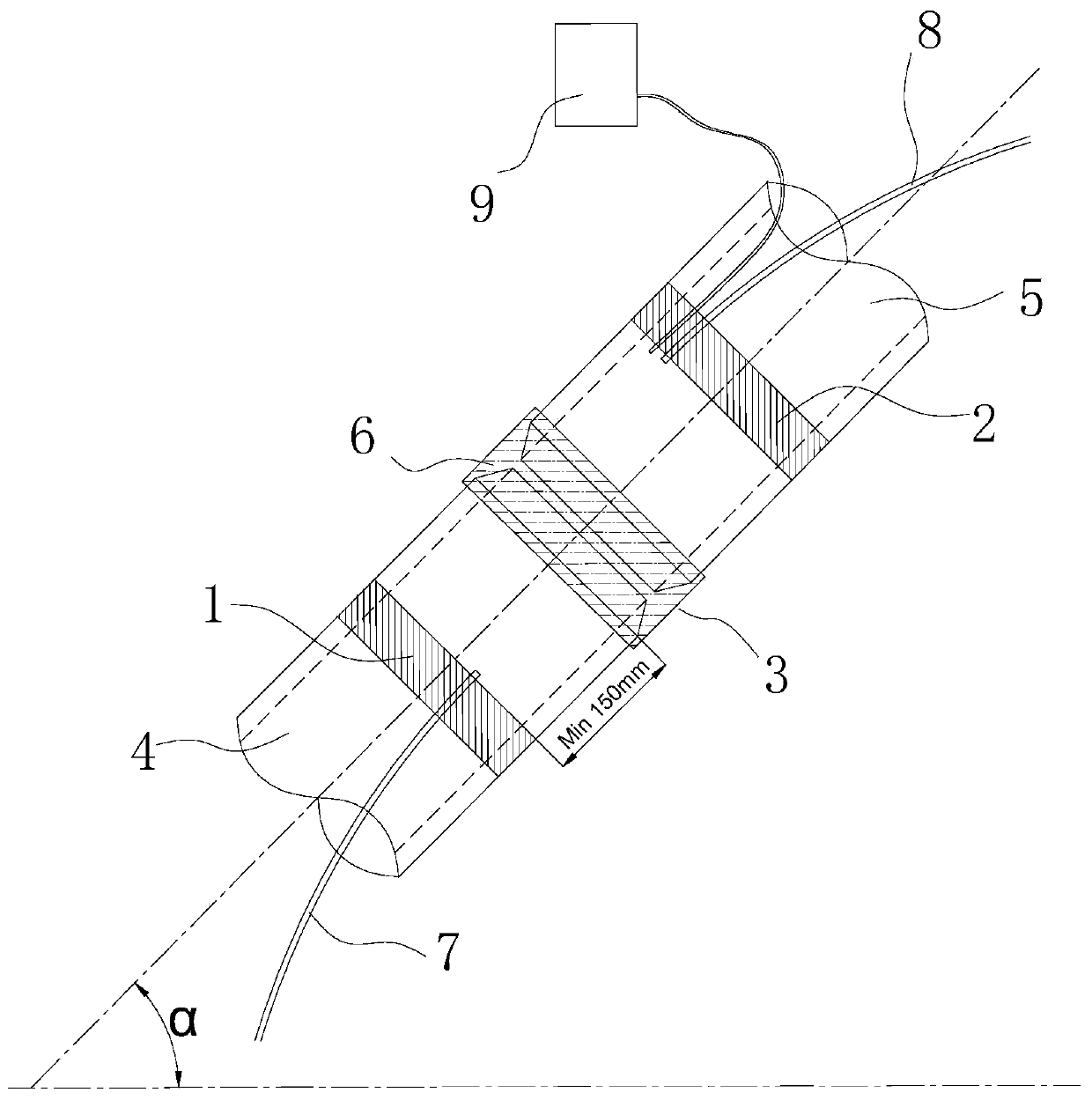

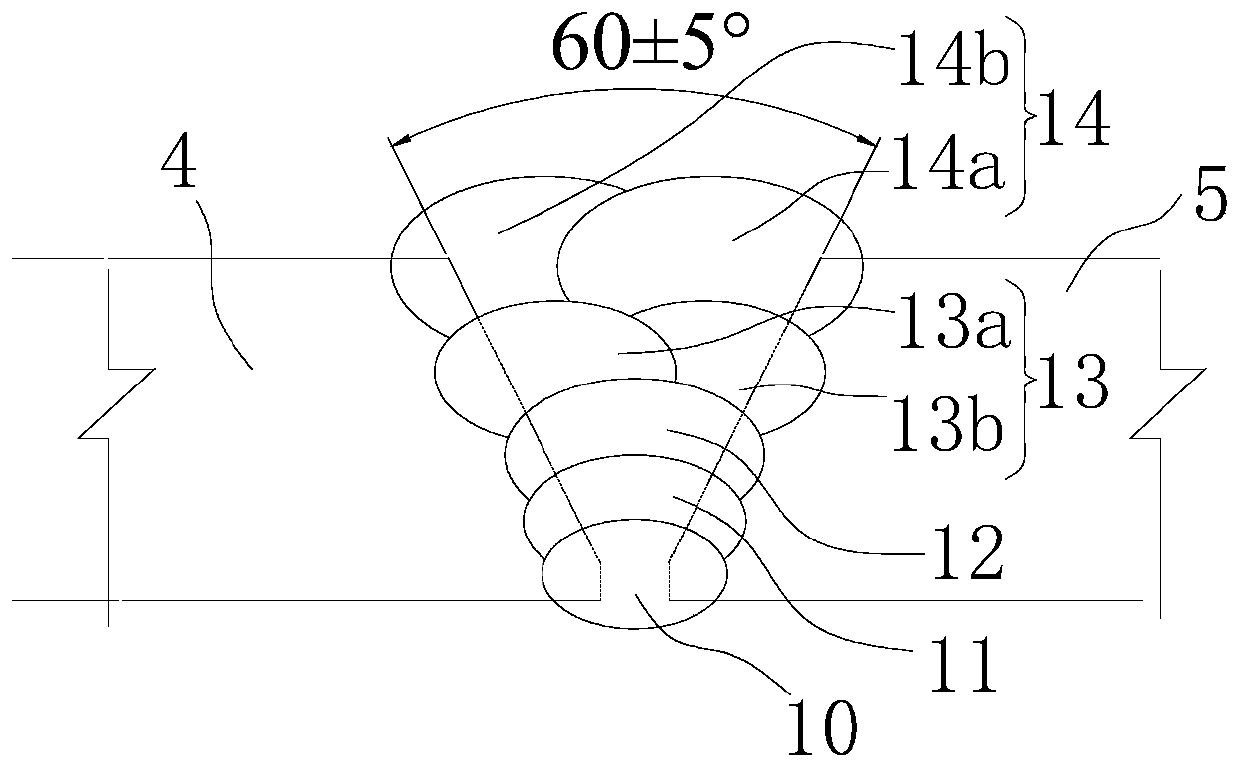

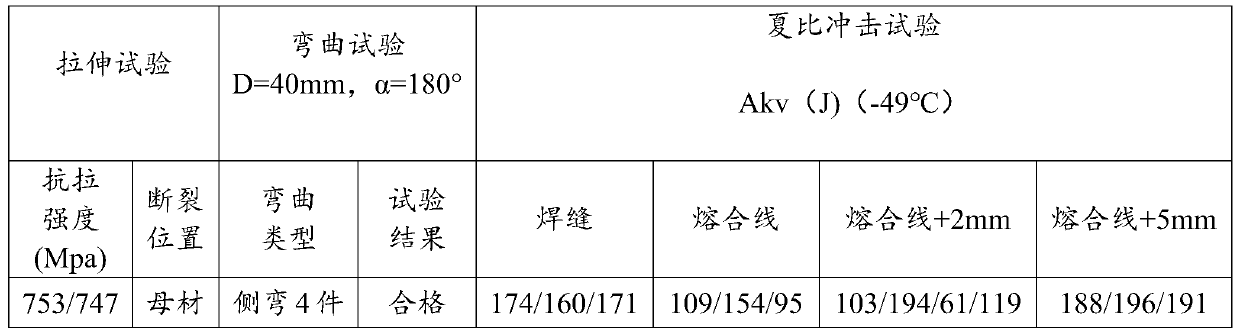

TIP TIG welding process of duplex stainless steel

InactiveCN110497068AQuality improvementImprove efficiencyArc welding apparatusWelding/soldering/cutting articlesFriction weldingThermal deformation

The invention provides a TIP TIG welding process of the duplex stainless steel. The TIP TIG welding process comprises the following steps of 1, preparation of welding material and formulation of welding process, 2, welding groove machining, 3, pre-welding preparation. 4, welding of duplex stainless steel, and 5, weld joint detection. According to the TIP TIG welding process , by means of the semi-automatic TIP TIG welding process, the problems that the existing duplex stainless steel manual GTAW welding speed is low, the welding efficiency is low, and the submerged-arc welding SAW welding position is limited are solved, the welding quality can be guaranteed, the welding efficiency can be improved, and semi-automatic full-position welding in the duplex stainless steel high-quality, high-efficiency, full-working-condition and full-thickness range is realized; the welding quality is ensured, the welding current is reduced, the welding heat input is reduced, the heat affected zone is reduced, the welding thermal deformation is low, the surface forming of the weld joint is good, and the operation controllability is high; and the welding efficiency is improved, and the full-position welding of the duplex stainless steel can be realized in a workshop or a field construction site.

Owner:ZHONGHAI FULU HEAVY IND CO LTD

Smelting and updraft continuous casting process of Cu-Cr-Zr alloy

The invention discloses an updraft continuous casting process of Cu-Cr-Zr alloy bar materials with high strength, high conductivity and high softening temperature, mainly adopting a smelting furnace with non-vacuum and low-furnace pressure tightness, a casting furnace and an updraft device. The invention adopts an updraft continuous casting device and technique under the condition of non-vacuum, realizes continuous production of Cu-Cr-Zr alloy bars, is not affected by the capacity of a furnace body, and can produce Cu-Cr-Zr alloy bar materials with any lengths. Obtained products are importantraw materials for producing copper alloy products with high strength and high conductivity, such as contact lines of high-speed trains, spot-welding electrodes, current contact nozzles, lead frames, motor conducting bars, and the like.

