Manufacturing method of high-silicon titanium-containing outer sleeve made of austenitic stainless steel

A technology of austenitic stainless steel and a manufacturing method, which is applied in the manufacturing field of an outer casing made of high-silicon titanium-containing austenitic stainless steel, and can solve the problems that the manufacturing process cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

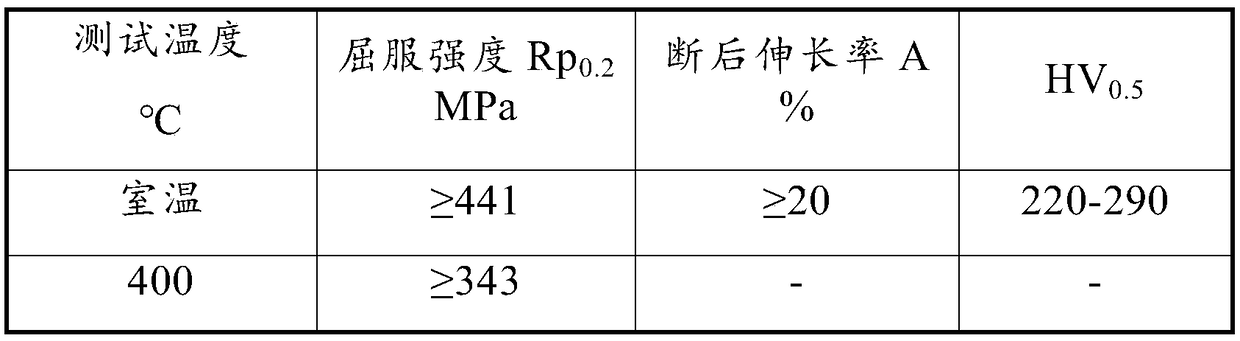

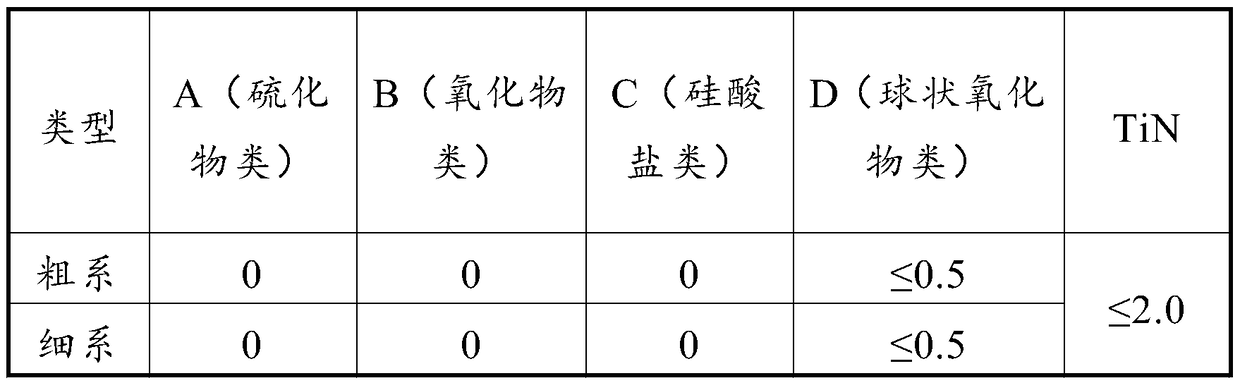

[0071] Embodiment 1: Manufacture and inspection of high-silicon and titanium-containing austenitic stainless steel outer casing (1)

[0072] The size of the outer casing prepared in this embodiment is the outer distance from the edge of 115 × 3 wall thickness (mm) (the weight percentage of the finished product is composed as follows: C: 0.62%, Si: 0.83%, P: 0.008%, S: 0.0010%, Mn: 1.56%, Ni: 14.92%, Cr: 16.17%, Mo: 2.11%, Ti: 0.45%, Co: <0.01%, B: 0.004%, N: 0.0050%, V: 0.19%, O: ≤0.0008%, Cu: ≤0.01%, Al: ≤0.03%, As: <0.003%, Mg<0.002%, Ca<0.005%, and the rest is Fe), including the following steps.

[0073] (1) Smelting

[0074] A 6-ton vacuum induction furnace is used for vacuum induction smelting of high-silicon-titanium-containing austenitic stainless steel (codenamed CN-1515), and a vacuum consumable furnace is used for consumable remelting. The chemical composition of the finished consumable ingot meets the chemical composition requirements.

[0075] (2) forging

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com