Smelting and updraft continuous casting process of Cu-Cr-Zr alloy

A continuous casting process, copper-chromium-zirconium technology, which is applied in the field of continuous casting integration and copper-chromium-zirconium alloy smelting. Production costs and other issues, to achieve the effect of excellent air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

[0016] This embodiment is described by taking the C18150 alloy produced according to the ASTM standard (the specification of cast copper-chromium-zirconium wire rod is Φ20mm) as an example.

[0017] Chemical composition of C18150 alloy:

[0018] Cr Zr Fe Si Pb Cu

[0019] 0.50~1.50 0.05~0.25 ≤0.10 ≤0.10 ≤0.05 margin

[0020] Raw material ratio: Cr: 0.9%, Zr: 0.1%, Cu: balance

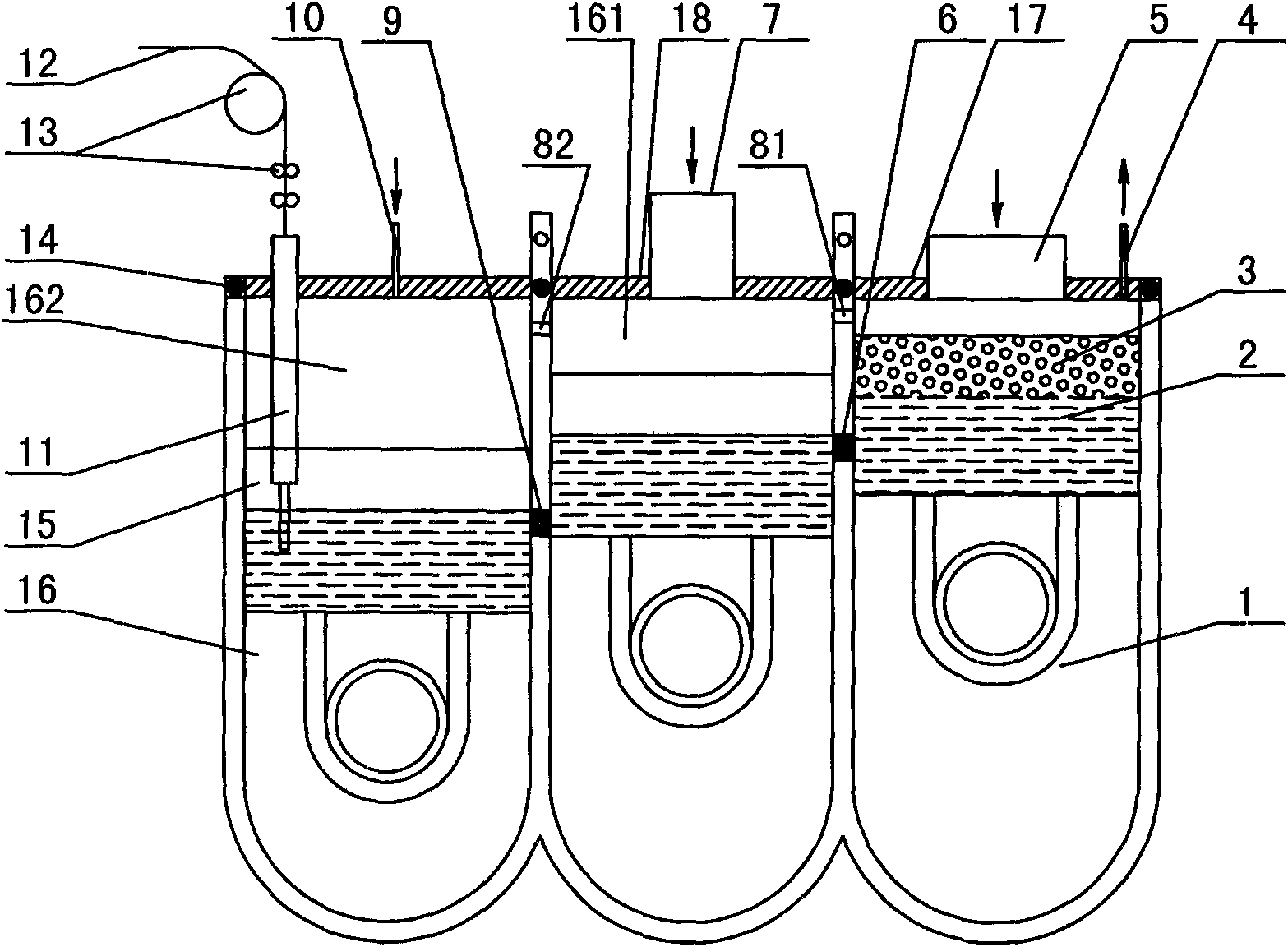

[0021] The smelting and upward continuous casting process of copper-chromium-zirconium alloy of the present invention, the equipment used in this process is as follows: figure 1 Shown, comprise: smelting furnace 1, casting furnace 16, traction casting equipment, smelting furnace 1 and casting furnace 16 have sealing cover 17,18 and feeding port 5,7 (in this example, charging port is arranged on sealing cover, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com