Owner:苏州中色华人铜业有限公司

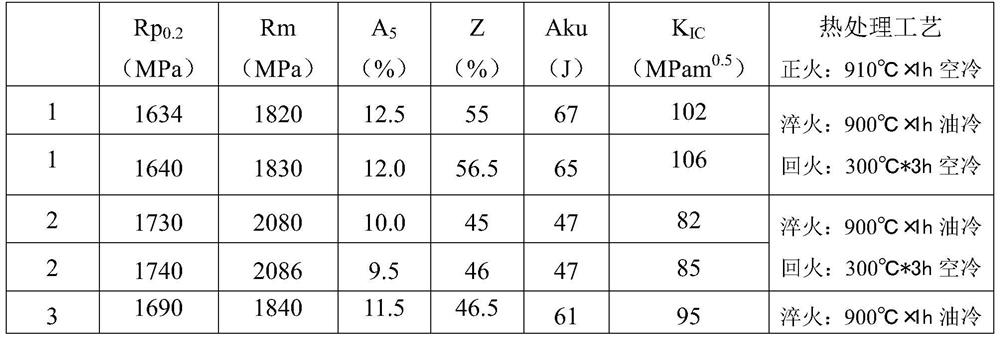

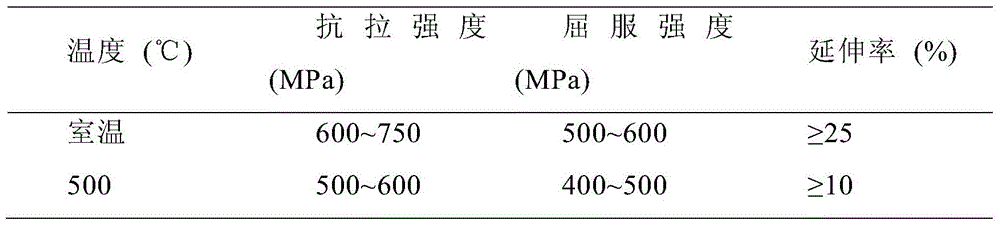

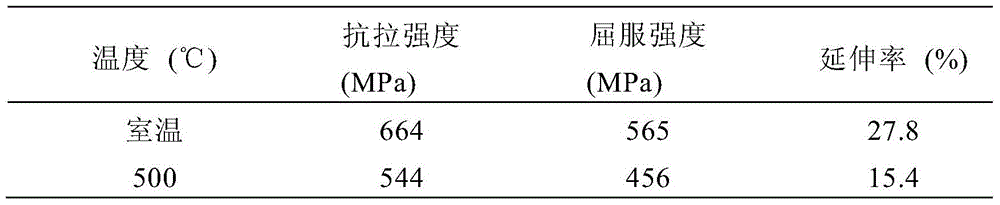

High-plasticity-toughness low-alloy ultrahigh-strength steel and preparation method

The invention provides high-plasticity-toughness low-alloy ultrahigh-strength steel and a preparation method, and relates to the technical field of engineering materials. The high-plasticity-toughnesslow-alloy ultrahigh-strength steel comprises the following chemical components in percentage by mass: 0.30-0.43% of C, 0.50-1.60% of Mn, 0.80-2.00% of Si, 0.80-1.50% of Cr, 2.50-3.50% of Ni, 0.50-1.50% of W, 0.20-0.80% of Mo, 0.05-0.20% of V, 0.01-0.20% of Nb, not greater than 0.005% of S, not greater than 0.010% of P, not greater than 0.050% of Al, and the balance Fe. The mechanical performanceof the steel material reaches the design index; the steel material can replace G50 and DT300 steel materials in a certain field; and the steel material is higher in hardenability, and can satisfy thelarge-specification requirements on the steel material.

Owner:上海佩琛金属材料有限公司

Lost-foam casting process

InactiveCN101554646AChange the organizational structureImprove mechanical propertiesFoundry mouldsFoundry coresChemical compositionMechanical property

The invention relates to a lost-foam casting process which overcomes the technical bias existing in the prior art of mould shell collapsing due to the uncovered plastic cloth after finishing casting and is successfully developed. The process comprises the following steps: after the casing step of the traditional lost-foam casting process is finished, the plastic cloth is immediately uncovered, the vacuum is continued to be extracted for a plurality of minutes under the negative pressure during the casting process until the surface of the casting part is hardened and shaped, and then the casting part is taken out form the box after sufficient cooling. The invention has the advantages that the process changes the organizational structure of the casting part, enables the crystal grain to become fine, enhances the mechanical property of the casting part, and enables the chemical composition to be more qualified as well as the shelling falling of the coating layer of the casting part to be more thorough.

Owner:刘则斌

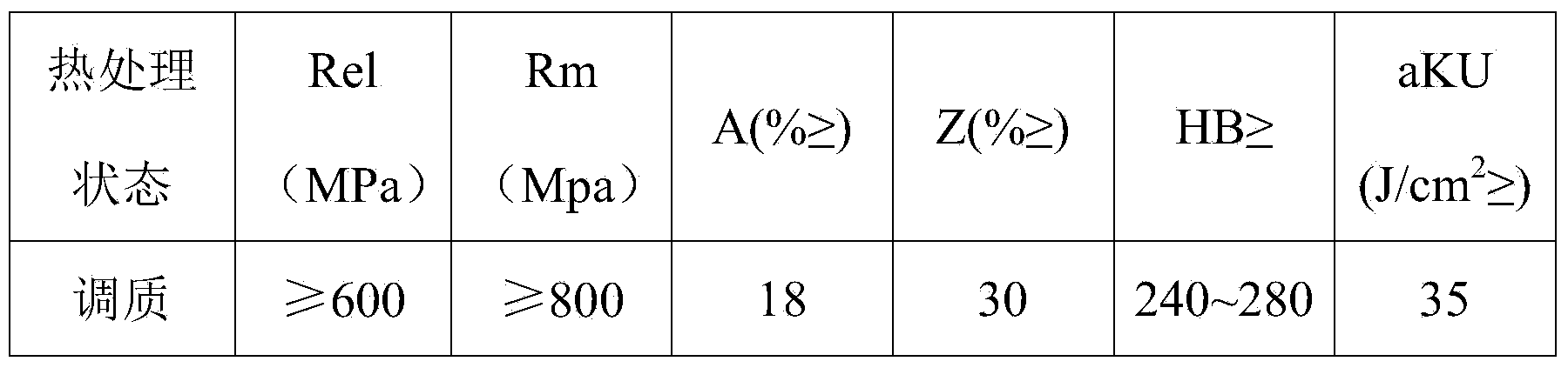

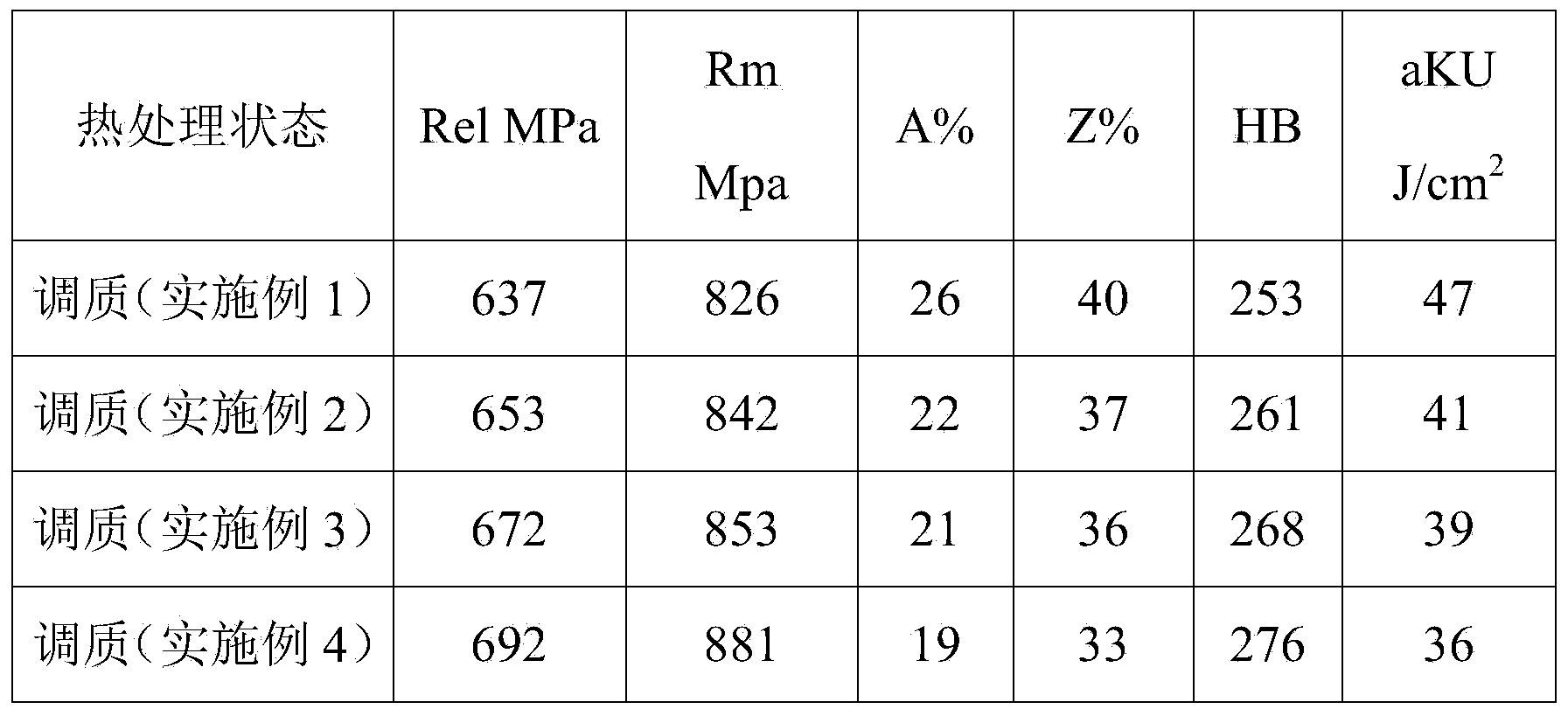

ZG25MnSY6 casting material and method for preparing casting

ActiveCN103667957AGuaranteed Chemical CompositionGood metallographic organizationElectric arc furnaceUltimate tensile strength

The invention discloses a ZG25MnSY6 casting material. The ZG25MnSY6 casting material consists of the following components by mass percent: 0.15-0.2% of C, 0.3-0.45% of Si, 0.8-1.1% of Mn, less than or equal to 0.01% of S, less than or equal to 0.015% of P, less than or equal to 0.06% of Al, 0.6-0.9% of Cr, 1-1.2% of Ni, 0.3-0.5% of Mo, 0.1-0.15% of V and the balance of Fe, 100% in total. The invention also discloses a method for preparing a casting by using the ZG25MnSY6 material. According to the casting material, a certain alloying element is reduced or increased, smelting is carried out in an electric-arc furnace and refining furnace, an alterant is added in the later refining stage and heat treatment is carried out, so that the metallographic structure of the casting is good, the mechanical property of the casting is greatly improved, the strength and toughness are enhanced, and the service time of the casting is prolonged.

