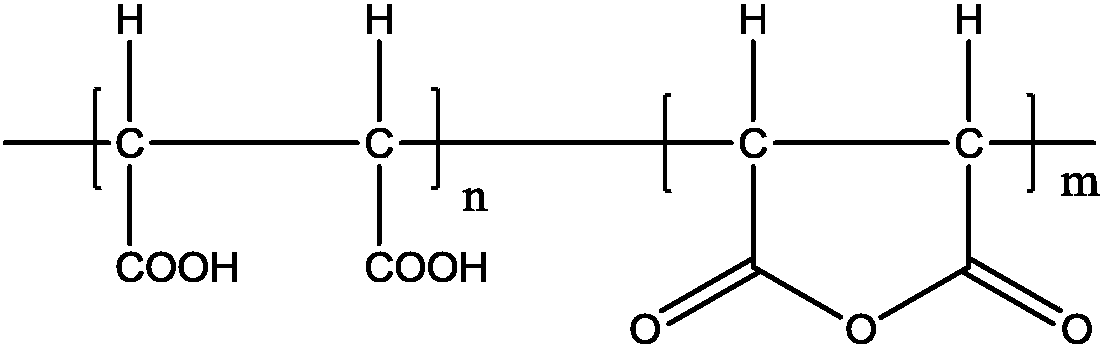

Crude oil decalcifying agent and preparation method and application thereof

A crude oil decalcifier and decalcifier technology, used in the petroleum industry, refining hydrocarbon oil, refining with metal salts, etc., can solve the problems of high cost, difficult to completely remove, increase crude oil sodium ions, etc., and achieve chemical stability. and high thermal stability, low pollution, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0044] Unless otherwise specified, the experimental methods used in the following examples are conventional methods; the reagents and materials used in the following examples, unless otherwise specified, can be obtained from commercial sources.

[0045] The hydrolyzed polymaleic anhydride was purchased from Hebei Jinhong Chemical Co., Ltd.

Embodiment 1-7 and comparative example 1-2

[0047] Mix the chelating agent and the precipitating agent, and mechanically stir until a uniform mixing system is obtained to obtain a crude oil decalcifying agent, wherein the composition and content of each component are as described in Table 1.

[0048] Components and content of the crude oil decalcifying agent of table 1-1 embodiment 1-7

[0049]

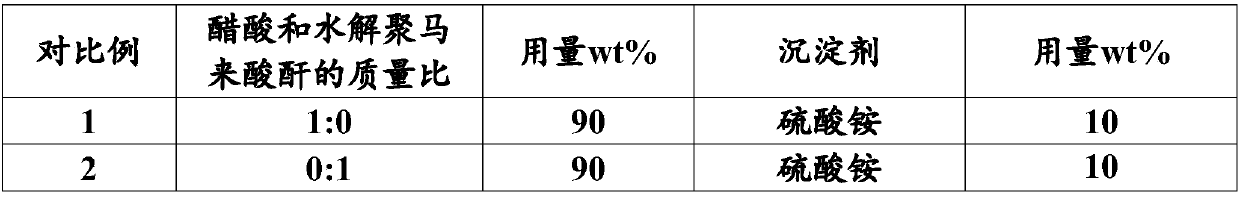

[0050] Components and content of the crude oil decalcifying agent of comparative example 1-3 of table 1-2

[0051]

Embodiment 8

[0052] Embodiment 8: Injection decalcification agent and demulsifier combined use test

[0053] 1. Configure an oil-soluble demulsifier, including polymer resin, diepoxide, sulfonic acid and solvent oil in a weight ratio of 100:20:3:40. The preparation method includes the following steps:

[0054] (1) Preparation of polymer resin:

[0055] Phenol and formaldehyde are mixed into a mixture according to a weight ratio of 1:1.6, and then water is added to the mixture to prepare an aqueous solution of the mixture. The mass concentration of the mixture in the aqueous solution of the mixture is 40%; then benzenesulfonic acid is added to adjust the pH to about 2.5, React at a temperature of 70°C until the reaction liquid is clear to obtain an alkylphenol-formaldehyde resin;

[0056] After the alkylphenol-formaldehyde resin is cooled to 50°C, propylene oxide and ethylene oxide are sequentially added to react for 1 hour to obtain a polymer resin, wherein the alkylphenol-formaldehyde re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com