Method for preparing high-entropy alloy powder through mechanical alloying

A technology of mechanical alloying and high-entropy alloy, which is applied in the field of preparing high-entropy alloy powder by mechanical alloying, can solve the problems of difficulty in achieving precise control of alloy composition, inability to realize industrial production application, and high cost, and overcome the loss of chemical composition. Or segregation, easy operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

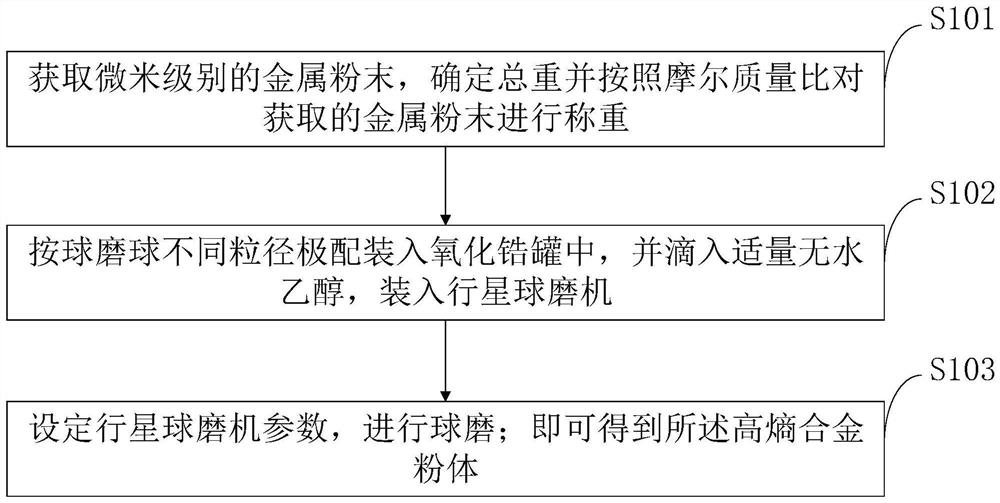

[0086] Obtain micron-level metal powder, prepare several zirconia ball milling tanks, prepare appropriate amount of zirconia balls with different particle sizes of 1mm, 3mm, and 5mm, and prepare appropriate amount of anhydrous ethanol, medicine spoon, oil paper, and electronic equipment accurate to 0.001 Balance, prepare QM-3SP04 planetary ball mill. 2. Determine the total weight and weigh the powder according to the molar mass ratio (operate with a medicine spoon, oil paper, and electronic balance), and match the different particle sizes of ball milling balls to 1:2:1, and put them into a zirconia tank. Drop in absolute ethanol, load it into a planetary ball mill, set the parameters as a, and set the operating speed of cd01 as "350" (the unit is rev / min). b. The operation mode of cd02 is set to one-way operation "0". c, cd03 running timing control is set to timing control "1". d. Set the running time of cd12 to "300" (the unit is minutes). e. The number of restarts of cd16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com