Patents

Literature

35results about How to "Meet the requirements of deep processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

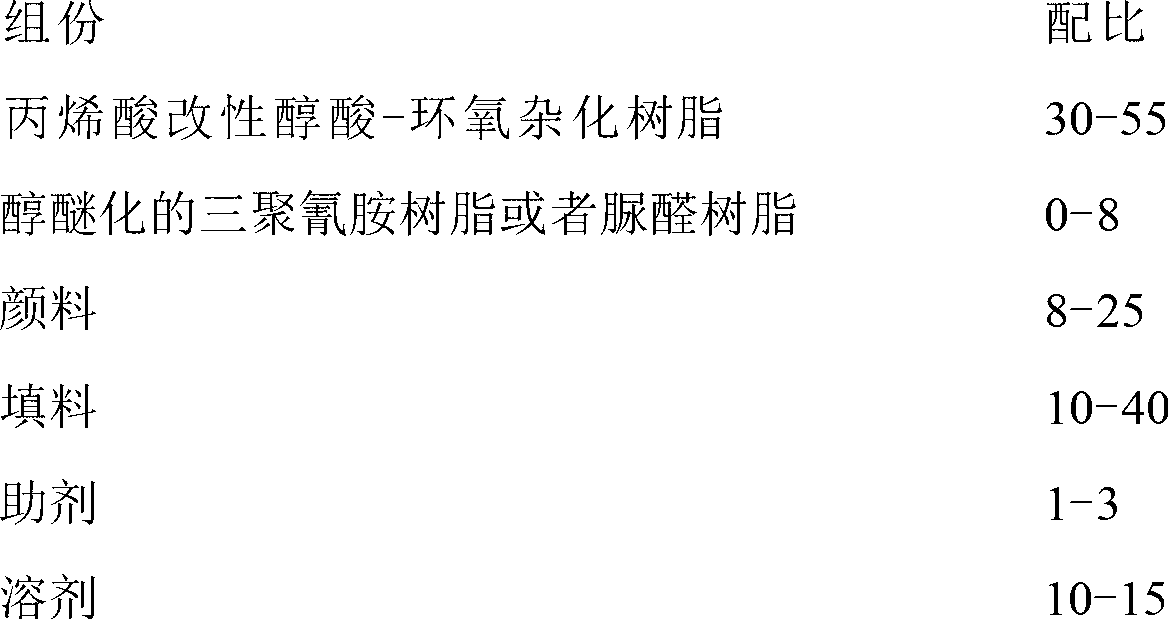

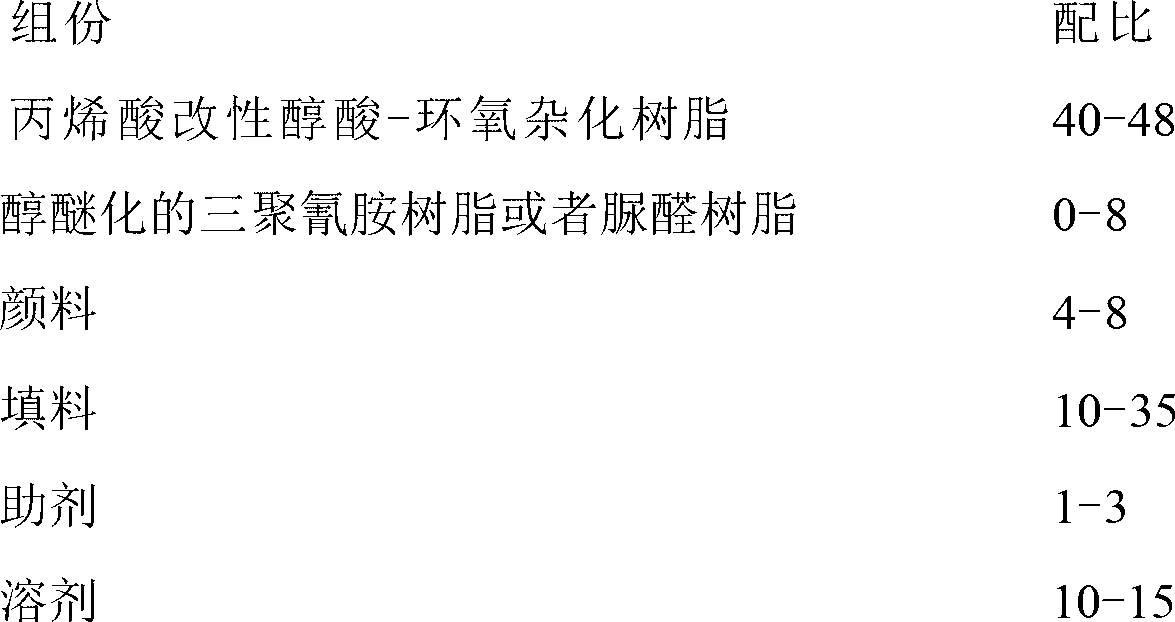

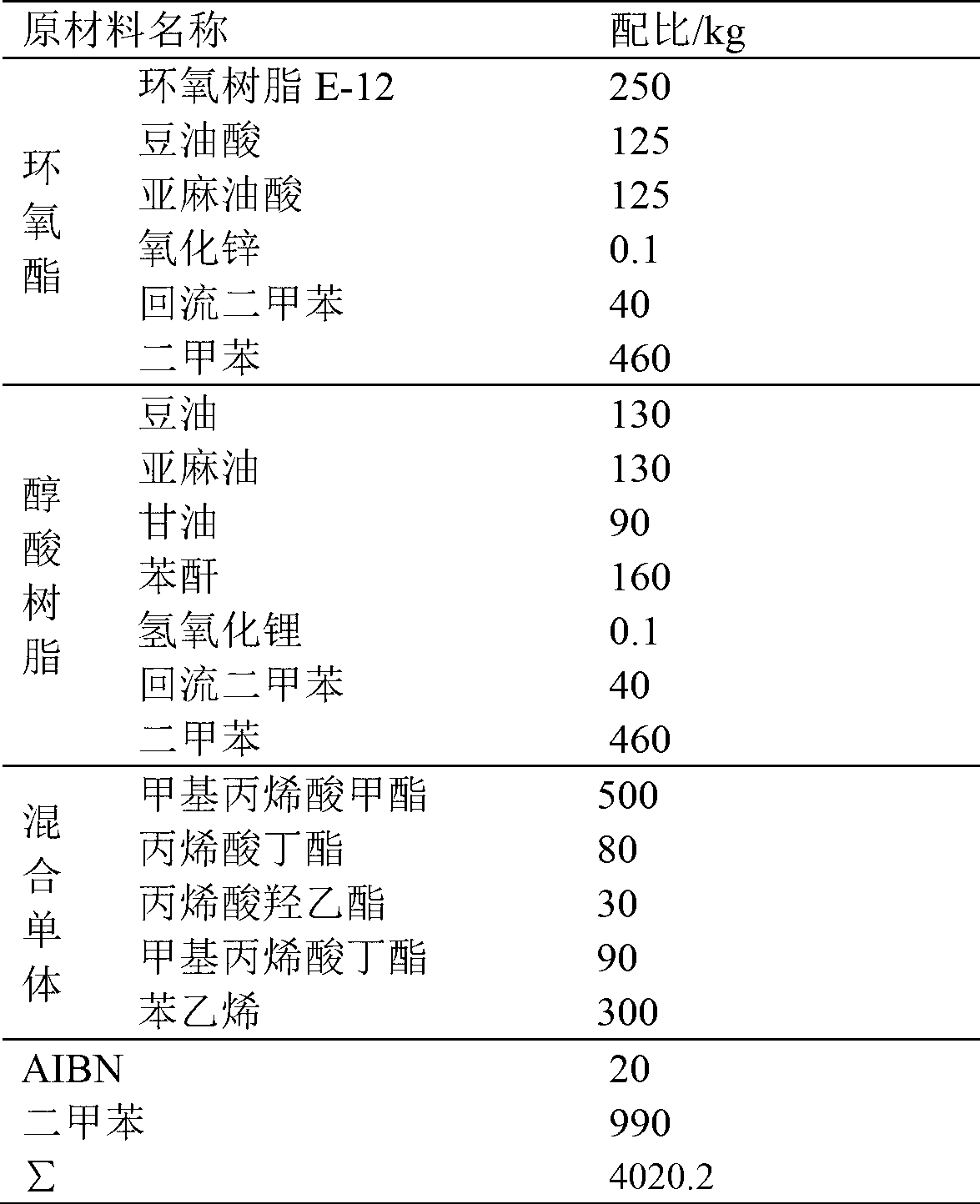

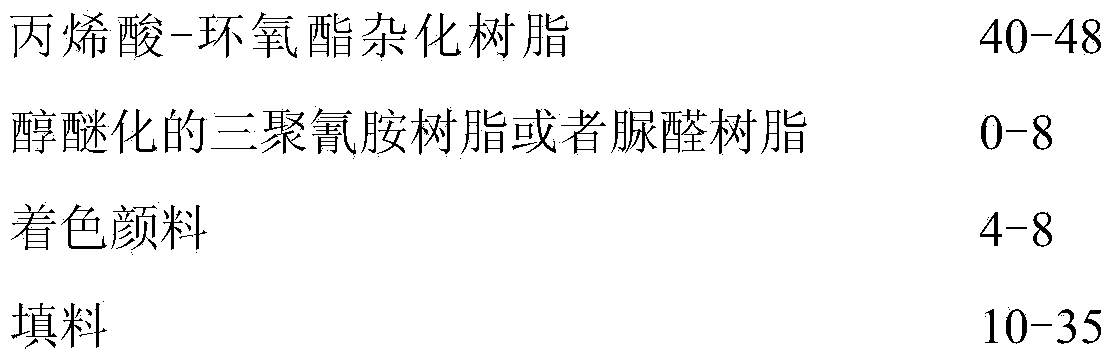

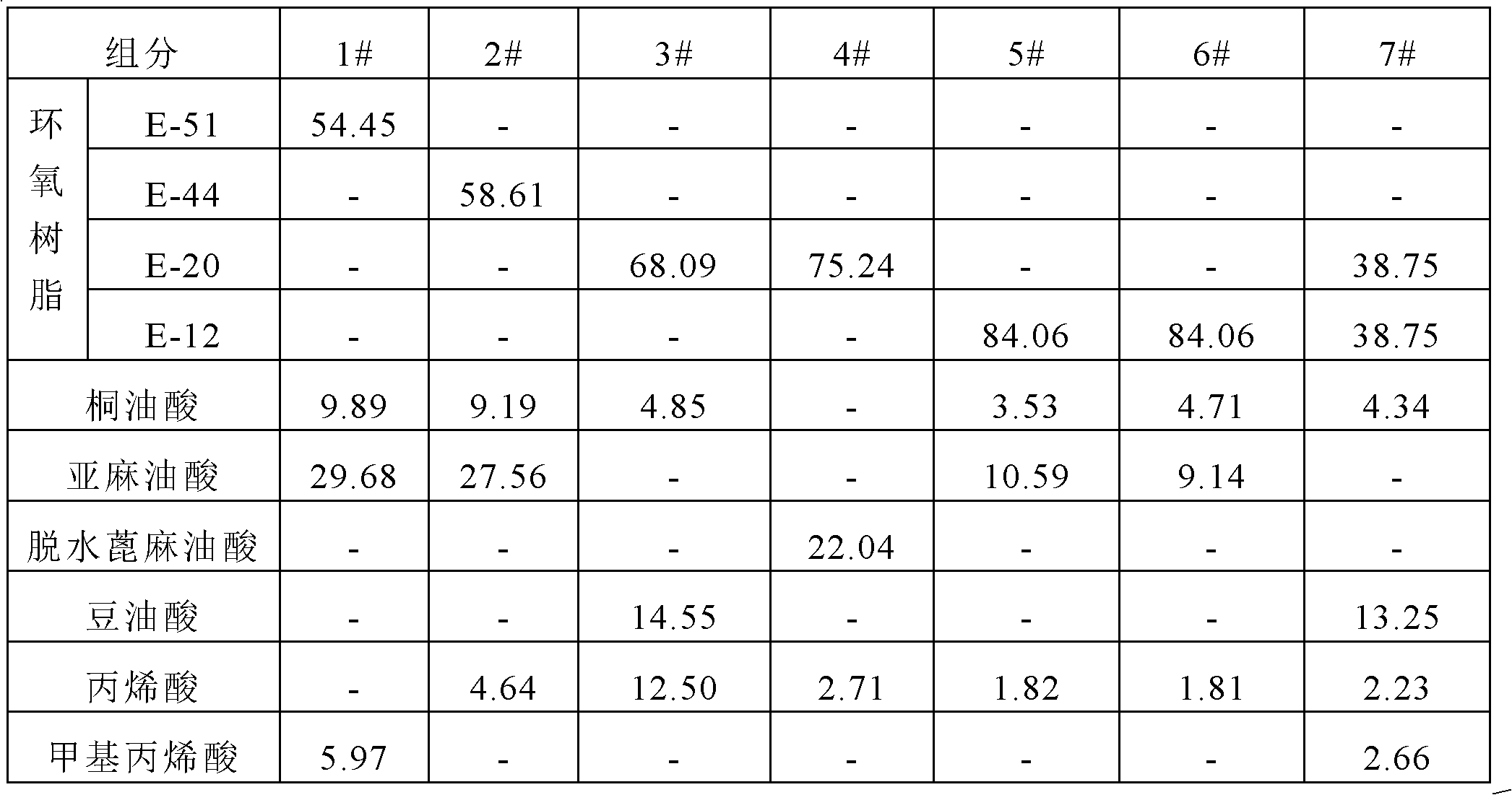

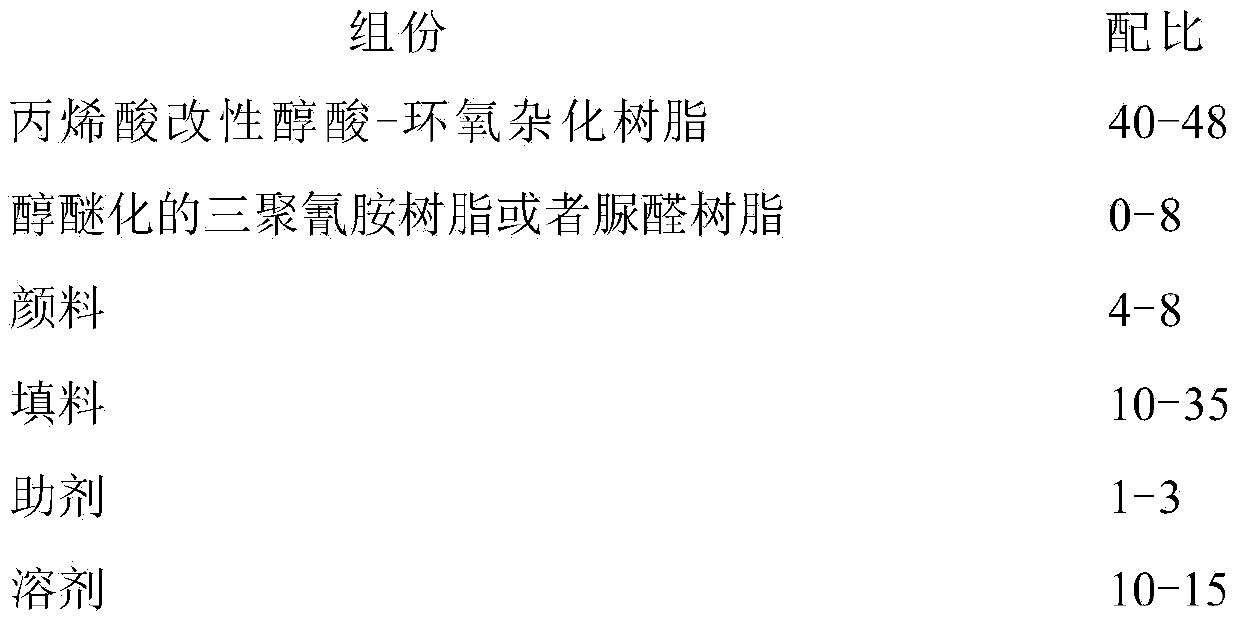

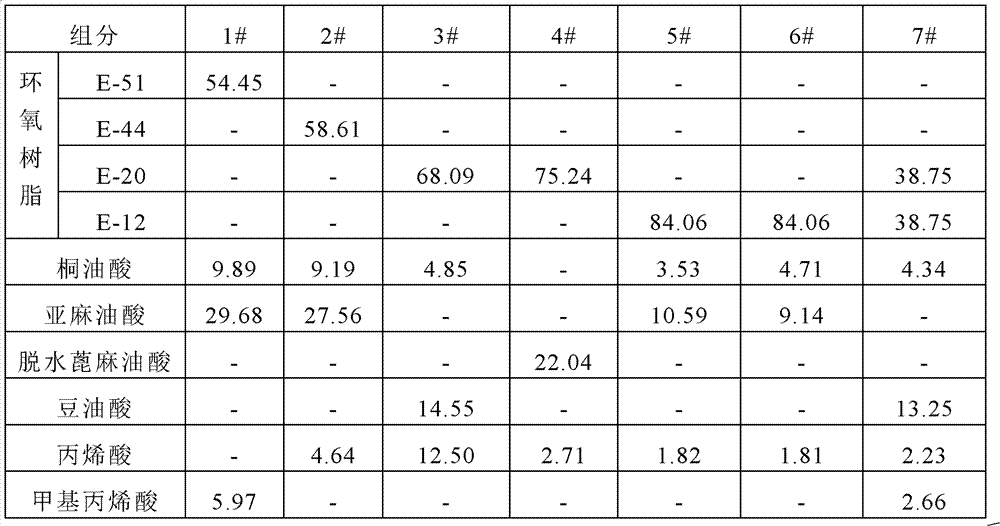

Acrylic-modified alcohol acid-epoxy ester hybrid resin and paint thereof

The invention relates to an acrylic-modified alcohol acid-epoxy ester hybrid resin which is prepared by the following steps: carrying out high-temperature esterification reaction on an epoxy resin and fatty acid under the action of an esterification catalyst to obtain epoxy ester; carrying out alcoholysis on vegetable oil and polyalcohol at high temperature, cooling, and adding polybasic acid for esterification, thereby obtaining an alkyd resin; and adding acrylic monomers into the epoxy ester-alkyd resin mixed solution, and carrying out graft polymerization under the action of an initiator to obtain the hybrid resin. The hybrid resin can be used as a main film forming material to prepare a high-temperature baking varnish together with a crosslinking agent. The high-temperature baking varnish can be used as various curtain-coating mirror back paints, including silver mirror back paints, aluminum mirror back paints, glass paints and the like, can satisfy the technological requirements for application of curtain coating production lines of which the width exceeds 3m, has a stable curtain coating, and can become completely dry after being baked at 150-130 DEG C for 3-5 minutes. The product has the advantages of low-temperature quick drying, high hardness, excellent adhesive force, dampness-heat resistance, chemical resistance, salt-fog resistance and the like.

Owner:常州市弘可利办公用品有限公司 +1

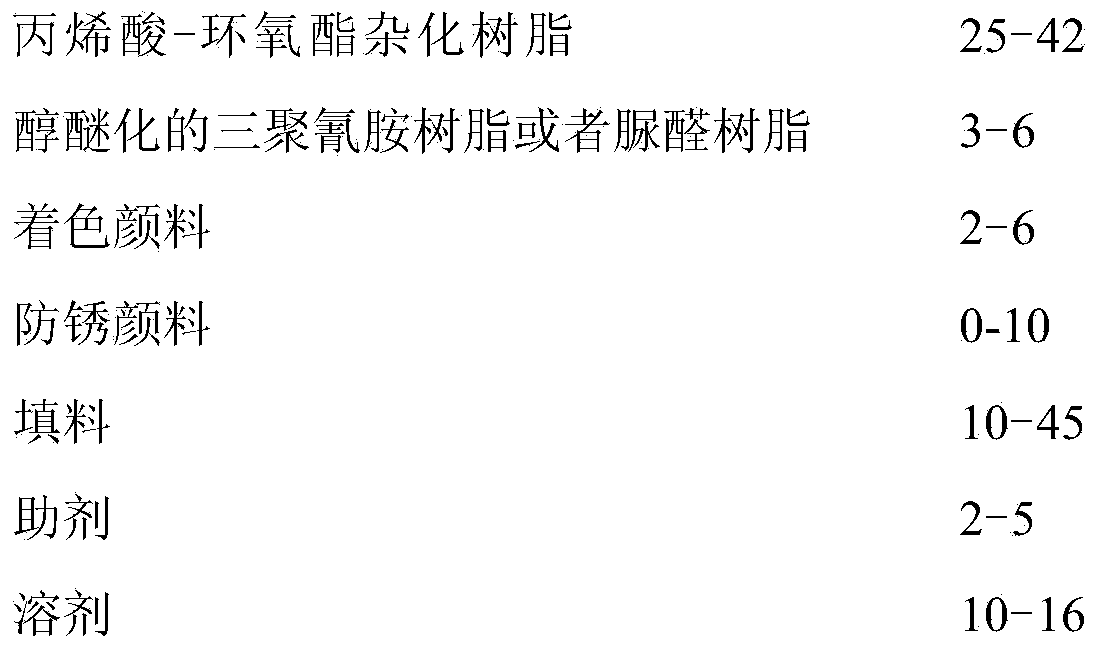

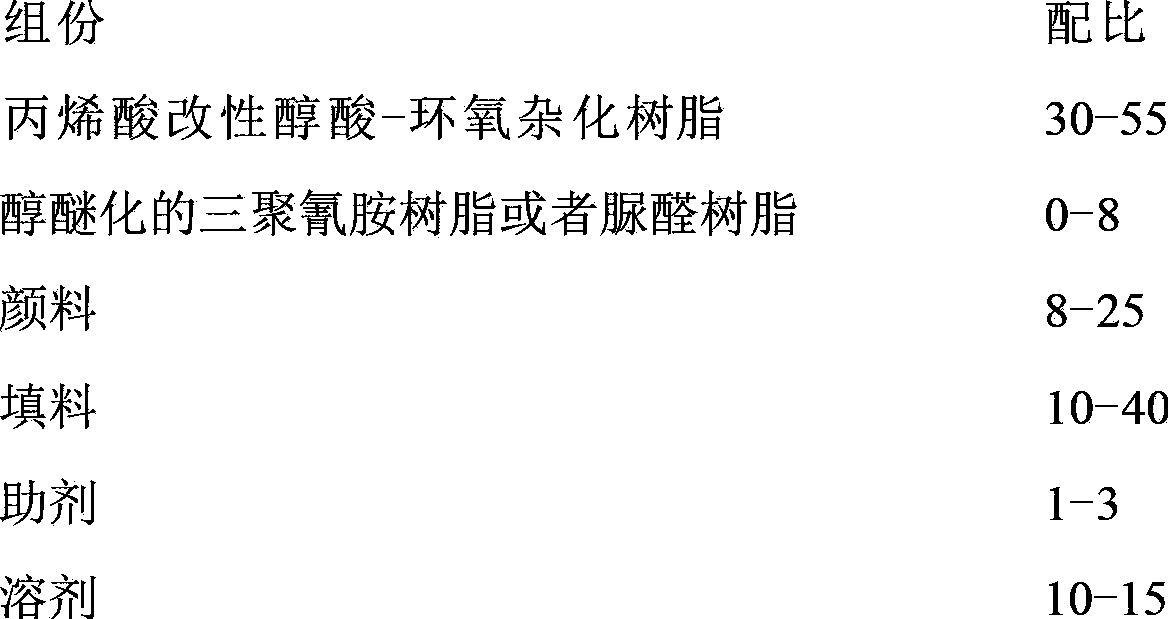

Acrylic acid-epoxy ester hybrid resin and coatings thereof

The invention provides an acrylic acid-epoxy ester hybrid resin. The acrylic acid-epoxy ester hybrid resin is prepared by reacting an epoxy resin and aliphatic acid under the action of a catalyst so as to prepare epoxy ester and then adding acrylic monomers and an initiator under certain conditions. A self-drying type antirust coating can be prepared with the acrylic acid-epoxy ester hybrid resin provided by the invention as a main film forming substance; a dried anticorrosive coating can also be prepared, especially coatings for curtain spraying sliver-coated mirrors, color films and aluminum mirrors; the coatings can meet coating process requirements of a wide-curtain spraying and coating production line with a maximum length of 3 m and are completely dried when baked at a temperature of 130 to 150 DEG C for 5 to 3 min, a film obtained after complete drying has excellent anticorrosion performance, can resist CASS, dampness, dryness and water with a temperature of 60 DEG C for more than 240 h, satisfy requirements of edging and texturing process of a downstream client and do not suffer from edge blackening and corrosion of clad layers.