Owner:MCC SFRE HEAVY IND EQUIP

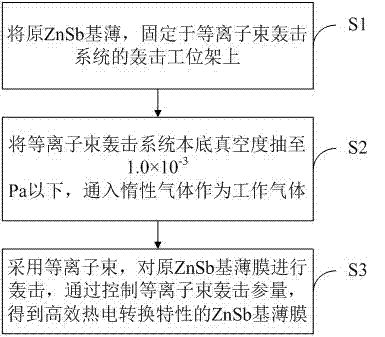

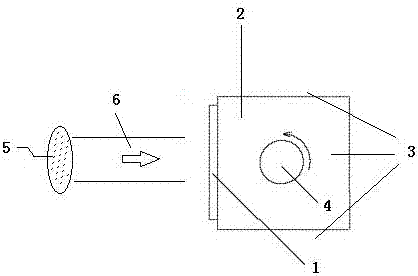

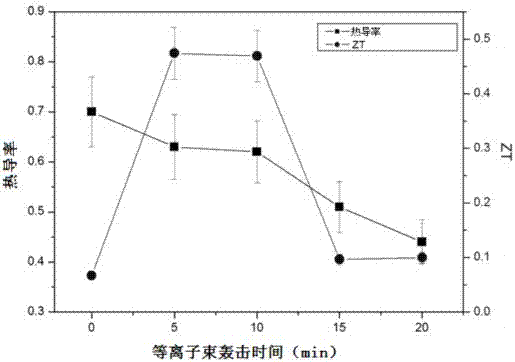

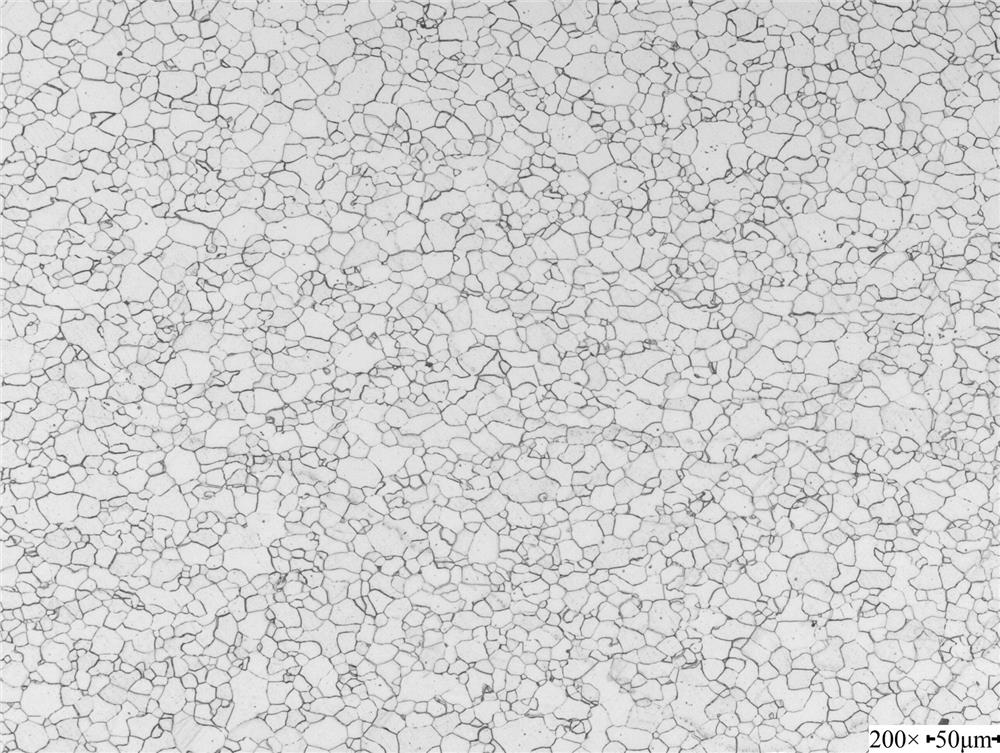

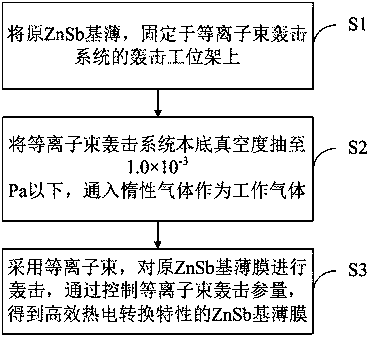

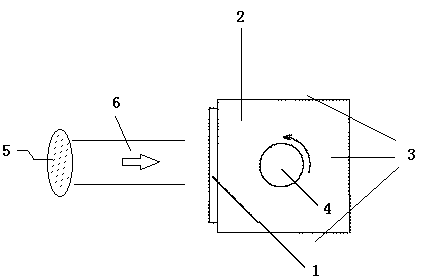

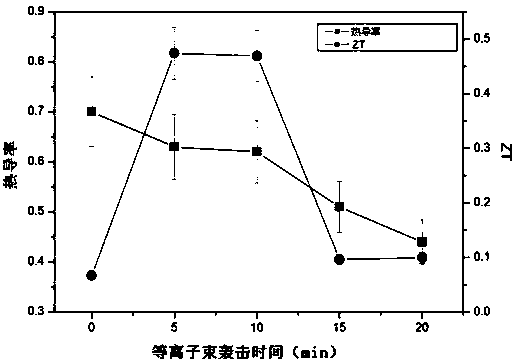

Efficient thermoelectric conversion characteristic ZnSb based thin film and preparing method thereof

ActiveCN106893977AGuaranteed Chemical CompositionImprove thermoelectric propertiesVacuum evaporation coatingSputtering coatingChemical compositionOptoelectronics

The invention discloses an efficient thermoelectric conversion characteristic ZnSb based thin film and a preparing method thereof. The method includes the following steps that plasma beams are adopted, bombardment is carried out on an original ZnSb based thin film, and the efficient thermoelectric conversion characteristic ZnSb based thin film is obtained by controlling the plasma beam bombardment parameter. According to the efficient thermoelectric conversion characteristic ZnSb based thin film and the preparing method, the plasma beams are adopted for bombardment of the thin film, a traditional heat treatment process is replaced, and chemical components of thin film key factors can be guaranteed; and meanwhile, microstructures of the ZnSb based thin film can be controlled; and through effective thin film structural optimization, thermoelectric characteristics of the ZnSb based thin film are improved accordingly.

Owner:SHENZHEN UNIV

Method for eliminating rapid tensile strain marks of cold-rolled sheet for stamping

ActiveCN113667895AMeet the requirements of deep processingGuaranteed Chemical CompositionManufacturing convertersSteelmakingTensile strain

The invention provides a method for eliminating rapid tensile strain marks of a cold-rolled sheet for stamping, which comprises the following steps of: steelmaking: smelting into molten steel by adopting a 150t oxygen top-bottom combined blown converter; RH refining, wherein the RH vacuum treatment time is not shorter than 25 min; continuous casting is conducted, and whole-course protection casting is adopted; the thickness of a continuous casting slab is 210 mm or 230 mm, and the pulling speed of a slab is 0.9-1.1 m / min; hot continuous rolling is carried out, the heating temperature of the slab is 1200-1230 DEG C, the finish rolling temperature is 890-910 DEG C, and the coiling temperature is 680-700 DEG C; the cold rolling production process comprises the following steps: continuous rolling is conducted by 5 racks, wherein the cold rolling reduction rate is 80-87%; a continuous annealing production process is carried out: the temperature of a heating section is 820 + / -5 DEG C, the temperature of a soaking section is 820 + / -5 DEG C, the temperature of a slow cooling section is 660 + / -10 DEG C, the temperature of a rapid cooling section is 420 + / -10 DEG C, the temperature of an overaging section is 400 + / -10 DEG C, the time of the overaging section is not less than 200 s, and the flattening elongation is 0.8-1.6%; and the metallographic structure of a cold-rolled sheet DC03 for stamping is ferrite and cementite. By means of the method, the cold-rolled sheet DC03 for stamping can be produced from ultra-low carbon steel components, and the method is simple in operation process, stable in product performance and good in stamping machining performance.

