Coal tar desalting and dewatering device integrating ultrasonic demulsification and high-voltage electrostatic field coalescence

A technology of high-voltage electrostatic field and dehydration device, which is applied in the process of removing tar by water, and processing tar by selective solvent extraction, etc., can solve the problem that the research on demulsification is still blank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

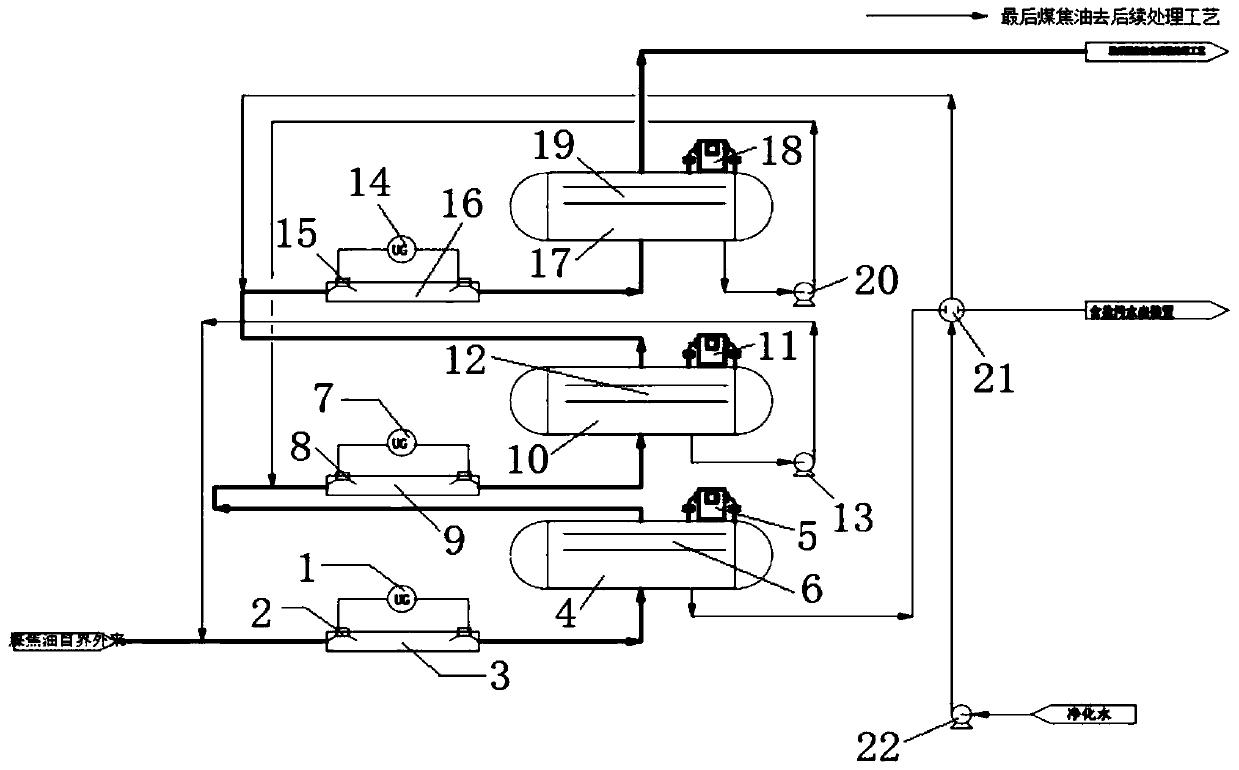

[0027] The following is attached with the manual figure 1 The technical scheme of a coal tar desalination and dehydration device integrating ultrasonic demulsification and high-voltage electrostatic field coalescence of the present invention will be further described in detail with specific examples.

[0028]The coal tar from outside the boundary is heated to the operating temperature (generally 140-150°C), enters the boundary area, mixes with the circulating water injection from the primary circulating water injection pump 13, enters the primary ultrasonic action section 3, and the primary ultrasonic action section 3 The first-level ultrasonic transducer 2 is arranged inside, and the first-level ultrasonic transducer 2 is connected with the first-level ultrasonic generator 1. The first-level ultrasonic generator 1 converts the power supply into a high-frequency electrical signal, and the first-level ultrasonic transducer 2 receives The frequency electric signal converts elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com