Owner:常州市弘可利办公用品有限公司 +1

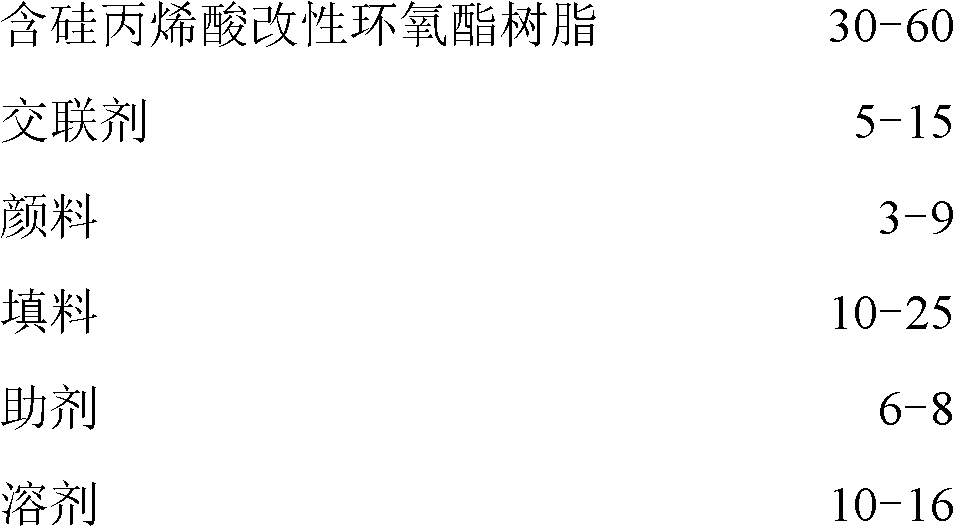

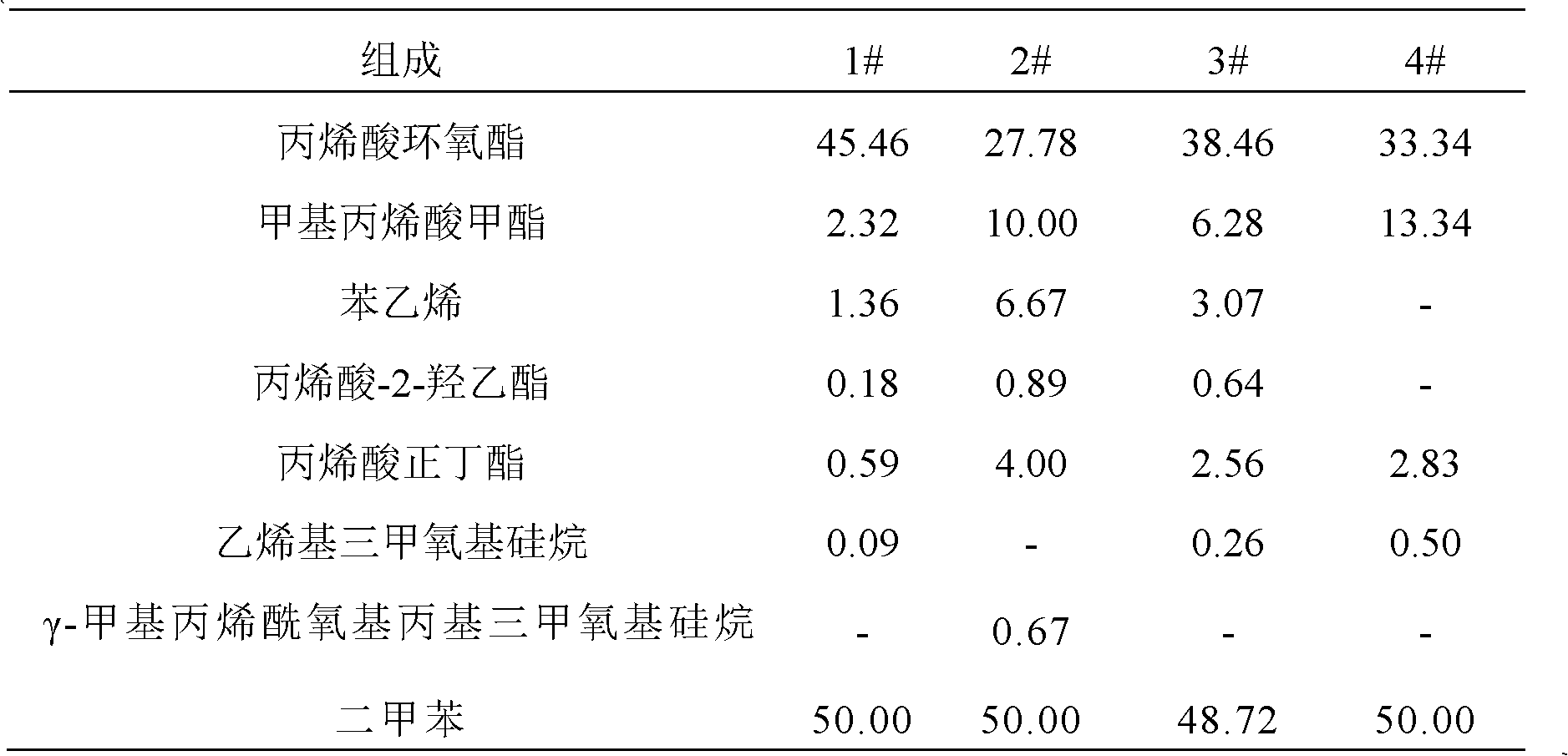

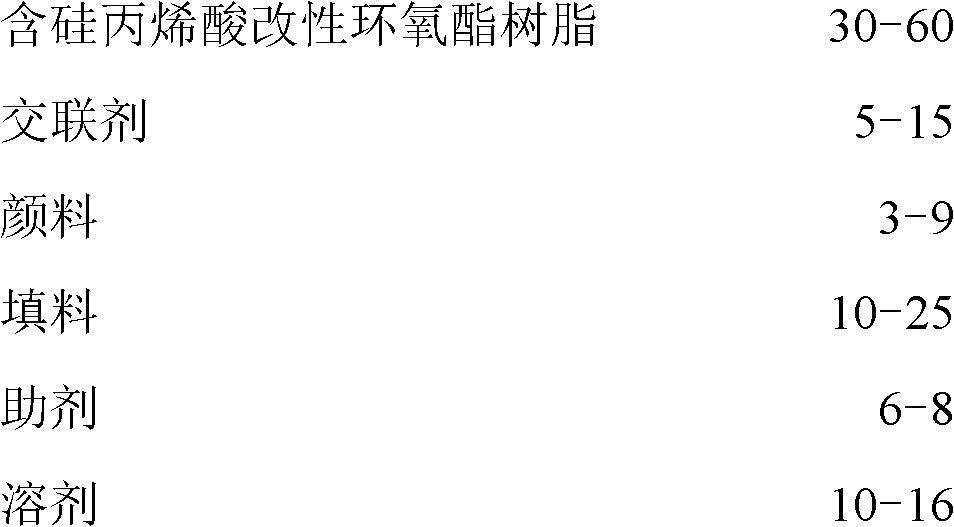

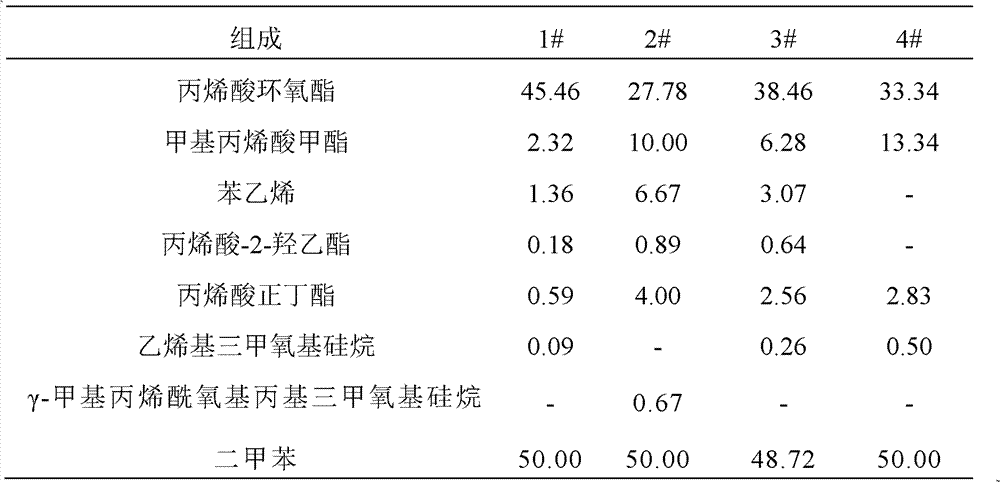

Silicon-containing acrylic-acid-modified epoxy ester resin and paint thereof

The invention provides a silicon-containing acrylic-acid-modified epoxy ester resin, which is prepared by the following steps of: carrying out a high-temperature esterification addition reaction on epoxy resin and fatty acid under the action of esterification catalyst, then reducing reaction temperature, adding acrylic acid, methacrylic acid or a mixture of acrylic acid and methacrylic acid, and carrying out an addition reaction under the action of low-temperature esterification catalyst to obtain acrylic acid epoxy ester resin; and then carrying out radical polymerization on the prepared acrylic acid epoxy ester resin, acrylic acid monomer and organic silicon monomer in the presence of an initiator to prepare the silicon-containing acrylic-acid-modified epoxy ester resin. The silicon-containing acrylic-acid-modified epoxy ester resin provided by the invention is a main film forming material; the paint for curtain spraying of glass is prepared by the silicon-containing acrylic-acid-modified epoxy ester resin and a cross-linking agent; the paint can satisfy the painting process requirements of painting production line of wide curtains as long as 3 m, and can be completely dried after being baked at 130-160 DEG C for 5-7 minutes; and after drying is finished, the hardness and flexibility of the coated film is balanced, thus a paint falling phenomenon during edging, perforating and sandblasting for deep processing of process glass is avoided.

Owner:常州市弘可利办公用品有限公司

Method for reducing arsenic in amine extracted germanium organic phase

ActiveCN101619390AMeet the requirements of deep processingProcess efficiency improvementFiltrationKerosene

The invention relates to a method for reducing arsenic in amine extracted germanium organic phase, which belongs to the technical field of non-ferrous metallurgy. Material containing germanium and arsenic is leached by sulfuric acid, arsenic reducing agent capable of reducing As5<+> into As3<+> is added into leaching solution according to 1-5g / l, and final acid PH is adjusted to 0.5-1.5; after desilication and filtration, germanium organic complexing agent is added into the solution according to the weight ratio of 8-12 of germanium organic complexing agent to germanium to increase the selective extraction of germanium; and germanium is extracted by a N235 kerosene system, obtained germanium organic phase is washed by oxalic acid solution with the weight percentage of 1-2 percent, and then alkalistripping and hydrolysis are carried out to prepare germanium concentrate. The Na2SO3 is preferably adopted as arsenic reducing agent, and tartaric acid is preferably adopted as the organic complexing agent. The method has the advantages that even the solution has high arsenic concentration, the arsenic content of the produced germanium concentrate can be reduced to below 1 percent to meet the requirements of deep processing of germanium.

Owner:YUNNAN WUXIN IND

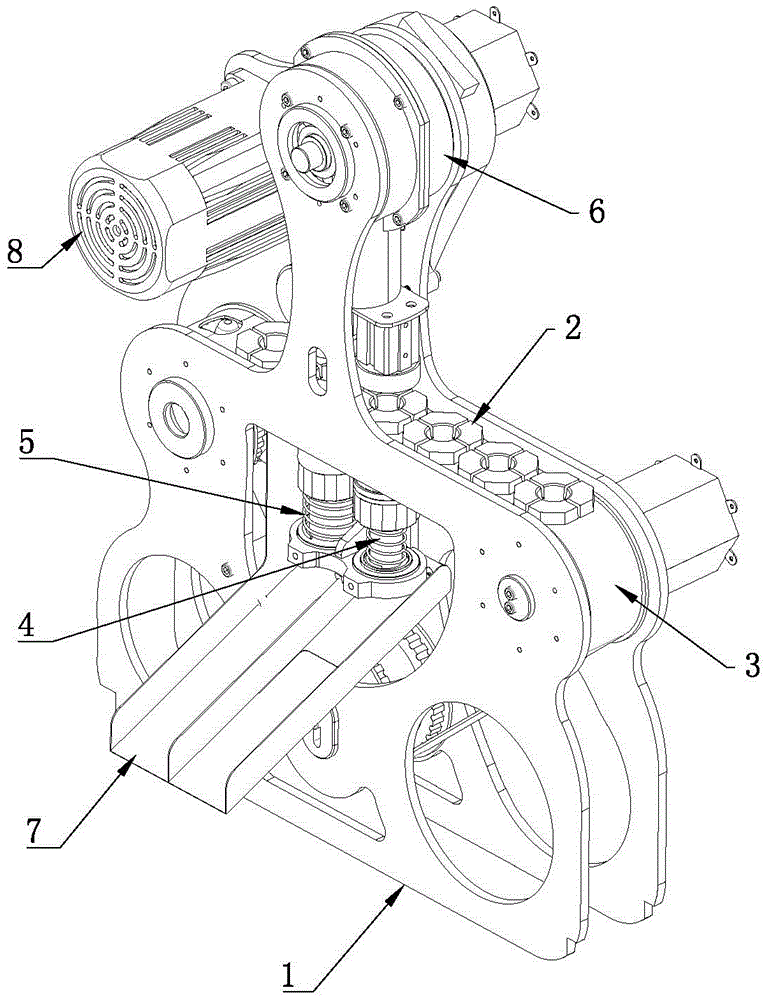

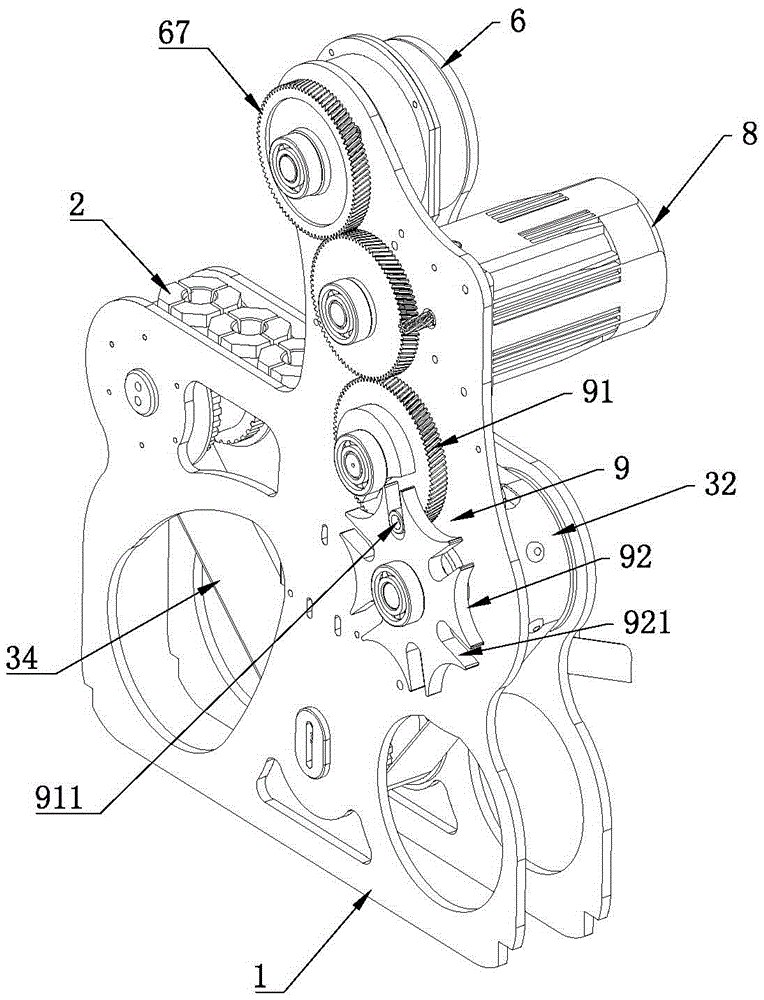

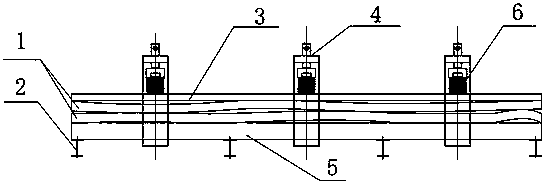

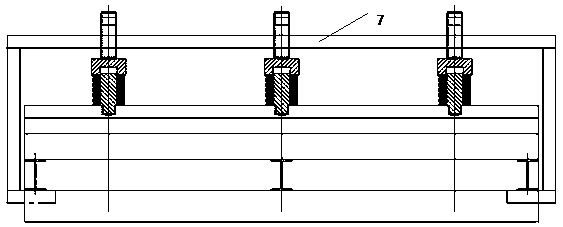

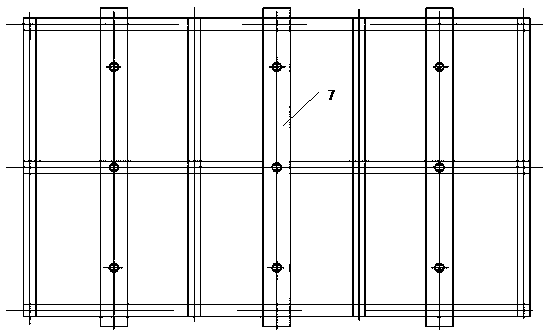

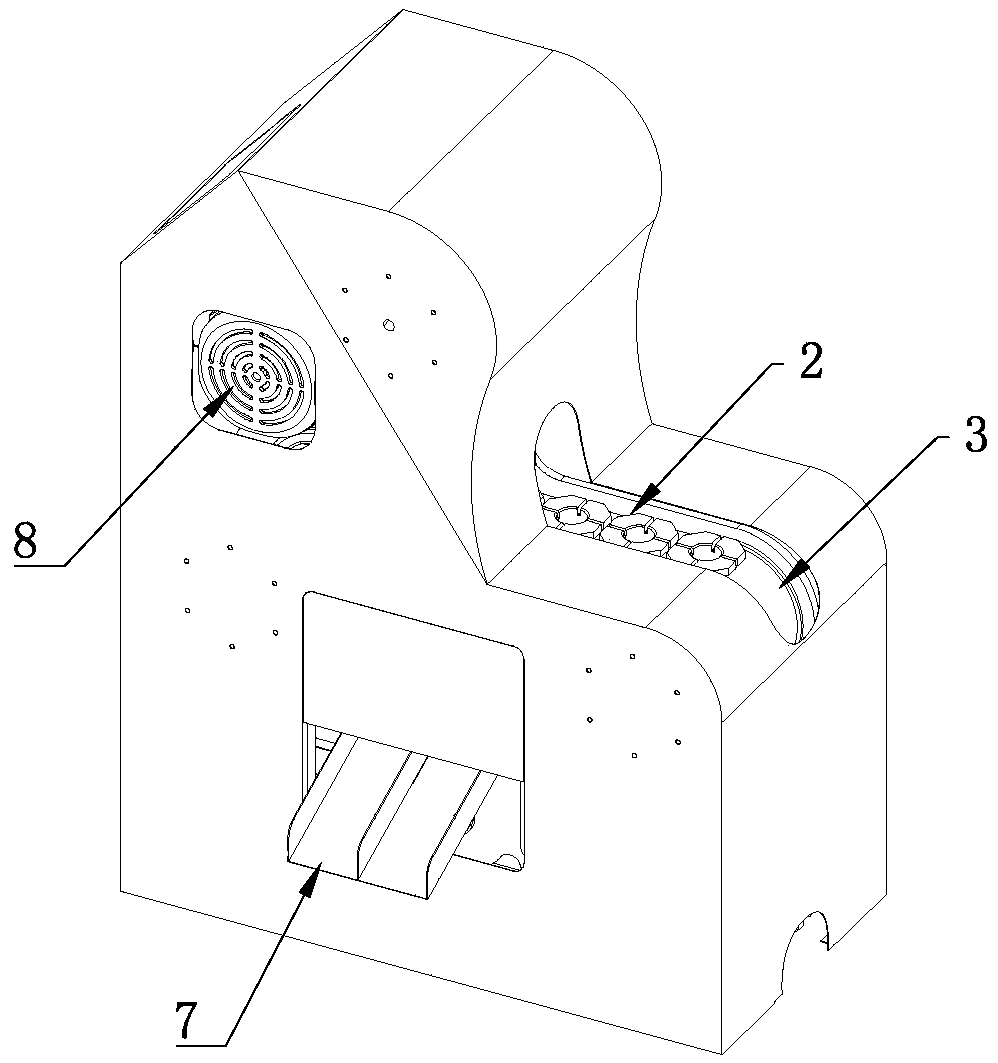

Method for removing longan seeds and pulp and automatic longan pulp removal machine

ActiveCN106072694AContinuous processingImprove integrityFruit stoningVegetable peelingPulp and paper industryDeep processing

The invention relates to the technical field of food processing equipment, in particular to a method for removing longan seeds and pulp and an automatic longan pulp removal machine. The method includes a seed removal step and a pulp removal step. The automatic longan pulp removal machine comprises soft fixtures, a feeding mechanism, a seed removal tool, a pulp removal tool and a punch mechanism. The soft fixtures are used for clamping longan, the feeding mechanism is used for conveying the soft fixtures, the seed removal tool and the pulp removal tool are sequentially arranged along a feeding direction, and the punch mechanism is used for respectively pushing the longan seeds out of the longan pulp and pushing the longan pulp out of longan shells and is correspondingly arranged above the seed removal tool and the pulp removal tool. Compared with the prior art, the method and the automatic longan pulp removal machine have the advantages that longan seed removal and shell removal working procedures can be automatically controlled, accordingly, the method and the automatic longan pulp removal machine are high in work efficiency and easy to implement, and the pure longan pulp can be continuously processed; the longan pulp obtained by the aid of the method and equipment is good in integrity, damage to the longan pulp can be prevented, the method and the automatic longan pulp removal machine are low in pulp loss ratio, and accordingly modern agricultural product deep-processing requirements can be effectively met.