Owner:安钢集团冷轧有限责任公司 +1

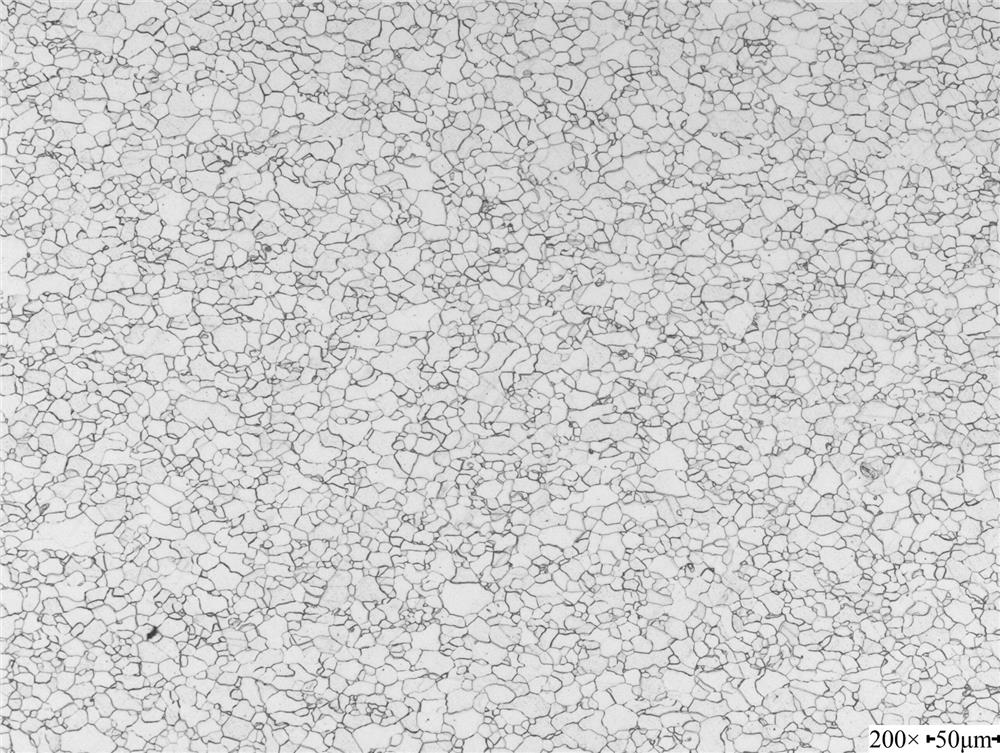

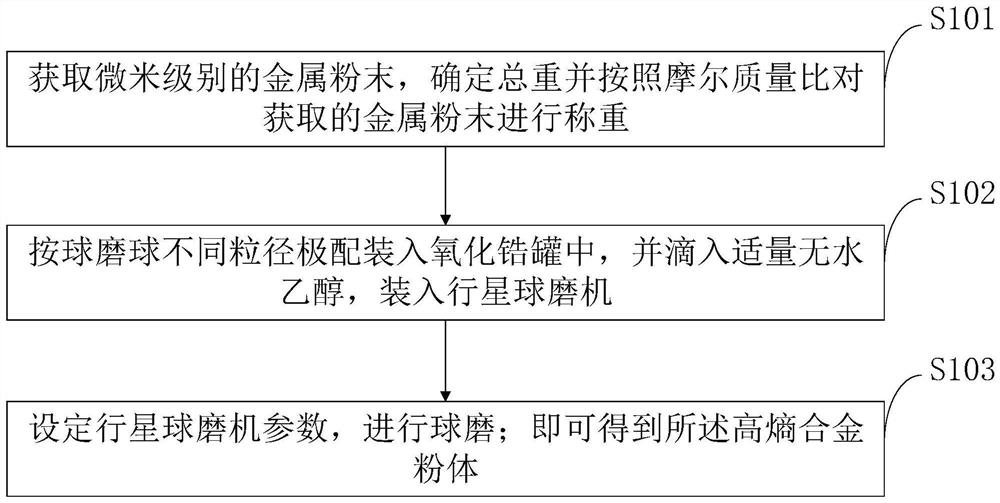

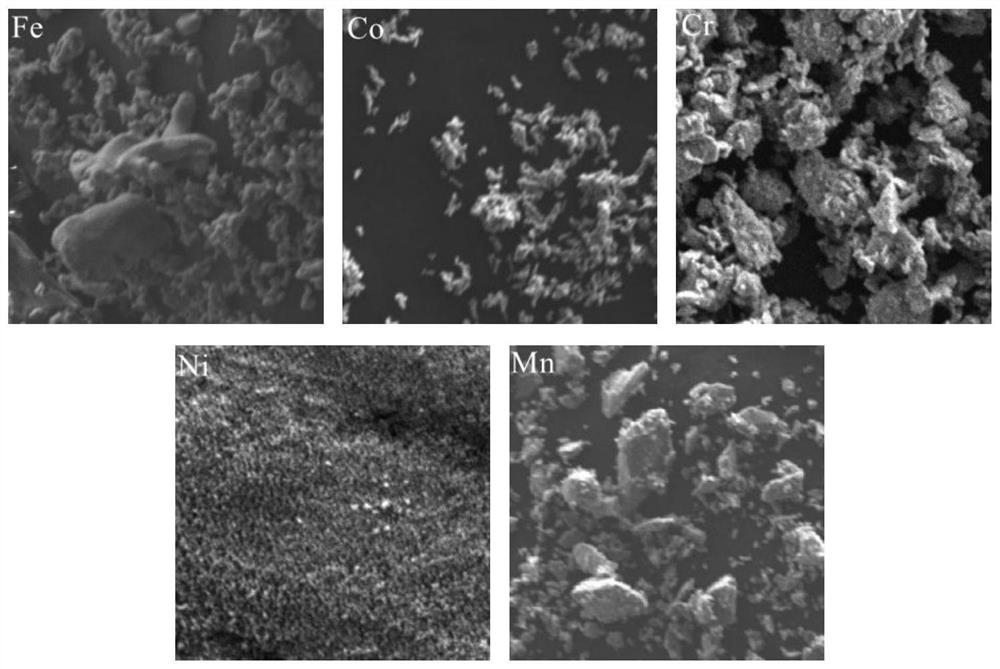

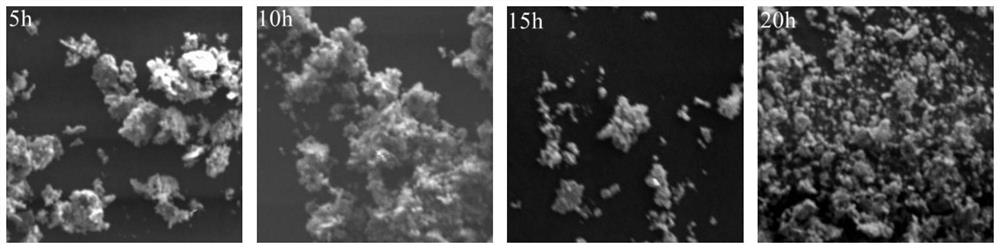

Method for preparing high-entropy alloy powder through mechanical alloying

The invention belongs to the technical field of alloy powder preparation, and discloses a method for preparing high-entropy alloy powder through mechanical alloying, and the method for preparing the high-entropy alloy powder through mechanical alloying comprises the steps that micron-level metal powder is obtained; the total weight is determined, and the obtained micron-level metal powder is weighed through a medicine spoon, oil paper and an electronic balance according to the molar mass ratio; putting the ball-milling balls into a zirconium oxide tank according to a ratio of 1: 2: 1 of different particle sizes, dropwise adding a proper amount of absolute ethyl alcohol, and putting into a planetary ball mill; setting parameters of a planetary ball mill, and carrying out ball milling for 2400 minutes at a time interval of 300 minutes; and the high-entropy alloy powder can be obtained. The method for preparing the high-entropy alloy powder material through mechanical alloying is not limited by the melting point of the alloy material, and adverse factors such as composition segregation, shrinkage porosity and shrinkage cavity in the smelting process can be avoided to a great extent.

Owner:JINCHUAN GROUP LIMITED +1

Melting process of high-medium carbon steel free of normalizing and annealing

InactiveCN108286009ANormalizing omittedIncrease productivityProcess efficiency improvementElectric furnaceMaterials preparationChemical composition

The invention discloses a melting process of high-medium carbon steel free of normalizing and annealing. The melting process comprises the following steps of material preparation, workpiece inspection, charging, melting, deoxidizing, and treatment and pouring. The melting process is simple in process, the normalizing and annealing processes in the high-medium carbon steel treatment process are omitted, the production efficiency is improved, and the production cost is reduced; and meanwhile, the process of the high-medium carbon steel by adding silicon steel sheets is guaranteed, the cutting and processing capability of a product is improved, and various mechanical properties of steel type are guaranteed, and the complexity of the production process is greatly reduced.

Owner:ANHUI HUSN KEWAN SPECIAL CASTING

Manufacturing method of high silicon titaniferous austenitic stainless steel cladding pipe

InactiveCN109013744AMeet the alloy compositionSatisfy tissue uniformityAustenitic stainless steelTitanium

The invention belongs to the technical field of metallurgical materials, and relates to a manufacturing method of a high silicon titaniferous austenitic stainless steel cladding pipe. The manufacturing method successively includes the following steps of (1), smelting, (2) forging, (3) hot extrusion, (4) intermediate cold rolling and intermediate heat treatment, (5) final heat treatment, and (6) final cold rolling. According to the manufacturing method of the high silicon titaniferous austenitic stainless steel cladding pipe, the manufactured cladding pipe can meet strict requirements of alloycomposition, microstructure uniformity, dimensional accuracy and surface quality and other aspects.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Eucommia ulmoides health preserving tobacco and preparation method thereof

InactiveCN110250563AGreat tasteNo side effectsTobacco treatmentCigar manufactureChemical compositionNatural product

The invention relates to the field of eucommia ulmoides health care tobaccos, in particular to a eucommia ulmoides health preserving tobacco and a preparation method thereof. Wild plant essence, licorice extracts, honeysuckle extracts and ginseng essential oil are prepared into a liquid material to be added into tobacco shreds of eucommia ulmoides leaves, and then rolled into cigarettes. In the preparation process, while the eucommia ulmoides leaves are dried by hot air, chemical components in the eucommia ulmoides leaves are well kept in the leaves, the eucommia ulmoides leaves turn yellow integrallyand are dried to reduce the water content and the loss of nutrients, and storage and transportation are easy; by separating lamina and veins, the lamina is cut into shreds to enable the tobacco shreds to be an optimal state, and the water content of the lamina is controlled to ensure the composition of natural products, meanwhile softness and flammability are enhanced, and the taste in the use process is enhanced; and by cold air drying, the water content of the tobacco shreds is further reduced while the mixture of the liquid material and the tobacco shreds is ensured, and while flavoring is carried out, the quality of tobacco is ensured.

