A high-purity aluminum plate shape straightening device and straightening method

A thick plate shape and straightening technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of uncertain feasibility and poor economy, and achieve high yield, avoid buckling, and straighten heat treatment. The effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

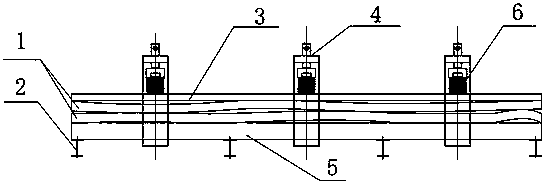

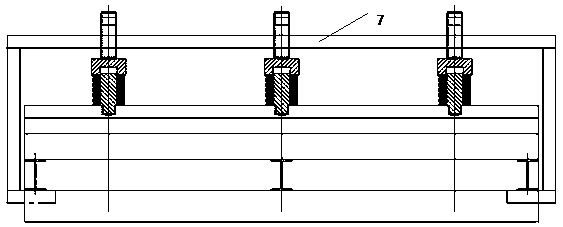

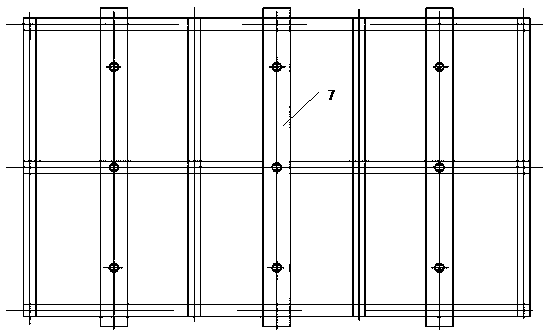

[0024] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0025] As shown in the figure, a high-purity aluminum plate-type straightening device includes a load-bearing platform and a pressure top plate. The high-purity aluminum plate is placed between the load-bearing platform and the pressure top plate, and is horizontally above the pressure top plate A straightening jig fixing plate is set, a straightening jig is set on the straightening jig fixing plate, the clamping rod of the straightening jig is set in the groove on the upper surface of the pressing top plate, and a spring is arranged outside the clamping rod, and the spring abuts on the upper surface of the pressing top plate. Apply pressure to the top surface or the inside of the groove.

[0026] Further, a bearing base is arranged at the bottom of the load-bearing platform, the bearing base is arranged on the bracket, the straightenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com