Owner:茂名市金皇冠智能科技有限公司

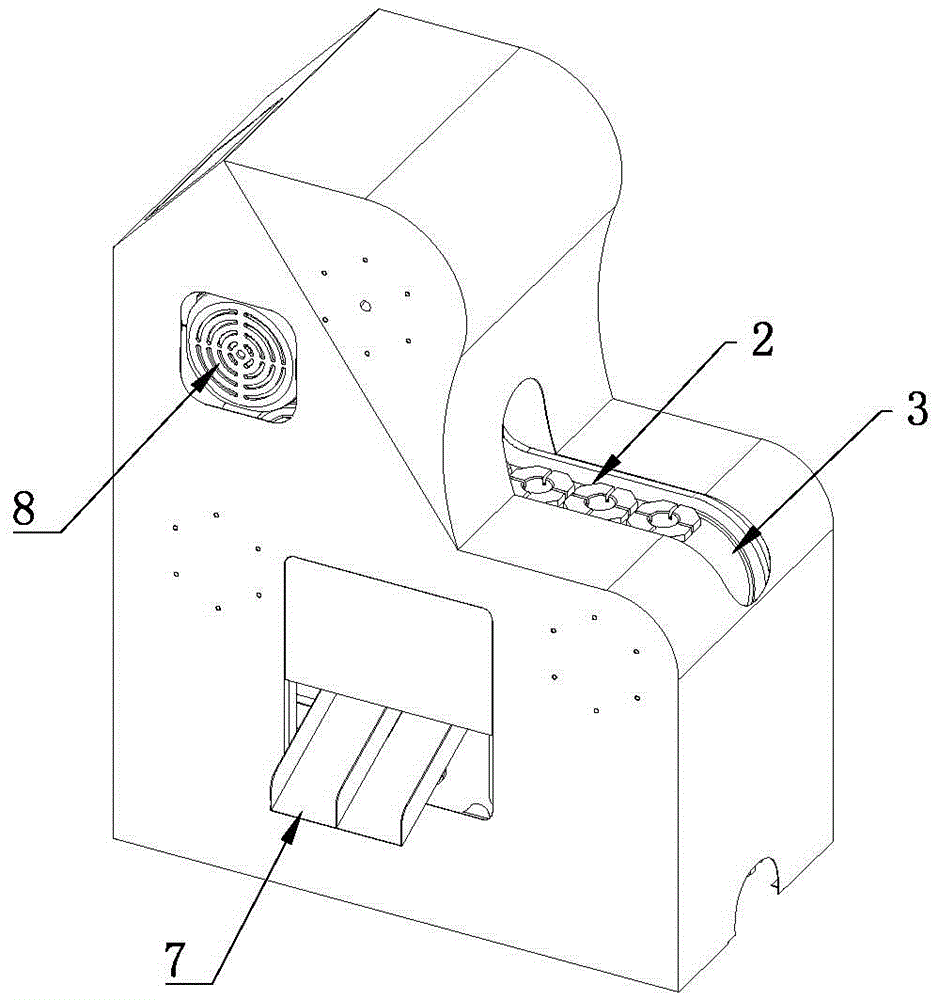

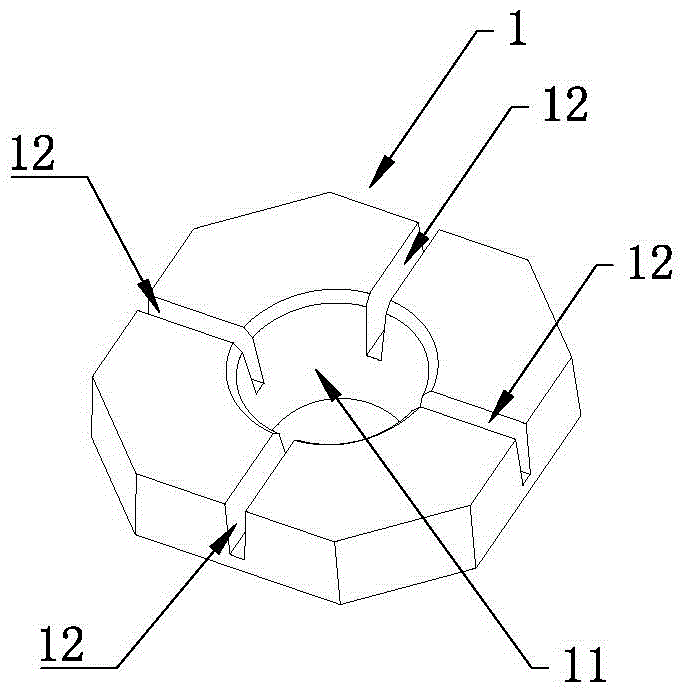

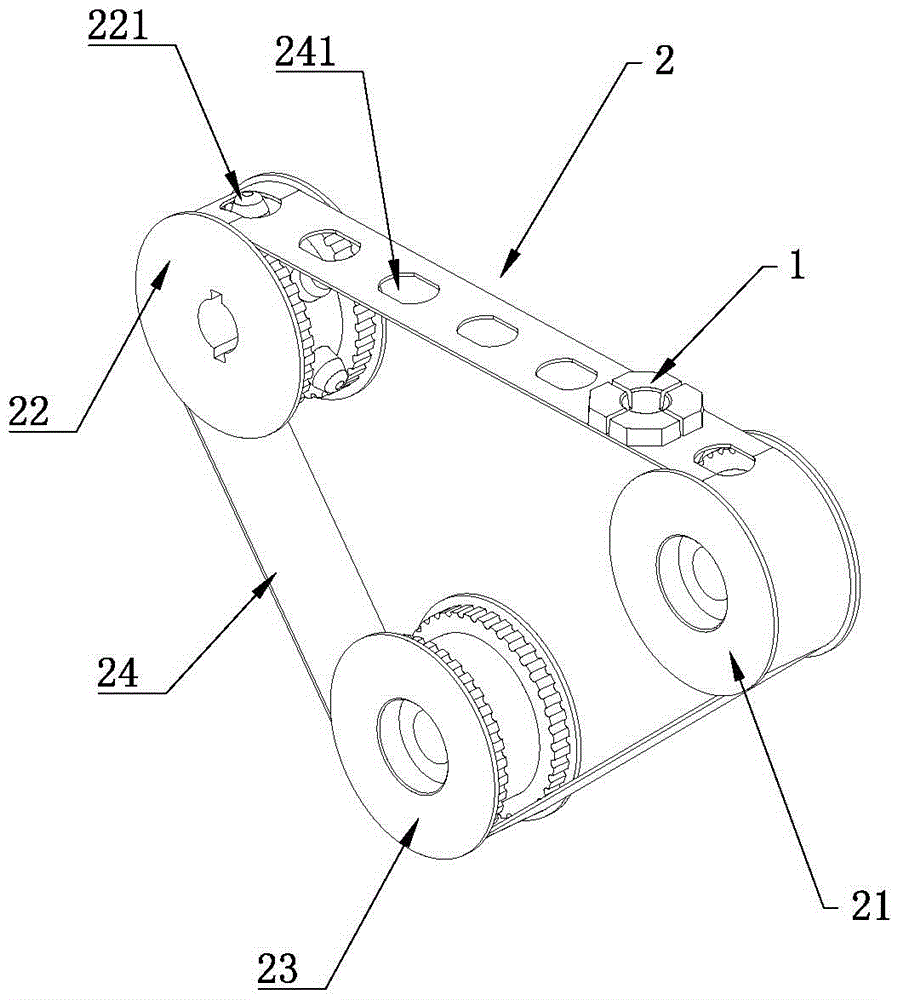

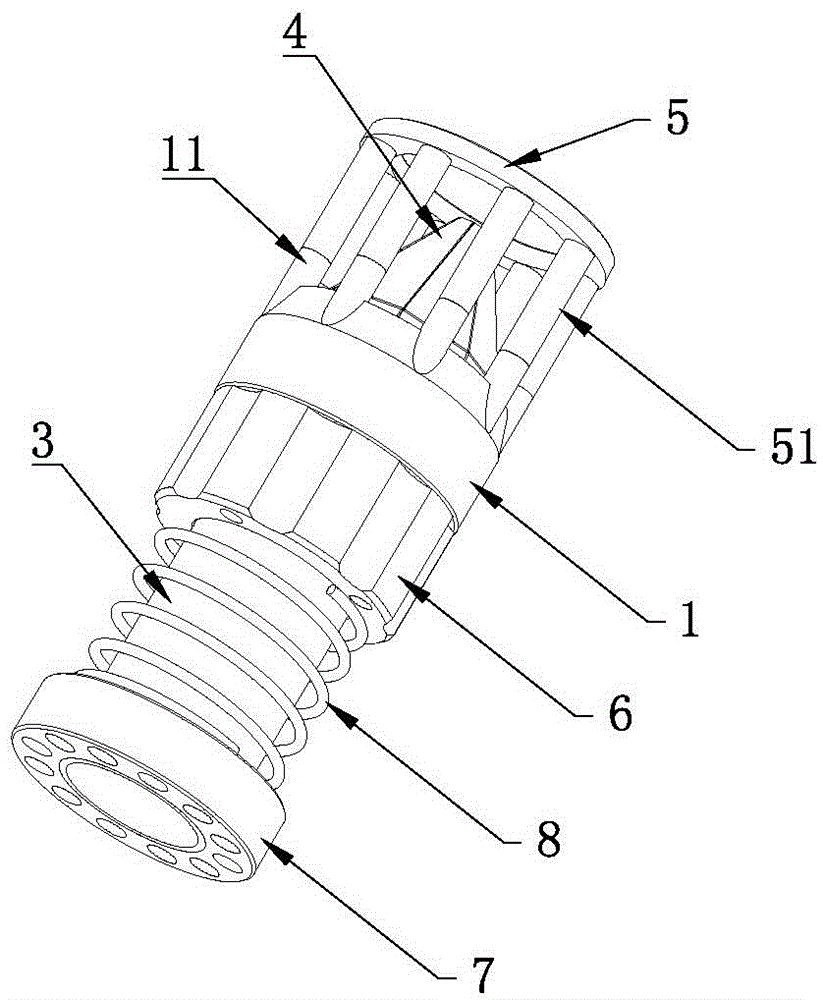

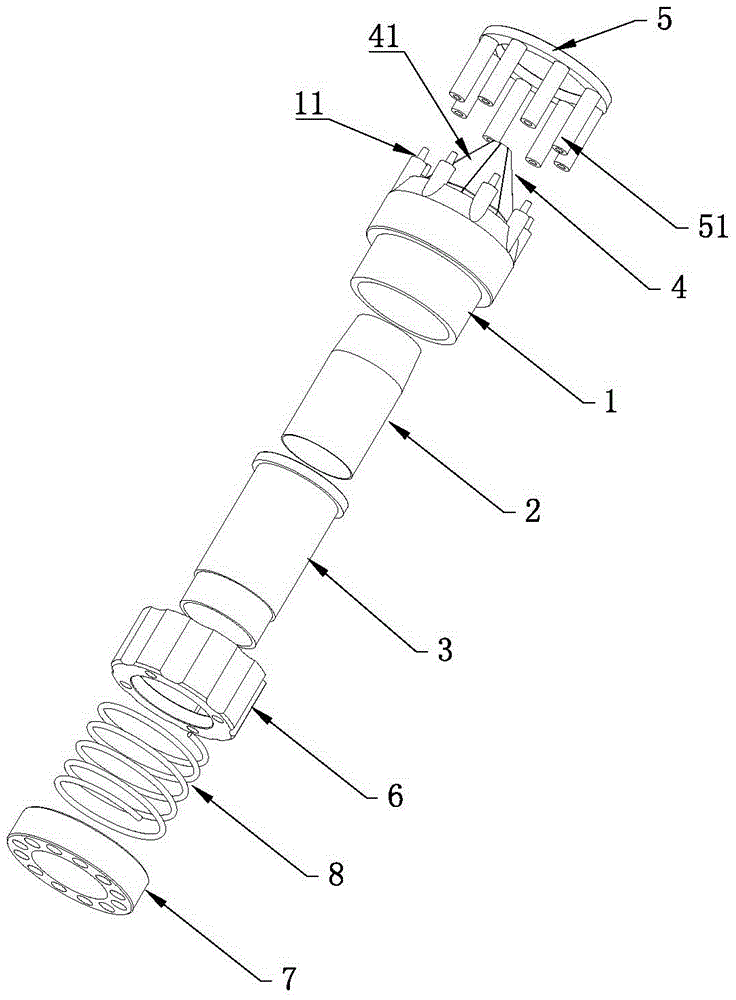

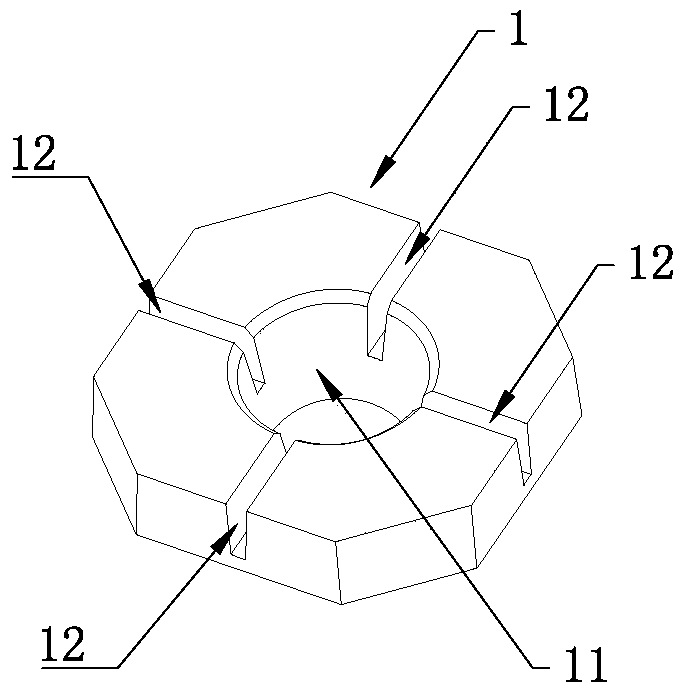

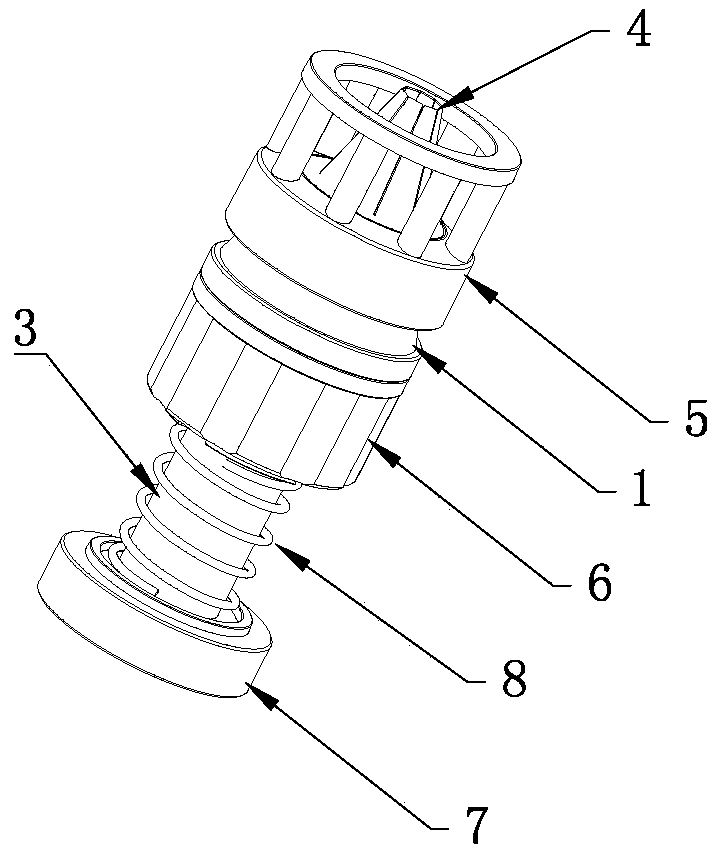

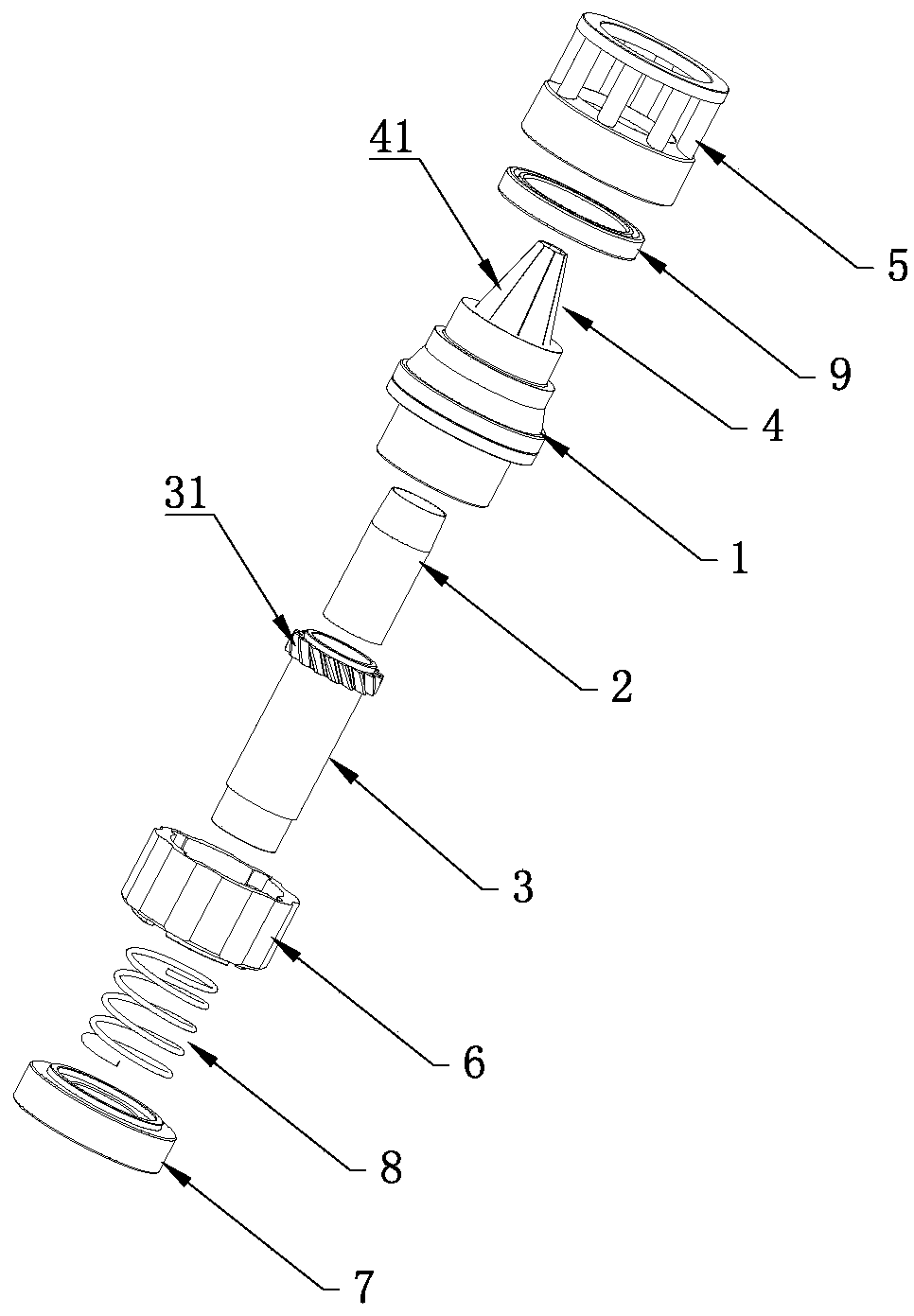

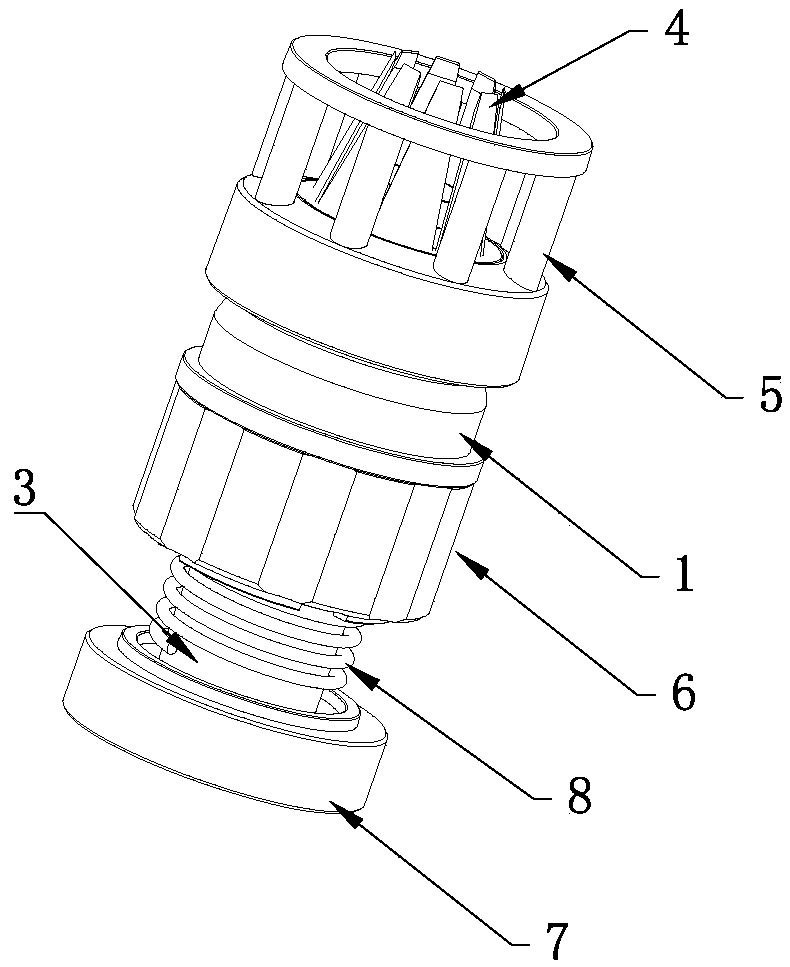

Soft clamp and feeding mechanism special for soft clamp

The invention relates to the technical field of fruit processing equipment, in particular to a soft clamp and a feeding mechanism special for the soft clamp. The soft clamp comprises a clamp body made of soft materials; a through hole used for clamping an article is formed in the middle of the clamp body; a gap hole is formed in the surface of the clamp body and extends to the inner wall of the through hole to communicate with the through hole; and when the clamp body is bent and stretches, the gap hole is opened, so that the opening of the through hole is opened to be in a horn shape. Compared with the prior art, the soft clamp and the feeding mechanism special for the soft clamp are suitable for automatic mechanical equipment for husking, core removing and processing of various fruits; the clamp is simple in structure, easy to process, convenient to operate, capable of ensuring integrity of processed fruit pulp, and low in fruit pulp loss ratio, thereby better meeting the requirement of modern agricultural product deep processing.

Owner:茂名市金皇冠智能科技有限公司

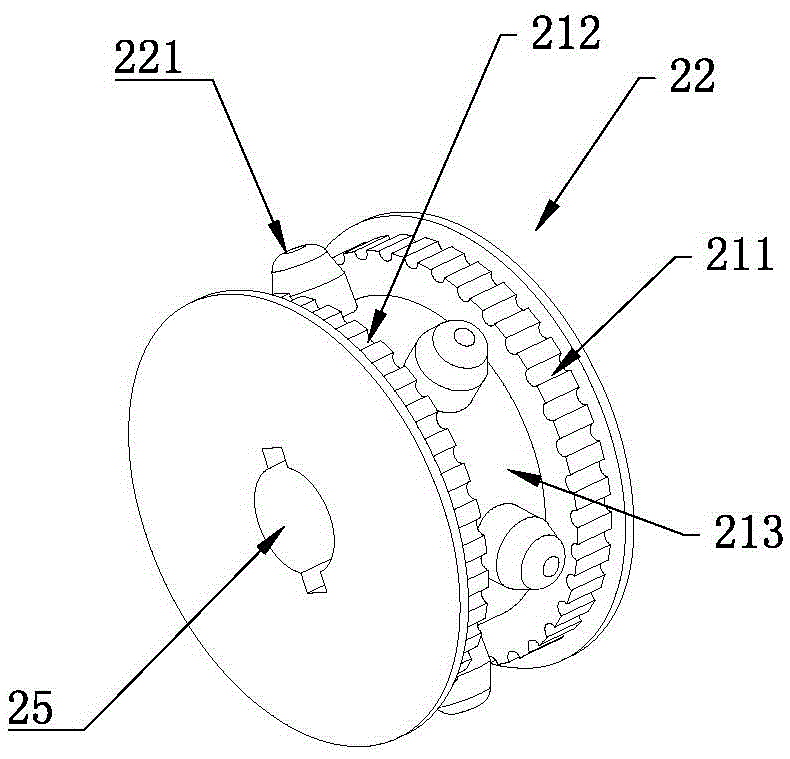

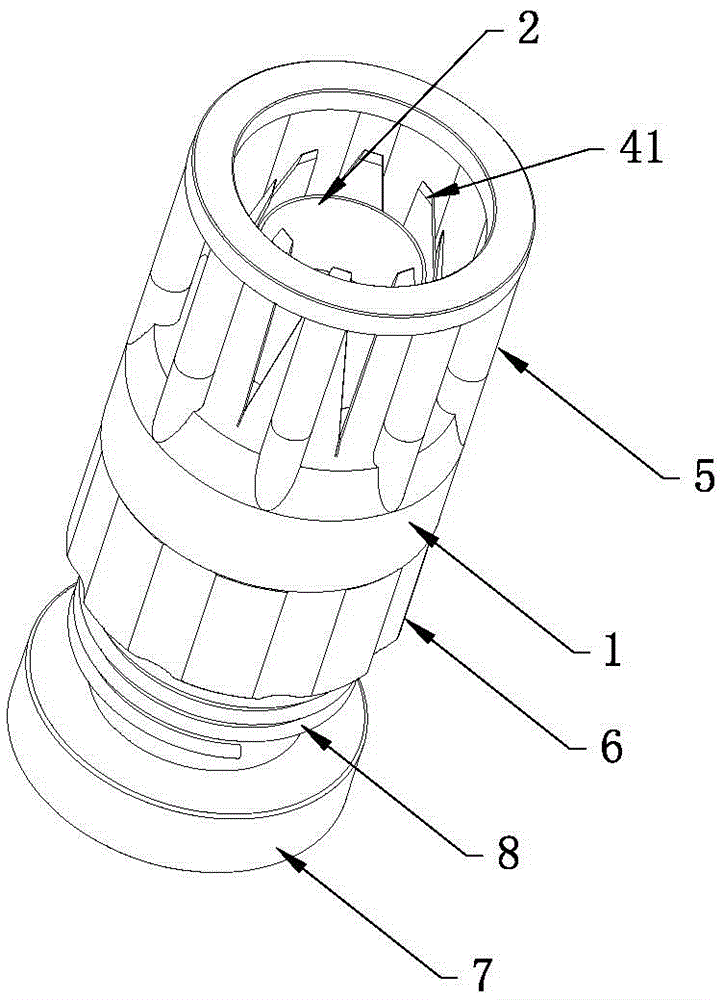

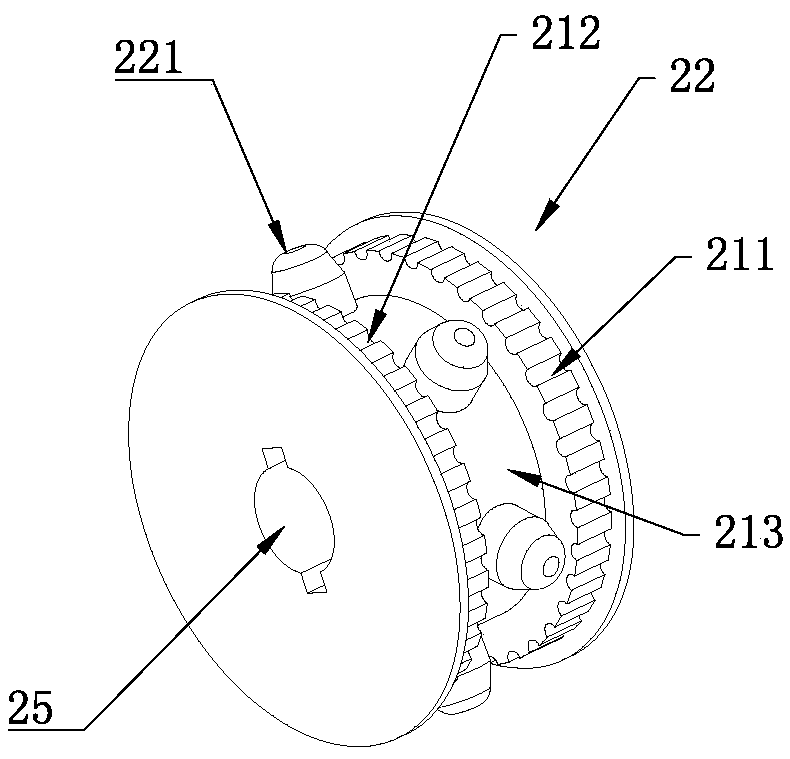

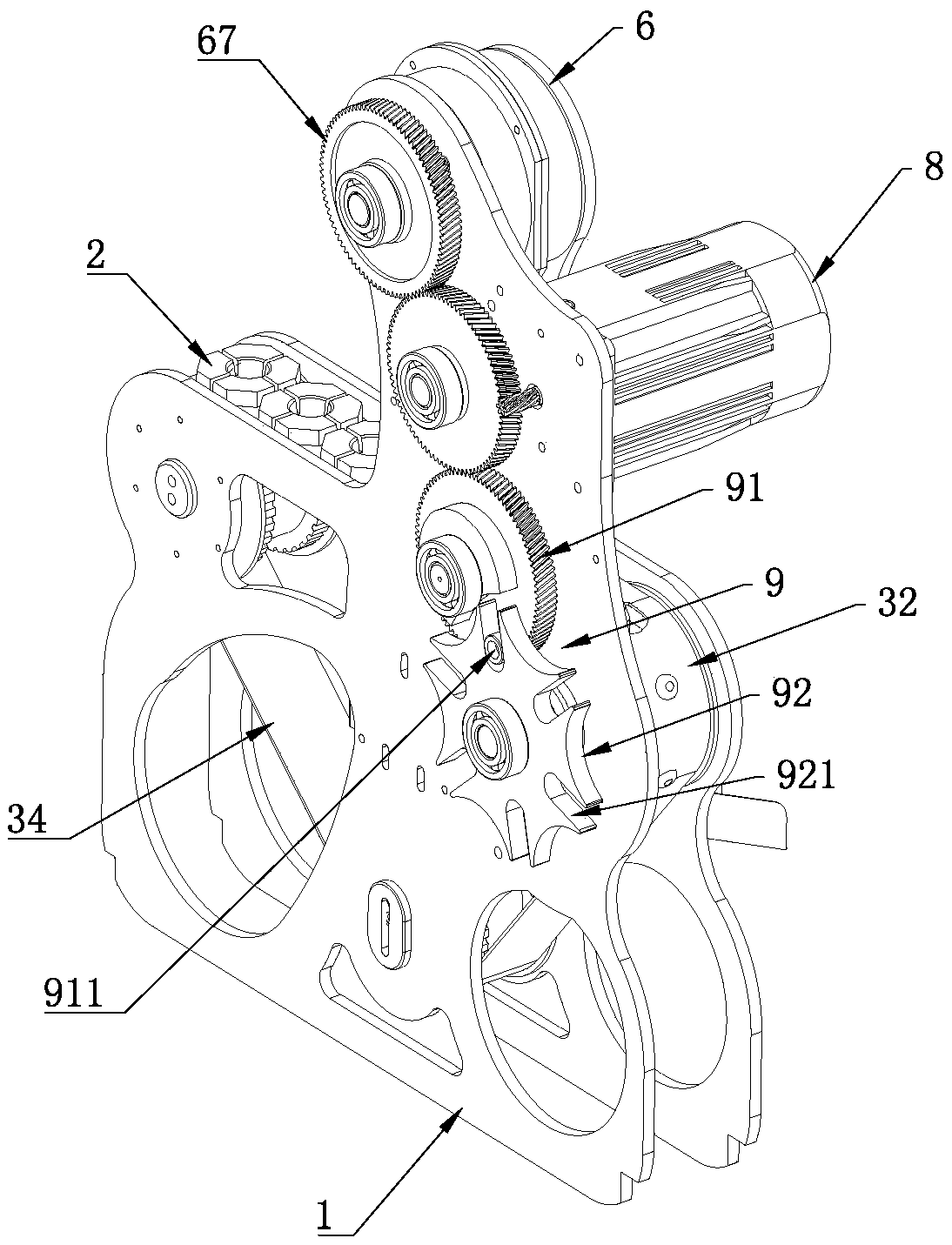

Longan seed removal tool

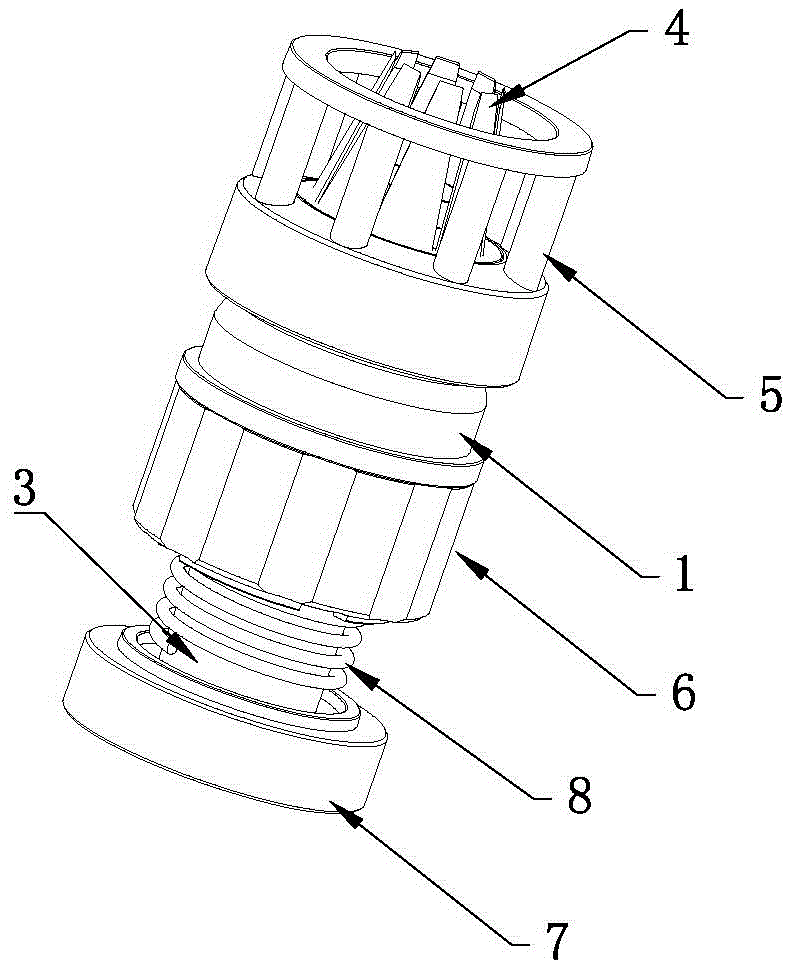

The invention relates to the technical field of food processing equipment, in particular to a longan seed removal tool which structurally comprises a tool rotator, a plurality of blades, a guide wheel and an expander. The blades are arranged on the top of the tool rotator and are spliced with one another along the circumferential direction to form a blade group in the shape of a circular truncated cone by means of enclosing, and the diameter of an opening in the upper end of the blade group in the shape of the circular truncated cone is smaller than that of an opening in the lower end of the blade group; the expander is used for outwardly opening the opening in the upper end of the blade group, the lower end of the expander is fixed to the inner wall of the guide wheel, and the upper end of the expander penetrates the tool rotator and can extends into the blade group in the shape of the circular truncated cone when the tool rotator rotates and moves downwardly relative to the guide wheel, so that the opening in the upper end of the blade group can be opened from the inside to the outside; the tool rotator, the guide wheel and the expander are provided with vertically through cavity structures. Compared with the prior art, the longan seed removal tool has the advantages that longan pulp and seeds can be automatically separated from one another by the aid of the longan seed removal tool, the longan seed removal tool is high in seed removal efficiency and low in pulp loss ratio, and the longan pulp without the seeds is good in integrity.

Owner:茂名市金皇冠智能科技有限公司