Owner:伟润诚生物科技(北京)集团有限公司

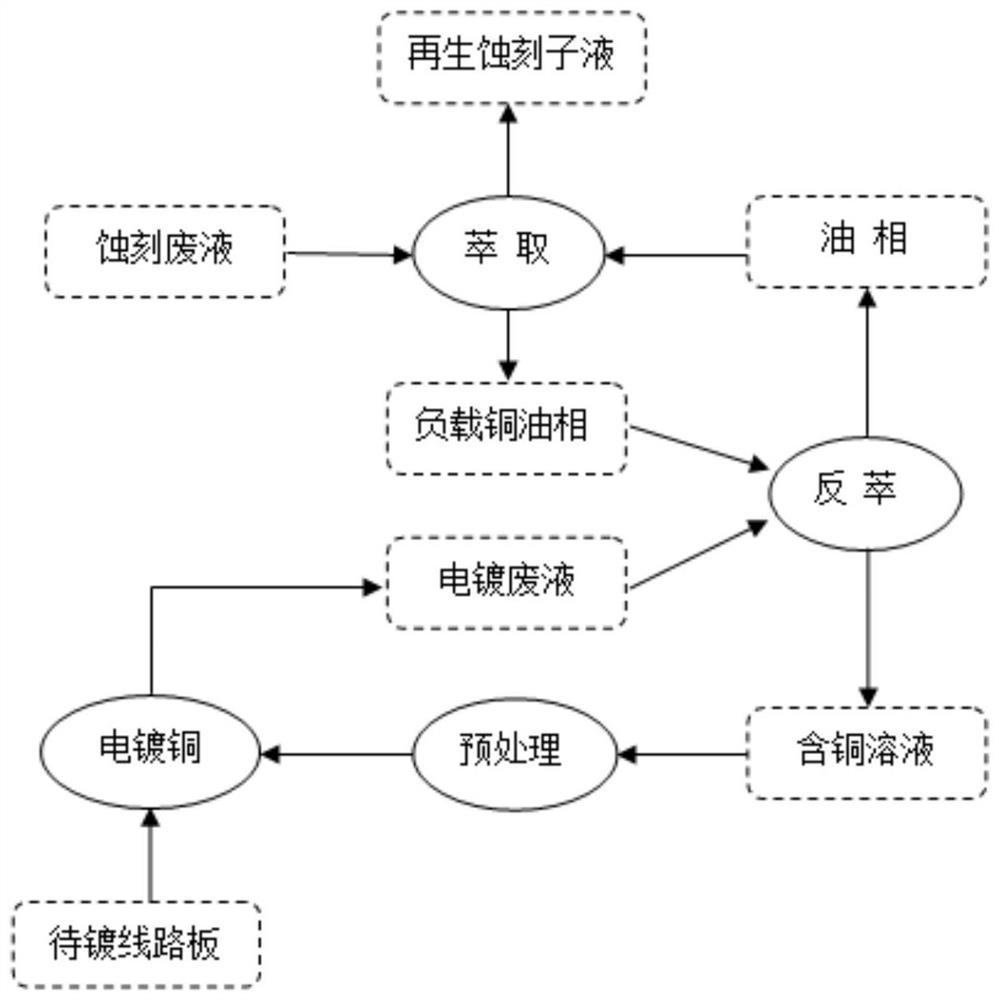

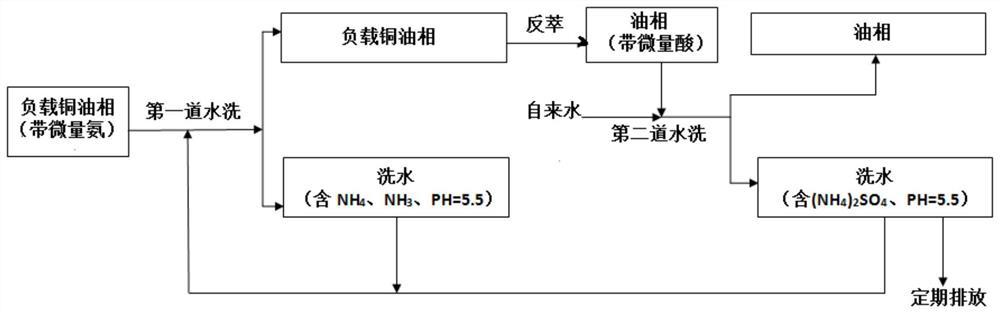

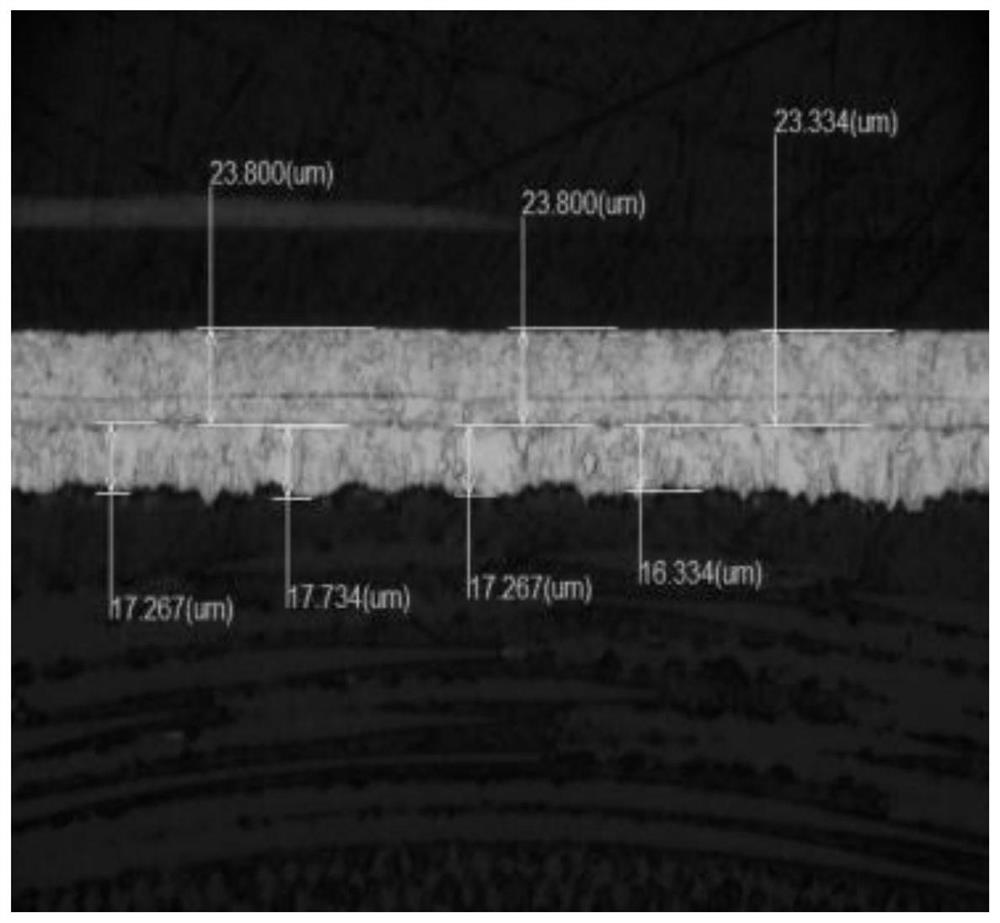

Recycling method of circuit board etching waste liquid

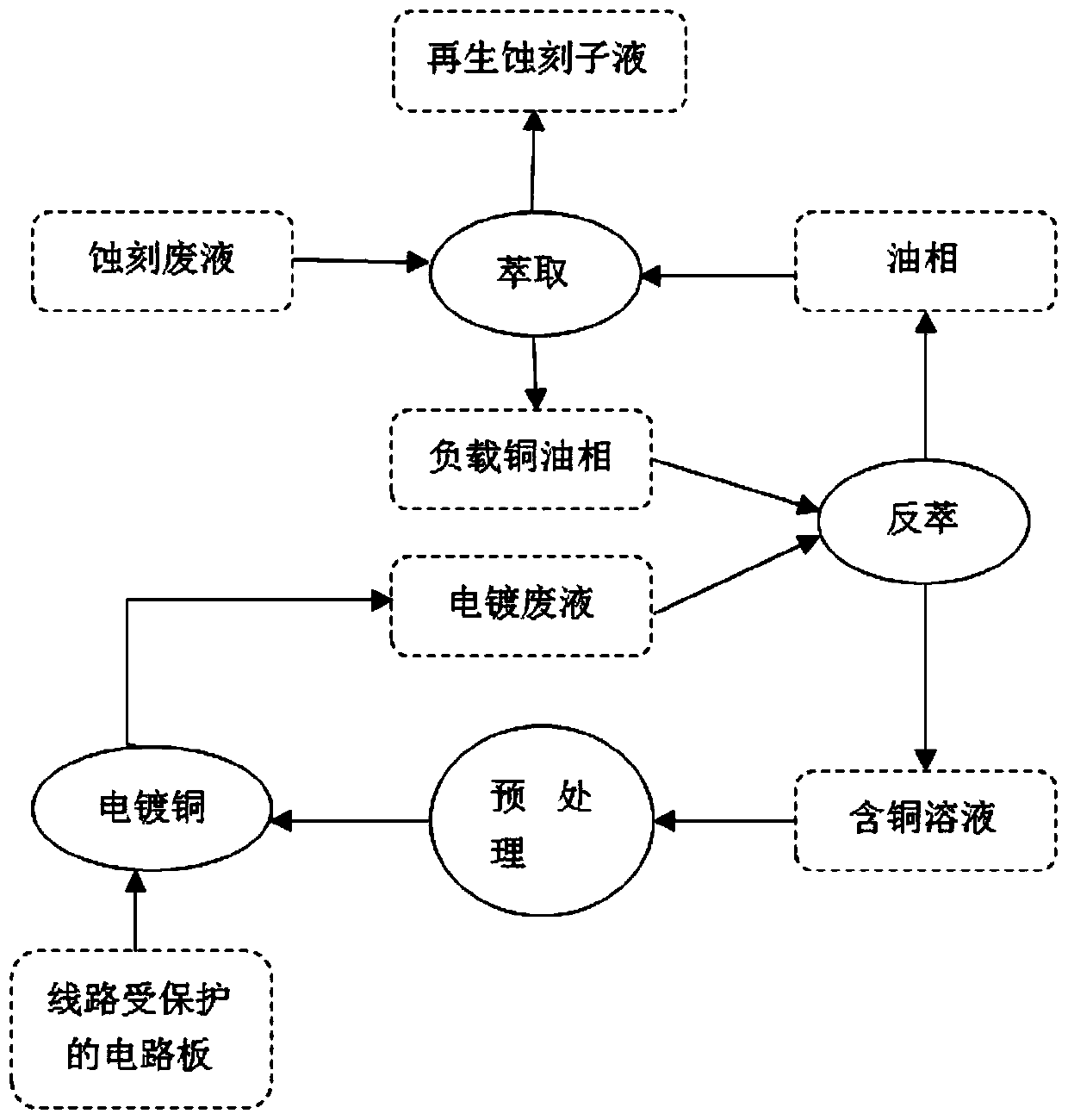

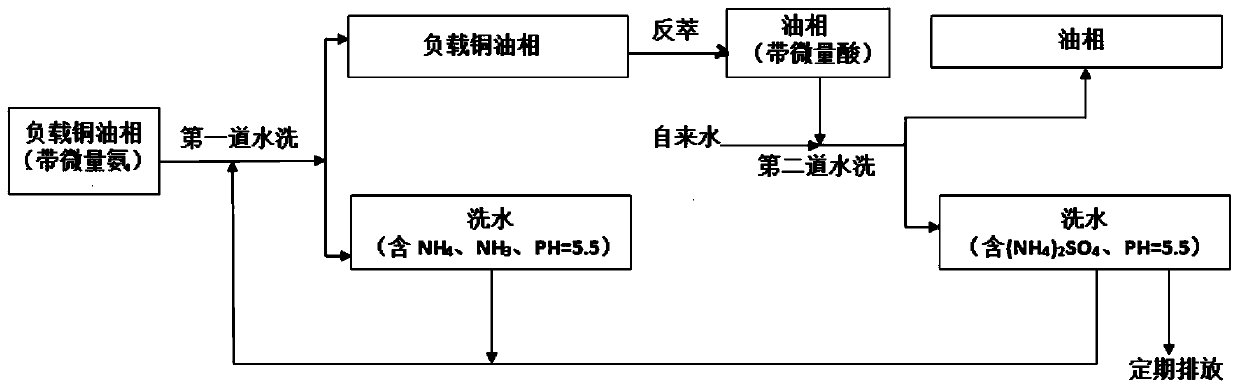

ActiveCN110359051AReduce dosageReduce pollutionPhotography auxillary processesProcess efficiency improvementLiquid wasteCopper plating

The invention relates to a recycling method of circuit board etching waste liquid. The method comprises the following steps that S1, an extraction agent is added into the etching waste liquid, and after layering, a water phase and a loaded-copper oil phase are obtained; secondly, electroplating waste liquid is added into the loaded-copper oil phase for reverse extraction, and after layering, a solution containing copper and an oil phase are obtained; thirdly, the copper-contained solution is pretreated, and copper plating liquid is obtained; and fourthly, the copper plating liquid is used forelectroplating a circuit board to be plated. Through the method, the etching waste liquid is not treated in a low-value manner, the copper in the etching waste liquid is sufficiently used, through a series of treatment, the plating copper liquid is obtained, when the copper plating liquid carries out electroplating on the circuit board to be plated, an infusibility anode is adopted for completelyor partly replacing a phosphor copper anode, the use amount of phosphor copper can be greatly reduced, the electroplating-level copper sulfate does not need to be added, energy is saved, pollutions are reduced, and benefits are brought to an enterprise.

