Mobile induction heating device and application thereof in dual-metal lining defect repair

An induction heating device and mobile technology, applied in the field of mobile induction heating devices, can solve problems such as economic losses, reduce investment and use costs, ensure product quality, and have good dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

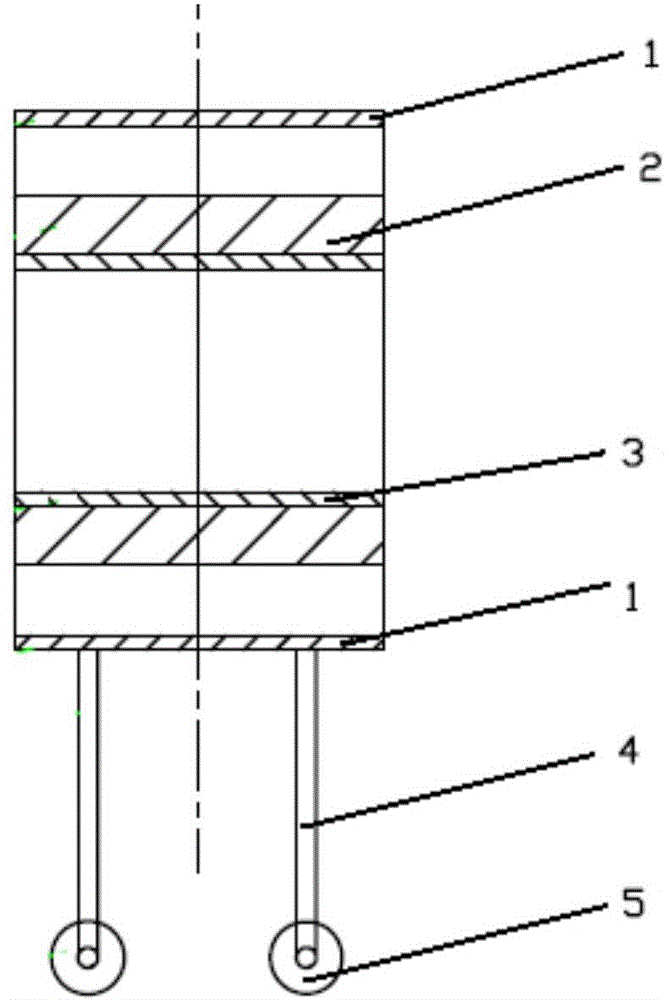

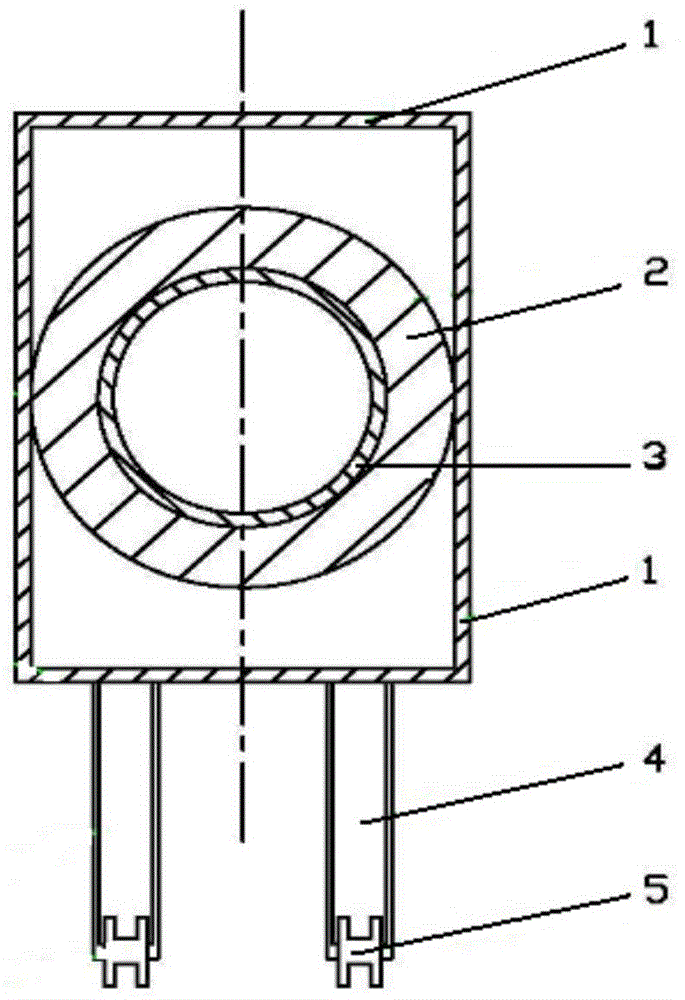

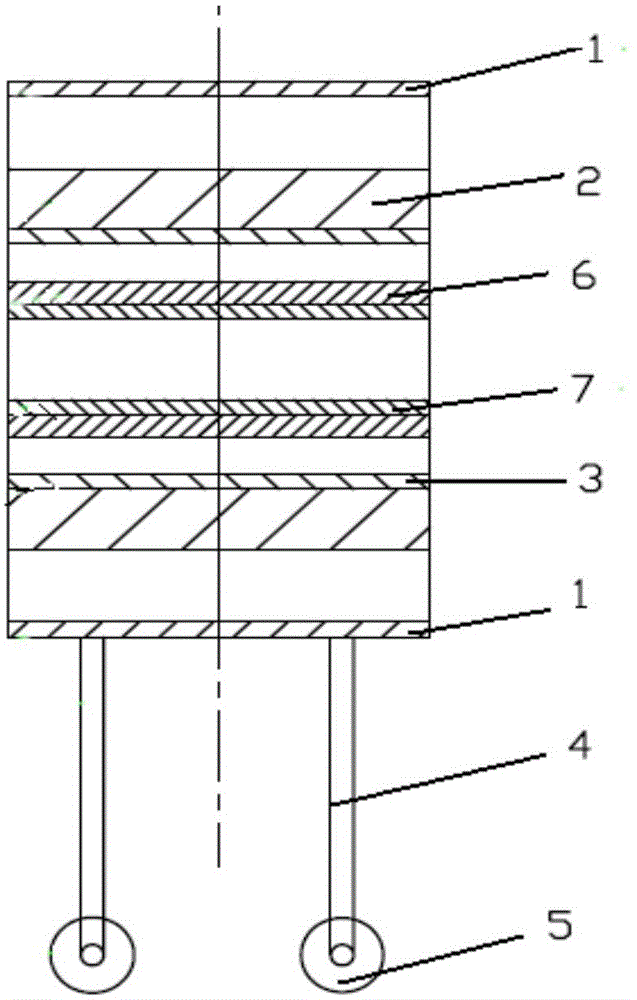

[0040] Such as figure 1 , 2 As shown, the mobile induction heating device includes an epoxy resin insulating frame 1, a multilayer induction coil 2, an induction coil inner lining 3 and a walking device, and the multilayer induction coil 2 is fixed on the epoxy resin insulating frame 1 with copper bolts and copper nuts. Above, the multilayer induction coil 2 includes an induction coil unit and a connecting member. The induction coil unit is composed of an induction coil and an epoxy resin plate nested inside the coil. The outer layer of the induction coil and the connecting member is wrapped with a glass ribbon 12 and dip-coated. Insulating varnish, the connecting members are respectively connected to the interfaces of two adjacent induction coils; multiple induction coil units are sequentially socketed to form a multilayer induction coil 2; the outerm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com