Production method and application of low-carbon steel containing boron and titanium, and high-speed wire rods thereof

A high-speed wire rod and production method technology, applied in the fields of iron and steel smelting and high-speed wire rod rolling, can solve the problems of poor performance of cold heading and wire drawing, and lower mechanical performance level of mechanical properties, so as to solve the problem of cold heading and wire drawing of low carbon steel Poor performance, the effect of meeting the requirements of deep processing of wire rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

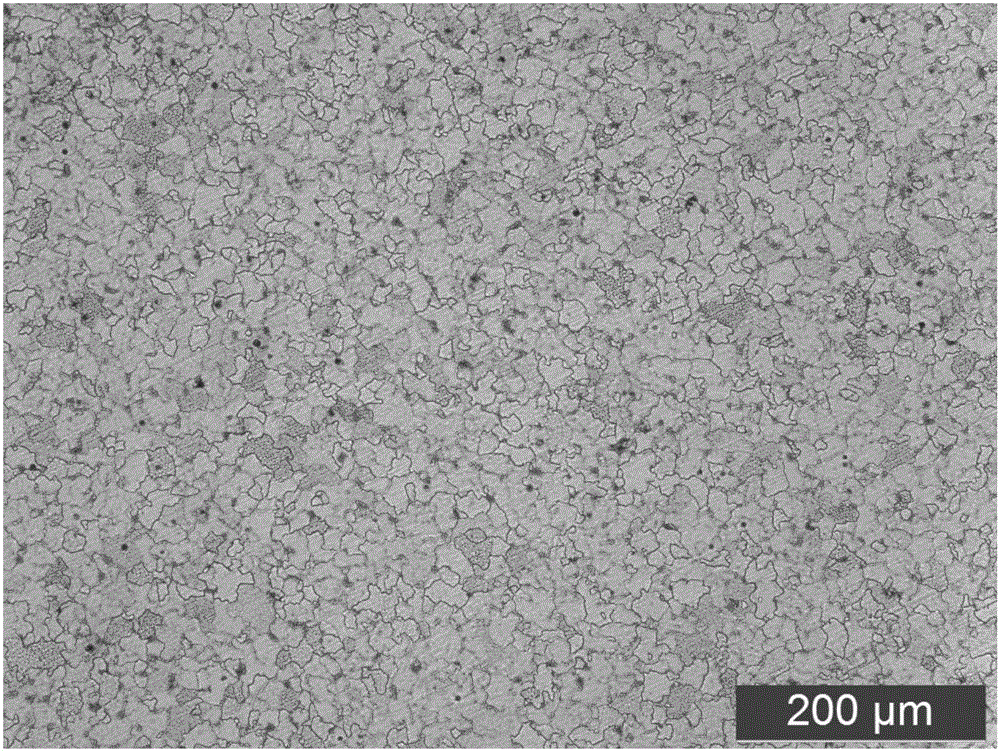

Embodiment 1

[0032] The chemical composition of boron-titanium low-carbon steel in this embodiment is as follows: the final billet composition is carbon content=0.07%, silicon content=0.06%, manganese content=0.32%, phosphorus content=0.008%, sulfur content=0.003%, aluminum content =0.030%, boron content=0.0080%, titanium content=0.060%, and the balance is Fe and other unavoidable impurities. Boron and titanium in boron-containing titanium low-carbon steel are added in the steelmaking process. After the LF furnace white slag is formed, ferro-boron and ferro-titanium are added. The amount of alloy raw materials added is adjusted according to the quality of ferro-boron and ferro-titanium raw materials and the composition of molten steel.

[0033] The size of the billet is 160mm×160mm×10700mm, which is used to produce boron-containing titanium low-carbon steel high-speed wire with a diameter of 5.5mm.

[0034] The specific production method is as follows: the boron-containing titanium low-car...