Owner:龙建国

Anti-welding oxide scale steel plate and production method thereof

PendingCN113774276AGood formabilityGuaranteed Chemical CompositionMetal rolling arrangementsSteel platesSmelting process

The invention discloses an anti-welding oxide scale steel plate and a production method thereof. The anti-welding oxide scale steel plate comprises the following chemical components in percentage by weight: 0.02%-0.06% of C, less than or equal to 0.035% of Si, 0.10%-0.30% of Mn, less than or equal to 0.025% of P, less than or equal to 0.015% of S, 0.01%-0.050% of Als and the balance of Fe and inevitable impurity elements, the yield strength of the steel plate is 190-250 MPa, the tensile strength is 290-350 MPa, and the ductility is 40%-52%. According to the anti-welding oxide scale steel plate and the production method thereof, the processes of molten iron pretreatment, converter smelting, argon stirring behind the converter, continuous casting, hot continuous rolling, leveling, acid pickling and oil coating are adopted for production, and the smelting process and the light leveling process can guarantee chemical components and improve the forming performance of the plate; and finally, the good matching of the deep drawing forming performance of the compressor and the scaling and falling of the oxide scale in the welding heat affected zone is met.

Owner:HANDAN IRON & STEEL GROUP +1

A ZNSB-based film with high-efficiency thermoelectric conversion characteristics and its preparation method

ActiveCN106893977BGuaranteed Chemical CompositionImprove thermoelectric propertiesVacuum evaporation coatingSputtering coatingThin membraneIon beam

The invention discloses an efficient thermoelectric conversion characteristic ZnSb based thin film and a preparing method thereof. The method includes the following steps that plasma beams are adopted, bombardment is carried out on an original ZnSb based thin film, and the efficient thermoelectric conversion characteristic ZnSb based thin film is obtained by controlling the plasma beam bombardment parameter. According to the efficient thermoelectric conversion characteristic ZnSb based thin film and the preparing method, the plasma beams are adopted for bombardment of the thin film, a traditional heat treatment process is replaced, and chemical components of thin film key factors can be guaranteed; and meanwhile, microstructures of the ZnSb based thin film can be controlled; and through effective thin film structural optimization, thermoelectric characteristics of the ZnSb based thin film are improved accordingly.

Owner:SHENZHEN UNIV

Machining technology for precipitation hardening stainless steel pump shaft

InactiveCN109128694AGuaranteed Chemical CompositionGuaranteed mechanical propertiesFurnace typesHeat treatment furnacesSurface finishHydrogen

The invention relates to a machining technology for a precipitation hardening stainless steel pump shaft. The machining technology includes the following steps of forging, rough turning I, UT detection, heat treatment, rough turning II, high-temperature aging, semi-finish turning I, semi-finish turning II, low-temperature aging, coping and lapping, finish turning I, grinding I, lineation, milling,grinding II, flaw detection, chromium plating, dehydrogenation treatment, chromium plating removing protection, grinding III, grinding IV, finishing and finish product obtaining. By means of the machining technology for the pump shaft, the machining hardening effect is small, size deformation is small, the pump shaft machining size precision is good, the surface smoothness is high, and the finishing size inspection is controlled to be below 40 DEG C; and in addition, the machining efficiency is high, the quality is good, it can be ensured that the size precision and the shape and position dimensional tolerance deformation of the pump shaft are small, and drawing size requirements and technical requirements are met.

Owner:NINGBO ZEE AUTOMATION EQUIP

A kind of production method of 2507 stainless steel pump casting

ActiveCN107745092BAvoid Casting DefectsReduce repair rateFoundry mouldsProcess efficiency improvementSlagCasting defect

The invention relates to a production method of a 2507 stainless steel pump casting. The method includes (1) die designing and manufacturing, (2) moulding and core manufacturing, (3) paint brushing, (4) sand mould and sand core drying, (5) mould assembling, (6) smelting, (7) pouring, (8) mould disassembling and sand removing, (9) gate and riser removing, (10) repair welding, and (11) polishing andshot blasting. Through a reasonable casting process design, casting defects including air holes, oxide slag inclusion and cracks are prevented, the repair rate and the rejection rate of casting are reduced, product quality is ensured, subsequent repair welding is greatly reduced, and the production cost of the casting is reduced.

Owner:CHENGDU YONGYI PUMPS

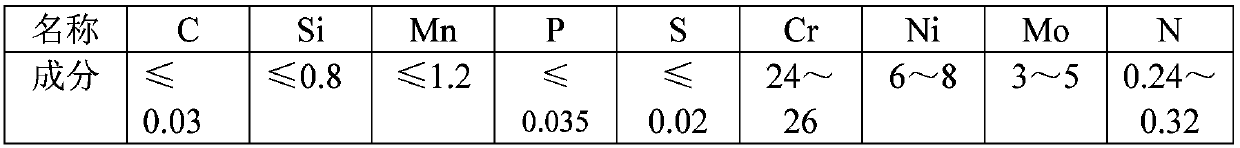

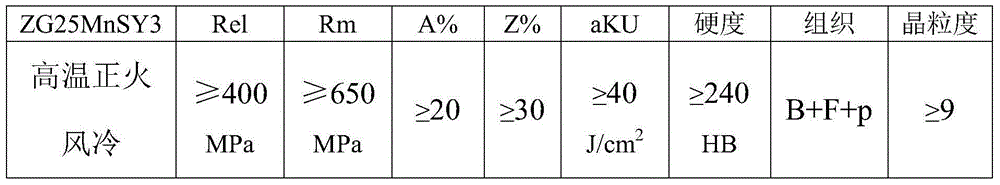

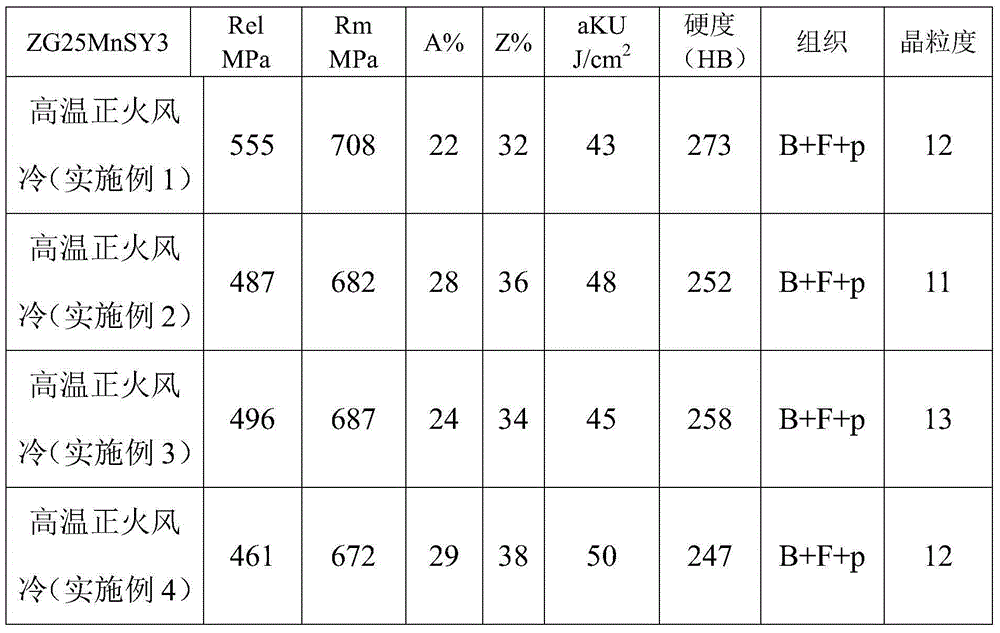

ZG25MnSY3 casting material and preparation method thereof

ActiveCN103627972BGuaranteed Chemical CompositionGood metallographic organizationElectric arc furnaceMechanical property

The invention discloses a ZG25MnSY3 casting material which consists of the following components in percentage by mass: 0.25-0.3 percent of C, 0.3-0.45 percent of Si, 1-1.2 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.015 percent of S, 0.3-0.6 percent of Cr, 04-0.6 percent of Ni, 0.3-0.45 percent of Mo, 0.09-0.15 percent of V, less than or equal to 0.05 percent of Nb, less than or equal to 0.3 percent of Cu, 0.03-0.06 percent of Al and the balance of Fe, totaling 100 percent. The invention also discloses a preparation method of a casting by utilizing the ZG25MnSY3 casting material. The casting material is smelted in an electric-arc furnace and a refining furnace, a leavening agent is added into the casting material at the later refining stage, the casting material has a good metallographic structure, the mechanical property is greatly improved, the strength and toughness are improved, and the service life is prolonged.

Owner:MCC SFRE HEAVY IND EQUIP

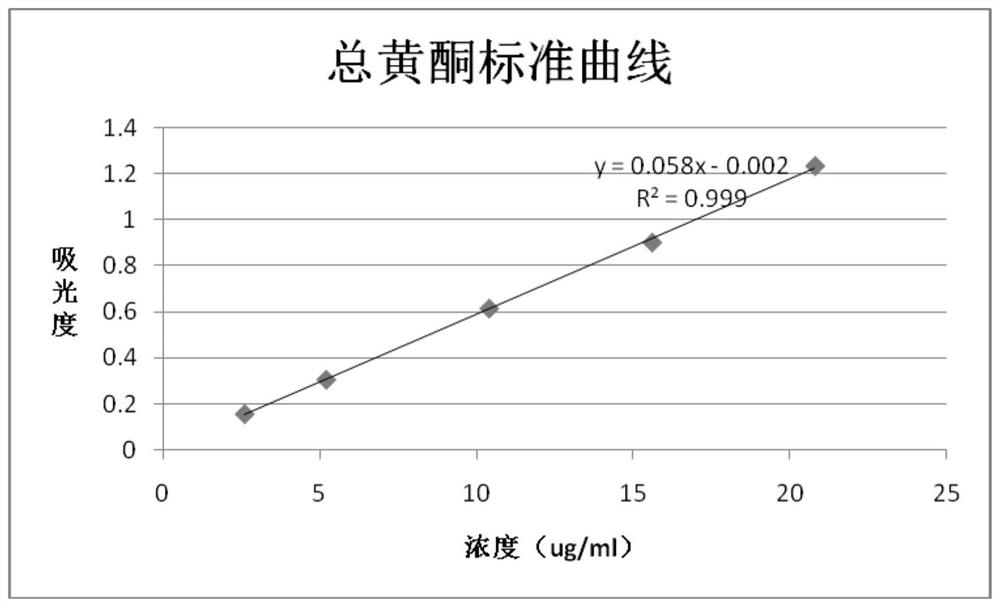

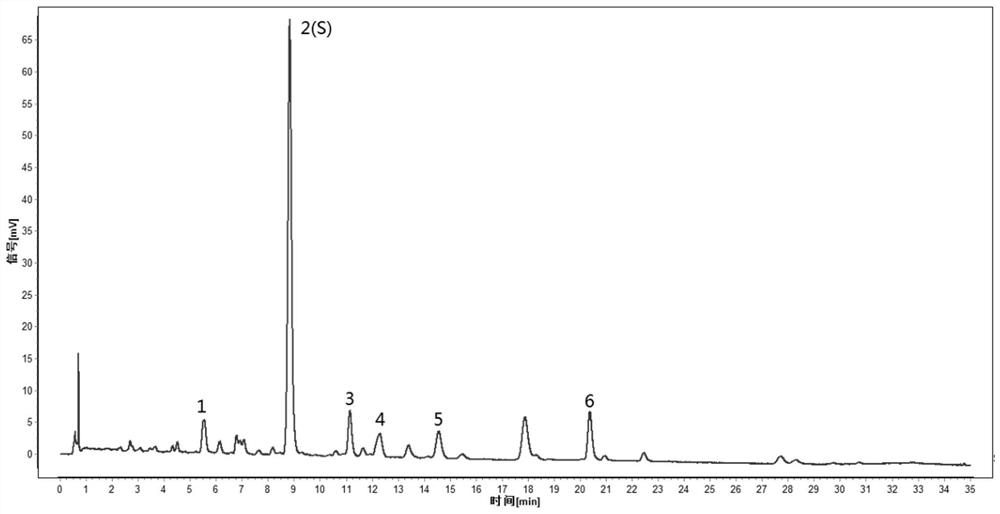

Preparation method and detection method of sculellaria barbata formula granules

PendingCN114028344AProcess steps are controllableDrug yield is highPreparing sample for investigationPharmaceutical non-active ingredientsPharmaceutical ExcipientScutellarin