Production method and application of low-carbon steel containing boron and titanium, and high-speed wire rods thereof

The invention discloses a production method and an application of low-carbon steel containing boron and titanium, and high-speed wire rods thereof. The low-carbon steel containing boron and titanium contains the main chemical ingredients in percentage by mass: not greater than 0.08% of carbon, not greater than 0.10% of silicon, not greater than 0.60% of manganese, not greater than 0.030% of phosphorus, not greater than 0.035% of sulphur, not less than 0.020% of aluminium, 0.0040-0.0080% of boron, not less than 0.060% of titanium, and the balance Fe and other inevitable impurities. The specific production method is that low-carbon steel billets containing boron and titanium are charged into a furnace and subjected to heating operation, a finish rolling temperature is 940+ / -10 DEG C, a spinning temperature is 910+ / -10 DEG C, and a slow cooling process is adopted for a cooling process for the wire rods. The tensile strengths of the high-speed wire rods made from the low-carbon steel containing boron and titanium are reduced to 360-380MPa, and the mechanical property of the low-carbon steel is close to the level of about 350MPa of the mechanical property of common low-carbon steel, thus the problem of low cold upsetting and wire-drawing use performance of the low-carbon steel after boron element and titanium element are added is solved, and the deep processing requirements of the wire rods are met.

Owner:XINGTAI IRON & STEEL

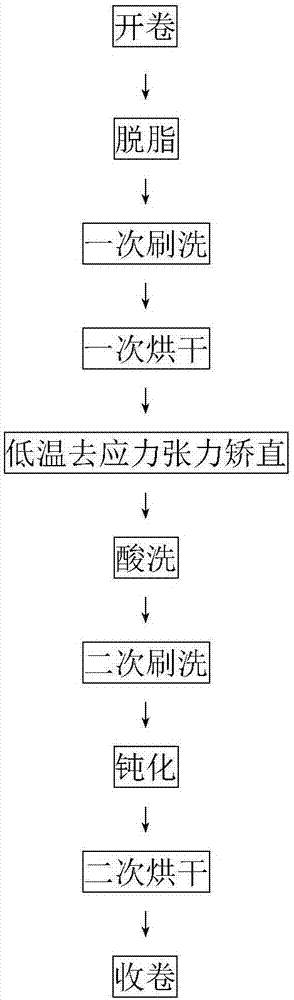

Low-temperature stress relieving and tension straightening process of copper alloy plate and strip foils

InactiveCN107988570AEliminate residual internal stressMeet the requirements of deep processingFurnace typesHeat treatment furnacesEtchingStress relieving

The invention relates to a low-temperature stress relieving and tension straightening process of copper alloy plate and strip foils. The process comprises the steps of uncoiling, degreasing, scrubbingfor the first time, drying for the first time, performing low-temperature stress relief and tension straightening, pickling, scrubbing for the second time, passivating, drying for the second time andcoiling. According to the low-temperature stress relieving and tension straightening process, expanded stress relief annealing is adopted, so that partial residual internal stress of materials is eliminated, the deep processing requirements of copper alloy materials are satisfied, and especially, the requirements of etching and half etching of high-end frame materials are preferably satisfied; high-tension straightening is adopted at low temperature, so that the plate shapes of the copper plate and strip foils are improved, and slight bad plate shapes such as edge waves and the like before annealing are eliminated; the materials are still kept at an original state after stress relief annealing, and additionally, the plasticity and the electrical performance of the materials are improved;copper strip expanded through type annealing is adopted, so that the phenomenon of nonuniformity in annealing is avoided; and the requirement on the internal stress of deep processing of the domesticcopper alloy plate and strip foils is satisfied at present, and especially for the requirement of half etching of the high-end frame materials, copper plates after etching do not warp or distort.

