Method for recycling circuit board etching waste liquid

A technology for etching waste liquid and circuit boards, applied in the improvement of process efficiency, instruments, optics, etc., can solve the problems of secondary pollution, high equipment cost, consumption of large social resources, etc., to reduce pollution, save energy, and reduce phosphorus. The effect of copper dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

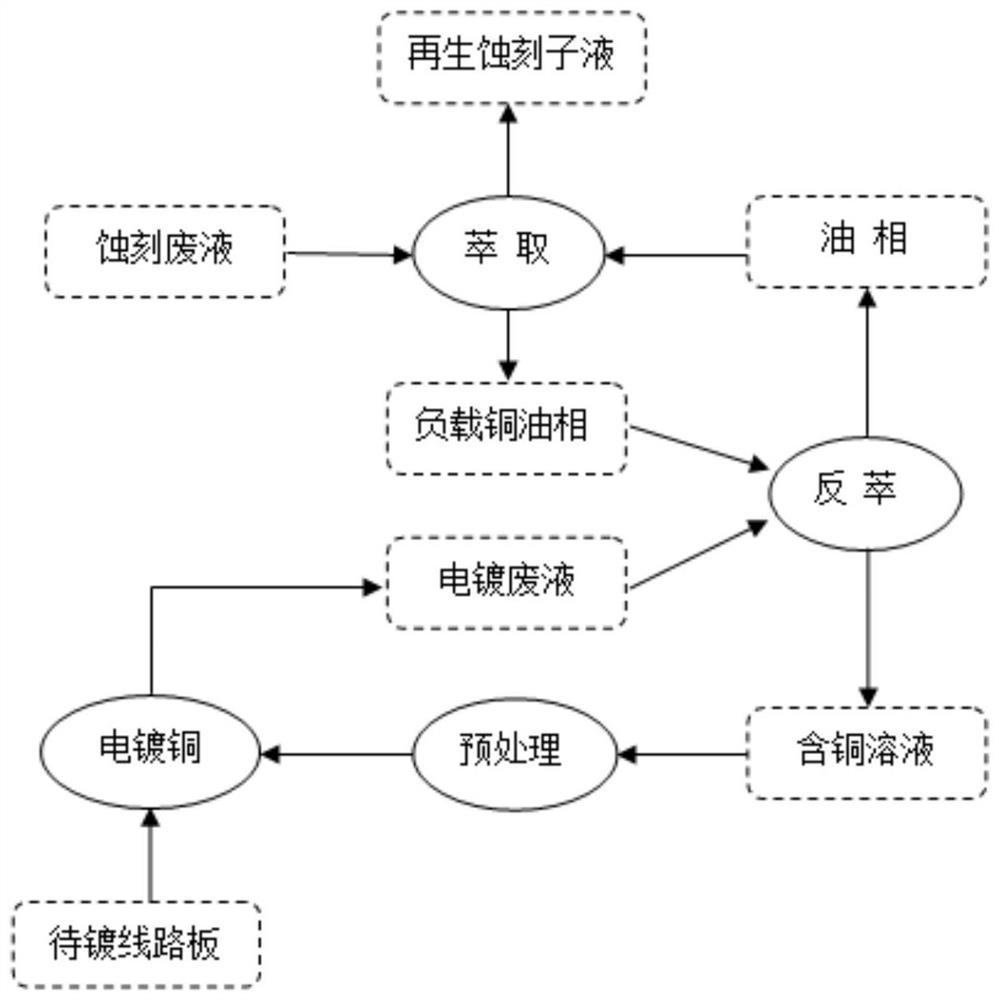

[0066] This embodiment provides a method for recycling and reusing circuit board etching waste liquid, which includes the following steps:

[0067] Step 1. Use 260# solvent oil (dearomatized, purchased from Zhengmao Petrochemical) to dilute the Mextral54-100 metal extractant to obtain the extractant, add the extractant to the alkaline etching waste liquid, and stand for stratification to obtain Water phase and copper-loaded oil phase. Add appropriate amount of etching salt, ammonia and anti-side etching agent to the water phase to restore the etching ability to form an alkaline regenerated etching sub-liquid, and then return to the etching process to participate in the etching. PH is 9.6, where Cu 2+ The content is 70g / L, Cl - The content is 170g / L.