The invention discloses a preparation method and a detection method of sculellaria barbata formula granules, and the preparation method comprises the following steps: selecting a sculellaria barbata raw material, and controlling the content of total flavonoids in the sculellaria barbata raw material to be 1.99%-4.41% and the content of scutellarin to be 0.36%-0.99%; performing dry cleaning and cutting treatment on a sculellaria barbata raw material to obtain sculellaria barbata decoction adding the sculellaria barbata decoction pieces into an extraction tank, adding water, decocting for the first time, filtering with a screen, extracting liquid medicine, and discharging dregs; adding water into the medicine residues, decocting for the second time, extruding the medicine residues to recover medicine liquid, and combining the medicine liquid to obtain a sculellaria barbata extracting solution; concentrating the sculellaria barbata extract under reduced pressure to obtain clear paste; dissolving the clear paste in pharmaceutic adjuvants, and performing spray drying to obtain dry extract powder; and adding pharmaceutical excipients into the dry extract powder, and carrying out dry granulation to obtain the sculellaria barbata formula granules. The invention can ensure that the obtained formula granules can be converted into traditional Chinese medicine decoction pieces with the same equivalent weight to meet prescription requirements.

Owner:SICHUAN NEO GREEN PHARMA TECH DEV +1

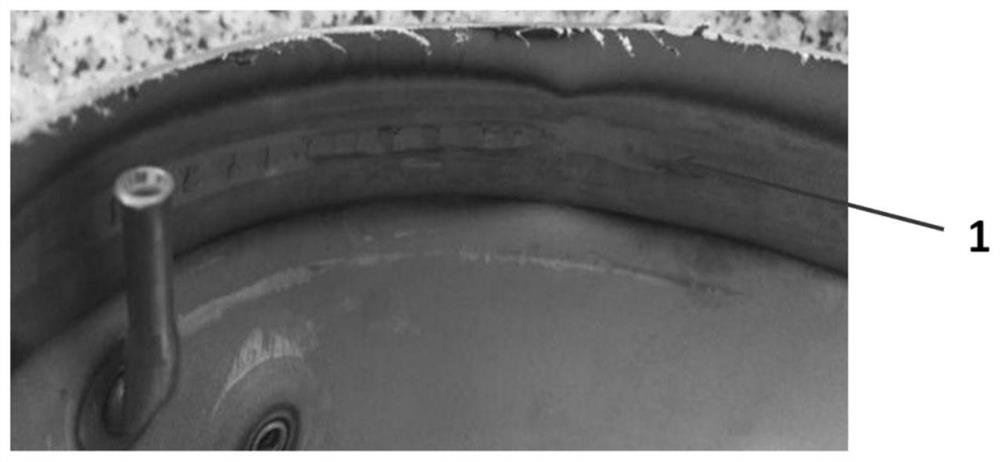

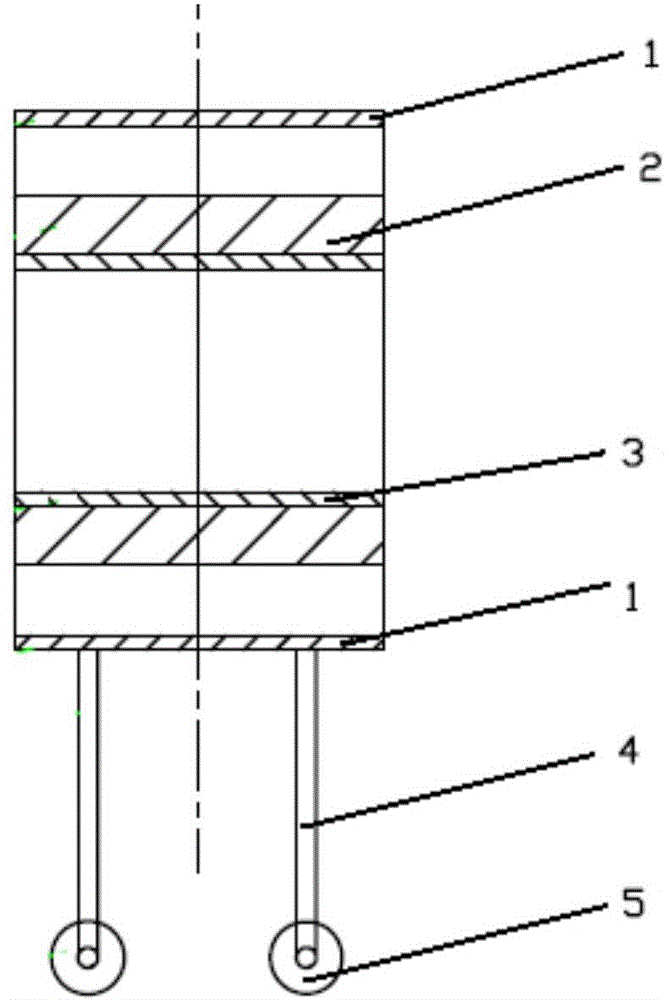

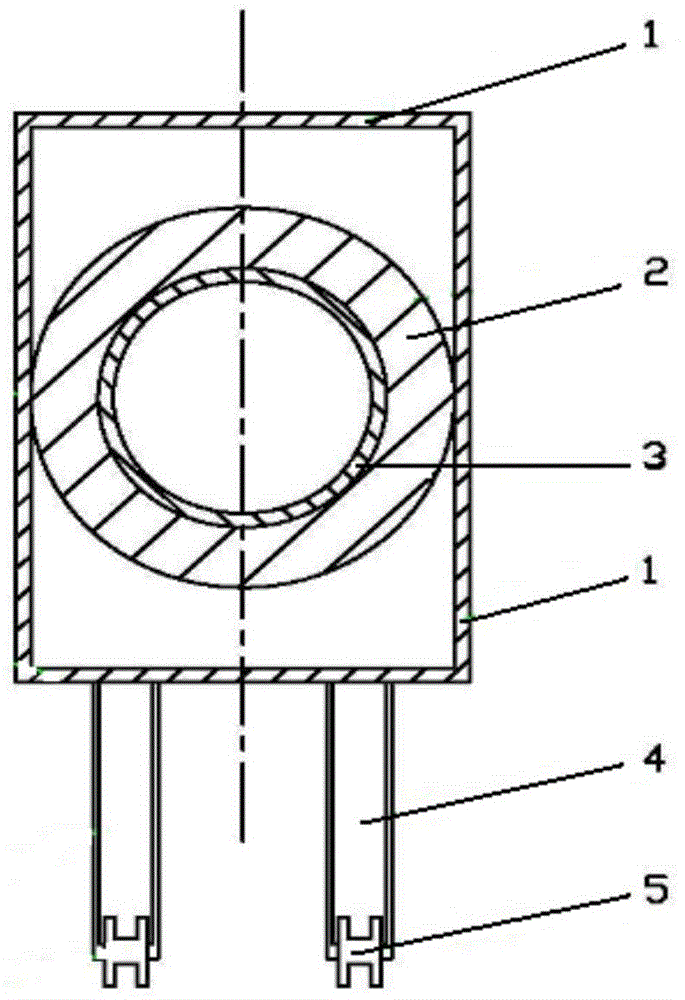

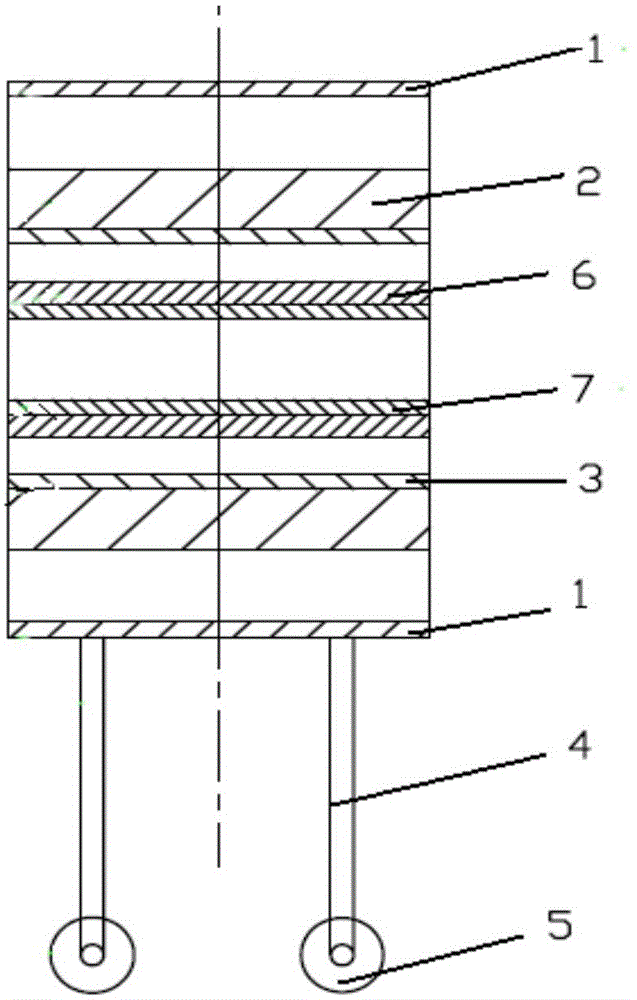

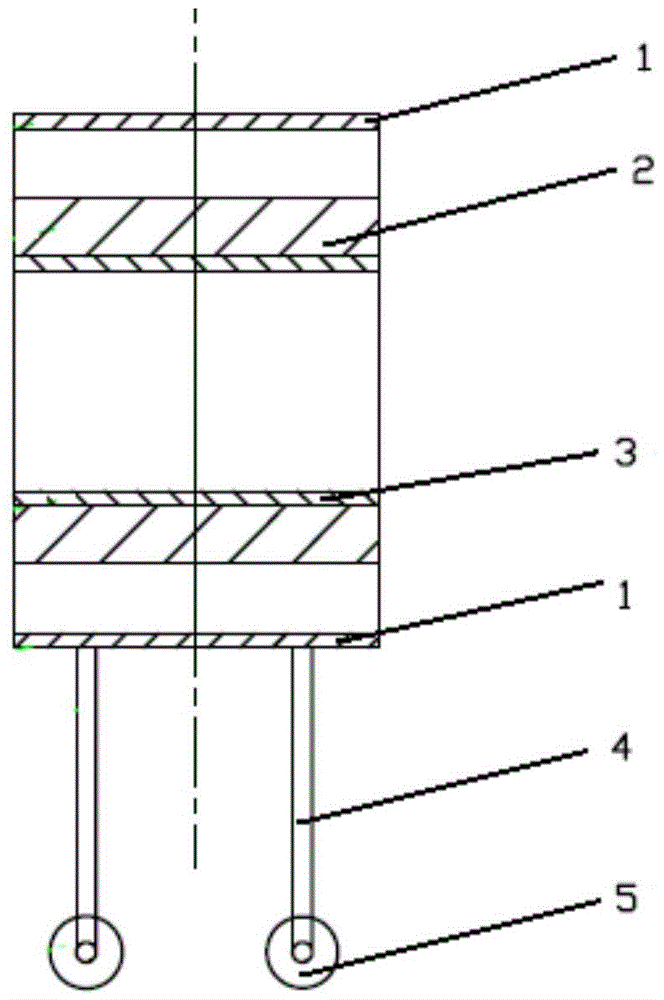

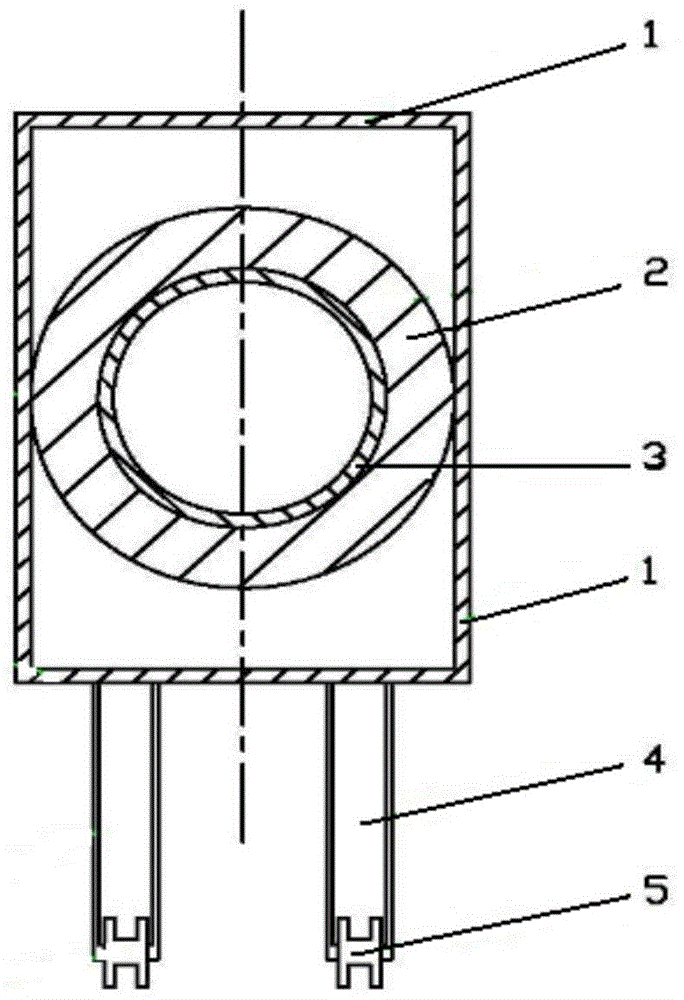

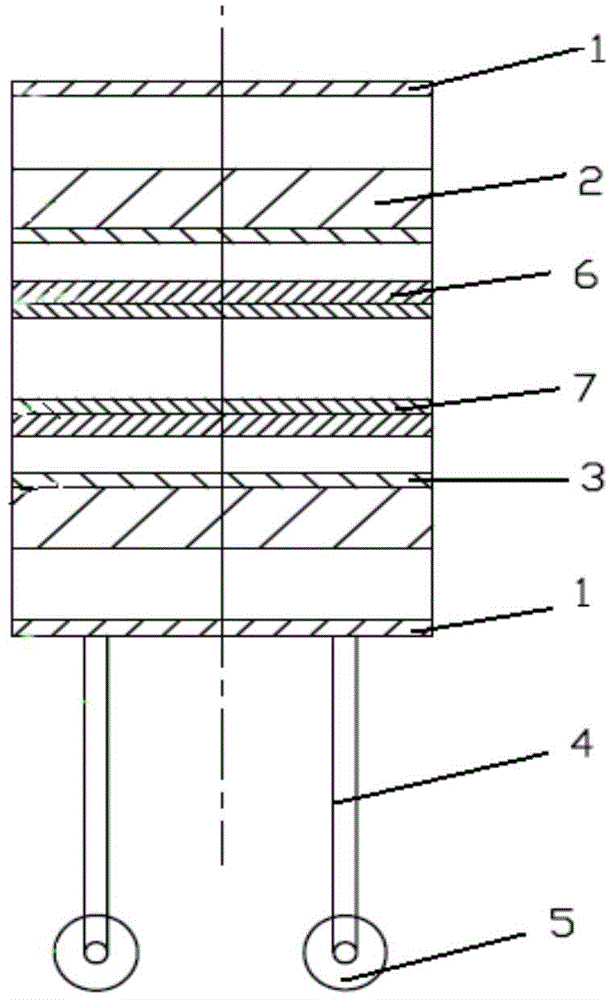

Mobile induction heating device and application thereof in dual-metal lining defect repair

ActiveCN104911310AImprove insulation performanceStable supportIncreasing energy efficiencyChemical compositionDefect repair

The invention provides a mobile induction heating device and an application thereof in dual-metal lining defect repair. A heating device comprises an epoxy resin insulation frame, a multilayer induction coil, an induction coil liner and a traveling device; the multilayer induction coil is fixed on the epoxy resin insulation frame, the multilayer induction coil comprises induction coil units and a connecting component, the induction coil unit is composed of induction coils and an epoxy resin plate sleeving the inner side of the coil, a glass tape is wound on each of the outer layers of the induction coil and the connection component, and the insulation varnish is dip-coated on the glass tape, and the connection component is used for connecting interfaces of two adjacent induction coils; a plurality of induction coil units are orderly sleeved to form the multilayer induction coil; the induction coil liner is arranged in the multilayer induction coil; and the travelling device comprises a support rod and a pulley. Through the adoption of the application of the mobile induction heating device in the defect repair of the dual-metal lining, a copper alloy layer on the steel backing copper alloy lining can be rapidly heated, not only is the chemical component of the alloy layer guaranteed, but also the security in the operation process can be guaranteed.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Method for recycling circuit board etching waste liquid

ActiveCN110359051BReduce dosageReduce pollutionPhotography auxillary processesProcess efficiency improvementCopper platingMetallurgy