Owner:中铝洛阳铜加工有限公司

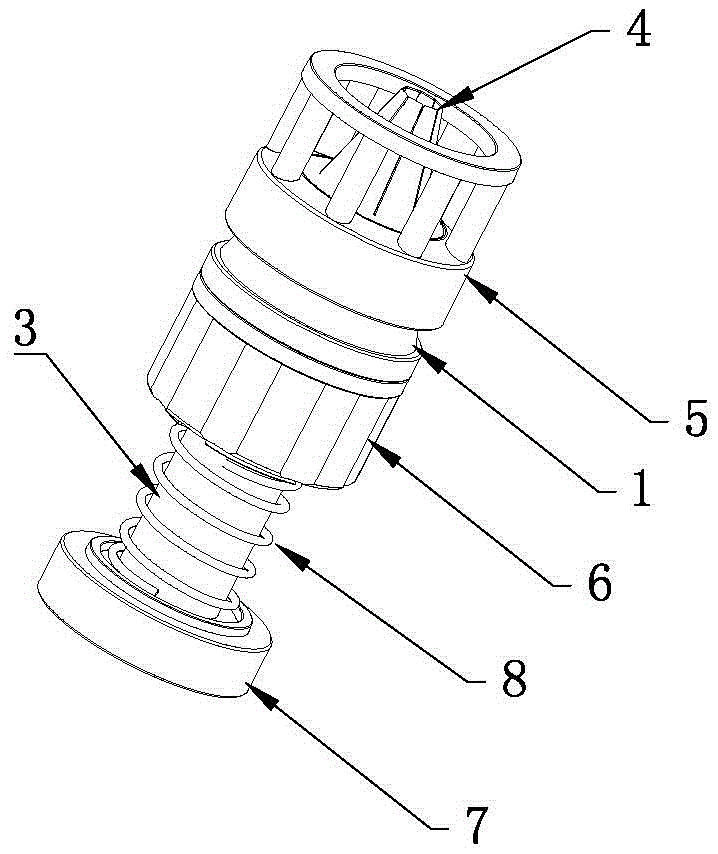

Longan pulp removal tool

ActiveCN106072682AEasy to operateAchieve separationFruit stoningHuskingPulp and paper industryKnife blades

The invention relates to the technical field of food processing equipment, in particular to a longan pulp removal tool which structurally comprises a blade mounting seat, a plurality of blades, a guide wheel and an expander. The blades are arranged on the top of the blade mounting seat, and the blade mounting seat sleeves the guide wheel and can move up and down relative to the guide wheel; the blades are spliced with one another along the circumferential direction to form a blade group in the shape of a circular truncated cone by means of enclosing, and the diameter of an opening in the upper end of the blade group in the shape of the circular truncated cone is smaller than that of an opening in the lower end of the blade group; the expander is used for outwardly opening the opening in the upper end of the blade group, the blade mounting seat, the guide wheel and the expander are provided with vertically through cavity structures, and the upper end of the expander can extend into the blade group in the shape of the circular truncated cone when the blade mounting seat moves downwardly relative to the guide wheel, so that the opening in the upper end of the blade group can be opened from the inside to the outside. Compared with the prior art, the longan pulp removal tool has the advantages that longan pulp and shells can be automatically separated from one another by the aid of the longan pulp removal tool, the longan pulp removal tool is high in pulp removal efficiency and low in pulp loss ratio, and the longan pulp is good in integrity.

Owner:茂名市金皇冠智能科技有限公司

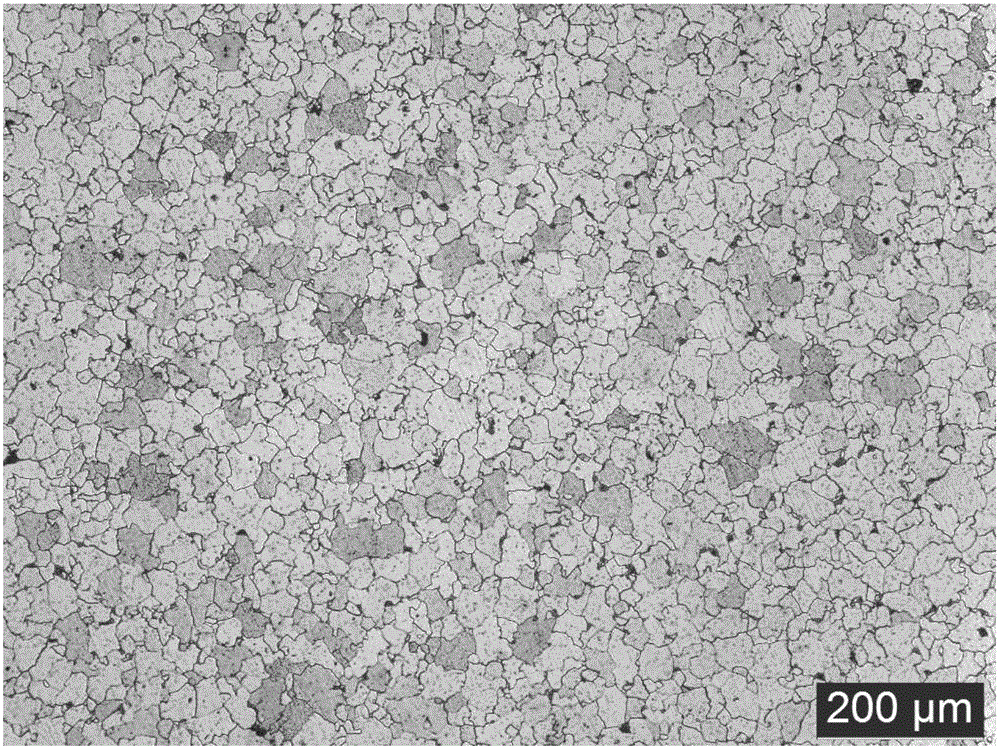

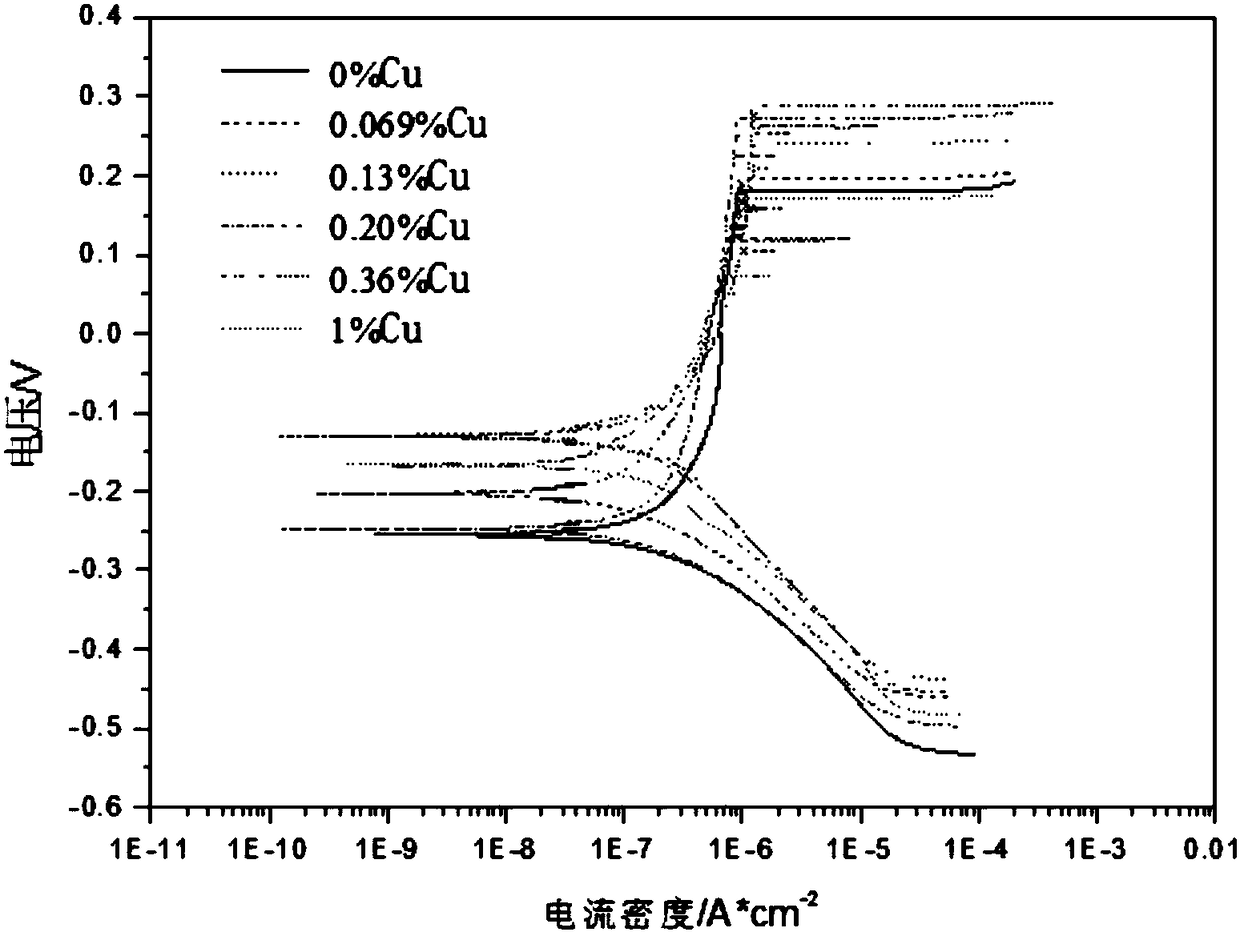

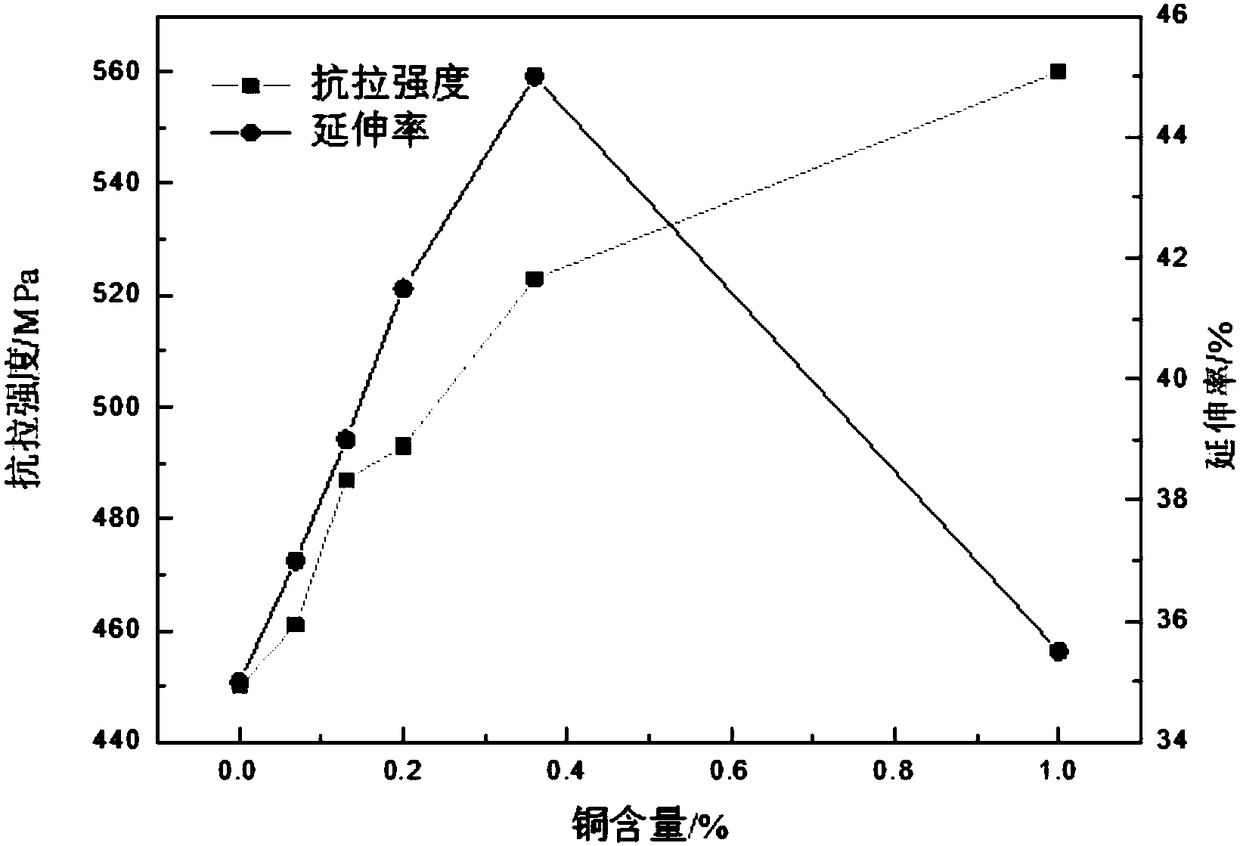

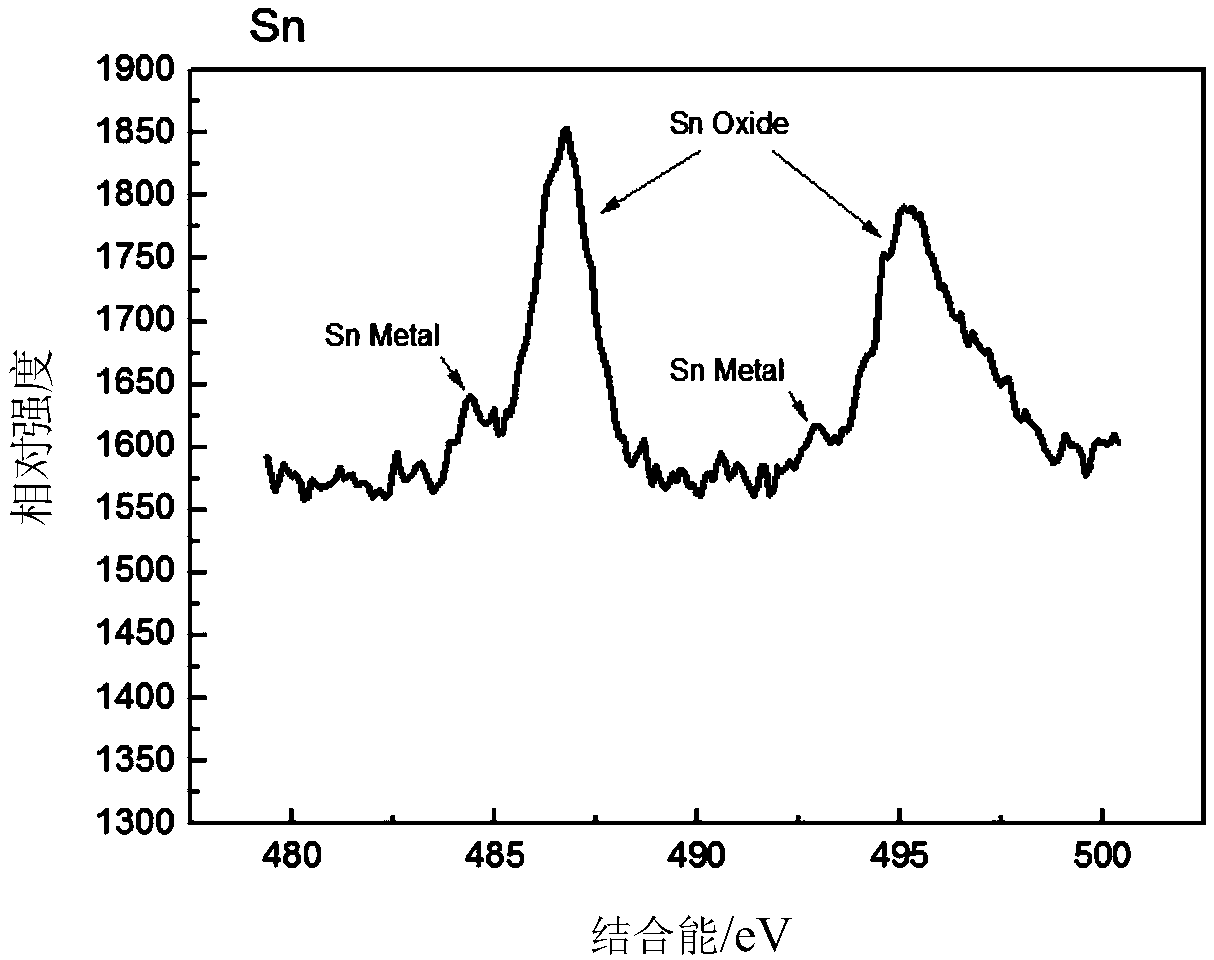

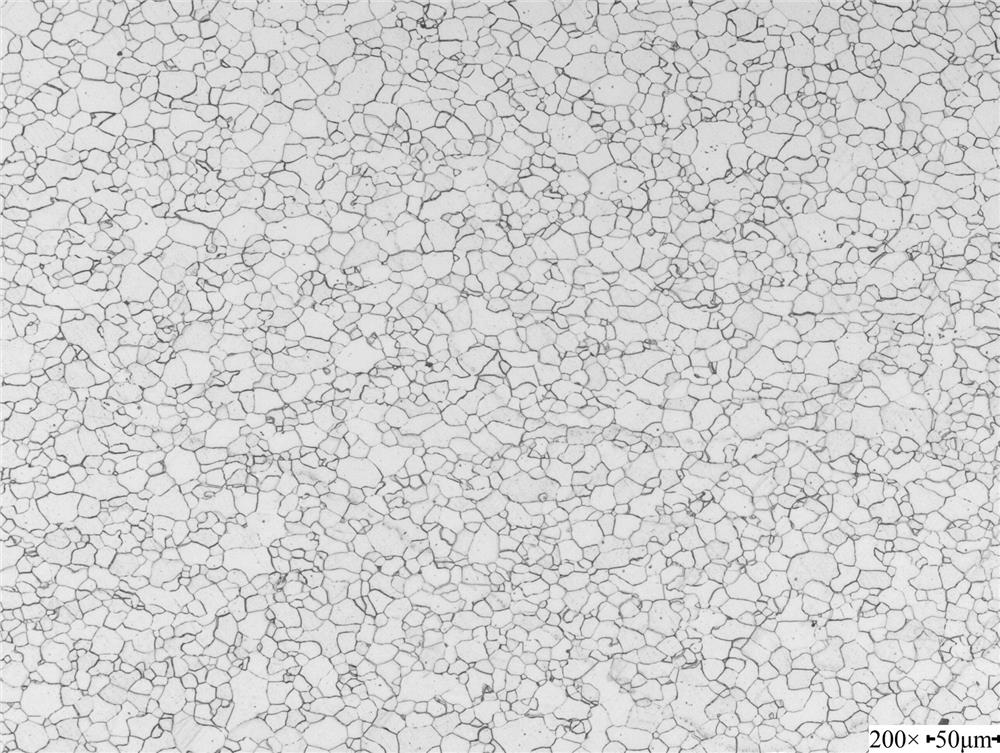

Ultra-pure ferrite stainless steel containing synergistic tin and copper and preparation method of ultra-pure ferrite stainless steel