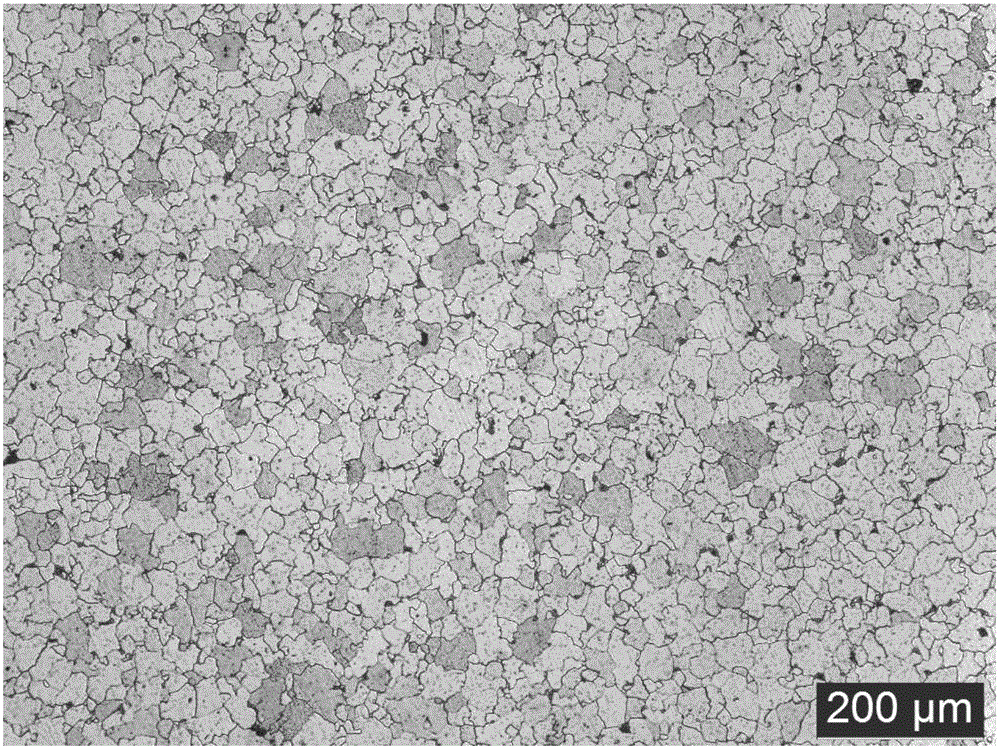

Embodiment 2

[0038]The chemical composition of boron-containing titanium low-carbon steel in this embodiment is as follows: the final billet composition is carbon content=0.07%, silicon content=0.06%, manganese content=0.35%, phosphorus content=0.012%, sulfur content=0.010%, aluminum content =0.032%, boron content=0.0040%, titanium content=0.070%, and the balance is Fe and other unavoidable impurities. Boron and titanium in boron-containing titanium low-carbon steel are added in the steelmaking process. After the LF furnace white slag is formed, ferro-boron and ferro-titanium are added. The amount of alloy raw materials added is adjusted according to the quality of ferro-boron and ferro-titanium raw materials and the composition of molten steel.

[0039] The size of the steel billet is 160mm×160mm×10700mm, which is used to produce boron-containing titanium low-carbon steel high-speed wire with a diameter of 9.0mm.

[0040] The specific production method is as follows: the boron-containing ...

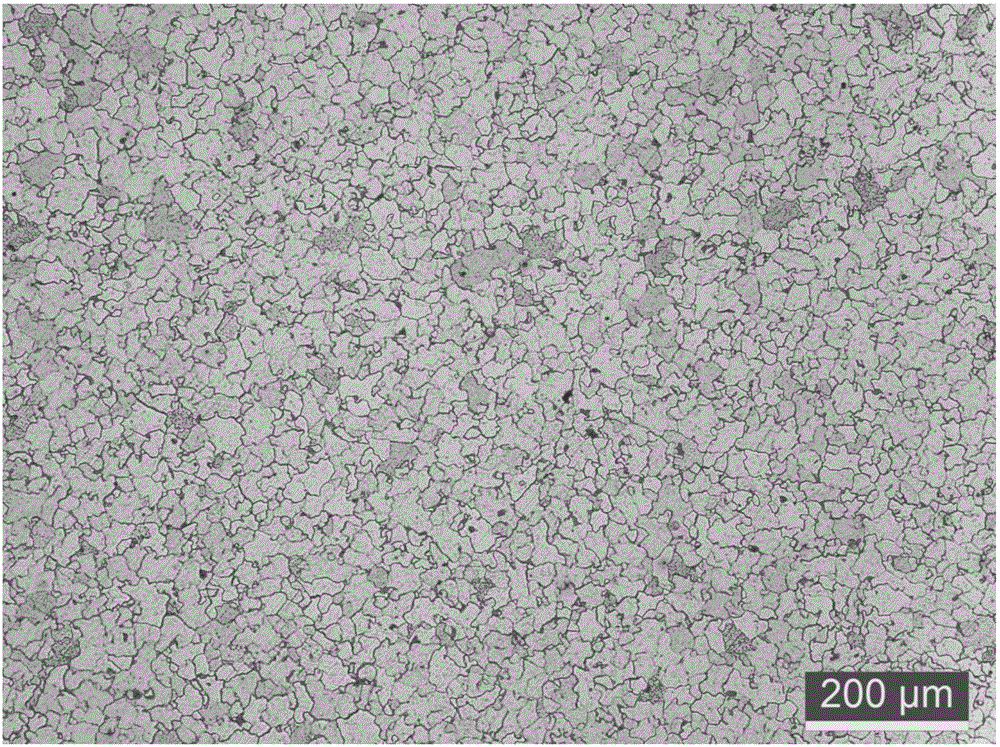

Embodiment 3

[0044] The chemical composition of boron-containing titanium low-carbon steel in this embodiment is as follows: the final billet composition is carbon content=0.06%, silicon content=0.08%, manganese content=0.40%, phosphorus content=0.0010%, sulfur content=0.005%, aluminum content =0.030%, boron content=0.0040%, titanium content=0.067%, and the balance is Fe and other unavoidable impurities. Boron and titanium in boron-containing titanium low-carbon steel are added in the steelmaking process. After the LF furnace white slag is formed, ferro-boron and ferro-titanium are added. The amount of alloy raw materials added is adjusted according to the quality of ferro-boron and ferro-titanium raw materials and the composition of molten steel.

[0045] The size of the billet is 280mm×325mm×5950mm, and the size of the billet after billeting is 160mm×160mm×10500mm. The billet after billeting is furnace-loaded to produce boron-containing titanium low-carbon steel high-speed wire with a dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com