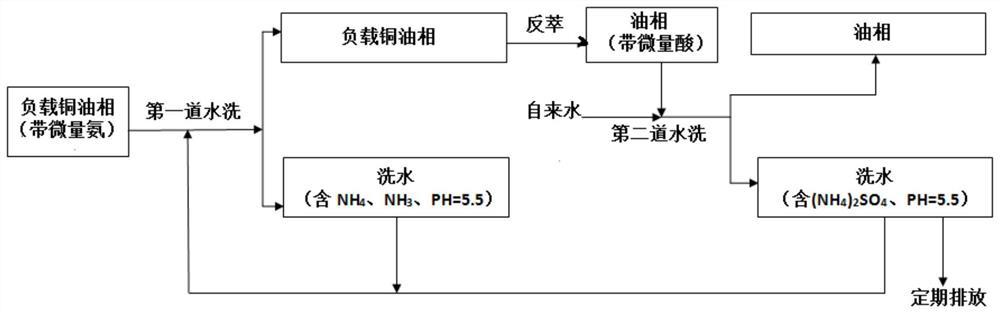

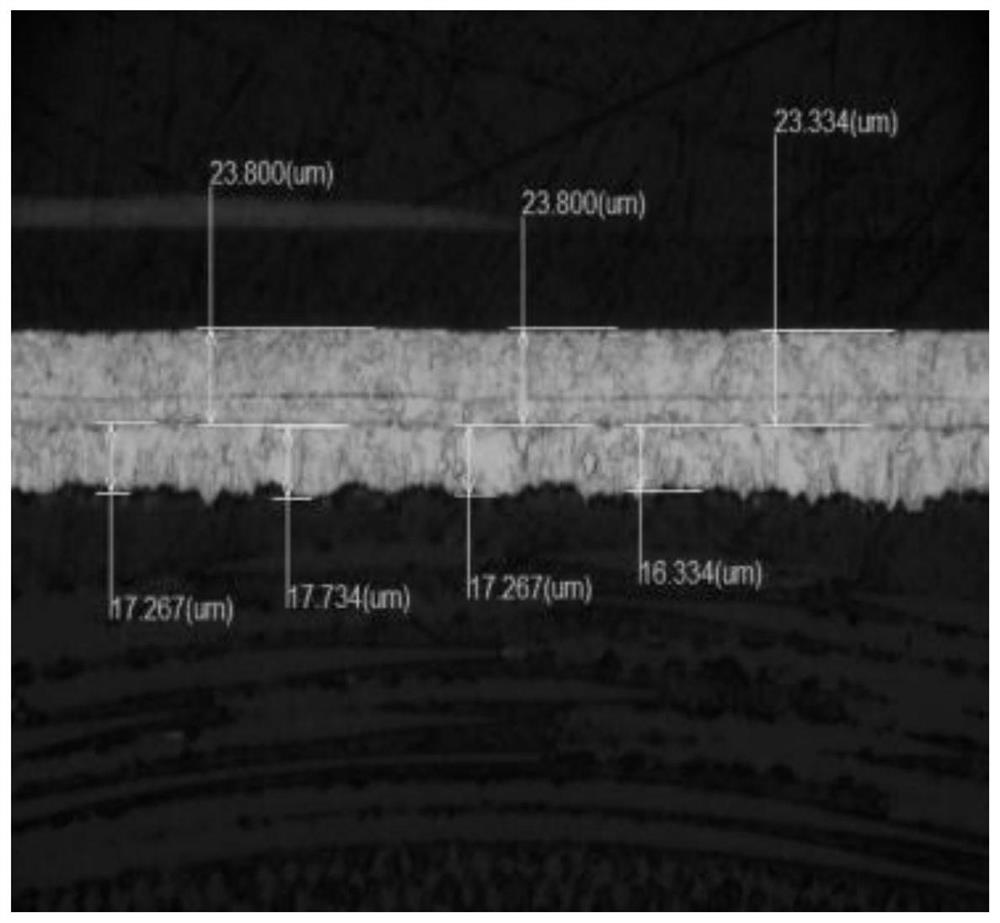

[0068] Step 2. Add electroplating waste liquid to the copper-loaded oil phase for back extraction, and after standing for stratification, a copper-containing solution and an oil phase are obtained. The electroplating waste liquid co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com