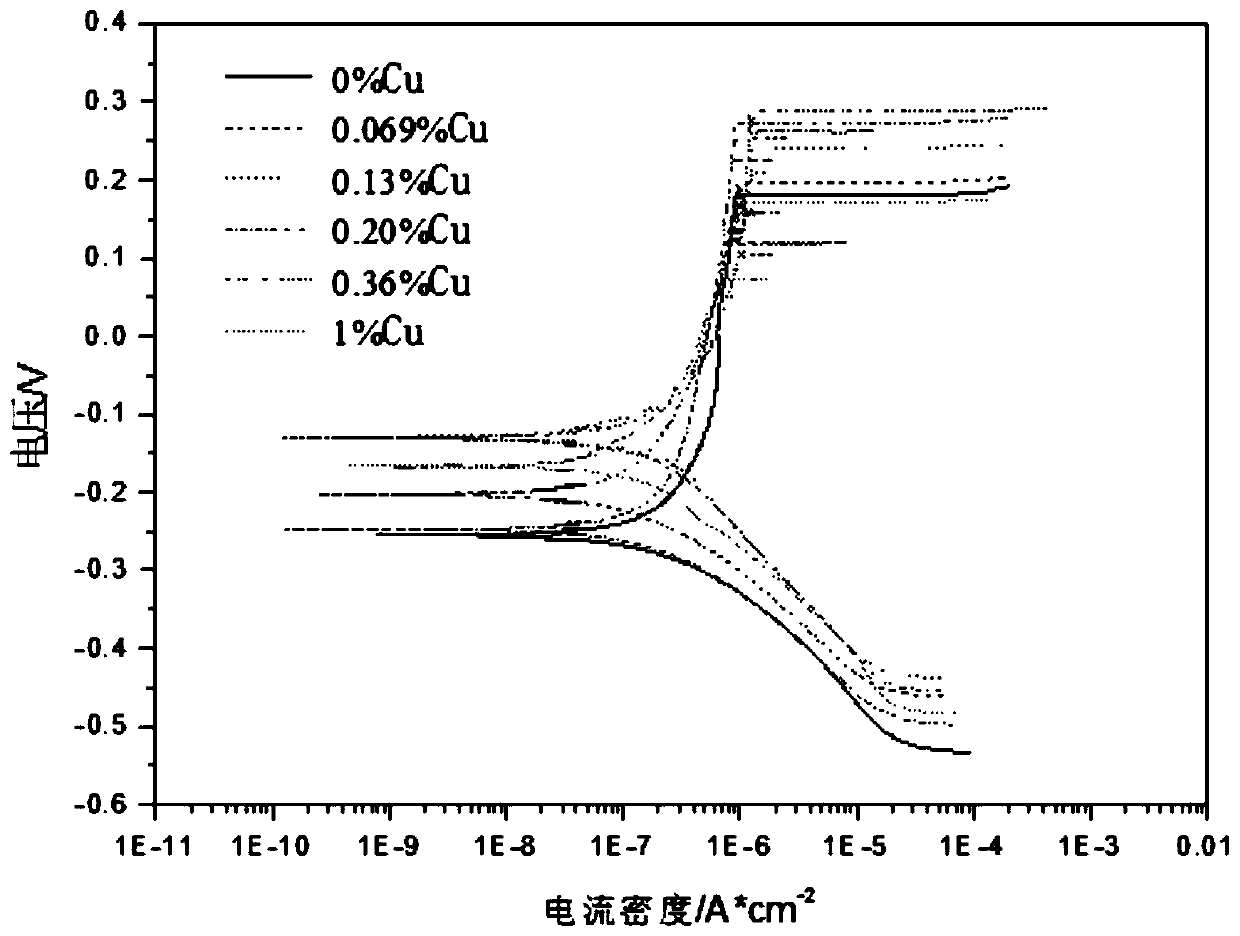

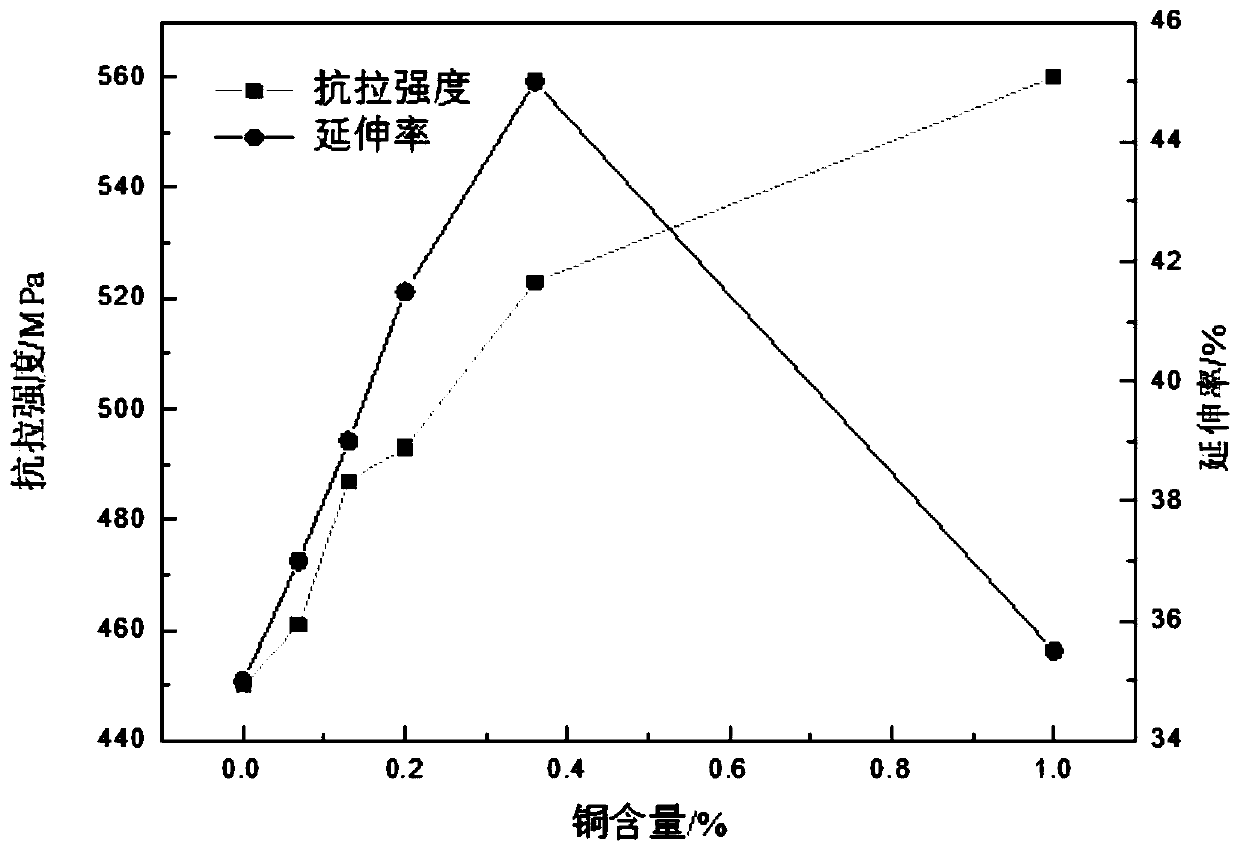

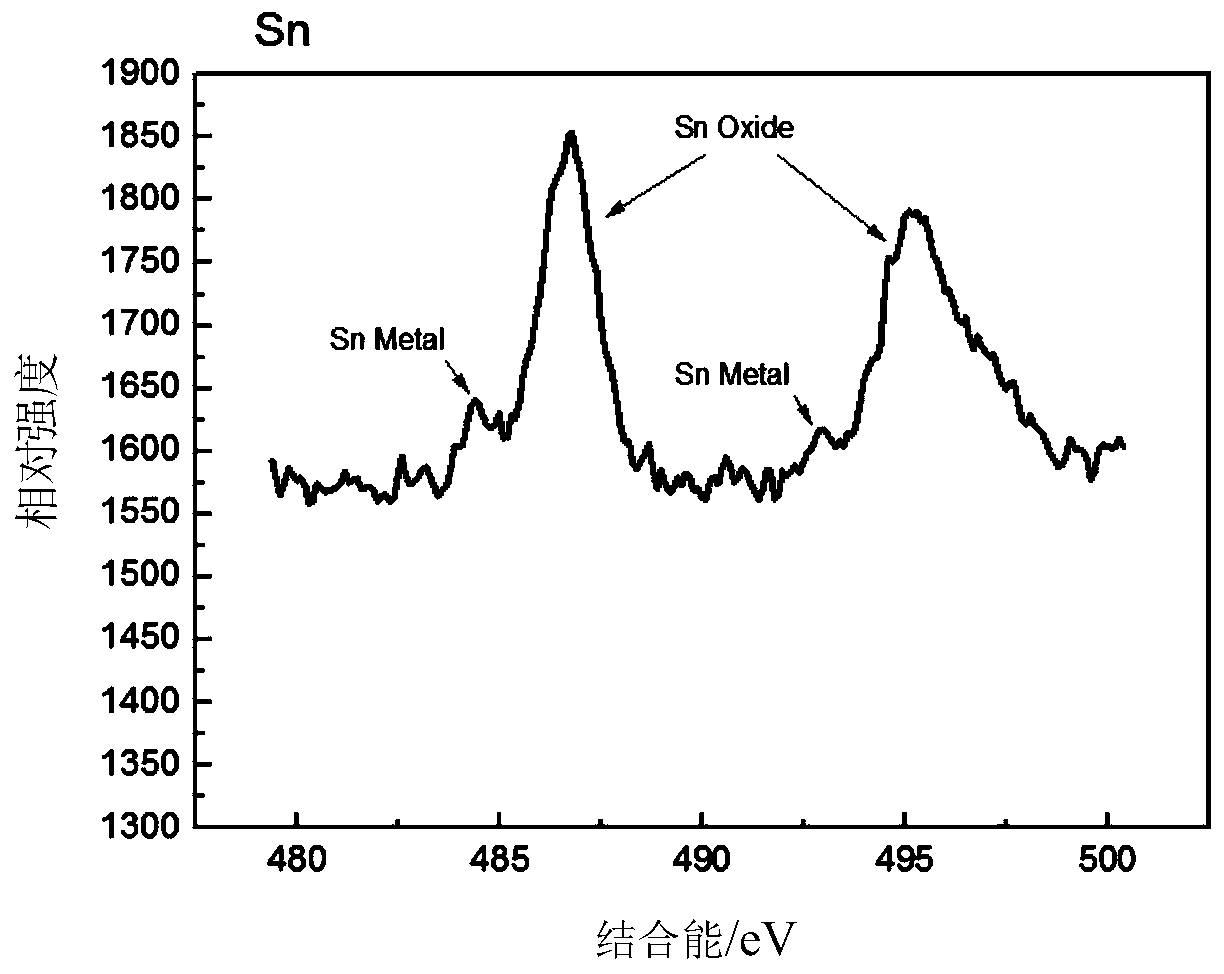

The invention relates to ultra-pure ferrite stainless steel containing synergistic tin and copper and a preparation method of the ultra-pure ferrite stainless steel. The ultra-pure ferrite stainless steel comprises the following components in percentage by mass: not greater than 0.005% of C, 0.2% to 0.4% of Si, 0.2% to 0.4% of Mn, smaller than or equal to 0.005% of P, smaller than or equal to 0.005% of S, 16% to 18% of Cr, smaller than or equal to 0.003% of N, 0.095% to 0.15% of Sn, 0.05% to 1% of Cu and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: (1) smelting according to set components and casting an ingot blank; (2) heating to the temperature of 1100+ / -10 DEG C, maintaining the temperature for 1-2 hours, and subsequently performinghot rolling to form a hot-rolled steel plate; and (3) performing thermal treatment, water cooling, heat maintaining and air cooling to obtain the ultra-pure ferrite stainless steel containing synergistic tin and copper. The method provided by the invention improves the mechanical properties and the corrosion resistance of the ferrite stainless steel on the basis of production cost reduction of theferrite stainless steel, the tensile strength of the ferrite stainless steel is as high as 450-560 MPa, the percentage elongation of the ferrite stainless steel is 30% t0 45%, and the pitting potential of the ferrite stainless steel is 200-285 mV.

Owner:NORTHEASTERN UNIV

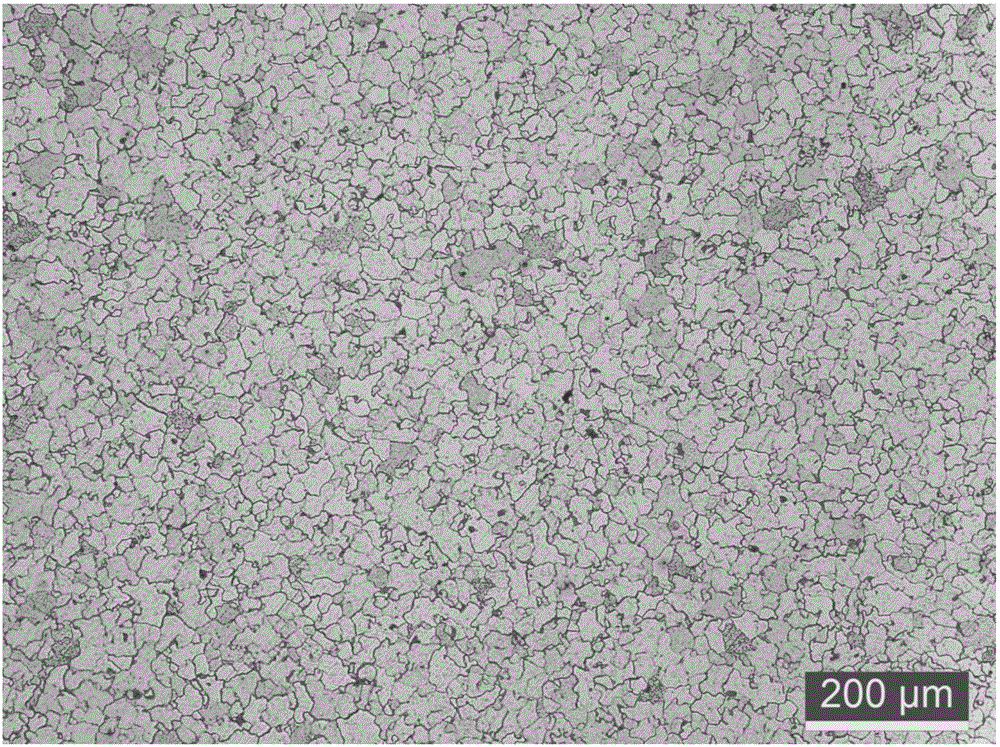

Method for eliminating rapid tensile strain marks of cold-rolled sheet for stamping

ActiveCN113667895AMeet the requirements of deep processingGuaranteed Chemical CompositionManufacturing convertersSteelmakingTensile strain

The invention provides a method for eliminating rapid tensile strain marks of a cold-rolled sheet for stamping, which comprises the following steps of: steelmaking: smelting into molten steel by adopting a 150t oxygen top-bottom combined blown converter; RH refining, wherein the RH vacuum treatment time is not shorter than 25 min; continuous casting is conducted, and whole-course protection casting is adopted; the thickness of a continuous casting slab is 210 mm or 230 mm, and the pulling speed of a slab is 0.9-1.1 m / min; hot continuous rolling is carried out, the heating temperature of the slab is 1200-1230 DEG C, the finish rolling temperature is 890-910 DEG C, and the coiling temperature is 680-700 DEG C; the cold rolling production process comprises the following steps: continuous rolling is conducted by 5 racks, wherein the cold rolling reduction rate is 80-87%; a continuous annealing production process is carried out: the temperature of a heating section is 820 + / -5 DEG C, the temperature of a soaking section is 820 + / -5 DEG C, the temperature of a slow cooling section is 660 + / -10 DEG C, the temperature of a rapid cooling section is 420 + / -10 DEG C, the temperature of an overaging section is 400 + / -10 DEG C, the time of the overaging section is not less than 200 s, and the flattening elongation is 0.8-1.6%; and the metallographic structure of a cold-rolled sheet DC03 for stamping is ferrite and cementite. By means of the method, the cold-rolled sheet DC03 for stamping can be produced from ultra-low carbon steel components, and the method is simple in operation process, stable in product performance and good in stamping machining performance.

Owner:安钢集团冷轧有限责任公司 +1

Matcha and barley green juice solid beverage and preparation method thereof

InactiveCN108185046APromote peristalsisAvoid healthPre-extraction tea treatmentAcute hyperglycaemiaAlcohol

The invention discloses a matcha and barley green juice solid beverage and a preparation method thereof. The solid beverage is prepared from the following raw materials in parts by weight: 30-60 partsof matcha powder and 40-70 parts of barley green juice powder. The preparation method comprises the following steps: step 1, preparing the matcha powder; step 2, preparing the barley green juice powder; and step 3, mixing the matcha powder with the barley green juice powder, packaging the mixture in different bags, and performing sterilization to obtain finished products. The solid beverage disclosed by the invention overcomes the problem of poor taste of the barley green juice, conforms to the taste of consumers, promotes the peristalsis of the intestinal tracts, removes the endotoxins of the intestinal tracts, is favorable for the health of the digestive system, also has the effects of reducing hypertension, hyperglycemia and hyperlipidemia, delaying senescence, enhancing immunity, dispelling the effects of alcohol, reducing fat and the like, is simple and reasonable in process route design, and is suitable for large-scale production.

Owner:西安凯伦生物科技有限公司

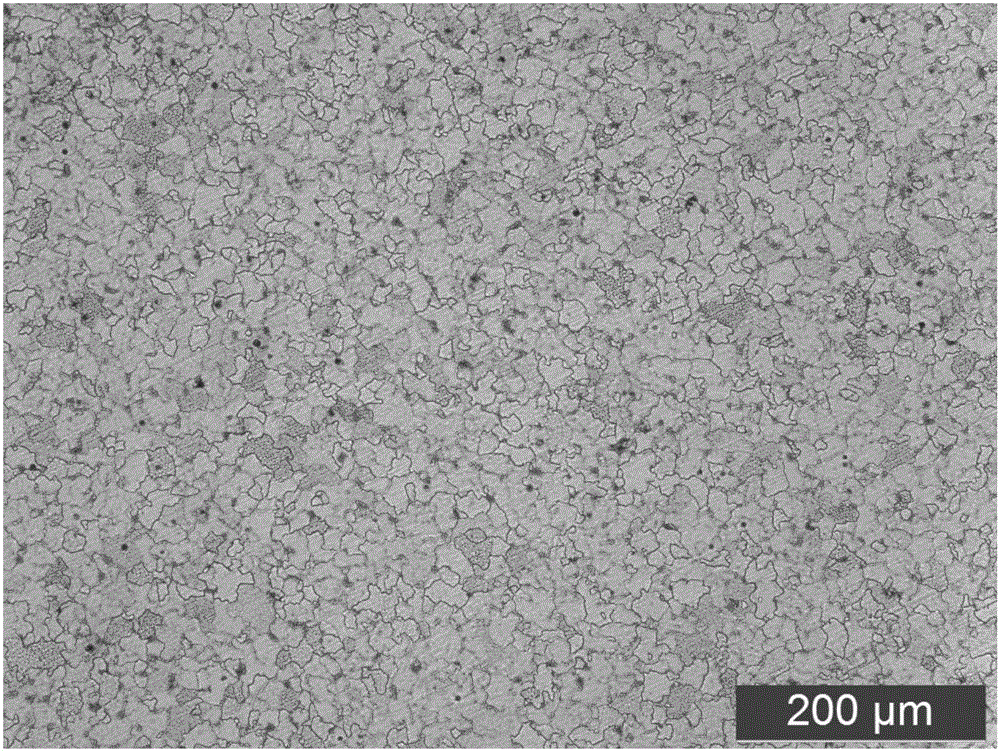

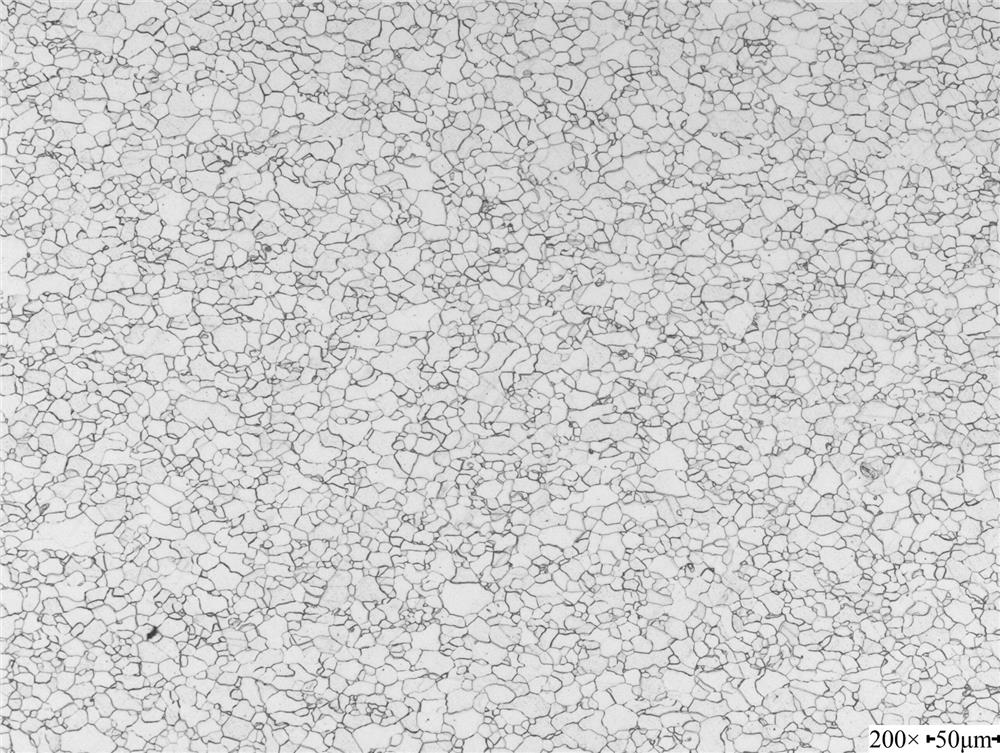

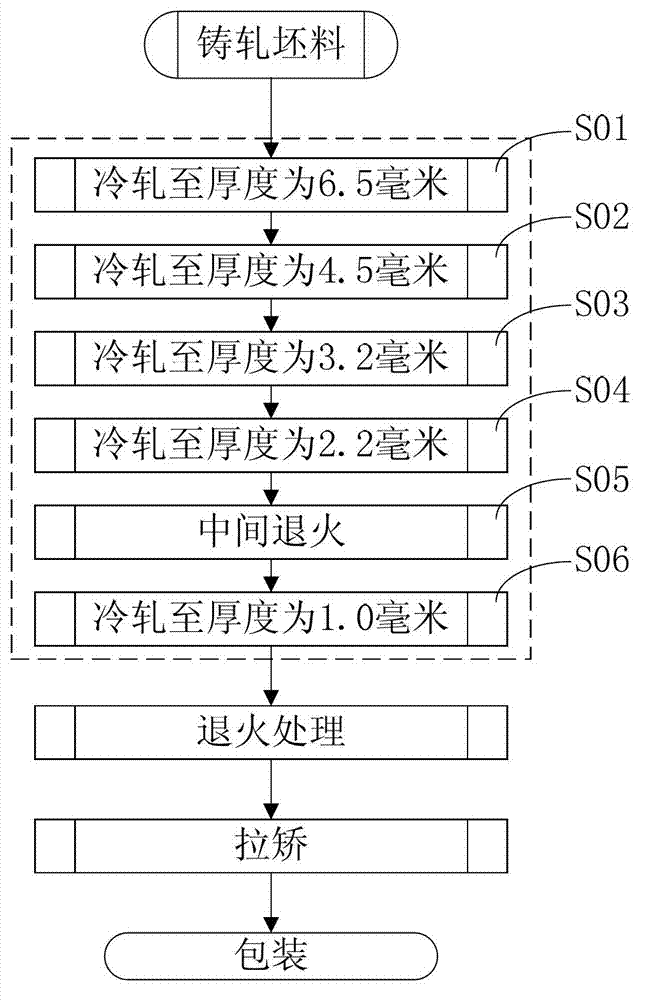

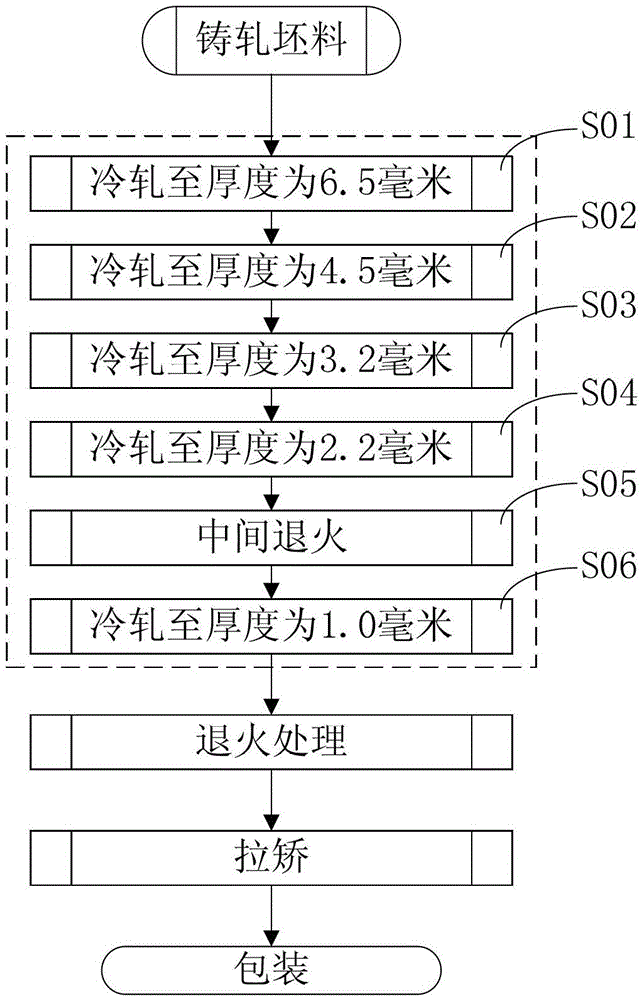

Manufacturing method for ceiling aluminum base material

ActiveCN103045973AMeet the requirements of deep processingUniform grain structureGrain structureMachining

The invention discloses a manufacturing method for a ceiling aluminum base material. A cast-rolled strip blank is coldly rolled, annealed, withdrawn and straightened as well as packaged in sequence, wherein in the cold rolling treatment process, the manufacturing method comprises the following steps: first, rolling the cast-rolled strip blank to a thickness of 6.5 mm, 4.5 mm, 3.0 mm and 2.2 mm in sequence; and then carrying out immediate annealing treatment on the 2.2 mm thick cast-rolled strip blank; and finally, rolling the cast-rolled strip blank treated through immediate annealing to a thickness of 1 mm. Experiments verify that a crystal grain structure in a finished product is more uniformr through selecting proper cold rolling pass distribution, a proper immediate annealing thickness and an annealing method, the bending performance of the finished product can satisfy machining requirements and a purpose of manufacturing the aluminum base material satisfying deep machining requirements by using the cast-rolled strip blank is achieved.