The invention relates to a recycling method of circuit board etching waste liquid. The method comprises the following steps that S1, an extraction agent is added into the etching waste liquid, and after layering, a water phase and a loaded-copper oil phase are obtained; secondly, electroplating waste liquid is added into the loaded-copper oil phase for reverse extraction, and after layering, a solution containing copper and an oil phase are obtained; thirdly, the copper-contained solution is pretreated, and copper plating liquid is obtained; and fourthly, the copper plating liquid is used forelectroplating a circuit board to be plated. Through the method, the etching waste liquid is not treated in a low-value manner, the copper in the etching waste liquid is sufficiently used, through a series of treatment, the plating copper liquid is obtained, when the copper plating liquid carries out electroplating on the circuit board to be plated, an infusibility anode is adopted for completelyor partly replacing a phosphor copper anode, the use amount of phosphor copper can be greatly reduced, the electroplating-level copper sulfate does not need to be added, energy is saved, pollutions are reduced, and benefits are brought to an enterprise.

Owner:龙建国

Mobile induction heating device and its application in defect repair of bimetal bushing

ActiveCN104911310BImprove insulation performanceStable supportIncreasing energy efficiencyChemical compositionDefect repair

The invention provides a mobile induction heating device and an application thereof in dual-metal lining defect repair. A heating device comprises an epoxy resin insulation frame, a multilayer induction coil, an induction coil liner and a traveling device; the multilayer induction coil is fixed on the epoxy resin insulation frame, the multilayer induction coil comprises induction coil units and a connecting component, the induction coil unit is composed of induction coils and an epoxy resin plate sleeving the inner side of the coil, a glass tape is wound on each of the outer layers of the induction coil and the connection component, and the insulation varnish is dip-coated on the glass tape, and the connection component is used for connecting interfaces of two adjacent induction coils; a plurality of induction coil units are orderly sleeved to form the multilayer induction coil; the induction coil liner is arranged in the multilayer induction coil; and the travelling device comprises a support rod and a pulley. Through the adoption of the application of the mobile induction heating device in the defect repair of the dual-metal lining, a copper alloy layer on the steel backing copper alloy lining can be rapidly heated, not only is the chemical component of the alloy layer guaranteed, but also the security in the operation process can be guaranteed.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Austenitic stainless steel cladding tube for lead-bismuth fast reactor and preparation method thereof

ActiveCN105112811BChemical composition control is accurateHigh dimensional accuracySolution treatmentLead bismuth

The invention discloses an austenitic stainless steel jacketing pipe for a lead-bismuth fast reactor and a preparation method of the austenitic stainless steel jacketing pipe. The austenitic stainless steel jacketing pipe comprises, by weight, 0.06%-0.1% of C, 0.5%-1.0% of Si, 14%-16% of Ni, 14%-16% of Cr, 0.3%-0.6% of Ti, 1.5%-2.0% of Mn, 1.2%-1.8% of Mo, smaller than or equal to 0.03% of P, smaller than or equal to 0.05% of Co, smaller than or equal to 0.05% of Al, smaller than or equal to 0.01% of B, smaller than or equal to 0.02% of N, and the balance Fe. The method for preparing the jacketing pipe through the materials includes the steps of smelting, forging, hot working, solution treatment, cold rolling and intermediate annealing, final heat treatment, final cold working, straightening, cleaning, finished product inspection, identification, packaging and the like. In the final heat treatment step, quenching is conducted in a high-pressure nitrogen cooling mode, and in the cleaning process, an acidic degreasing agent is prohibited.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com