Owner:SOUTHWEST ALUMINUM GRP

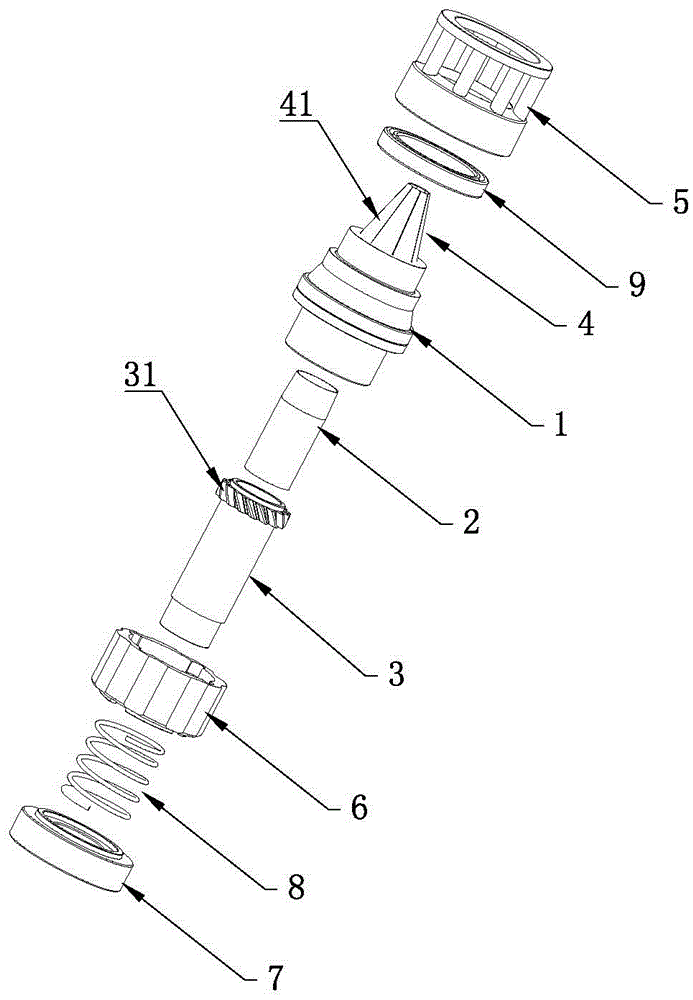

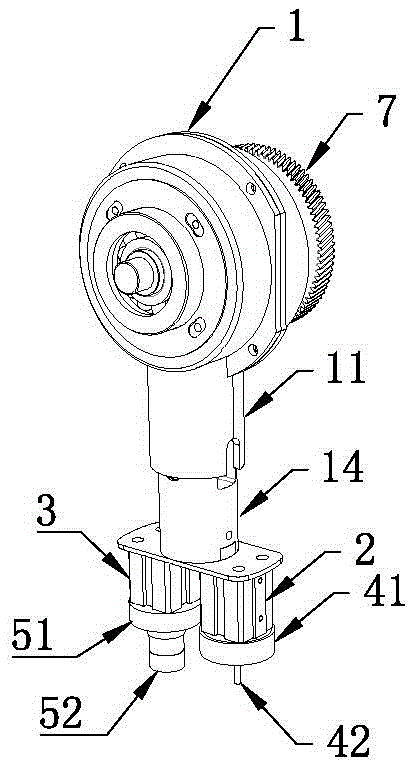

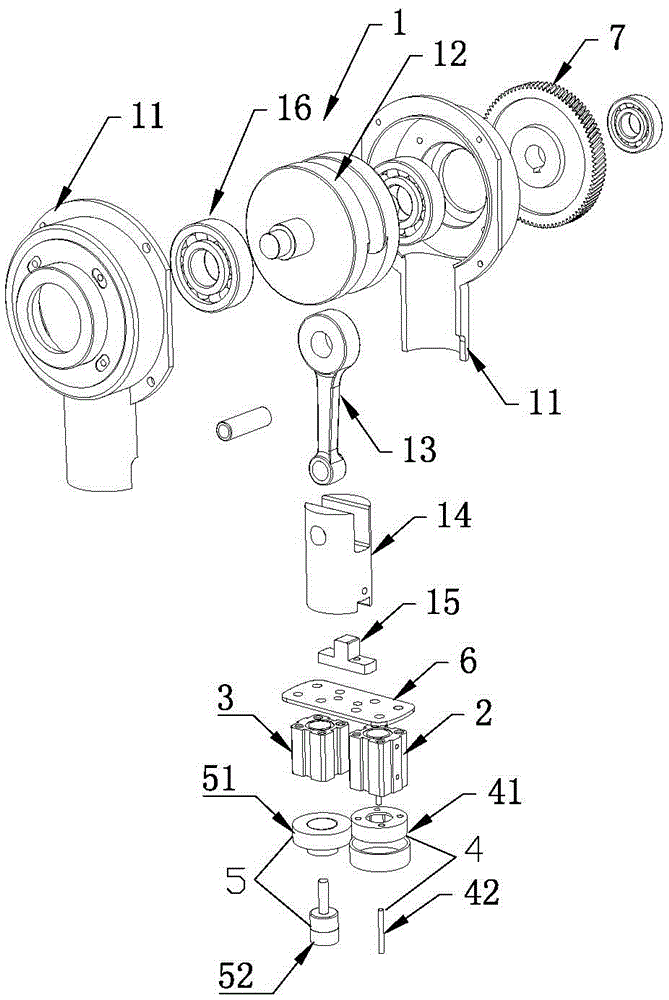

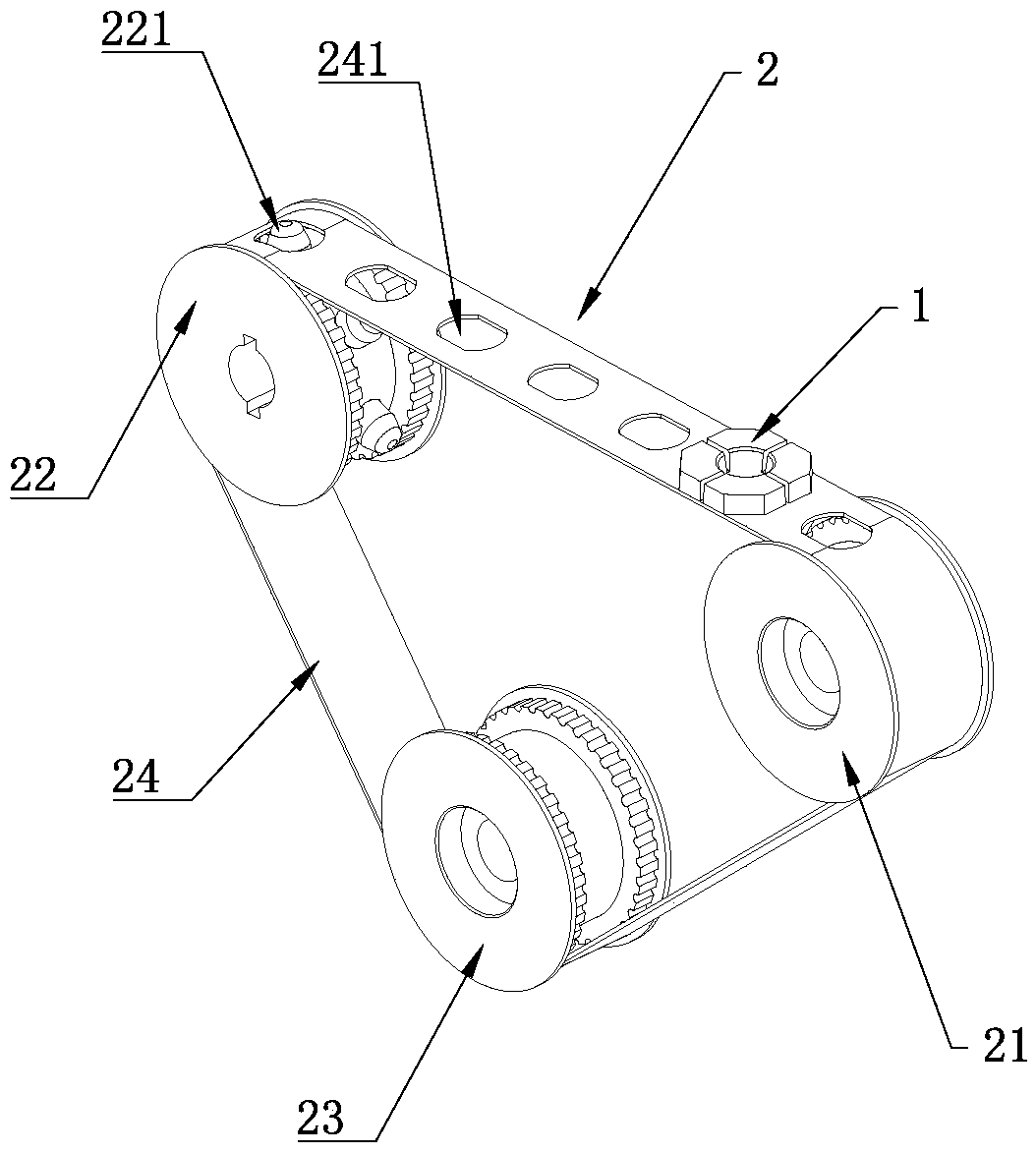

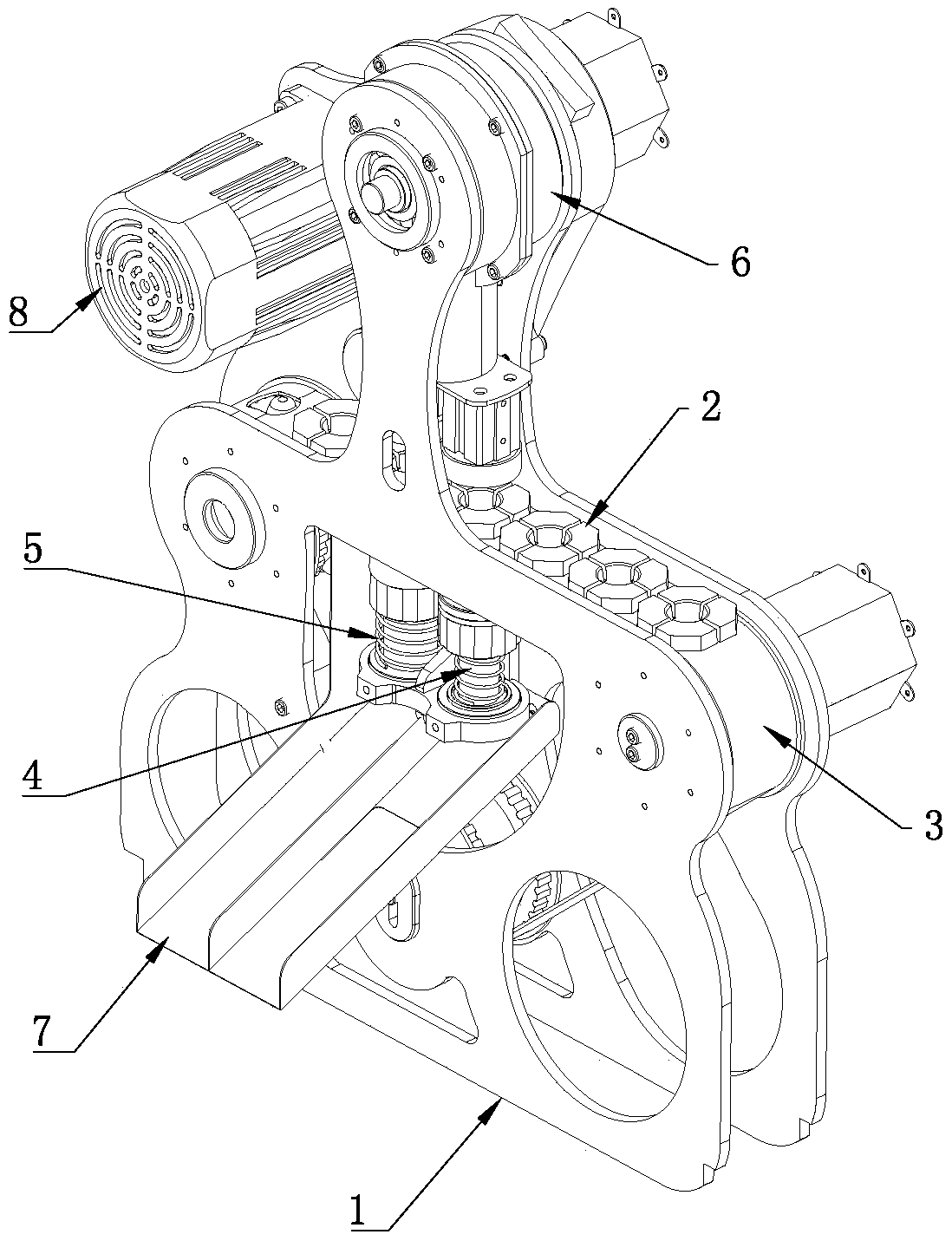

Punch mechanism used for removing longan stones and separating longan pulp and processing method using the punch mechanism to remove longan stones and separate longan pulp

ActiveCN106072695AImprove work efficiencyImprove integrityFruit stoningVegetable peelingCrankshaftFood processing

The invention relates to the technical field of food processing equipment, in particular to a punch mechanism used for removing longan stones and separating longan pulp and a processing method using the punch mechanism to remove the longan stones and separate the longan pulp. The punch mechanism comprises a longan-stone-removing punch for pushing the longan stones out of the longan pulp and a longan-pulp-separating punch for pushing the longan pulp out of longan shells, a longan-stone-removing air cylinder, a longan-pulp-separating air cylinder and a crankshaft connecting rod system driving the longan-stone-removing air cylinder and the longan-pulp-separating air cylinder to reciprocate up and down, wherein the air cylinder rod of the longan-stone-removing air cylinder is connected with the longan-stone-removing punch, and the air cylinder rod of the longan-pulp-separating air cylinder is connected with the longan-pulp-separating punch. Compared with the prior art, the punch mechanism has the advantages that longan stone removing and longan pulp separating can be performed at the same time to obtain pure longan pulp, the punch mechanism is high in work efficiency and capable of continuously processing the pure longan pulp, and the obtain longan pulp is good in integrity; accordingly, the punch mechanism is applicable to mechanical automatic equipment for processing longan pulp, and the deep processing requirements of modern agricultural products can be well satisfied.

Owner:茂名市金皇冠智能科技有限公司

Manufacturing method for ceiling aluminum base material

ActiveCN103045973BMeet the requirements of deep processingUniform grain structureGrain structureMachining

The invention discloses a manufacturing method for a ceiling aluminum base material. A cast-rolled strip blank is coldly rolled, annealed, withdrawn and straightened as well as packaged in sequence, wherein in the cold rolling treatment process, the manufacturing method comprises the following steps: first, rolling the cast-rolled strip blank to a thickness of 6.5 mm, 4.5 mm, 3.0 mm and 2.2 mm in sequence; and then carrying out immediate annealing treatment on the 2.2 mm thick cast-rolled strip blank; and finally, rolling the cast-rolled strip blank treated through immediate annealing to a thickness of 1 mm. Experiments verify that a crystal grain structure in a finished product is more uniformr through selecting proper cold rolling pass distribution, a proper immediate annealing thickness and an annealing method, the bending performance of the finished product can satisfy machining requirements and a purpose of manufacturing the aluminum base material satisfying deep machining requirements by using the cast-rolled strip blank is achieved.

Owner:SOUTHWEST ALUMINUM GRP

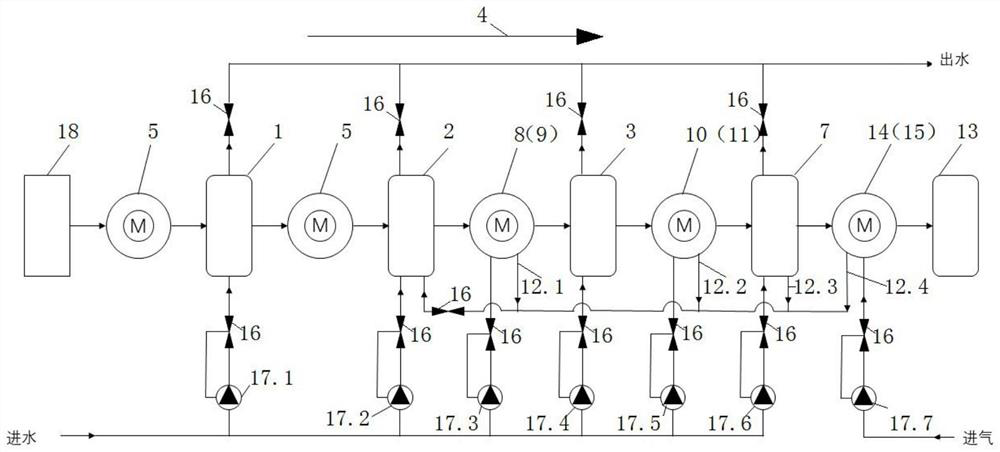

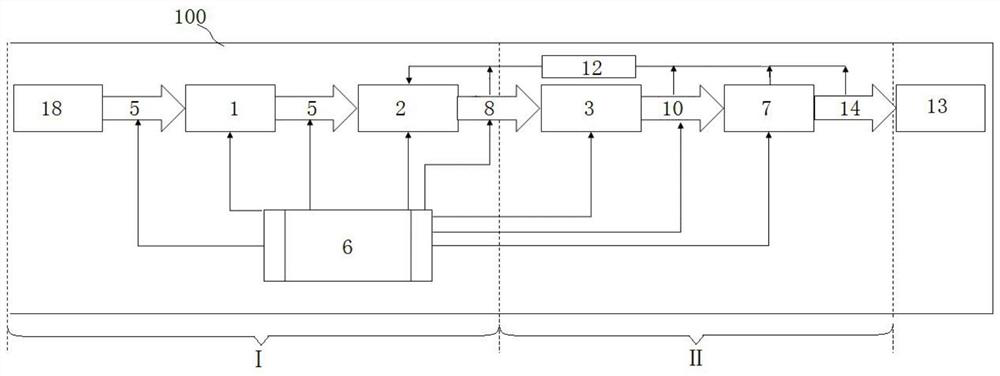

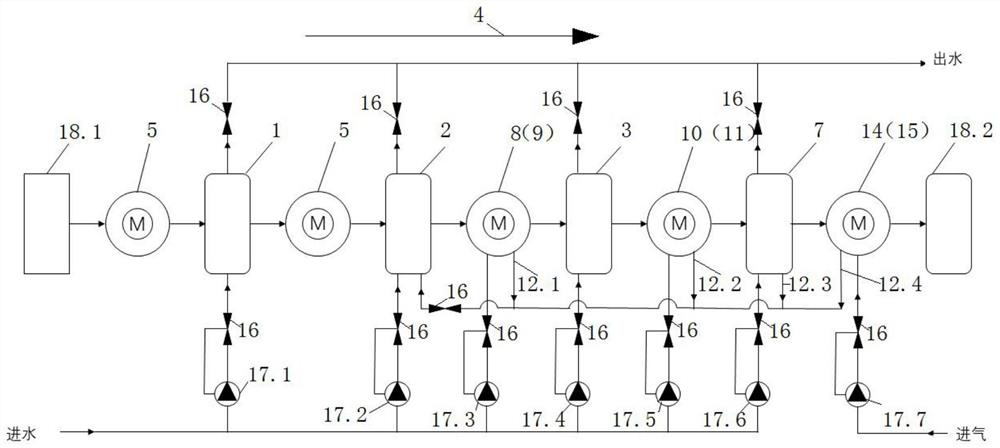

Assembly line equipment and process for cleaning surfaces of insects

PendingCN113600546AImprove cleaning efficiencyImprove cleaning qualityDrying gas arrangementsCleaning using liquidsAutomatic controlControl system

The invention disclose assembly line equipment for cleaning surfaces of insects. The assembly line equipment comprises a cleaning module, a conveying module and an automatic control system, and the cleaning module comprises a first immersion cleaning machine, a vortex cleaning machine and an ultrasonic cleaning machine which are sequentially arranged in the propelling direction of an assembly line; the conveying module is used for sequentially conveying to-be-cleaned insects to the first immersion cleaning machine, the vortex cleaning machine and the ultrasonic cleaning machine; the automatic control system is in communication connection with the cleaning module and the conveying module so that automatic operation of the assembly line equipment can be achieved; and the to-be-cleaned insects are cleaned layer by layer through the mechanical and full-automatic assembly line type equipment, dirt and impurities on the outer surfaces of the insects are thoroughly removed, the subsequent deep processing treatment requirements of the insects are met, the insect cleaning efficiency and quality are improved, and the manpower requirement and the work intensity are reduced. The invention further provides an assembly line process for cleaning the surfaces of the insects, according to the insect surface characteristics, dirt and impurities on the surfaces of the insects can be effectively removed through the insect surface cleaning assembly line cooperating with multiple cleaning modes.

Owner:杭州谷胜科技有限公司

A kind of ultra-pure ferritic stainless steel with tin-copper synergistic effect and preparation method thereof

Owner:NORTHEASTERN UNIV LIAONING

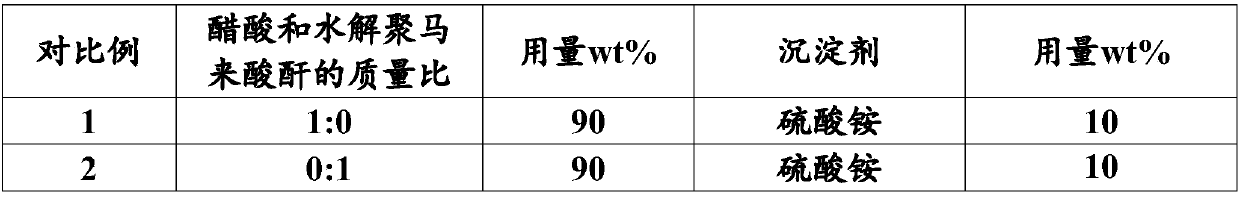

Crude oil decalcifying agent and preparation method and application thereof

InactiveCN110964556AMeet the requirements of deep processingRapid responseRefining with metal saltsDemulsifierDesalination

The invention provides a crude oil decalcifying agent and a preparation method and application thereof. The crude oil decalcifying agent enables decalcified crude oil to meet the requirement of deep processing of crude oil. The crude oil decalcifying agent has the advantages of a chelating type decalcifying agent and a precipitation type decalcifying agent, calcium is firstly removed and dissolvedin a water phase from an oil phase by virtue of a chelating mechanism, then slightly soluble or indissolvable calcium salt is formed by virtue of a precipitation mechanism, and the slightly soluble or indissolvable calcium salt can be discharged along with desalted sewage under the action of a high-voltage electric field and a demulsifying agent. The crude oil decalcifying agent has the advantages of being rapid in reaction and the like, calcium in crude oil can be removed in a short reaction time, and the crude oil decalcifying agent is easy to dissolve in water, has low corrosivity and lowpollution, cannot cause secondary pollution to crude oil products and cannot introduce new impurities.

Owner:广东粤首新科技有限公司

A kind of soft fixture and its special feeding mechanism

ActiveCN106081484BLarge apertureSimple structureConveyorsFruit stoningEngineeringMechanical equipment

The invention relates to the technical field of fruit processing equipment, in particular to a soft clamp and a feeding mechanism special for the soft clamp. The soft clamp comprises a clamp body made of soft materials; a through hole used for clamping an article is formed in the middle of the clamp body; a gap hole is formed in the surface of the clamp body and extends to the inner wall of the through hole to communicate with the through hole; and when the clamp body is bent and stretches, the gap hole is opened, so that the opening of the through hole is opened to be in a horn shape. Compared with the prior art, the soft clamp and the feeding mechanism special for the soft clamp are suitable for automatic mechanical equipment for husking, core removing and processing of various fruits; the clamp is simple in structure, easy to process, convenient to operate, capable of ensuring integrity of processed fruit pulp, and low in fruit pulp loss ratio, thereby better meeting the requirement of modern agricultural product deep processing.

Owner:茂名市金皇冠智能科技有限公司

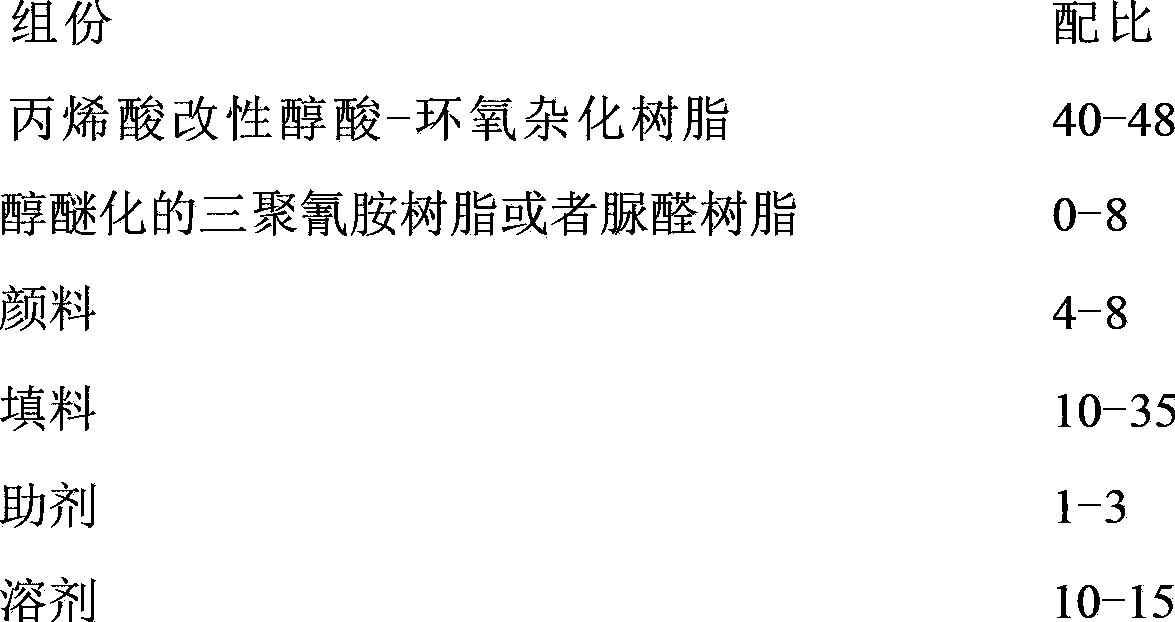

Acrylic-modified alcohol acid-epoxy ester hybrid resin and paint thereof

The invention relates to an acrylic-modified alcohol acid-epoxy ester hybrid resin which is prepared by the following steps: carrying out high-temperature esterification reaction on an epoxy resin and fatty acid under the action of an esterification catalyst to obtain epoxy ester; carrying out alcoholysis on vegetable oil and polyalcohol at high temperature, cooling, and adding polybasic acid for esterification, thereby obtaining an alkyd resin; and adding acrylic monomers into the epoxy ester-alkyd resin mixed solution, and carrying out graft polymerization under the action of an initiator to obtain the hybrid resin. The hybrid resin can be used as a main film forming material to prepare a high-temperature baking varnish together with a crosslinking agent. The high-temperature baking varnish can be used as various curtain-coating mirror back paints, including silver mirror back paints, aluminum mirror back paints, glass paints and the like, can satisfy the technological requirements for application of curtain coating production lines of which the width exceeds 3m, has a stable curtain coating, and can become completely dry after being baked at 150-130 DEG C for 3-5 minutes. The product has the advantages of low-temperature quick drying, high hardness, excellent adhesive force, dampness-heat resistance, chemical resistance, salt-fog resistance and the like.

Owner:常州市弘可利办公用品有限公司 +1

Production method of hot-rolled strip steel for low-cost and low-yield-strength DC01 cold-rolled sheet

ActiveCN113714288AIncreased ferrite grainRefine grain sizeTemperature control deviceManufacturing convertersSlab casterSmelting process

Production method of hot-rolled strip steel for low-cost and low-yield-strength DC01 cold-rolled sheet The invention discloses a production method of hot-rolled strip steel for a low-cost and low-yield-strength DC01 cold-rolled sheet, and relates to the technical field of ferrous metallurgy. The production method specifically comprises the following procedures of being subjected to a 150t converter, a 210mm / 230mm slab continuous casting machine, hot-state slab heating, two roughing mills and seven 1780mm hot continuous rolling units, coiling and warehousing after steel coil cooling, and cold rolling. Under the condition that the product quality is guaranteed, the smelting process is simplified, and the smelting efficiency is improved; the mode of heating a plate blank in a heating furnace is improved, the heating time is shortened, the heating temperature is reduced, the gas consumption is reduced, and the production cost is reduced; and the rolling temperature after rolling is optimized, ferrite grains of hot-rolled raw materials are properly increased, the distribution state of cementite is improved, under the condition that the cold-rolling production process is not changed, the yield strength of the DC01 cold-rolled sheet is reduced, and the deep processing requirement of a user is met. The production method is clear, simple to operate, obvious in effect and wide in popularization and application.

Owner:安钢集团冷轧有限责任公司 +1

Comprehensive utilization technique for hamartite and celestite symbiosis ore

InactiveCN100587090CImprove recycling rateRaise the gradeProcess efficiency improvementSlagRare earth

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

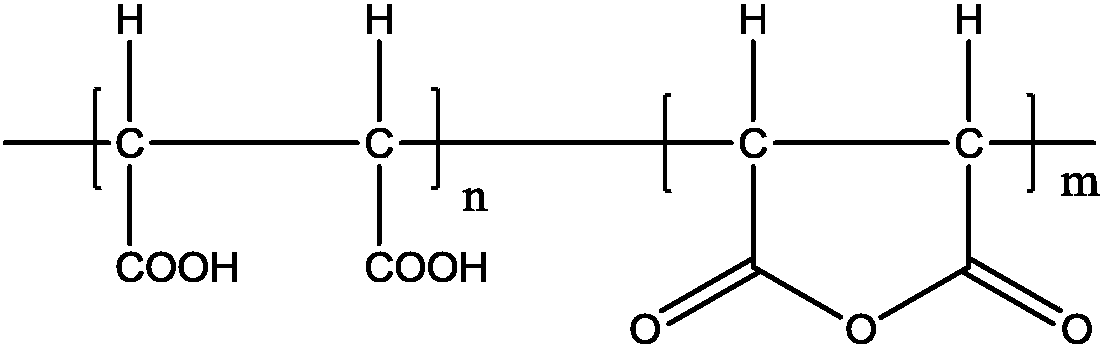

Water-based hydroxyl acrylic resin and water-based acrylic amino baking varnish beneficial to deep processing, preparation method and metal workpiece

The invention discloses a water-based hydroxyl acrylic resin facilitating deep machining, a water-based acrylic amino baking finish, a preparation method and a metal workpiece. The water-based hydroxyl acrylic resin is prepared from acrylic acid, methyl methacrylate, butyl acrylate, butyl methacrylate, vinyl versatate, cyclohexyl methacrylate, hydroxyethyl acrylate, 3-thiohydracrylic acid, an initiator, an oxidizing agent, a reducing agent, an organic solvent and water. The vinyl versatate and the 3-thiohydracrylic acid are introduced to a monomer part of the water-based hydroxyl acrylic resin, and branched chains in the vinyl versatate and the 3-thiohydracrylic acid make resin molecule arranged smoothly, so that a coating prepared by adopting the prepared water-based hydroxyl acrylic resin is very good in coating toughness, and a metal surface has good toughness after being coated. Therefore, the requirements of deep machining of a lot of metal workpieces can be met.

Owner:广东海顺新材料科技有限公司

Silicon-containing acrylic-acid-modified epoxy ester resin and paint thereof

The invention provides a silicon-containing acrylic-acid-modified epoxy ester resin, which is prepared by the following steps of: carrying out a high-temperature esterification addition reaction on epoxy resin and fatty acid under the action of esterification catalyst, then reducing reaction temperature, adding acrylic acid, methacrylic acid or a mixture of acrylic acid and methacrylic acid, and carrying out an addition reaction under the action of low-temperature esterification catalyst to obtain acrylic acid epoxy ester resin; and then carrying out radical polymerization on the prepared acrylic acid epoxy ester resin, acrylic acid monomer and organic silicon monomer in the presence of an initiator to prepare the silicon-containing acrylic-acid-modified epoxy ester resin. The silicon-containing acrylic-acid-modified epoxy ester resin provided by the invention is a main film forming material; the paint for curtain spraying of glass is prepared by the silicon-containing acrylic-acid-modified epoxy ester resin and a cross-linking agent; the paint can satisfy the painting process requirements of painting production line of wide curtains as long as 3 m, and can be completely dried after being baked at 130-160 DEG C for 5-7 minutes; and after drying is finished, the hardness and flexibility of the coated film is balanced, thus a paint falling phenomenon during edging, perforating and sandblasting for deep processing of process glass is avoided.

Owner:常州市弘可利办公用品有限公司

A longan pitting cutter

The invention relates to the technical field of food processing equipment, in particular to a longan seed removal tool which structurally comprises a tool rotator, a plurality of blades, a guide wheel and an expander. The blades are arranged on the top of the tool rotator and are spliced with one another along the circumferential direction to form a blade group in the shape of a circular truncated cone by means of enclosing, and the diameter of an opening in the upper end of the blade group in the shape of the circular truncated cone is smaller than that of an opening in the lower end of the blade group; the expander is used for outwardly opening the opening in the upper end of the blade group, the lower end of the expander is fixed to the inner wall of the guide wheel, and the upper end of the expander penetrates the tool rotator and can extends into the blade group in the shape of the circular truncated cone when the tool rotator rotates and moves downwardly relative to the guide wheel, so that the opening in the upper end of the blade group can be opened from the inside to the outside; the tool rotator, the guide wheel and the expander are provided with vertically through cavity structures. Compared with the prior art, the longan seed removal tool has the advantages that longan pulp and seeds can be automatically separated from one another by the aid of the longan seed removal tool, the longan seed removal tool is high in seed removal efficiency and low in pulp loss ratio, and the longan pulp without the seeds is good in integrity.

Owner:茂名市金皇冠智能科技有限公司

A high-purity aluminum plate shape straightening device and straightening method

The invention relates to a plate shape straightening device and straightening method for a high-purity-aluminum medium-thick plate. The plate shape straightening device comprises a bearing platform and a pressure applying top plate. The high-purity-aluminum medium-thick plate is arranged between the bearing platform and the pressure applying top plate. Straightening clamp fixing plates are horizontally arranged above the pressure applying top plate. Straightening clamps are arranged on each straightening clamp fixing plate. A clamping rod of each straightening clamp is arranged in a groove in the upper surface of the pressure applying top plate. Each clamping rod is sleeved with a spring. Each spring abuts against the upper surface of the pressure applying top plate or the inner surface of the corresponding groove. By the adoption of the plate shape straightening device and straightening method for the high-purity-aluminum medium-thick plate, the high-purity-aluminum medium-thick plate is straightened through the high-temperature pressure straightening method, different pressure platforms and annealing process packages are adopted according to different thicknesses and broadbands, a curing production mode is formed, and generation of the buckling of the high-purity-aluminum medium-thick plate is avoided. By the adoption of the plate shape straightening device and straightening method, the large fixed assets are reduced, and the economic benefits are increased. The plate shape straightening device and straightening method are particularly suitable for straightening production of the high-purity-aluminum medium-thick plate.

Owner:CHINALCO RUIMIN

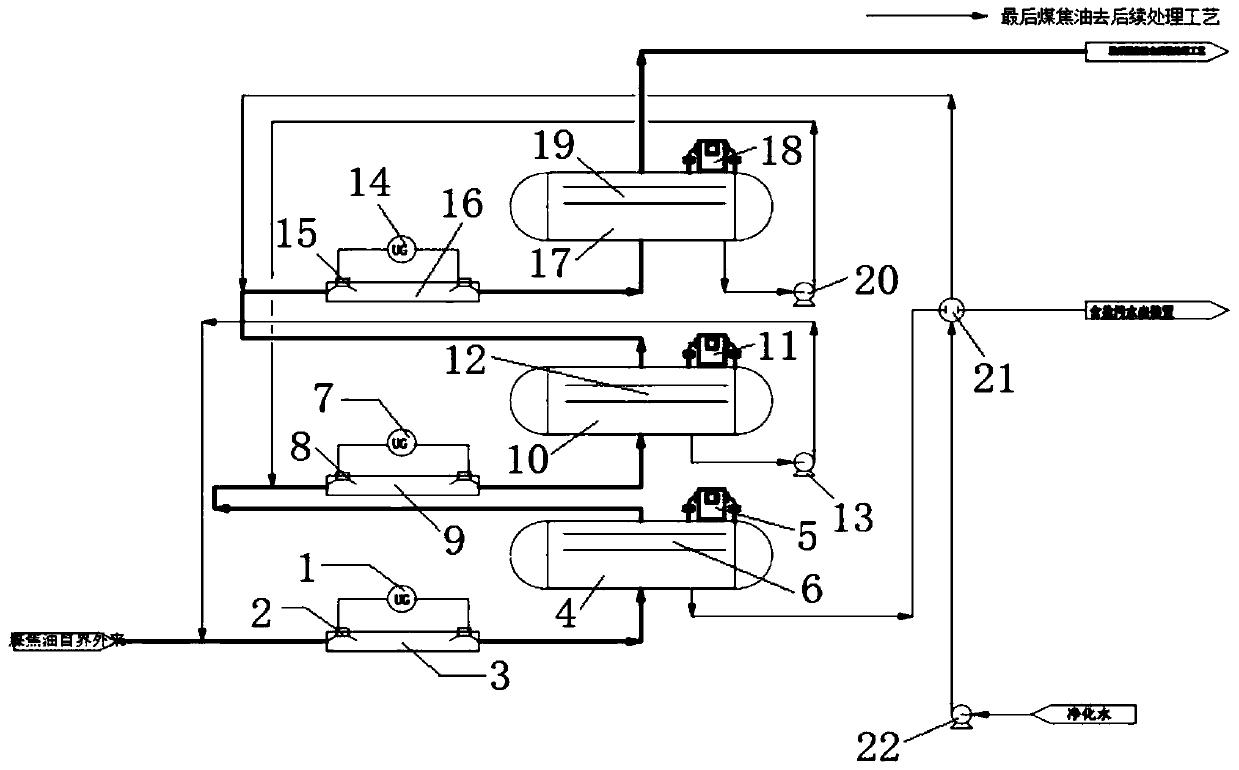

Coal tar desalting and dewatering device integrating ultrasonic demulsification and high-voltage electrostatic field coalescence

PendingCN111088056AMeet the requirements of deep processingTar working-up by water removalTar working-up by solvent extractionUltrasound - actionTransformer

The invention belongs to the technical field of coal tar processing, and particularly relates to a coal tar desalting and dewatering device integrating ultrasonic demulsification and high-voltage electrostatic field coalescence. The device comprises an ultrasonic generator, an ultrasonic transducer, an ultrasonic acting section, an electric desorption tank, a transformer, an electrode plate, a water injection-drainage heat exchanger, a water injection pump and a circulating water injection pump, wherein the ultrasonic transducer is arranged in the ultrasonic acting section and is connected with the ultrasonic generator, the ultrasonic acting section is connected with the electric desorption tank through a guide pipe, the transformer is arranged at the top of the electric desorption tank, and the electrode plate is arranged in the electric desorption tank. Coal tar is demulsified in an ultrasonic-assisted strengthening mode, the demulsified coal tar enters an electric dehydration tank,and electric field strengthened dehydration is conducted under the high-voltage electric field strengthened coalescence effect.

Owner:南京威朗德能源科技有限公司

Method for reducing arsenic in amine extracted germanium organic phase

ActiveCN101619390BMeet the requirements of deep processingProcess efficiency improvementFiltrationKerosene

The invention relates to a method for reducing arsenic in amine extracted germanium organic phase, which belongs to the technical field of non-ferrous metallurgy. Material containing germanium and arsenic is leached by sulfuric acid, arsenic reducing agent capable of reducing As5<+> into As3<+> is added into leaching solution according to 1-5g / l, and final acid PH is adjusted to 0.5-1.5; after desilication and filtration, germanium organic complexing agent is added into the solution according to the weight ratio of 8-12 of germanium organic complexing agent to germanium to increase the selective extraction of germanium; and germanium is extracted by a N235 kerosene system, obtained germanium organic phase is washed by oxalic acid solution with the weight percentage of 1-2 percent, and then alkalistripping and hydrolysis are carried out to prepare germanium concentrate. The Na2SO3 is preferably adopted as arsenic reducing agent, and tartaric acid is preferably adopted as the organic complexing agent. The method has the advantages that even the solution has high arsenic concentration, the arsenic content of the produced germanium concentrate can be reduced to below 1 percent to meetthe requirements of deep processing of germanium.

Owner:YUNNAN WUXIN IND

A kind of longan pitting and de-meat method and longan automatic de-meat machine

ActiveCN106072694BContinuous processingImprove integrityFruit stoningVegetable peelingPulp and paper industryDeep processing

The invention relates to the technical field of food processing equipment, in particular to a method for removing longan seeds and pulp and an automatic longan pulp removal machine. The method includes a seed removal step and a pulp removal step. The automatic longan pulp removal machine comprises soft fixtures, a feeding mechanism, a seed removal tool, a pulp removal tool and a punch mechanism. The soft fixtures are used for clamping longan, the feeding mechanism is used for conveying the soft fixtures, the seed removal tool and the pulp removal tool are sequentially arranged along a feeding direction, and the punch mechanism is used for respectively pushing the longan seeds out of the longan pulp and pushing the longan pulp out of longan shells and is correspondingly arranged above the seed removal tool and the pulp removal tool. Compared with the prior art, the method and the automatic longan pulp removal machine have the advantages that longan seed removal and shell removal working procedures can be automatically controlled, accordingly, the method and the automatic longan pulp removal machine are high in work efficiency and easy to implement, and the pure longan pulp can be continuously processed; the longan pulp obtained by the aid of the method and equipment is good in integrity, damage to the longan pulp can be prevented, the method and the automatic longan pulp removal machine are low in pulp loss ratio, and accordingly modern agricultural product deep-processing requirements can be effectively met.

Owner:茂名市金皇冠智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com